IBM 7785 Owner's manual

IBM 7785

Hardware

Maintenance

Reference/Service

----

----

-

----

---

-----

-

-----

-----

---

·-

SA12-7017-05

•

•

IBM 7785

Hardware Maintenance

Reference/Service

----

----

-

----

---

-----

------

-----

---

·-

S

A1

2-701

7-

05

Note

----------------------------------------------------,

Before using this information and the produci it supports, be sure to read the

generai information under Appendix, "Notices"

on

page 209.

Fifth Edition (Aprii, 1993).

The following paragraph does not apply

to

the United Kingdom or any country

where such provisions are inconsistent with locallaw: INTERNATIONAL BUSI-

NESS MACHINES CORPORATION PROVIDES THIS PUBLICATION "

AS

IS"

WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS

FORA

PARTICULAR PURPOSE. Some states

do not allow disclaimer of express or implied warranties in certain transactions, there-

fore, this statement may noi apply

lo

you.

This publication could include technical inaccuracies or typographical errors. Changes

are periodically made

lo

the information herein; these changes will be incorporated

in

new editions of the publication. IBM may make improvements and/or changes

in

the

product(s) and/or the program(s) described

in

this publication al any lime.

lt

is

possible that this publication may contain reference lo, or information about, IBM

•

products (machines and programs), programming, or services that are not announced •

in

your country. Such references or information musi noi

be

construed lo mean that

IBM

intends to announce such IBM products, programming, or services

in

your

country.

Requests for technical information about

IBM

products should be made

to

your IBM

Authorized Dealer or your IBM Marketing Representative.

Copyright lnternational Business Machines Corporation 1990, 1991, 1992, 1993. Ali

rights reserved.

~

•r l l

~

-~

a

•

~

•

@=<==

•

Q--

~

•

~

=E3liE=

===~

~

~

..

~

~

~

• &·

l l l

l J

~

-~

a

.

~

~

~

=E3liE=

~~

~

~

~

..

~

..

Q-=

~

..

@=<==

t

iii

Generai Safety during Work

Use these rules to ensure generai safety:

• Observe good housekeeping

in

the area of the machines during

maintenance and after completing work.

• When lifting any heavy object:

1.

Ensure that you can stand safely without slipping.

2.

Distribute the weight of the object equally between your feet.

3.

Use a slow lifting force. Never move suddenly

or

twist when

you attempt to lift.

4.

Lift by standing

or

by pushing up with your leg muscles; this

action removes the strain from the muscles

in

your back. Do

not attempt

to

lift any objects that you think are too heavy for

you.

• Do not perform any action that causes hazards to the customer

or

that makes the equipment unsafe.

• Before you start the machine, ensure that other service represen-

tatives and the customer's personnel are not

in

a hazardous

position.

• Put removed covers and other parts

in

a safe piace, away from

ali personnel, while you are servicing the machine.

• Keep your tool case away from walk areas so that other people

will not trip over

it;

for example, put it under a desk

or

table.

• Do not wear loose clothing that can be trapped

in

the moving

parts of a machine. Ensure that your sleeves are fastened

or

rolled up above your elbows.

lf

your hair

is

long, fasten

it.

• lnsert the ends of your necktie

or

scarf inside other clothing or

fasten the necktie with a clip, preferably nonconductive, approxi-

mately 8 centimeters (3 inches) from the end.

• Do not wear jewelry, chains, metal-frame eyeglasses,

or

metal •

fasteners for your clothing.

Remember: A metal object lets more current flow if you touch a

live conductor.

iv Service Bay System

•

•

• Wear safety glasses when

you

are:

-

Us

i

ng

a hammer to drive pins or similar parts.

Drilling with a power, hand drill.

-Using spring hooks or attaching springs.

-Soldering parts.

-Cutting wire or removing steel bands.

-Cleaning parts with solvents, chemicals, or cleaning fluids.

-Working

in

any other conditions that might

be

hazardous to

your eyes.

• After maintenance, reinstall ali safety devices such as shields,

guards, labels, and ground wires. Exchange any safety device

that

is

worn or detective

fora

new one.

Remember: Safety devices protect personnel from hazards.

You destroy the purpose of the devices

if

you do not reinstall

them before completing your service cali.

• Reinstall ali covers correctly before returning the machine to the

customer.

Safety with Electricity

Observe these additional rules when working

on

equipment powered

by electricity:

• Find the room Emergency Power-Off (EPO) switch or discon-

necting switch. lf

an

electrical accident occurs,

you

can then

operate the switch quickly.

•

Do

not work alone under hazardous conditions or near equip-

ment that has hazardous voltages.

• Disconnect ali power:

-Before removing or installing main units.

-Before working near power supplies.

-Before doing a mechanical inspection of power supplies.

-Before installing changes

in

machine circuits.

• Before

you

start to work

on

the machine, unplug

the

power

cable. lf you cannot unplug the cable easily, ask the customer to

v

switch otf the wall box that supplies power to the machine and to

lock the wall box

in

the off position.

• lf you need

to

work

on

a machine that has exposed electrical

circuits, observe the following precautions:

-Ensure that another person, who

is

familiar with the

power-otf controls,

is

near you.

Remember: Another person must

be

there to switch off the

power,

if

necessary.

CAUTION:

Some hand

tools

have handles covered

with

a

soft

mate-

ria!

that

does

not

insulate

you

when

working

with

live

electrical currents. Use

only

tools

and

testers

that

are

suitable

for

the

job

you

are

doing.

Attention !

Les manches

de

certains

outils

sont

recouverts

d'un

matériau

souple

qui

n'assure

pas

l'isolation

lorsque

vous

travaillez

sur

des

circuits

électriques

actifs. Utilisez

uniquement les

outils

et les appareils de

contròle

adaptés à la tache

que

vous

exécutez.

-Use only one hand when working with powered-on electrical

equipment; keep the other hand

in

your pocket or behind

your back.

Remember: There must

be

a complete circuit to cause elec-

trical shock.

By

observing the above rule, you may prevent

a current from passing through your body.

-When using testers, set the controls correctly and use the

approved probe leads and accessories for that tester.

CAUTION:

Many

customers

have, near

their

equipment, rubber

floor

mats

that

contain

small

conductive

fibers

to

decrease

electrostatic

discharges. Do

not

use

this

type

of

matto

protect

yourself

from

electrical

shock.

Attention

!

Certains

clients

disposent,

au

voisinage

de

leur

matériel,

des

tapis

de

sol

en

caoutchouc

contenant

des

fibres

Vi

Service Bay System

•

•

•

•

•

conductrices destinées à réduire les décharges

électrostatiques. N'utilisez pas

ce

type de tapis pour

vous protéger contre les risques électriques.

-Stand

on

suitable rubber mats (obtained locally,

if

necessary)

to insulate you from grounds such

as

meta! floor strips and

machine frames.

• Observe the special safety precautions when you work with very

high voltages; these instructions are

in

the safety sections of

maintenance information. Use extreme care when measuring

high voltages.

• Regularly inspect and maintain your electrical hand tools for safe

operational condition.

•

Do

not use worn or broken tools and testers.

• Never assume that power has been disconnected from a circuit.

First, check that

it

is

powered-off.

• Always look carefully for possible hazards

in

your work area.

Examples of these hazards are moist floors, nongrounded power

extension cables, power surges, and missing safety grounds.

•

Do

not touch live electrical circuits with the reflective surface of a

plastic dental mirror. The surface

is

conductive; such touching

can cause personal injury and machine damage.

• Unless the maintenance information specifically lets you, do not

service the following parts with power on them when they are

removed from their normal operating places

in

a machine:

-Power supply units

-Pumps

-Blowers and fans

-Motor generators.

• lf

an

electrical accident occurs:

-

Use

caution; do not become a victim yourself.

-Switch off power.

-Send another person to get medicai aid.

vii

Safety lnspection Guide

The intent of this inspection guide

is

to assist

you

in

identifying

potentially unsafe conditions

on

these products. Each machine, as

it

was designed and built, had required safety items installed to protect

users and service personnel from injury. This guide addresses only

those items. However, good judgment should

be

used to identify

potential safety hazards due to attachment of non-IBM features or

options not covered by this inspection guide.

lf any unsafe conditions are present, a determination must

be

made

on how serious the apparent hazard could

be

and whether you can

continue without first correcting the problem.

Consider these conditions and the safety hazards they present:

• Electrical hazards, especially primary power: primary voltage

on

the frame can cause serious or fatai electrical shock.

• Explosive hazards, such as a damaged CRT tace or bulging

capacitar, can cause serious injury.

• Mechanical hazards, such as loose or missing hardware, can

cause serious injury.

Related Publications:

• Hardware Maintenance Reference manual for the IBM Personal

System/2 Mode! 80.

• Any applicable safety publications.

viii Service Bay System

•

•

•

•

Checklist:

1. Check exterior covers for damage (loose, broken, or sharp

edges).

2.

Power-off the system. Disconnect the power cord from the elec-

trical outlet.

3.

Check the power cord for:

a. A third-wire ground connector in good condition. Use a

meter to measure third-wire ground continuity for 0.1 ohm or

less between the external ground

pin

and frame ground.

b. The cord set should be the appropriate molded type as spec-

ified

in

the Parts Catalog

in

this manual.

c. lnsulation must not be frayed or worn.

4. Remove the cover.

5. Check for any obvious non-IBM alterations. Use good judgment

as to the safety of any non-IBM alterations.

6. Check inside the unit for any obvious unsafe conditions, such as

metal filings, contamination, water or other liquids, or signs of fire

or smoke damage.

7. Check for worn, frayed, or pinched cables.

8. Check that the proper fuse

is

installed.

CAUTION:

For continued protection against risk of fire, replace only

with the same type and rating

of

fuse (250 V-/3AIFB).

Attention !

Sécurité incendie: Ne remplacer

un

fusible que par

un

autre

fusible de meme type et de meme calibre (250 V-/3AIFB).

9. Check that the power supply cover fasteners (screws or rivets)

have not been removed or tampered with.

1O. Check for the following safety labels:

• Battery warning (label kit 33F6191

)-found

on

the battery

and

in

the base of the chassis under the battery

ix

• Voltage (part

15F7905)-on

the power distribution control

box

• FCC (part

33F6207)-

on

the back of the display and

on

the

back of the system unit under the cover

• Power rating (part 15F7858 for Model

11

O, 114, and

15F7859 for Model

120)-on

the back of the system unit

under the cover

• Weight label (label kit 33F6191

)-on

the back of the system

unit under the cover

• Are and Spark (label kit 33F6191

)-

on the back of the

system unit under the cover

• Danger label

on

the power supply.

X Service

Bay

System

•

•

About This Book

The Hardware Maintenance Library for the Service Bay System

(SBS) consists of two diagnostic tools: a two-part manual and a

diskette.

The first part of the manual, labeled Hardware Maintenance Refer-

ence, contains:

• "SECTION 1. Generai lnformation

,"

which contains the product

description, theory of operation, and environmental specifica-

tions.

• "SECTION 2. lntroduction to Diagnostics

,"

which explains the

diagnostic aids.

• "SECTION 3. Removai/Replacement Procedures" which gives

the location of the various components and the information

needed to remove and replace any of the Field-Replaceable

Units (FRUs).

The second part of the manual, labeled Hardware Maintenance

Service, contains:

• "SECTION

4.

Start

,"

the entry point for the diagnostic tests of the

SBS.

• "SECTION 5. Diagnostic MAPs

,"

which gives step-by-step

instructions to isolate the failing FRU.

• "SECTION 6. Parts Catalog

,"

wh

i

ch

contains illustrations and

part numbers of FRUs.

A part-number index and

an

alphabetic index also are provided.

The reference diskette is self-explanatory. Help screens are avail-

able by pressing the

F1

key. The reference diskette

is

used with the

MAPs to:

• Test ea

eh

area of the Service Bay System

• Isolate problems to a specific FRU using error codes

• Verify correct installation and operation of the system.

Options might require supplements to this manual.

About This Book

xi

•

•

xii

Service Bay System

•

•

•

Contents

Generai Safety during Work

Safety with Electricity

Safety lnspection Guide

About This Book

Hardware

Maintenance

Reference

SECTION

1.

Generai lnformation

Generai Description

Models

Microprocessor

2MB RAM

CMOS RAM

ROM BIOS

Serial Port

Parallel Port

Diskette Drive Controller

Keyboard Connector and Pointing Device Connector

Power Distribution Contrai Box

Display

CD-ROM Drive . .

Internai 2400-Baud Modem

lmage Adapter/A

Dual Asynchronous Adapter

SCSI Adapter

Generai-Purpose lnterface Bus Adapter

Ethernet Adapter

Diskette Compatibility

Hard Disk Drive

Terminating Resistors

Power Supply

Power-On Self-Test (POST)

Setting Password Security (Power-On Password)

System Board Memory

Adapter Memory

iv

v

viii

xi

3

4

5

5

5

6

6

6

7

7

7

8

9

11

11

11

12

12

13

13

13

14

15

15

16

17

18

18

Contents xiii

Environmental Specifications

Field Replaceable Units

Special Tools

SECTION

2.

lntroduction to Diagnostics

Diagnostic Aids

...

. .

..

.

Using the Reference Diskette

Starting the Reference Diskette

Power-On Self-Test (POST)

Advanced Diagnostic Tests

Starting the Advanced Diagnostic Tests

Diagnostic Program

Presence Test

lnstalled Devices List

System Checkout

Errar Log

Adapter Diagnostics

Memory Diagnostics

Formatting a Hard Disk Drive

Maintenance Analysis Procedures (MAPs)

Symptom-to-FRU lndex

SECTION

3.

Removai/Replacement Procedures

Using the Procedures

Service Position

Removals and Replacements

1005 Left Cover

1

006 Right Cover

1

007 Rear Cover

1008 Front Cover

1015 Memory Card

1020 Adapters

1025 lmage Adapter/A Modules

1035 Front Bezel . .

1

055 Power Supply

1056 Optional Power Supply

1057 Power Distribution Control Box

1058 Fan

1059 Fan (Optional)

1060 Diskette Drive

xiv Service Bay System

20

21

21

23

24

24

27

27

28

29

29

29

30

30

30

31

31

32

32

33

35

37

38

40

40

42

44

45

46

48

49

50

51

53

55

56

58

60 •

1061

Speaker and Battery

61

1062 Emergency Power Off (EPO) Switch 64

1065 DRB Power Supply 66

1074

CD

-ROM Drive Assembly 68

1080 System Board

71

1090 Hard Disk Drive 73

1095 Display 75

1096 Keyboard 77

Locations 78

Front View 78

Rear View 79

lnterior View (Left)

80

lnterior View (Right)

81

Power and Internai Cables (Left)

82

Power and Internai Cables (Right)

83

System Board

84

System Board Connectors

85

Cabling and Safety Ground Wiring 86

Power Distribution Card

88

• Power Distribution Contrai Box

88

SCSI Configuration & Switch/Jumper Settings

89

Hardware Maintenance Service

101

SECTION

4.

Start 103

MAP 0000: Start 104

Undetermined Problem 119

SECTION

5.

Diagnostic MAPs

121

MAP 0020: System Power 123

MAP 0200: Memory 140

MAP 0300: Keyboard 146

MAP 0610: Diskette Drive 152

MAP 2000: lmage Adapter/A 155

MAP 2100: SCSI Devices 165

MAP 3000: DRB and Power Supply 169

MAP 4000: Generai-Purpose lnterface Bus (GPIB) 176

SECTION

6.

Parts Catalog . . . ' . . . 179

Contents XV

How To Use This Parts Catalog 182

Assembly

n:

Example Parts List 182

Assembly 1: Covers .

...

. 183

Assembly 2: Cart/Main Chassis 184 •

Assembly 3: Rear Pane! Cables 185

Assembly 4: Main Chassis, Left 187

Assembly 5: Main Chassis, Right 189

Assembly

6:

Front Pane!, Left 190

Assembly

7:

Front Pane!, Right

191

Assembly 8: Left Pane! Cables 192

Assembly

9:

Right Pane! Cables 193

Assembly

10:

DRB Storage Box 194

Assembly

11:

DRB Power Supply 195

Assembly

12:

CD-ROM Drive Type A 196

Assembly

13:

CD-ROM Drive Type 8 198

Assembly

14

: Hard Disk Drive 199

Assembly

15

: System Board 200

Assembly 16: Fan

201

Assembly 17: Display/Keyboard 202

Assembly

18

: Cart/Drawer 204

Assembly

19:

Tools 206

Assembly

20:

Decals 207

Appendix. Notices 209

FCC Statement 209

Glossary of Terms and Abbreviations

211

Part Number lndex 213

lndex . . . . . 217

•

xvi

Service Bay System

Hardware Maintenance Reference

•

•

•

Hardware Maintenance Reference 1

•

2 Service Bay System

•

•

Generai lnformation

SECTION

1.

Generai lnformation

Generai Description

Models

Microprocessor

2MB

RAM

CMOS

RAM

ROM BIOS

Serial Port

Parallel Port

Diskette Drive Controller

Keyboard Connector and Pointing Device Connector

Power

Distribution Control Box

Display

CD-ROM Drive

Internai 2400-Baud

Modem

lmage Adapter/A

Dual Asynchronous Adapter

SCSI Adapter

Generai-Purpose lnteriace Bus Adapter

Ethernet Adapter

Diskette Compatibility

Hard Disk Drive

Terminating Resistors

Power

Supply

Power-On Self-Test (POST)

Setting Password Security (Power-On Password)

System Board Memory

Adapter Memory

Environmental Specifications

Field Replaceable Units

Special Tools

4

5

5

5

6

6

6

7

7

7

8

9

11

11

11

12

12

13

13

13

14

15

15

16

17

18

18

20

21

21

SECTION 1. Generai lnformation 3

Table of contents

Other IBM Keyboard manuals

IBM

IBM 5475 User manual

IBM

IBM Preferred USB Keyboard with Hub User manual

IBM

IBM TrackPoint USB Space Saver Keyboardwith Hub User manual

IBM

IBM Rapid Access III USBKeyboard User manual

IBM

IBM 3277 User manual

IBM

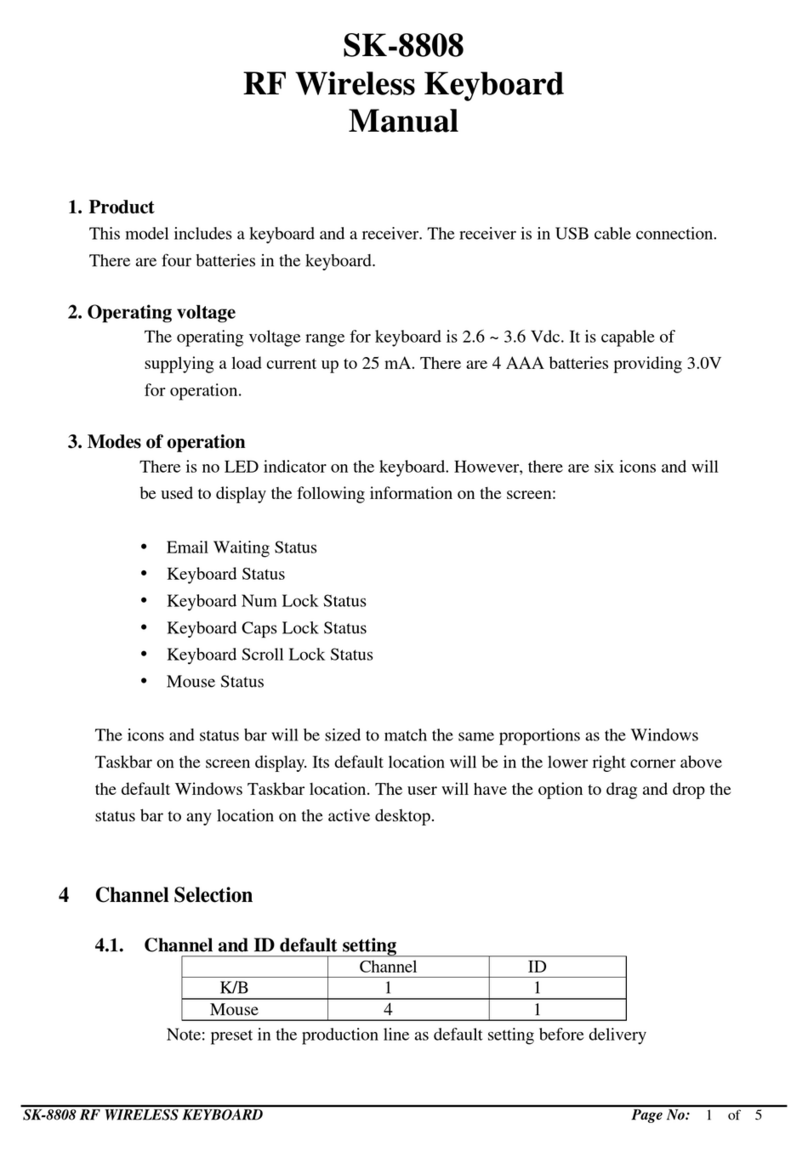

IBM SK-8808 User manual

IBM

IBM 3215 User manual

IBM

IBM 4685-K03 Technical Document

IBM

IBM TrackPoint User manual