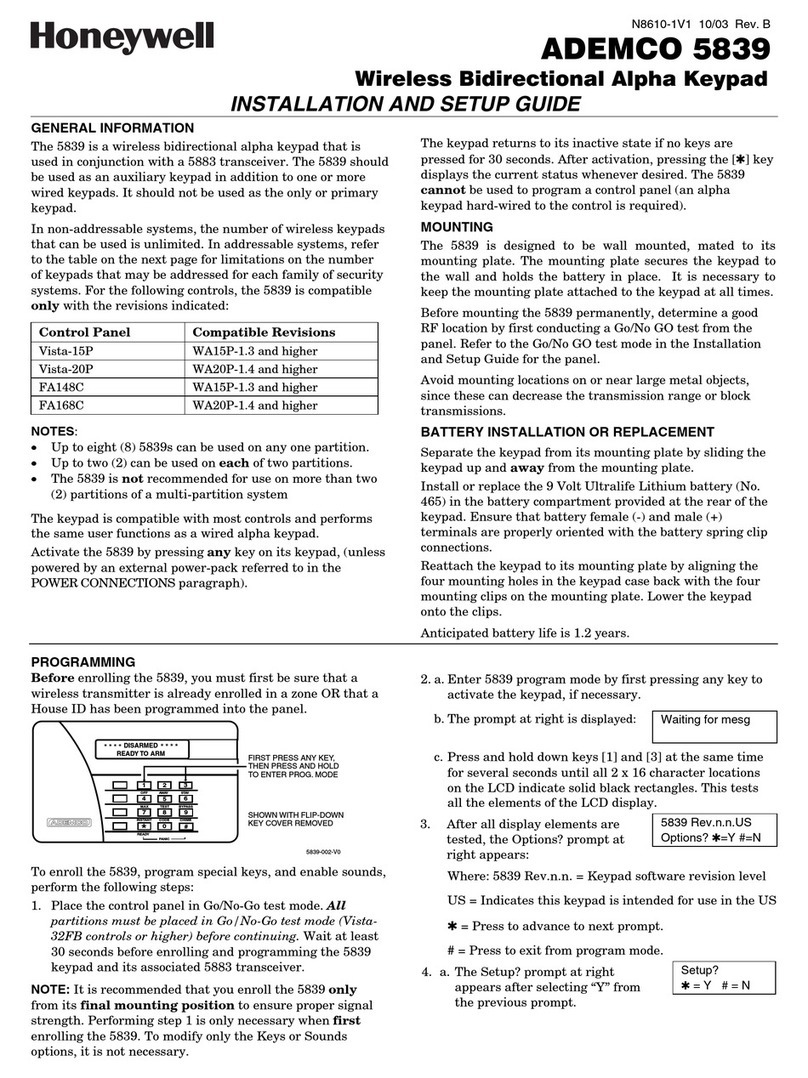

MACHINE OPERATION

Keyboard Functions

The keyboard has

44

character keys and the normal shift,

shift lock, return keys, and space bar that perform normal

typewriter functions. Figure 2 shows the control keys and

indicator lights for the keyboard.

Intervention Required

This light indicates that the not-ready key has been pressed,

the printer has run out

of

forms, or the cover

is

openo

Loading forms, closing the cover, and/or pressing the ready

key turns offthis light.

Cancel

Pressing this key terminates a read operation and signals the

system to disregard the data being transmitted.

If

this key

is

used to end an alter/display operation,

an

error condition

results.

Ready

Pressing this key places the printer-keyboard in a ready state

when forms

are

in the printer and the cover

is

closed,

Not

Ready

Pressing this key places the printer-keyboard

in

a not-ready

state.

Alter/Display

Pressing this key submits a request for an alter/display

operation. The proceed (and alter/display mode lights)

must be on before input data can be typed at the keyboard.

Alter/Display Mode

This light indicates that a request for

an

alter/display

operation has been accepted.

End

Pressing this key terminates a read, write, or alter/display

operation.

Proceed

This light indicates that input data can be typed at the

keyboard.

Alarm

This light,indicates that

an

alarm command was issued

to

alert the operator that the system requires manual attention.

An audible tone sounds for about 1-1/2 seconds.

Alarm Reset

Pressing this key turns offthe alarm light.

Request

Pressing this key indicates

to

the system that the operator

is

ready to key information. The request pending light

turns on

if

the system

is

busy.

Request Pending

This light indicates that the request key has been pressed,

but that the system

is

not yet ready to accept data. This

light turns off and the proceed light turns on when the

system

is

ready to accept data.

Printer Functions

All

functions

of

the

321

S are controlled by the system

either manually from the keyboard or by program control.

In addition

to

printing, the functions are:

Space

This function moves the print head one character space to

the right without printing.

New Line

This function combines the carrier-return and line-feed

operations. A new-line signal returns the print head to

the left margin at 1S inches (381 mm) per second minimum

and advances the platen a single or double line space

according to the setting

of

the line-feed select lever. This

function can be initiated manually, from the program, or

when the right margin

is

sensed. Using this function

successively provides variable vertical spacing.

Test Switches

Three switches facilitate servicing the

printec

Off-Line, On-Line. This switch places the printer off-line.

The two other switches operate only when this switch

is

in the off-line position.

Reset Off-Line. Operating this spring-loaded switch resets

the circuitry for the printer.

Continuous, Off/Keyboard, Stop-Start. Placing this switch

in its top position causes the machine

to

print a line

of

H's for testing printer operation in continuous mode. With

the switch in the

bottom

position, the machine prints a

line of H's in stop-start mode. In the middle position, the

action

of

the switch depends upon the attached system:

System/370 Model14S -Off, no action

System/370

Modell

SS

-printer responds to the key

pressed on the keyboard.

3215 Console Printer-Keyboard 7