CX-3195

8

1234

1234

C

D

F

A

B

E

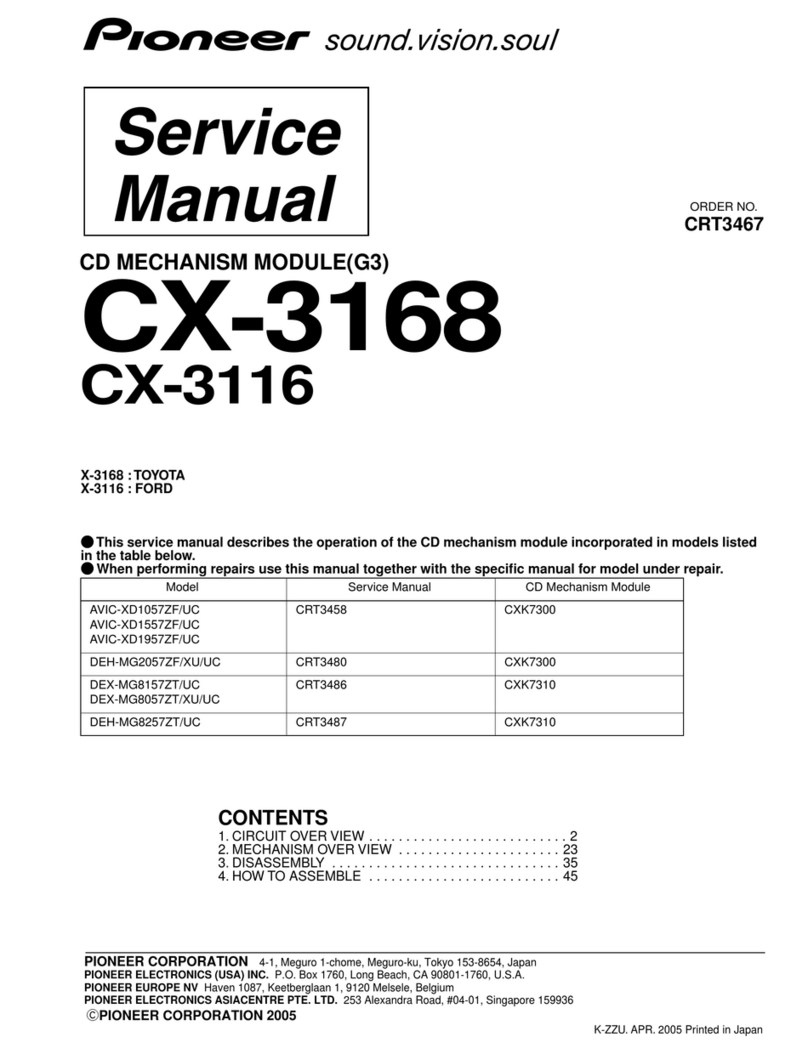

The servo block performs servo control such as error signal equalizing, in-focus, track jump and carriage move. The DSP

block is the signal-processing unit, where data decoding, error correction, and compensation are performed. The FE and

TE signals, generated in the preamplifier stage, are A/D-converted, and output drive signals for the focus, tracking, and

carriage systems via the servo block. Also, the EFM signal is decoded in the signal-processing unit, and ends up in

outputting D/A-converted audio signals through the D/A converter. Furthermore, in this decoding process, the spindle

servo error signal is generated, supplied to the spindle servo block, and used to output the spindle drive signal.

Each drive signal for focus, tracking, carriage, and spindle servos (FD, TD, SD, and MD) are output as PWM3 data, and

then converted to analog data through the LPF. These drive signals, after changed to analog form, can be monitored with

the FIN, TIN, CIN, and SIN signals, respectively. Subsequently, the signals are amplified and supplied to the actuator and

motor for each signal.

1.2.1 Focus servo system

The main equalizer of the focus servo consists of the digital equalizer block. The figure 1.2.1 shows the block diagram of

the focus servo system.

In the focus servo system, it is necessary to move the lens within the in-focus range in order to close the focus loop. For

that purpose, the in-focus point is looked for by moving the lens up and down with the focus search voltage of triangular

signal. During this time, the rotation of the spindle motor is retained at a certain set speed by kicking the spindle motor.

The servo LSI monitors the FE and RFOK signals and automatically performs the focus-close operations at an appropriate

timing. The focus-close operation is performed when the following three conditions are satisfied at the same time:

1) The lens moves toward the disc surface.

2) RFOK = "H"

3) The FE signal is zero-crossed.

Consequently, the FE converges to "0" (= REFO).

When the above-mentioned conditions are met and the focus loop is closed, the FSS bit is shifted from "H" to "L," and

then, in 10 ms, the CPU of the LSI starts monitoring the RFOK signal obtained through the low-pass filter.

If the RFOK signal is determined to be "L," the CPU of the LSI takes several actions including protection.

Fig.1.2.2 shows a series of actions concerning the focus close operations. (It shows a case where the focus loop cannot

be closed.)

With the focus mode selector displaying 01 in the test mode, pressing the focus close button, allows to check the

S-shaped curve, search voltage, and actual lens behavior.

Fig.1.2.1 Block diagram of the focus servo system

1.2 SERVO BLOCK (PE5547A: IC201)

129

130

A + C

B + D

PWM FD

109

IC201 PE5547A

6

11

12 FOP

FOM

LENS

IC301 BA5839FP

FE

AMP A/D DIG.

EQ

FOCUS SEARCH

TRIANGULAR

WAVE GENERATOR

CONTROL