1.1 INTRODUCTION

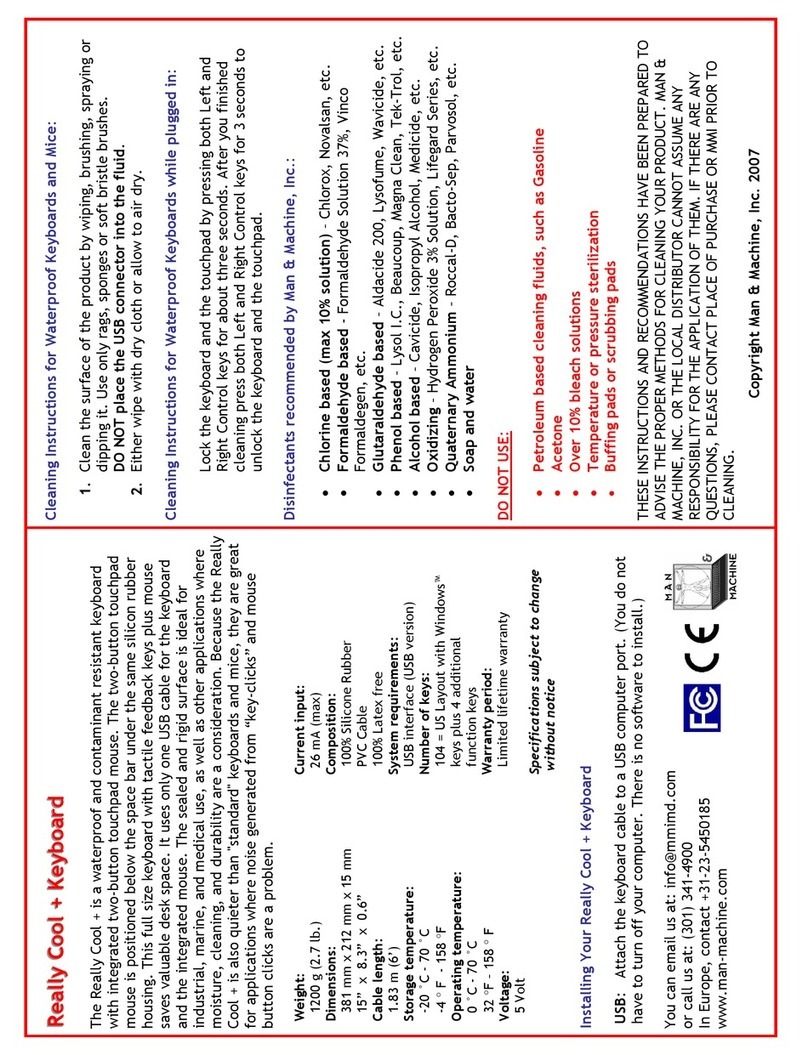

Maintenance

of

IBM

3277 Display Stations (including

repair and adjustment

of

Model 1 and Model 2 units) and

of

attached features

is

described

in

this manual. Features

that

can

be

attached

to

a 3277 include keyboards, a selector

light-pen, and an operator identification card reader.

The objective

of

display station maintenance

is

to

return

the failing

unit

to

customer service as quickly as possible.

This manual guides the Customer Engineer through

procedures

that

enable him

to

adjust

or

replace a

malfunctioning component.

1.1.1 Online/Offline Maintenance

Display Station maintenance and testing can be performed

online

and/or

offline. It

is

better, however,

to

service

the

unit

offline when possible because

it

eliminates

the

possibility

of

interaction with

other

units

of

the display

system. Unnecessary delays

in

normal customer infor-

mation processing are thereby avoided. The maintenance

approach described

in

this manual

is

structured

to

perform

offline analysis first

to

resolve reported troubles.

1.1.2 Field Replaceable Units (FRU)

Component replacement

is

limited

to

certain field-

replaceable units (FRU). When

the

trouble

is

isolated

to

an

FRU

the

unit should be replaced immediately rather

than

repaired. The FRU parts replacement philosophy

is

practical because functionally packaged logic and densely

packed components are used throughout

the

display

station.

1.1.3 Troubleshooting Aids

Several tools are available

to

the Customer Engineer

to

simplify trouble analysis. The following paragraphs describe

these aids.

1.1.3.1 Symptom Index

The Symptom Index (Section

3)

lists (by category)

malfunctions

that

may be encountered on display stations.

The categories include such areas as display malfunctions,

power malfunctions, keyboard malfunctions, etc.

In

each

category, subcategories specify unique trouble areas. The

subcategories direct the Customer Engineer

to

an entry

in

the Troubleshooting Diagrams (Section 4), which contain

step-by-step isolation procedures. In some cases, the

Symptom Index points directly

to

a replaceable unit

causing the problem.

Section 1. Maintenance Approach

1.1.3.2 Troubleshooting Diagrams

The Customer Engineer

is

directed

to

Troubleshooting

Diagrams from

the

Symptom Index.

The

diagrams detail

procedures

to

isolate a failing F

RU

or

an out-of-tolerance

adjustment.

The

diagrams call

out

specific checks

and

observations

that

shou

Id

be made during

the

diagnostic

procedure.

The

logic probe test device

is

used

in

many

of

the diagrammed procedures.

1.

1.3.3 Diagnostic Programs

Two types

of

diagnostic programs may be available

to

the

Customer Engineer. Diagnostic program aids are described

in

Section 2

of

this

manual.

1.1.3.4 Customer Engineer Tool

Kit

Special tools are

not

required

to

maintain

3277

Display

Stations. The basic Customer Engineer

tool

kit,

the

IBM

volt-ohmmeter, and

the

logic probe can successfully isolate

most display station problems. An oscilloscope may be

required

in

some instances when

the

basic tools fail

to

resolve a problem.

1.2 TROUBLE ANALVSIS

The sequence

in

which display station trouble analysis

is

performed

is

important

in

minimizing machine down-time.

Diagram

1-1

shows

the

five-step procedure

that

should be

used

to

isolate display station failures.

The

main points

of

the display station maintenance approach are summarized

below.

1.2.1 Obvious Symptoms

Obvious symptoms are those

that

do not require any

operator or Customer Engineer action

to

bep>me evident.

Failures

that

could cause obvious symptoms

to

occur

include display image quality and positioning, mechanical

problems, and component breakage. These failures should

be

remedied by going directly

to

the Symptom Index

or

to

the appropriate adjustment or removal procedure

in

Section

5.

Use

the

first entry

that

matches the failure.

1.2.2 Isolation

to

a Display Station

If

an obvious symptom does

not

exist on a display station,

the cause

of

the failure must

be

isolated between the

control unit and the display station. Sheet 1

of

the

Troubleshooting Diagrams describes

the

procedure for

isolating the cause

of

a failure

to

either

the

control unit,

connecting coaxial cable,

or

display station.

Maintenance

Approach

1-1