IBM 5475 User manual

-- -

--

--

-

----.

----

-

---

- - -

---

- - - =:

~

§:

Maintenance

Library

Elastic

Diaphragm

Encoded

Keyboards

and

5475

Data

Entry

Keyboard

Theory-Maintenance

Manual

SY27-0073-1

Preface

This manual covers

both

the theory

of

operation and the

maintenance for keyboards using Elastic Diaphragm

Switches.

It

is

intended for use

by

the Customer Engineer.

The manual

is

divided into two major parts: Part 1

contains the

FE

Theory

of

Operation and Part 2 contains

the

FE

Maintenance Documentation.

In

addition,

Appendix A covers information peculiar to the 5475

keyboard and its use

with

a system. This information

consists

of

keyboard layouts, connector and code charts,

diagnostic flowcharts, and differences from the basic

keyboard. Information peculiar to

other

keyboards and

their use with a system

is

covered in the using system's

documentation.

No companion or prerequisite manuals are necessary

for use with this publication.

Second Edition (March 1971)

This is a major revision of,

and

makes obsolete, SY27-0073-0.

It

includes additional line

drawings

to

enhance

both

the

theory and maintenance sections. Associated changes to

the

text

and illustrations are indicated

by

a vertical line to the left

of

the change. New

material, added

to

Parts 1 and 2, covers the new encode board and elastic diaphragm

switch assembly. These additions, being entirely new, are

not

marked with vertical lines;

they

can

be

easily located

by

use

of

the table of contents

or

the index.

Changes are periodically made

to

the

specifications herein; any such changes will be

reported

in subsequent revisions

or

Technical Newsletters.

This manual has been prepared

by

the

IBM

Systems Development Division, Publications

Center, Department EOl, Building 060, Research Triangle Park,

North

Carolina 27709.

A form for reader's comments

is

provided

at

the back

of

this publication.

If

the form

has been removed, comments may be sent to the above address.

© Copyright International Business Machines Corporation 1969, 1971

Part

1.

Theory

of

Operation

Introduction .

Functional Units

Principles

of

Operations

Key Mechanisms

Latch Key Operation

Momentary Key Operation

Typamatic Key Operation

Elastic Diaphragm Switch

Encode Circuit Board

Bail Drive Card .

Shift Key

New Encode Circuit Board and Switch Assembly

Part

2. Maintenance

Preventive Maintenance

Lubrication .

Figure Title

1-1

Keyboard: Elastic Diaphragm Encoded

(Example)

1-2 Latch Key (Normal Position)

1-3 Latch Key (Operated Position)

1-4 Latch Key (Restoring) .

1-5

Uall

Interlocks

1-6

Momentary Key (Normal Position)

1-7

Momentary Key (Operated Position) .

1-8

Typamatic Key (Single Cycle Operation)

1-9 Typamatic Key (Repeat Operation)

1-lOA Elastic Diaphragm Switch Asm. (EDS)

1-lOB Elastic Diaphragm Switch Asm. (EDS)

1-11 Elastic Diaphragm Switch Substrate

1-12 Encode Board

1-13 Encode Circuits (Example)

1-14 Restore

Uail

Interposer and Latch Interposer

Comparison

1-15

Shift Key Lock Mechanism

1-16 Redesigned Encode Board and Switch Asm.

1-1

1-1

1-1

1-1

1-1

1-1

1-4

1-4

1-6

1-7

1-9

1-9

1-10

2-1

2-1

2-1

Page

1-1

1-2

1-2

1-3

1-3

1-4

1-5

1-5

1-6

1-6

1-7

1-8

1-8

1-9

1-9

1-9

1-10

Cleaning .

Maintenance .

Checks, Adjustments, and Removals

Key Lever

Interposer

Restore Bail and Magnet Assembly

EDS

Latch

Spring and Actuator .

New Encode Board and Switch Assembly

Ball Interlock Assembly

Space Bar Assembly

Shift Key Mechanism

Appendix A.

5475

Keyboard

Index .

Contents

2-1

2-1

2-1

2-1

2-2

2-3

2-4

2-5

2-5

2-6

2-6

A-1

X-1

Illustrations

Figure Title Page

1-17 Encode Circuits (New Style Encode Board) 1-11

2-1

Latch Key Adjustments 2-2

2-2 Interposer to Guide Comb Clearance . 2-2

2-3

Dabber

Adjustment (To Lower Dabber) 2-3

2-4

Dabber

Adjustment (To Raise Dabber) 2-3

2-5

Momentary Key Interposer Overtravel 2-3

2-6 Bail Adjustments 2-4

2-7

Bail Stop Adjustment . 2-4

2-8

Latch Spring and

Actuator

Adjustment

2-5

2-9 Encode Board and Diaphragm Replacement 2-5

2-10 Ball Interlock Assembly Adjustment .

2-5

2-11 Space Bar Operating Tab Adjustment 2-6

A-1

5475 Keyboard Arrangement .

A-1

A-2

System/3 Card Code A-2

A-3

5475 Electrical and Mechanical Timings

A-3

A-4

Control Panel A-3

A-5

5475 Interface Connectors

A-4

A-6

5475 Control Panel Connectors

A-5

A-7

5475 Keyboard Diagnostic Flow Chart

A-6

iii

INTRODUCTION

The keyboard

is

a manual entry device providing coded

outputs to the using system through cable connections.

Different models'provide various codes, key configurations,

J and control keys for the using system (Figure

1-1

). A

circuit board creates

output

codes that are compatible

with the coding scheme

of

the system. The system samples

• the bit

output

lines and signals the keyboard reset. The

keyboard can be used for entering data or for inquiry

by

the use

of

the data keys. The keyboard control keys can

format data or can control functions for various

output

devices.

Keyboard interlocking prevents pressing two latch keys

at the same time or pressing a second latch key before a

keyboard cycle

is

complete. The using system locks the

keyboard when it

is

not in use.

It

is

locked when power

is

off.

Refer to the keyboard pictured in Figure

1-1

for

locations and orientations used throughout this manual.

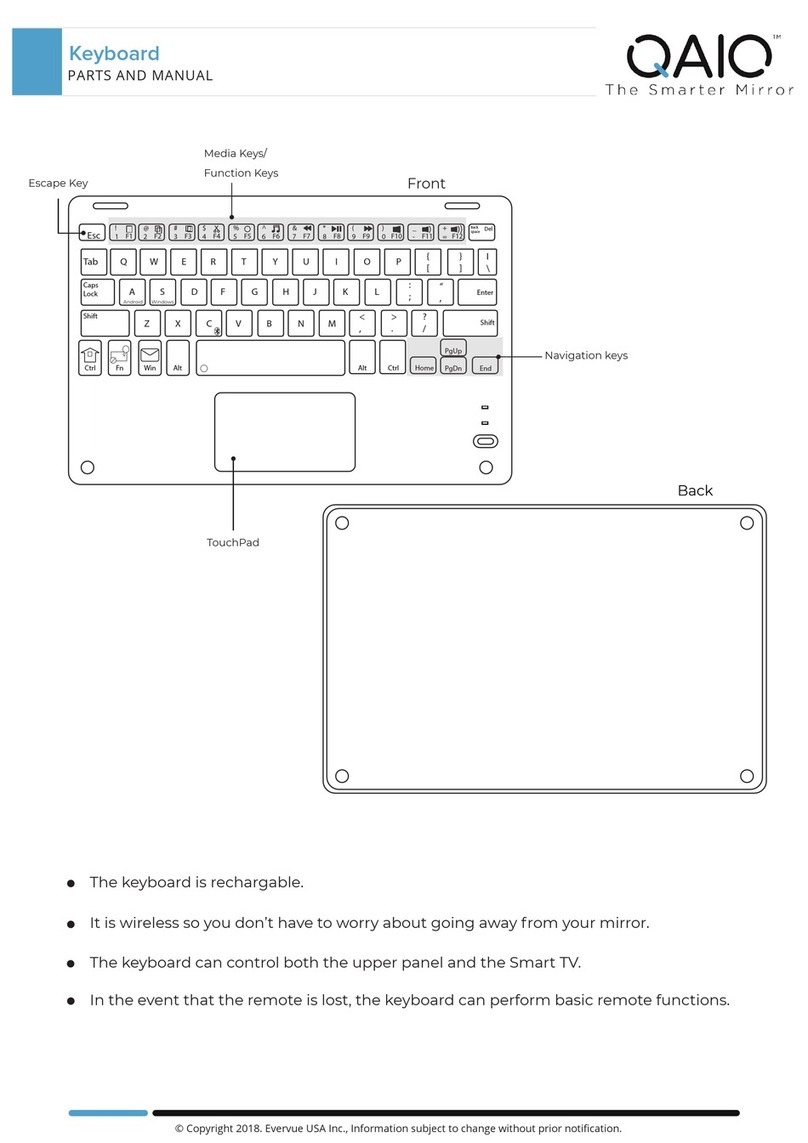

FUNCTIONAL UNITS

The information usually found in the Functional Units

section has been incorporated in the Principles

of

Operation

section.

•

All

locations

and

directions are referenced from the

operator

•

Front

of

tho

keyboard·

Portion closest

to

the

operator

• Right

and

left of

the

keyboard -Operators right and left

• Key rows -First row

is

farthest from

the

operator

and

the

fourth row

is

tho closest

to

the

operator

I Figure 1-1. Keyboard: Elastic Diaphragm Encoded (Example)

Part

1.

Theory

of

0 peration

PRINCIPLES OF OPERATION

Key

Mechanisms

The keyboard may include three types

of

keys, depending

on

the model: latch keys, momentary keys, and typamatic

keys. A latch key provides

on·e

coded

output

to the

interface lines each time the key

is

pressed. All graphic

keys and some control keys use the latch key mechanism.

A momentary key provides an

output

to the interface only

while the key

is

held

Clown.

Most control keys or function

keys use the momentary key mechanism. When a repetitive

function

is

desired, graphic or control keys use the typamatic

key mechanism.

Latch

Key

Operation

Pressing a latch key (Figure 1-2) pivots the keylever on its

fulcrum rod. The dabber transfers the downward motion

to the interposer. A latch spring rests against the rear

of

the interposer. As the interposer moves down

at

the rear,

the latch spring moves forward over the interposer (Figure

1-3). The latch spring latches the interposer down and

closes the associated elastic diaphragm switch (EDS).

Closing an EDS makes a circuit

to

the encode circuit board,

which generates coded

outputs

and a signal indicating data

is

available.

Elastic Diaphragm Enc Kybds and 5475 Data

Entry

Kybd (3/71)

1-1

front

_..,.

____

..:..,..

... Rear

Restore Magnet

Figure 1-2. Latch Key (NormalPosition)

Restore Bail

figure

1-3. Latch Key (Operated Position)

1-2

(3/71)

When the 'data available' signal and the data character

are accepted

by

the system, power to the restore magnets

is

dropped. The keyboard restoring bail moves to the

front

of

the keyboard (under spring tension) carrying the

latched interposer with

iL

An elongated interposer pivot

hole allows the interposer to move to the front, clearing

the latch spring (Figure 1-4). The interposer return spring

forces the interposer up

off

of

the bail and behind the latch

spring. The interposer pushes the latch spring to the rear,

allowing the EDS to open.

As

the interposer moves to the rear, the interposer

projection strikes the <lobber, and pivots it from its rest

position. When the keylever

is

released, it pivots upward

and the <lobber return spring restores the <lobber to its

normal position above the interposer.

As

the bail moves to the front, it moves under all the

unoperated interposers (Figure 1-2) and prevents them

from operating. While the keyboard restore bail travels

toward its forward stop, the bail contacts (which are EDS

switches) close, providing the 'bail contact' or 'restore'

signal to the system, or keyboard logic. This indicates the

bail has traveled its full restoring stroke and the restore

magnets can again be energized. The keyboard remains .

locked and the 'bail contact' or 'restore' signal remains

until the restore bail magnets are picked and sealed.

The 'bail contact' or 'restore' signal drops the

'data

available' signal and holds it reset. These electronic inter-

locks allow the time for the EDS switch to open. Thus,

there

is

only one

output

from the keyboard for each latch

key pressed.

Figure 1-4. Latch Key (Restoring)

The keyboard

is

locked

by

the ball interlock (Figures

1-3

and 1-5) while the interposer

is

latched down. An

operated interposer goes between the interlocking balls

and takes up

the·

clearance between the balls. Other inter-

posers can

not

be operated until the first one

is

restored

because the balls can

not

separate to allow another inter-

poser to enter. The keyboard

is

locked

by

the restore

bail during restore time. Therefore, the next key cycle

can begin only when the restore magnets are again picked

and sealed.

lnte,pom•

n

c:Qo

Ball

Interlocks

Figure 1-5. Ball Interlocks

Interposer Return Spring

Elastic Diaphragm Enc Kybds and 5475 Data Entry Kybd (3/71)

1-3.

I

Momentary Key Operation

Momentary control keys do

not

provide a coded

output

to

the interface

bit

lines,

but

do activate a control line to the

keyboard interface. The momentary key interposer, unlike

the latch key interposer, has a link (Figure 1-6) that operates

on the latch spring, and the pivot hole

is

not elongated.

As the key

is

pressed, the <lobber moves the interposer

down, causing the link

to

pivot (Figure 1-6). The latch

spring closes the EDS

as

it follows the arc

ot

the link

(Figure 1-7). The interposer

is

not

latched down by the

latch spring, and the using system determines

if

a keyboard

restore cycle occurs

as

a result

of

pressing a momentary

key. The circuit through the EDS remains closed

as

long

as

the key

is

held down.

When the key

is

released, the interposer

is

restored

by

its

return spring and the link cams the latch spring away from

the EDS.

Typamatic Key Operation

When a typamatic key

is

held down with a slightly more

than

normal pressure, it permits automatic repetition

of

a

graphic, space,. or function key. Normal pressure

on

the

key causes only one operation,

as

with

a standard latch-

type key.

The typamatic keylever (Figure 1-8) has a typamatic

latch pivoting

on

the keylever at the front. When the

keylever

is

pressed, the typamatic latch downstop strikes

the

top

of

the interposer fulcrum. This

is

the normal stop

for

the

typamatic keylever, and actions

of

the <lobber,

interposer, and switch are identical to a standard latch key

Figure 1-6. Momentary Key (Normal Position)

1-4

(3/71)

mechanism. Additional pressure

on

the keylever overcomes

the typamatic latch spring tension, causing the latch to

pivot downward from the keylever. The turned-over ear

on the typamatic latch then strikes the

top

of

the interposer

projection, and holds the interposer down in the latched

position. When the restore magnet

is

de-energized during

this cycle, the restore bail moves the interposer to the front.

The turned-over ear pivots down behind the interposer

projection (Figure 1-9) and holds the interposer forward.

The interposer remains in this position, with the EDS closed,

until the key

is

released. Data

is

sampled

by

the system

until the interposer

is

restored and the EDS switch opens.

When the keylever

is

released, the interposer restores

immediately. The interposer return spring pulls the inter-

poser to the rear

of

the keyboard, where

it

strikes the latch

spring and allows the switch

to

open. The electronic circuits

complete the keyboard cycle

that

may already be in progress

by providing proper timing for the data lines and the

'data

available' signal (refer to the timing chart for the 5475 in

Appendix A).

Another method can begin a typamatic operation.

If

the keylever

is

not

pressed to its limit soon enough, a full

restore cycle occurs. The <lobber

is

out

of

position because

the keylever

is

down.

If

the keylever

is

pressed to its limit

at this time, the turned-over ear

of

the typamatic latch will

strike the interposer projection. The interposer will move

down and latch under the latch spring. As the restore

portion

of

the cycle begins, the interposer will again move

behind the turned-over ear

of

the typamatic latch and will

be held in this position until the key

is

released. The

remainder

of

the operation

is

the same

as

the first repeat

operation described.

\nterposer Return Spring

---

Latch Spring

Link

Figure 1-1. ).\omcntatY

J{eY

(Operated Fosition)

f igUfC 1-S. 'fypamatic

J{ey

(Single Cycle Operation)

ElasticDiaphragm

Enc

J{ybd>

and 5415 DataEnttY J{ybd

(3/11l

1-5

Figure 1-9. Typamatic Key (Repeat Operation)

I Elastic Diaphragm Switch

(Old

Style)

The EDS (elastic diaphragm switch assembly) consists

of

a

substrate, a separator, an elastic diaphragm, a Mylar* spacer,

a slotted clamp, a spacer, an actuator spring, a beveled

spacer, a latch spring, and a clamp (see Figures 1-lOA and

1-lOB). The substrate

is

flexible plastic, with copper-ribbon

land patterns running from the

EDS

to the encode circuit

board assembly (Figure

1-11

). The land patterns laminated

on

the substrate terminate at one end in a solder connection

to

the encode circuit board and at the other end behind a

hole in the separator. The end behind the separator hole

is

Figure 1-lOA. Elastic Diaphragm Switch Asm. (EDS)

1-6

(3/71)

Turned-Over

Ear

lnte1poser Projection

the N/O contact

of

an elastic diaphragm switch. The plastic

diaphragm

of

the switch has a laminated conductor that

is

electrically common to all the switch positions. The

separator layer, which separates the substrate and diaphragm,

contains holes aligned with each

of

these contacts. The sub-

strate, separator, and elastic diaphragm are clamped together

to the rear

of

the keylever support (Figure 1-lOB). When

a latch spring

is

released, the elastic diaphragm

is

pressed

through the hole in the separator

by

the actuator spring

projection. The diaphragm common conductor contacts

the N/O contact on the substrate, which completes the

circuit to the encode circuit board.

....,--Spacer

!+---

Actuator Spring

,....,.."'/1-+--- Spacer

Latch Spring

Clamp

Fulcrum

--

-

_.-

Actuator

Spring

Latch Spring

Figure 1-lOB. Elastic Diaphragm Switch Asm. (EDS)

I Encode Circuit Board (Old Style)

The encode circuit board (Figure 1-12) attaches to the top

of

the keyboard side frames and can be pivoted for access

to the mechanical portions

of

the keyboard. The SLD

logic circuits receive inputs from the elastic disphragm

switches to initiate outputs to the using system. Control

inputs from the using system control keyboard operations.

SLD logic encodes the inputs from the EDS into the code

of

the using system and routes these codes to the system

interface. Connection to the interface

is

through pluggable

SLD connectors at either side

of

the circuit board.

Actuator

Spring

Substrate

The elastic diaphragm switch completes a circuit through

the encode board diode matrix or logic block depending on

the model (Figure 1-13). This input ANDs with the shift

mode (uppercase or towercase) and sets the appropriate

bit

latches. The

'bit'

latch outputs are ORed

to

generate a

'data available' signal. 'Data available' indicates to the

system that a key

is

down and the

'bit'

lines are up.

In some models, the 'data available' signal

is

the hold and

reset for the

'bit'

latches. When accepting data, the system

drops its hold

on

the restore magnets. The restore bail then

operates the restore bail interposer, closing the bail contacts

(Figure 1-14), which generate a 'bail contact' signal in the

encode board. 'Bail contact' resets the

'bit'

latches.

Elastic Diaphragm Enc Kybds and 5475 Data

Entry

Kybd (3/71)

1-7

Figure 1-11. Elastic Diaphragm Switch Substrate

• •

• •

• •

N

••

2 : :

~

..

c

••

8

••

II@

I

Encode Board

Encode Board

land

Patterns

013

• •

• •

• •

• I a

•

• I u

•

~

• • d

• •

"• •

•

J13

I

r-~~

...............

....-n-~~~~~---~~~~~~~~~~~~--ril'"TT..,.,..

......

~~-.

I

002

G13

I

L-------__J

EDS

Positions

Substrate

Pin Side (Viewed

from

Rear

of

K.B.)

*Can

have

up

to

88 positions

Note

1 Some models do not have two connectors-Connector 1 will always be

In

the

tame location

Figure 1-12. Encode Board (Old Style)

1-8

(3/71)

Inputs {

from

EDS

Switches

Shift

(Upper

or

Lower Case}

A

*Note:

Some

Models

Use

Diode

Matrix

in

Place

of

SLD

Logic

Figure 1-13. Encode Circuits (Example)

Bit Latch

FL

2 Bit

4 Bit

Figure 1-14. Restore Bail Interposer and Latch Key Interposer Comparison

Bail

Drive Card

A

SMS

drive card,

mounted

below the keyboard,

is

used

to

drive the restore bail magnets. It

is

con~rolled

by

the using

system. The using system prevents the flow

of

current

through the magnets which restores the keyboard during

operation

or

locks the keyboard when

not

in use.

Shift

Key

The SHIFT key shifts the keyboard into uppercase, causing

the character key

output

to be coded differently. The

shift key operates the same

as

any momentary key. The

SHIFT key

is

not

interlocked because

other

keys

must

be

operated with it.

Some models have a SHIFT key LOCK (Figure 1-15)

that

allows continuous uppercase operation. When the LOCK

key

is

pressed, the turned-over ear pivots the latch against

the lock bar. Additional pressure causes the keylever to Figure 1-15. Shift Key Lock Mechanism

(Data

Available)

Restore

Bail

Latch

Key

lnterp~ser

Shift

Key

Elastic Diaphragm Enc Kybds and 5475 Data

Entry

Kybd (3/71)

1-9

pivot down and the latch to slide along the lock bar.

As

the latching surface

of

the latch passes the lock bar, it pivots

under the lock bar and latches in this position

as

pressure

is

released

on

the LOCK key. To release the lock, the SHIFT

key

is

pressed. The latch moves free

of

the lock bar and

returns

to

its normal position under spring tension.

The binary counter, driven

by

a free running oscillator,

generates counts

to

scan the horizontal and vertical lines

of

the switch matrix. When the scan coincides with a switch

closure, the data selector generates 'scan complete', which

stops the counter. The

output

of

each

ROS

address (counter

output)

is

stored in a 4-bit register. When 'scan

co~plete'

occurs, the bits stored in the register (A,

B, C,

and D) from

the previous

ROS

address and the bits from the present

ROS address (1, 2, 4, and 8) make up the 8 bits

of

the

character. 'Scan complete' also brings up 'any data', which

tells the using system that data.is on the

'bit'

lines. A 'reset'

line

is

generated to reset the counter.

Invalid characters are detected before the set

of

'any

data'. 'Any data'

is

timed to ensure valid data on the data

bus; and timing ensures that 'scan complete'

is

ignored,

during count transitions, to prevent false addressing.

New

Encode

Circuit Board

and

Switch

Assembly

Some models

of

the keyboard have a redesigned encode

board and switch assembly (Figure 1-16). This board

is

mounted on the rear

of

the keyboard instead

of

on the top,

and does not have a flexible substrate. The components

of

the new board are the substrate, separator, diaphragm,

switch spacer, and latch assembly. Operation

of

the switch

assembly

is

the same

as

with the old board.

The encode board portion

of

the assembly uses T2L

logic in place

of

SLD logic, and has a different theory to

produce the same

output

lines (Figure 1-17). A

ROS

(read

1-10 (3/71)

...._~----v-~~~~~--'

Note

2

Notes:

1• The Latch Spring Assembly provides

the

combined functions

of

the

Activator

and

Latch Springs

of

the

previous design.

2.

The Logic Card and Switch

are

Factory-Assembled

and

to

be

replaced

as a

unit.

Figure 1-16. Redesigned Encode Board and Switch Assembly

only storage) unit, programmed for the proper

output

code,

is

used instead

of

the

'bit'

latches, and

is

addressed

for

each

switch position. A switch matrix, a seven-bit binary counter,

and a data selector generate the ROS address and take the

place

of

the AND/OR circuits used to set

'bit'

latches.

Counter

~~c~o_u_n_t_l

___

--1-r--r------------lr-------i

Count 2

.-----i~

Clo~

Reset

Tl

---~N

i

Count 4 Spec

Count 8

Count 16

Count

32

Switch

M1-at-r-ix-

...

-----~------------

...

-=--=--=-~-=-~-1~·1--S-ca_n_C

I

...

~

....

,

p_l_e_te

_

___,

-

1~~

r , "

~

>I

~

"?

.-------1

Bit

D

+-t-t--+--

1----+-~-1-+-<~+-!4.-'4~+"4'!:

4-7

J R

Spec

>I<

~

>I<

I<

>I

>

~

>i~>

!<~>+<

&

>+<

>i

)'-

>+<>+<

~

• R

Bit

C

...______.

"r'

7

lo.I

'""

'""'

'--~~~~1-+-+-Hl-f---IEl-----f:-i-·~G_a_te~-+--+--~---a~]

R

~1----------'

J -

R

Bit

B

Bit

A

Shift

~ROS

Bitl

-------1

256X4

-----Bi-t-

2

Bit

4

Bit

8

Error

Scan Complete A

1-----------11~1------A_n_y_D_a_ta_(D_a_t_a_A_v_a_il_a_b_le_)

------iN._

_____

___.

Delayed

Bail

Forward

Figure 1-17. Encode Circuits (New Style Encode Board)

Elastic Diaphragm Enc Kybds and 5475 Data

Entry

Kybd (3/71) 1-11

PREVENTIVE MAINTENANCE

CAUTION

Remove power before performing

PM

or

removing

keyboard.

Perform preventive maintenance to the keyboard during

unscheduled interruptions when possible.

If

unscheduled

interruptions do

not

occur in a twelve

month

period, a

preventive maintenance schedule must be provided. The

keyboard can be removed from its mounting (remove

power first) for easy servicing. Cable connections on the

left and right sides

of

the keyboard, and plug-on connectors

for the drive card, make removal easy.

Lubrication

Always lubricate with number 23 grease.. Grease the

following points every twelve months:

• Keylevcr pivots

• Keylever leaf and return springs

•

Front

interposer guide combs

• Space bar shaft pivots and keylever tab

• Dobber pivots

• Space bar pivots

• Restore bail armature pivots

• Reset drive spring anchors

• Latch spring and momentary link connections

• Interposer latch spring tips

• Shift bar shaft pivots

Cleaning

Clean the unit before each

lubri~ation

and when the environ-

ment indicates it

is

necessary.

MAINTENANCE

CAUTION

In localing troubles in the circuit portion

of

the keyboard,

do

not

use a test light; it could cause damage to the

circuits. Also when using an ohmmeter, take care to

prevent shorting pins or overloading the circuits. Do

not use the ohmmeter on less

than

R X 100.0 scale.

Part

2. Maintenance

Maintenance consists

of

adjusting mechanical parts and

replacing worn parts. When troubles are in the encode

board

or

the magnet driver card, these items must be

replaced. Trouble with the EDS

may

require replacing

the separator and the diaphragm, or adjusting

or

replacing

the actuator

or

the latch spring.

Test points for troubleshooting EDS switches and the

encode board are in the keyboard logics for the using

system.

CHECKS, ADJUSTMENTS,

AND

REMOVALS

Key Lever

Checks

The keylever, when pressed, should move around its pivot

at the rear

of

the keyboard until the lever

bottoms

in the

front guide comb. When released, it should rise until the

lever strikes the upstop rod in the front comb (Figure

2-1

).

The <lobber should clear the interposer and should return

to its rest position above the interposer projection when

the key

is

released.

Note: Unused key positions require their elastic

diaphragm switches

to

be either open or closed.

If

the switches are

to

be

held open, the keylevers are

blocked

by

a plastic lockout (Part 5994922)

to

prevent

the operation

of

the interposer. Closed switches do

not

have interposers and are held closed continuously

by

the latch spring assembly.

Adjustment

There is no keylever adjustment

to

meet keylever travel

called for in the checks. Failure to

meet

these conditions

indicates some defect in the keylever operation

or

with

the associated mechanisms. Refer

to

the diagnostic

flowchart in Appendix A or the diagnostic flowchart for

the specific system.

For

<lobber clearance, refer

to

"Adjustment-Latch

Key".

Removal

1.

Loosen the two front and the two rear encode board

mounting screws, and tilt the board

to

the rear

of

the

keyboard (old style only).

2. Remove

keybutton

from the keylever

that

is

to be

replaced.

3. Remove

other

keybuttons

that

extend over the

keylever that

is

to

be replaced.

Elastic Diaphragm Enc Kybds and 5475 Data

Entry

Kybd (3/71)

2-1

Front

Guide

Comb

Figure 2-1. Latch Key Adjustments

4. Pull

out

the pivot rod

with

pliers

or

use a follower rod

to push it

out

until the keylever

is

free.

5. Raise the pivot end

of

the keylever

to

be removed and

work it

to

the rear until it clears the upstop rod. Work

the keylever

out

of

the keyboard.

6. Replace in the reverse order.

7. Perform checks and necessary adjustments.

Interposer

Checks

The interposer should be latched

by

the

EDS

latch spring

before the downward

motion

of

the keylever

is

complete.

When the keylever hits its downstop, the interposer should

have some travel left before it

bottoms

on the guide comb

slot at the rear

of

the keyboard.

Adjustment-Latch

Key

The interposer tip must clear the EDS latch spring, and must

be at least 0.005 inch above the

bottom

of

the interposer

guide comb slot (Figure 2-2) when the keylever

is

fully

operated. To obtain these conditions, the keylever must be

formed.

If

the interposer

is

not

traveling far enough, form

the keylever (Figure 2-3)

by

placing pliers across the pro-

jections provided on the keylever. Squeeze gently to obtain

the desired position

of

the <lobber.

If

the interposer

is

traveling

too

far, form the keylever (Figure 2-4)

by

placing

2-2 (3/71)

Rear Interposer

Guide

Comb

Restore

Bail

Latch Spring

f

0.005

Minimum

Gap

Figure 2-2. Interposer to Guide Comb Clearance

pliers

on

one projection and a screwdriver between the

projections then spreading the projections. Hold the screw-

driver tip against the pliers and the shank against the

opposite projection applying force to spread the projections.

The theory

of

this adjustment

is

to raise or lower the

tail

of

the keylever, thus changing the relative position

of

the <lobber.

The

travel

of

the keylever

is

not

affected.

If

the tail

is

raised, it will strike the upstop sooner and the

<lobber will be lower and closer

to

the interposer. The

opposite

is

true if the tail

is

lower; it will strike the upstop

later and the <lobber will be further from the interposer.

Needle-Nose

Pliers

{or

Duck Bills)

Figure 2-3. Dobber Adjustment (To Lower Dobber)

Keylever

Needle-Nose

Pliers

(or Duck Bills)

Screwdriver

Keylever

Figure 2-4. Dobber Adjustment (To Raise Dobber)

Adjustment-Momentary Key

Momentary key interposers must travel at least 0.025 inch

before the switch closes, and must have a minimum over-

travel

of

0.005 inch. The keylever

is

to be adjusted to

.obtain these dimensions, and

it

may be necessary to form

the momentary link to obtain the proper overtravel

(Figure 2-5).

Removal

1.

Loosen the front and rear encode board screws and tilt

the encode board up and

to

the

rear

of

the keyboard

(old style only).

2.

Remove the keylever upstop rod.

3.

Remove the spacebar rod.

4. Raise the keylevers evenly.

5. Pull

out

the interposer pivot rod with pliers or push

it

out

with a follower rod.

6. Remove the spring from the interposer to be removed.

7. Raise the pivot end

of

the interposer and remove to the

front

of

the keyboard.

8. Replace in the reverse order.

9. Perform checks and necessary adjustments.

Interposer Return Spring

Interposer

Figure

2-5.

Momentary Key Interposer Overtravel

Restore

Bail

and

Magnet Assembly

Checks

Latch Spring

Link

(Form

for

Overtravel)

The bail should clear the restored interposers when it passes

beneath them. The interposers should clear the bail when

they are latched and should be restored fully when the

magnets are

not

energized.

CAUTION

Magnet yoke nuts are

not

to

be tightened more

than

finger tight plus 1/4 turn.

Adjustments

Each bail spring should require 130

to

170 grams

of

force

to pull its end

of

the bail away from the stop with

the

magnet not energized. The top surface

of

the bail (Figure

2-6) should be 0.015

inch±

0.014 inch below the inter- 1

posers when the magnets are energized. There

is

no adjust-

ment for the

top

surface

of

the bail other than the play in

the yoke mounting holes. The restore surface

of

the bail

should be 0.015

to

0.030 inch from the restore surface

of

the interposer with the magnets energized. Adjust the

restore surface clearance

by

positioning the magnet yoke

assemblies within

the

side frames.

It

may be necessary to

form the feeler gage

to

make this adjustment

as

the magnet

yoke interferes with the gage.

Adjust the bail stops

to

allow proper restoring

of

the

interposers. Place a 0.020 inch shim between the bail and

the bail stop (Figure 2-7). When the bail

is

operated, the

interposers should restore. The interposers should

not

restore with a 0.030 inch shim between the bail and the

bail stop.

Elastic Diaphragm Enc Kybds and 5475 Data Entry Kybd (3/71)

2-3

Table of contents

Other IBM Keyboard manuals

IBM

IBM TrackPoint USB Space Saver Keyboardwith Hub User manual

IBM

IBM 3277 User manual

IBM

IBM TrackPoint User manual

IBM

IBM Preferred USB Keyboard with Hub User manual

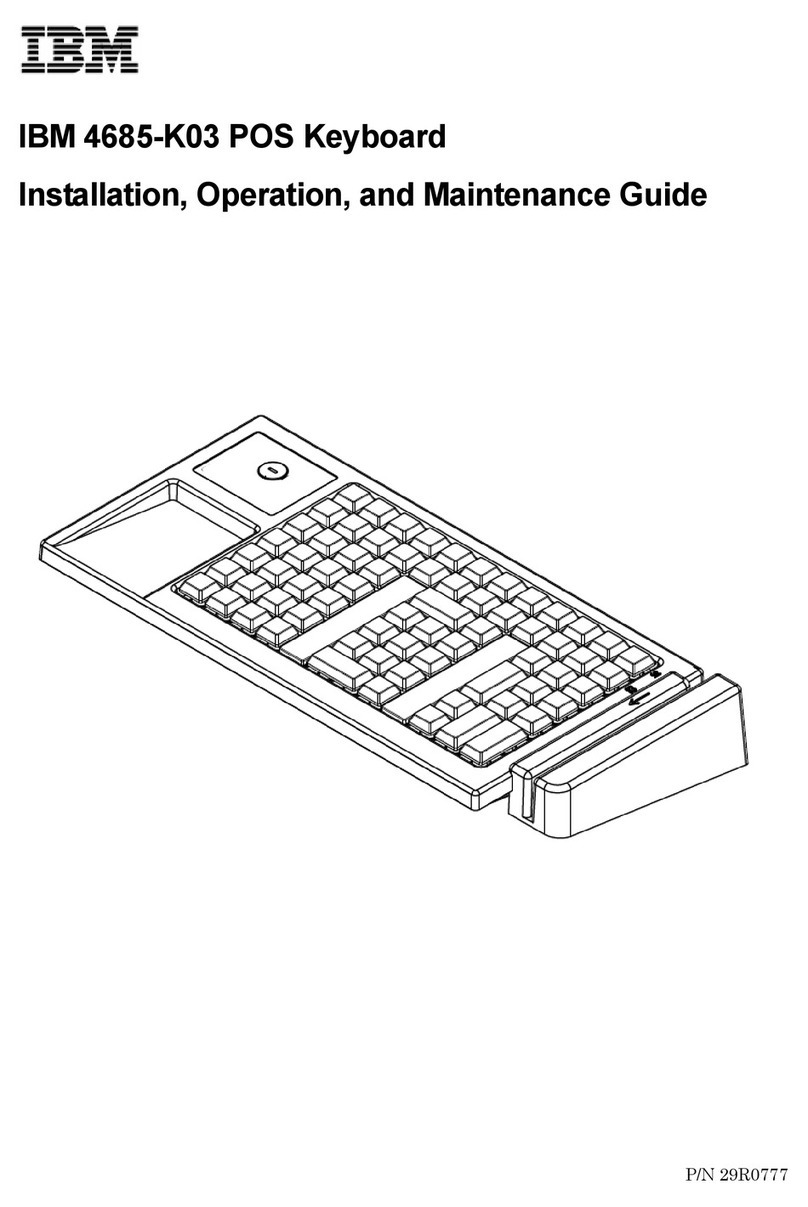

IBM

IBM 4685-K03 Technical Document

IBM

IBM 7785 Owner's manual

IBM

IBM 3215 User manual

IBM

IBM Rapid Access III USBKeyboard User manual

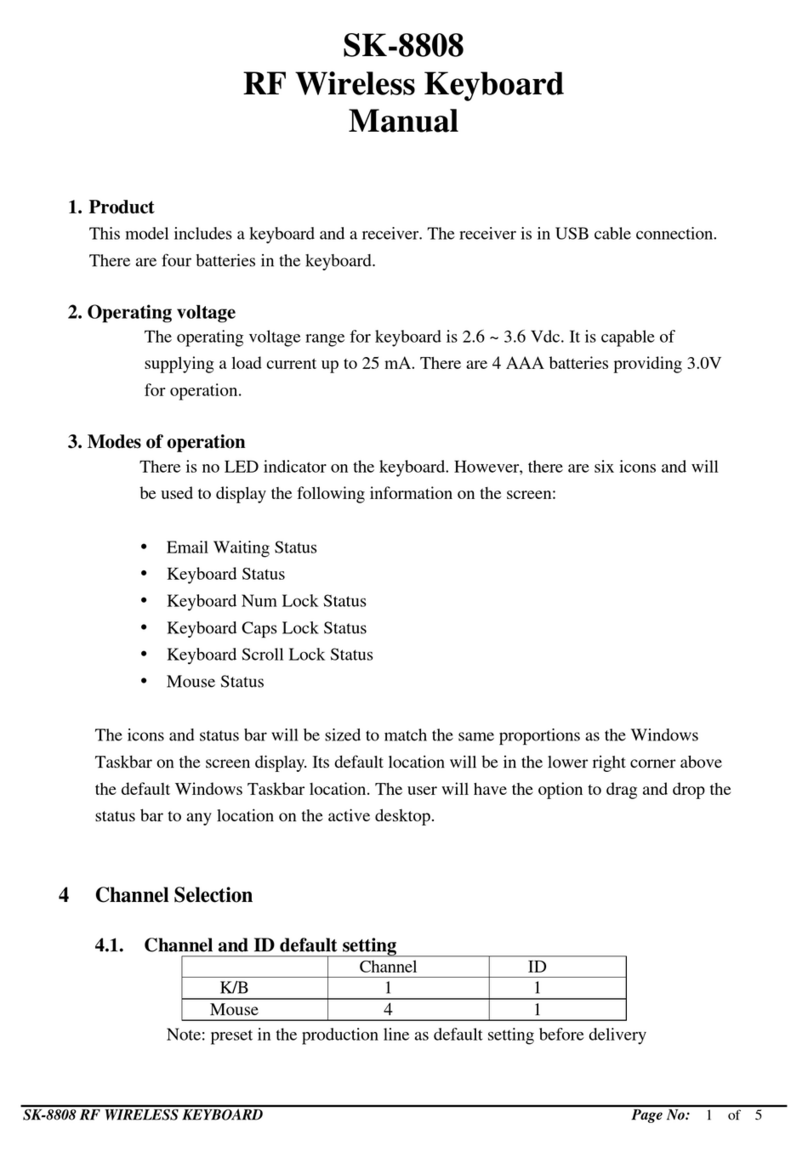

IBM

IBM SK-8808 User manual