MANUAL FOR KG20 KG6 KG6 BASIC

DRY ICE BLASTING EQUIPMENT FROM ICETECH | PAGE 3

“ Drastic reduction of waste problems.

No abrasive effect. ”

DRY ICE BLASTING – HOW IT OPERATES

Method

Dry ice blasting equipment uses small CO2”par-

ticles” as the blasting medium – in the following

called Dry Ice pellets. (CO2– the chemical denomi-

nation for carbon dioxide). Liquid CO2is expanded

in a special unit to CO2snow. This substance is then

subjected to high pressure and is forced through a

matrix to create hard and uniform pellets of approx.

3 mm in diameter and 10 mm long.

These Dry Ice pellets have a temperature of

-79°C/110°F and when used for dry ice blasting

immediately change from solid to gaseous form on

contact with the object being cleaned, i.e. the pel-

lets heat up on impact. This change, from solid to

gaseous form, and the accompanying tremendous

expansion in volume, are among the factors which

result in the loosening of impurities.

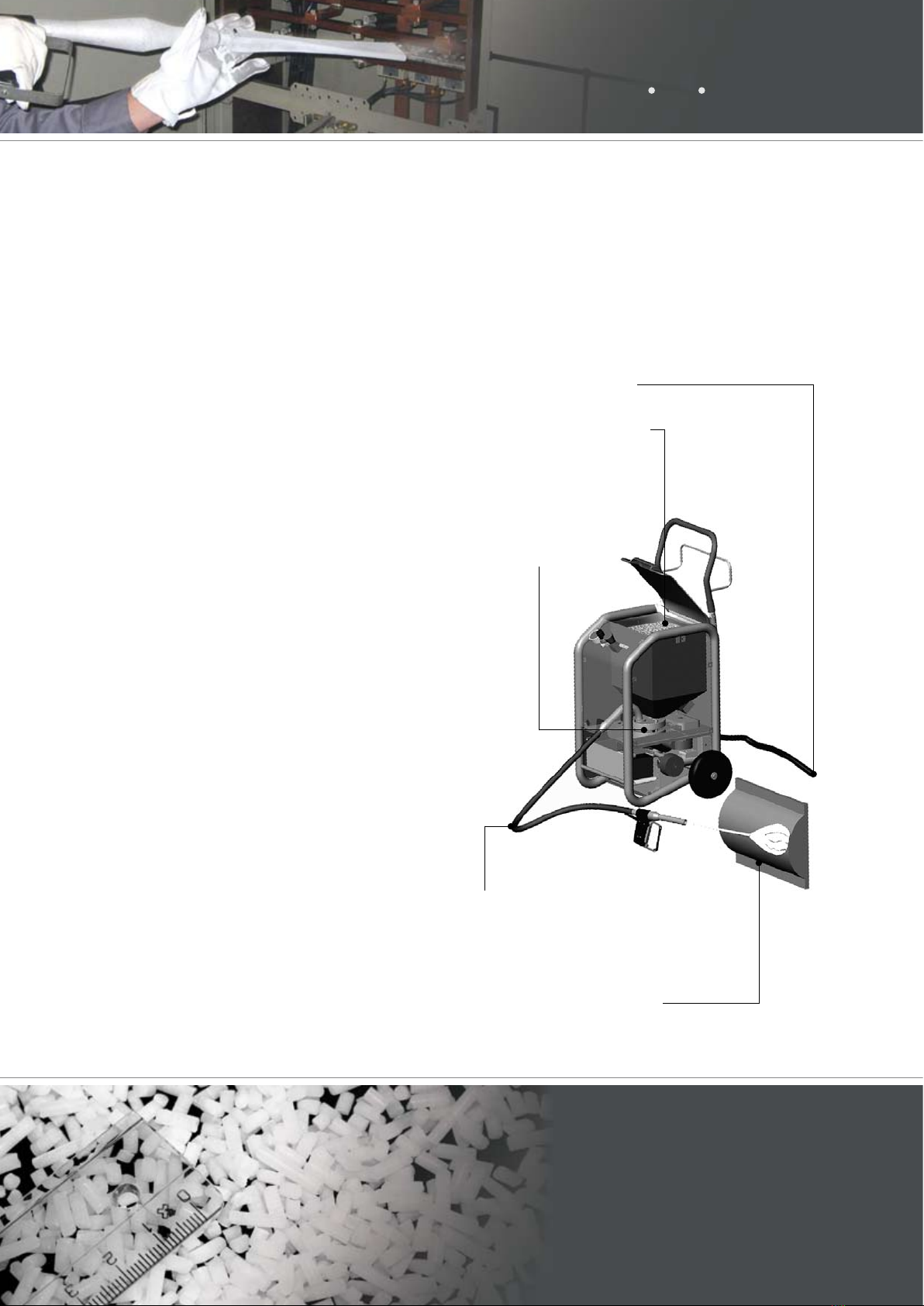

The transportable dry ice blasting machine

contains a dry ice container and a dispensing unit

which forces the dry ice through a hose to the

blasting gun.

In the gun, the air stream is accelerated and with

it the velocity of the Dry Ice pellets. They leave the

nozzle of the blasting gun at very high velocity and

gain high kinetic energy (movement energy) before

striking the impurities.

The Cleaning Effect of Dry Ice Pellets

The cleaning effect of dry ice is based on

three principles –

•The thermal effect

•The kinetic effect

• Volume expansion

• Thermal Effect:

Dry Ice pellets have a temperature of

-79°C/110°F and impurities are therefore cooled

down drastically: They shrink and loosen.

• Kinetic Effect:

When Dry Ice pellets leave the blasting gun

nozzle they have high kinetic energy; an

important characteristic in removing deposits.

• Sublimation Effect:

When a Dry Ice pellets impacts the object being

cleaned it is immediately transformed from solid

to gaseous form and its volume increases by a

factor of approx. 700. In the process, deposited

dirt become loose and brittle and is torn away

from the underlying surface.

In some cases the thermal effect will be the most

signicant (e.g. where deposits of bitumen, resin,

glue are involved), in other cases the kinetic effect

will be the most signicant (e.g. on brittle deposits).

MANUAL FOR KG20 KG6 KG6 BASIC

DRY ICE BLASTING EQUIPMENT FROM ICETECH | PAGE 4

It is important that operators carefully follow the

safety regulations located on the machine or con-

tained in the manual. Operators must read and un-

derstand the contents of the whole manual before

starting the machine.

The signs located on the machine are to remind

operators that use without risk depends on their

following all regulations, including those describing

work clothing.

Precautions during Blasting

Ai r, CO2gas and Dry Ice pellets leave the gun nozzle

at a very high velocity (up to 300 m/s).

Therefore,

• do not aim the nozzle at persons or in the

direction of places where other people work

• remember that the Dry Ice pellets can be

thrown back from the object being cleaned,

• do not aim the nozzle in directions where

damage might result.

The machine must not be used in “fun” and the gun

nozzle must never be aimed at persons or other

living creatures.

“ Dry ice blasting has some

important advantages over other

cleaning methods. ”

SAFETY REGULATIONS

General

This manual contains instructions and safety regula-

tions which must be followed on starting, operating

and servicing the dry ice blasting machine.

It is important that the manual be kept so that the

operators always know its exact location.

It is also important that the owner makes sure that

operators understand and follow the contents of the

manual.

Personnel Qualications

Personnel responsible for installation, servicing and

maintenance must be suitably qualied to perform

these functions. If personnel are not in possession

of sufcient knowledge they must be instructed and

trained. Such training can be arranged in coopera-

tion with the manufacturer of the machine.

The owner of the machine must ensure that the

person appointed to operate the dry ice blasting

machine fully understands and is able to follow the

SAFETY REGULATIONS laid down in the following

pages.

The regulations must also be located on the

machine and should be carefully studied.

Security and Risk

The machine is constructed to comply with the

standards and clauses contained in the terms

of sale. Therefore, provided the manufacturer’s

instructions are followed, the machine will not pose

any risk to operators.