Thecutoutspeeddialadjuststhemotorvoltagerange.Setthecutout

voltagedialaccordingtothetypeofmotoryouhave.

Sleeve Bearing Motors:

Setthecutoutspeeddialtothemiddleofthesleevebearingrange.In

thisrange,themotorcanrundownapproximately40-50%ofthefullline

voltage,whichallowssufcientRPMsforcoolingandlubrication.

CAUTION!:

Withsleevebearingmotors,itisimportantnottoadjust

outsidethesleevebearingrangeorbearingfailuremayresult.

Ball Bearing Motors:

SetthecutoutspeeddialtotheMINpositionintheballbearingrange.Thispositionoffersthegreatestrangeof

speedcontrol.AttheMINsettingthemotorcanrundowntoapproximately20-30%ofthefulllinevoltage.

Note:After starting at the recommended settings for either sleeve or ball bearing motors, you can ne tune the

cutout speed to achieve the desired results.

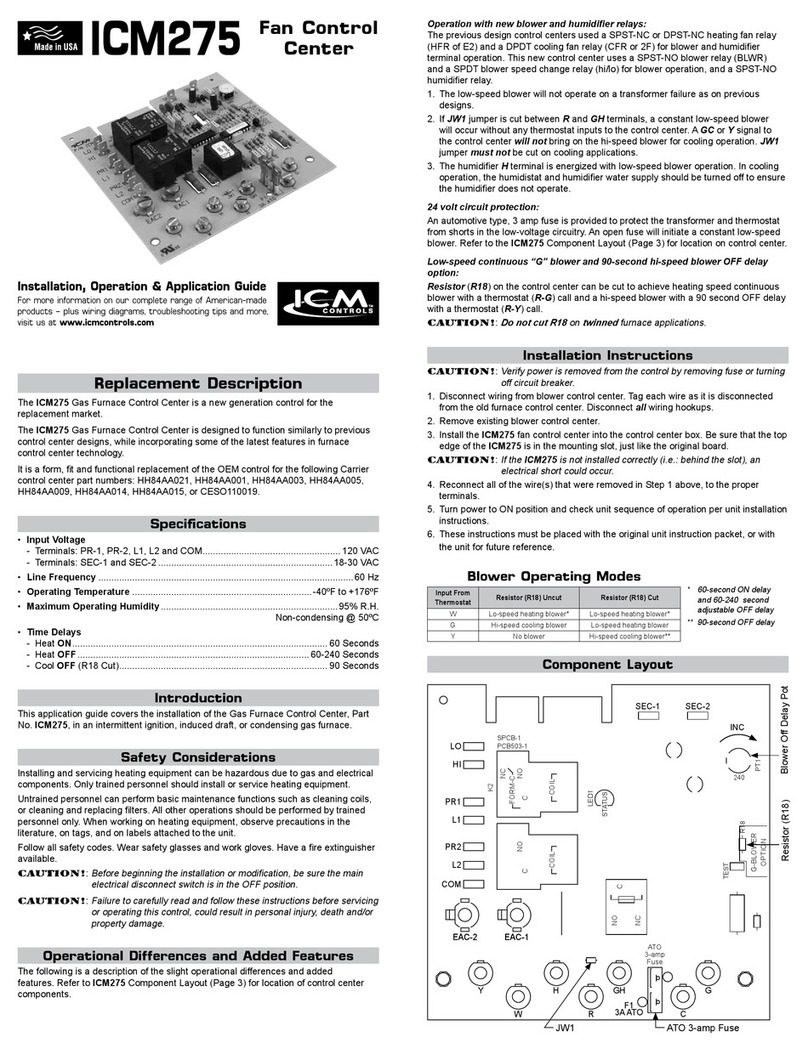

1. TheHeat Pumpterminalsacceptthe24VACsignalfromthereversingvalveholdingcoil.Makeaparallel

connectionfromthereversingvalvetotheHPterminals.

Note: Do not apply a voltage higher than 30 VAC to the HP terminals.

2. IftheHeat PumpisintheHeatingmodeandthereversingvalveisenergized,thentheHeat Pump

SelectjumpermustbeintheDefault(N.O.)position.

3. IftheHeat PumpisintheHeatingmodeandthereversingvalveisnotenergized,thentheHeat

Pump SelectjumpermustbeintheN.C.position.

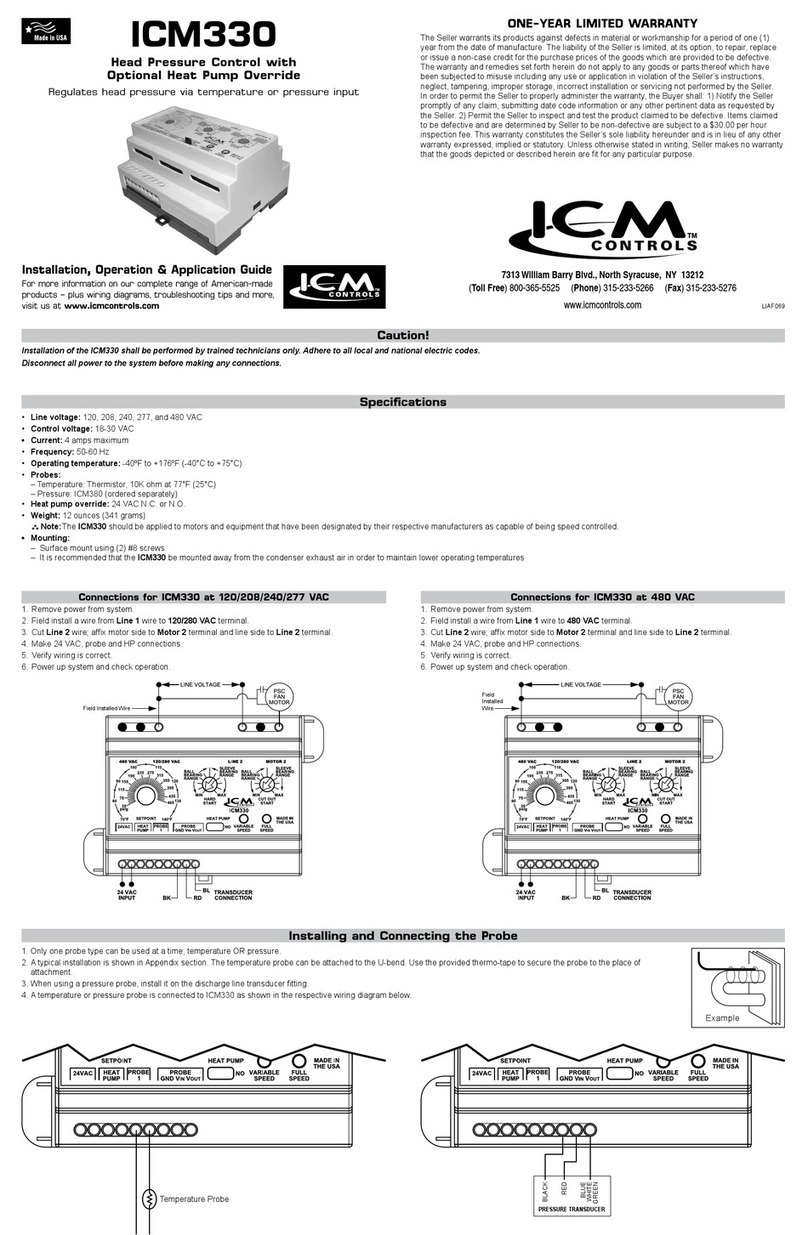

Connections for Heat Pump Systems

N.O.

N.C.

Temperature

Probe

24VAC ConnectParallelto

24VACReversingValve

Additional

Probes

ProbeS1

HP

HeatPump

SelectJumper

DefaultPosition

Normal Function

Withprobetemperaturesabove100°F,thecontrolappliesfullvoltagetothemotor.Thegreenlightisilluminated(full

speedLED).

Withprobetemperaturesbetween70°Fand100°F,themotorspeedisproportionaltotheprobetemperature.The

yellowlightisilluminated(variablespeedLED).

Whenthemotorstartsattemperaturesbetween70°Fand100°F,itwillhardstartforthelengthoftimedictated

bythehardstartdialsetting.Afterthehardstarttimehaselapsed,themotorspeediscontrolledbytheprobe

temperature.

Asthetemperaturebeingsenseddecreases,theoutputvoltagedecreases.Theoutputvoltagemaydecreaseto

thedeterminedcutoutspeeddictatedbythecutoutspeeddial.Uponreachingthecutoutspeedsetting,theoutput

voltagegoestozerovolts.

Systemrestartwilloccurwhenthetemperatureexceeds70°F.

Withprobetemperaturesbelow70°F,themotorremainsoff.Thegreenlightandtheyellowlightareoff.

Heat Pump Bypass Operation

Heatpumpbypassmoderunsthefanatfullspeedwhenthesystemisoperatinginheatmode.Thismovesasmuch

airaspossibleacrossthecondensercoil.

IftheheatpumpselectjumperisintheN.O.position,and24VACisappliedtotheHPterminals,themotorwillbe

broughttofullspeed.

IftheheatpumpselectjumperisintheN.C.position,and24VACisnotpresentattheHPterminals,themotorwill

bebroughttofullspeed.

Aseparaterelayisnotneeded.

Mode of Operation

Setting the Hard Start Time

DuringtheHard Startmode,fullvoltageisappliedtothemotorduringstartupto

overcomewindmillingandtolubricatethebearings.

Thepositionofthehardstartdialdeterminesthetimeperiodofthehardstartmode.

Thedialcanbeadjustedbetween0.1secondandapproximately5seconds.

Setthehardstartdialaccordingtothetypeofmotoryouhave.Ifyouhaveaball

bearing motor,setthehardstartdialtotheMINposition.Ifyouhaveasleeve

bearing motor,setthehardstartdialtothemiddleofthesleevebearingrange.

Afteryoubeginattherecommendedsetting,youcannetunethehardstarttime

withintherecommendedrangeforthetypeofmotoryouhave.

Itisrecommendedthatyouusetheminimumpossiblehardstarttimetoavoid

blowingtoomuchcoldairoverthecondenser.

Hard Startmodeisactivatedwhen24VACisapplied(ordisconnectedandre-applied)ortheprobetemperature

increasestoabove70°F.Thehardstartmodeappliesfullvoltagetothemotorforthesettimeperiod.Afterwards,the

motorspeedisdictatedbythetemperaturesensor(s).

Symptom Problem

Unitfailstostart Thesensormaynotbeconnectedoritisdefective.

Withtheprobedisconnected,useanohmmetertomeasuretheresistancebetweenthe

probewires.ItshouldmatchthechartinAppendixB(seebelow).IfyoureadanOPENor

SHORT,replacethesensor.

Fuseand/or

circuitblows

Theunithasbeenmiswiredandmaybepermanentlydamaged.

Thefancycles

fromfullONtofull

OFFwithlittleor

nomodulation

TurnOFFthecontrolcircuitpower(24VAC).Re-apply24VACpowerandconrmhardstart

operation.Reducethehardstartperiodtotheminimumsettingrequiredtoacceleratethe

fan.Excessivehardstartingcauseslargepressuredropsbyrunningtoomuchcoldairover

thecondenser.

Shouldthecyclingpersist,movetheprobeupseveralbendsintothecondensertoincrease

thesensitivitytocondensingtemperature.

Adjustprobelocation.Finetunecutoutadjustment.

Thefandoesnot

comeonatall

UsinganACvoltmeter,measurethevoltagebetweenthe24VACterminals.Itshouldread

approximately24volts.

MeasurethelinevoltagebetweenLINE 1andLINE2toconrmthatthelinevoltageis

present.

Removethethermistorprobefromtheterminalblockandmeasureitsresistanceatambient

temperature.CompareyourreadingattheappropriatetemperatureinAppendixB(seePage

9)toseeiftheactualresistanceapproximatesthelistedvalue.Next,holdtheprobeinyour

handandconrmthattheresistancedecreases.

PlaceatemporaryjumperacrosstheS2orS3terminals.Fanshouldrunatfullspeed.Ifit

does,recheckprobeconnectionandverifyprobeisoperatingcorrectly.

Thehighpressure

switchtripsoff

Movetheprobefurtherintothecondenserwherethetemperatureishigher.Thiswillproduce

ahigherfanRPMandwilldecreasetheheadpressure.

Fineadjustthecutoutandhardstartsettings.

Greenandyellow

LEDsalternate

UsinganACvoltagemeter,measurethevoltagebetweenthe24VACterminals.

AlsoverifyyouhavethevoltagebetweenLine 1andLINE2terminals.

Troubleshooting

Mountingasensorintothecondenser

vs. mounting it on the liquid line

Whenasensorismountedintothecondenser,the

controlrespondsmorerapidlytochangesinhead

pressurethanwhenitismountedontheliquidline.This

isespeciallytrueforhighefciencycondensers.

Whenthesensorismountedontheliquidline,the

controlrespondsmoreslowlyandtheresultscanbea

fanthatcyclesonandoff.

Wheneverpossible,itispreferabletomountthesensor

intheupper1/3ofthecondenserinsteadofmountingit

ontheliquidline(seeillustrationbelow).Aspotonthe

condenserthatis100Fwhenthepressuresarecorrect

isideal.

Temperature vs. Probe Resistance

°C °F Resistance (KΩ)

0° 32° 32.7

5° 41° 25.4

10° 50° 19.9

15° 59° 15.7

20° 68° 12.5

25° 77° 10.0

30° 86° 8.1

35° 95° 6.5

40° 104° 5.3

45° 113° 4.4

50° 122° 3.6

Appendix A Appendix B

Setting the Cutout Speed

ONE-YEAR LIMITED WARRANTY

TheSellerwarrantsitsproductsagainstdefectsinmaterialorworkmanshipforaperiodofone(1)yearfromthe

dateofmanufacture.TheliabilityoftheSellerislimited,atitsoption,torepair,replaceorissueanon-casecreditfor

thepurchasepricesofthegoodswhichareprovidedtobedefective.Thewarrantyandremediessetforthherein

donotapplytoanygoodsorpartsthereofwhichhavebeensubjectedtomisuseincludinganyuseorapplication

inviolationoftheSeller’sinstructions,neglect,tampering,improperstorage,incorrectinstallationorservicingnot

performedbytheSeller.InordertopermittheSellertoproperlyadministerthewarranty,theBuyershall:1)Notify

theSellerpromptlyofanyclaim,submittingdatecodeinformationoranyotherpertinentdataasrequestedbythe

Seller.2)PermittheSellertoinspectandtesttheproductclaimedtobedefective.Itemsclaimedtobedefective

andaredeterminedbySellertobenon-defectivearesubjecttoa$30.00perhourinspectionfee.Thiswarranty

constitutestheSeller’ssoleliabilityhereunderandisinlieuofanyotherwarrantyexpressed,impliedorstatutory.

Unlessotherwisestatedinwriting,Sellermakesnowarrantythatthegoodsdepictedordescribedhereinaretfor

anyparticularpurpose.

LIAF042

PatentNo.424,953

7313WilliamBarryBlvd.,NorthSyracuse,NY13212

(Toll Free)800-365-5525(Phone)315-233-5266(Fax)315-233-5276

www.icmcontrols.com