7313 William Barry Blvd.

North Syracuse, NY 13212

ICM CONTROLS 800.365.5525

www.icmcontrols.com LIAF107-1

FEATURES SPECIFICATIONS

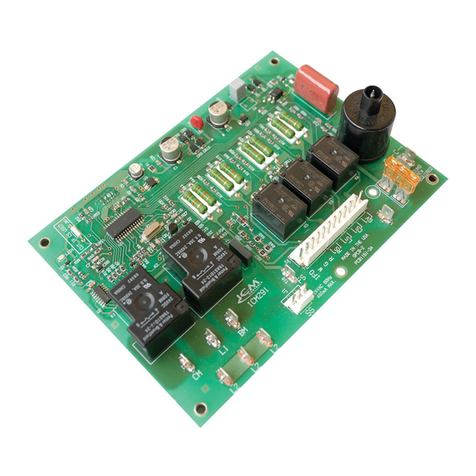

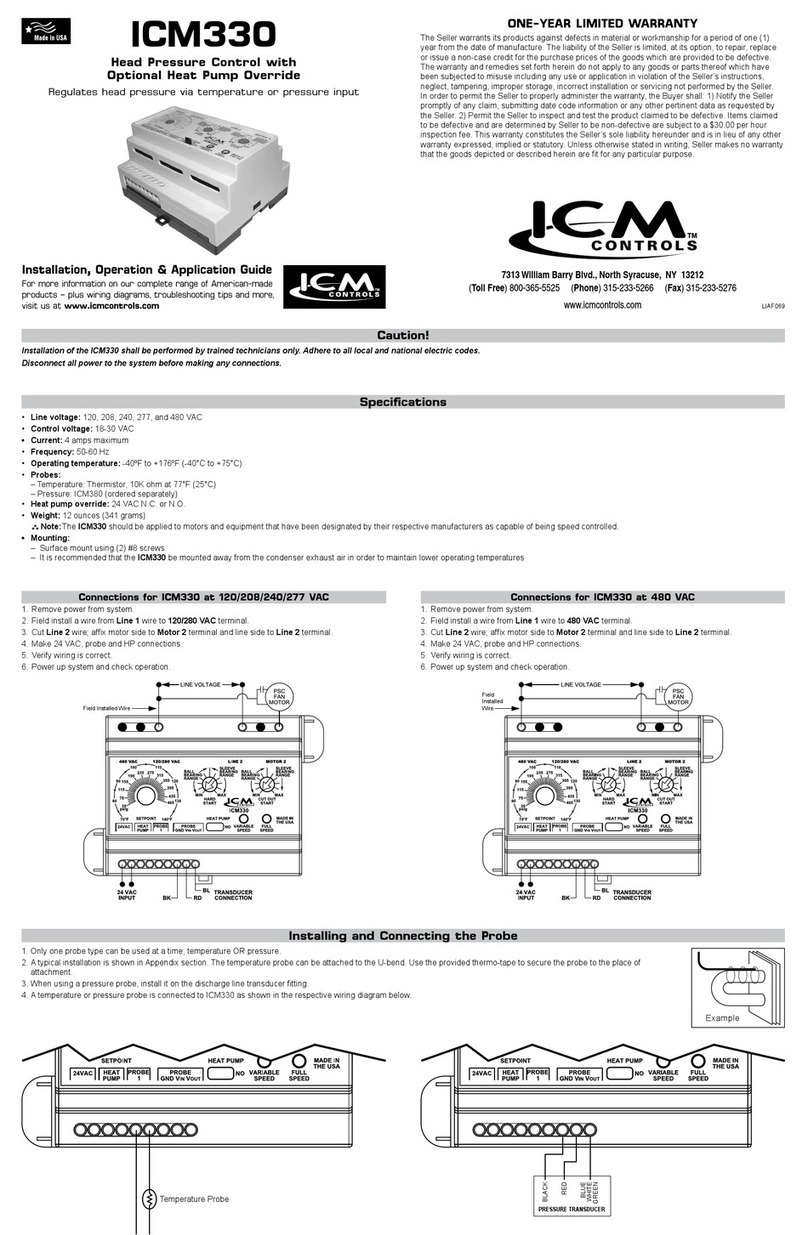

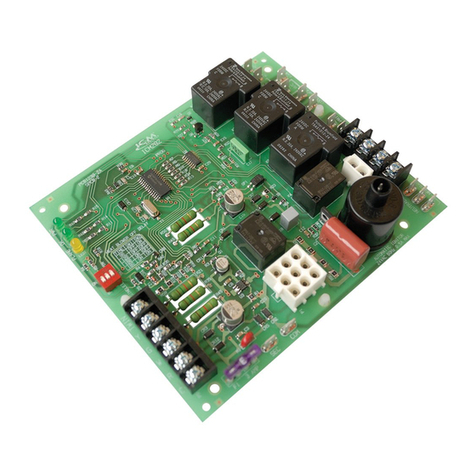

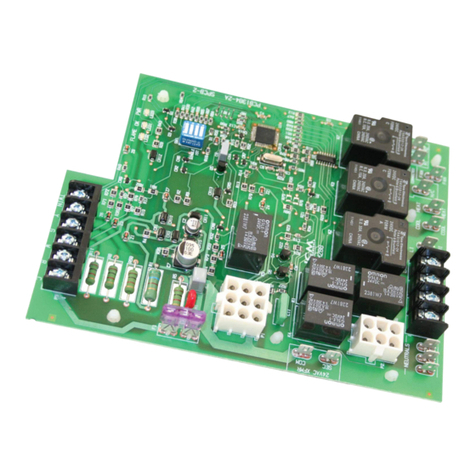

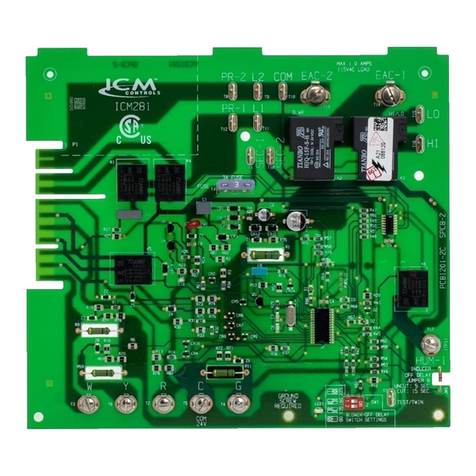

ICM292

Gas Ignition Control Board

• Control voltage:24VAC(18-30VAC),60Hz

• Line voltage:115VAC,60Hz

• Power consumption:0.3Aplusgasvalvecurrentat24VAC

• Operating temperature:-40°C(-40°F)to75°C(176°F)

Timing

• Pre-purge:30seconds

• Trial for ignition:7seconds

• Retries:Twogroupsoftwo,30secondsdelaywithinthe

groupand3minutesdelaybetweengroups

• Lockout:1hour

• Post-purge:90,120,160and180seconds

Inputs

• Power:24VACandCOM

• Thermostat interface:R,W,YandG

• System switches:VentPressureandLimitswitches

(MainandOver-temperatureswitchesinseries)

• Flame Sensing

• Heat blower OFF delay: SW1toggleswitch

Install New Control

1. Groundyourself.Whenhandlingcircuitboard,holditbytheedges.

2. Fastencircuitboardwithretainingscrews.

3. Connectalllinevoltage,lowvoltage,andaccessorywires.

4. Verifythesequenceofoperation.

Safety Considerations

Onlytrainedpersonnelshouldinstallorserviceheatingequipment.Whenworkingwithheatingequip-

ment,besuretoreadandunderstandallprecautionsinthedocumentation,onlabels,andontags

thataccompanytheequipment.Failuretofollowallsafetyguidelinesmayresultindamagetoequip-

ment,severepersonalinjuryordeath.

Introduction

TheICM292DSIgasignitioncontrolreplacesthefollowingRheemmodel:62-24140-04.TheICM292

hasincorporatedLEDdiagnosticstoassistintroubleshooting.Faultcodeinformationcanbefound

inthisapplicationguide.Pleasekeepthisapplicationguidewiththefurnaceinstallationmanualfor

futurereference.

Electrostatic Discharge (ESD) Precautions

CAUTION!

Use caution when installing and servicing the furnace to avoid and control electrostatic discharge;

ESD can impact electronic components. These precautions must be followed to prevent

electrostatic discharge from hand tools and personnel. Following the precautions will protect the

control from ESD by discharging static electricity buildup to ground.

1. Disconnectallpowertothefurnace.Donottouchthecontrolorthewiringpriortodischargingyour

body’selectrostaticchargetoground.

2. Togroundyourself,touchyourhandandtoolstoaclean,metal(unpainted)furnacesurfacenear

thecontrolboard.

3. Servicethefurnaceaftertouchingthechassis.Yourbodywillrechargewithstaticelectricityasyou

shufeyourfeetormovearound,andyoumustregroundyourself.

4. Regroundyourselfifyoutouchungroundeditems.

5. Beforehandlinganewcontrol,regroundyourself;thiswillprotectthecontrol.Storeusedandnew

controlsinseparatecontainersbeforetouchingungroundedobjects.

6. ESDdamagecanalsobepreventedbyusinganESDservicekit.

AWcallfromthethermostatwillengagetheInducerDraftmotor.TheVentPressureswitchcloses.

Ignitionsequencebegins,gasvalveandsparkareengaged,providingthatsystemsafetyswitches

(MainandOver-temperatureswitchesinseries)areclosed.TheBlowermotorwillengageatHEAT

speed20secondsafterameisestablishedandsensed.OnWcallsatisfaction,theInducermotor

turnsoffafter10secondsandBlowermotorturnsoffaccordingtoHeatBlowerOffdelaysetting.

AGcallfromthethermostatwillengageBlowermotorwithoutdelayatFANspeed.Itdisengages

withoutdelaywhenGcallisremoved.

AYcallfromthethermostatwillengageBlowermotorwithoutdelayatCOOLspeed.Itdisengages

45secondsafterYcallissatised.

Sequence of Operation

Flame not established

1. Ifameisnotestablishedduringthe7secondinitialsequencethenthecontrolwillstartthenext

trialforignitionin30seconds.

2. Therewillbetwomoreattemptstoigniteafter3minutedelay,30secondsapartbeforethe

respectivefaultcodeistriggeredandignitiontrialsarestopped.

3.Thegasvalveisenergizedonlyduringtheignitionsequenceof7seconds.

4. Blowermotorisoffuntil20secondsafterameisestablished.

Flame out

1. Flameoutisconsideredwhenameislostduringheating.

2. WhenWsignalispresentandameisnotsensed,thengasvalvewilldisengageuntilthenexttrial

forignition

3. Ifameisnotestablishedontheimmediatesequence(2above)thenthecontrolwillcontinuewith

additionaltrialsforignition

4. InducerandBlowermotorswillcontinuerunningduringameoutscenario

Flame out of sequence

1. FlameoutofsequencerepresentsascenariowhenameissensedwhileWsignalisnotpresent.

2. InducerandBlowermotorswillbeengaged(ifnotalreadyrunning)andkeeprunningforaslongas

thefaultconditionispresent.

3.Thereis1hourlockoutbeforeaWcallcanbeexecutedoronpowerreset

Troubleshooting Tips

LED Fault Codes

Outputs

• Spark:SE

• Gas Valve:GV

• Inducer draft motor:IDM

• Blower motor:FAN,COOLand

HEATspeeds

• Electric Air Cleaner:EAC

• Humidier relay:HUM

• Heat/Cool relay:H/C

LED indicators

• Power, green LED:PWR

• Status, green LED:OK

• Flame status, yellow LED:FLAME

• Direct Spark Ignition (DSI) control board

• Microprocessor-based

• Controls inducer motors, air cleaner (if equipped), humidier (if

equipped), spark ignitor and the gas valve

• Monitors timing, trial for ignition, system switches, ame sensing

and lockout

• 100% lockout safety feature

• Compatible with LP or Natural Gas

• LED indication for status and fault codes to aid in troubleshooting

• Replaces: Rheem 62-24140-04

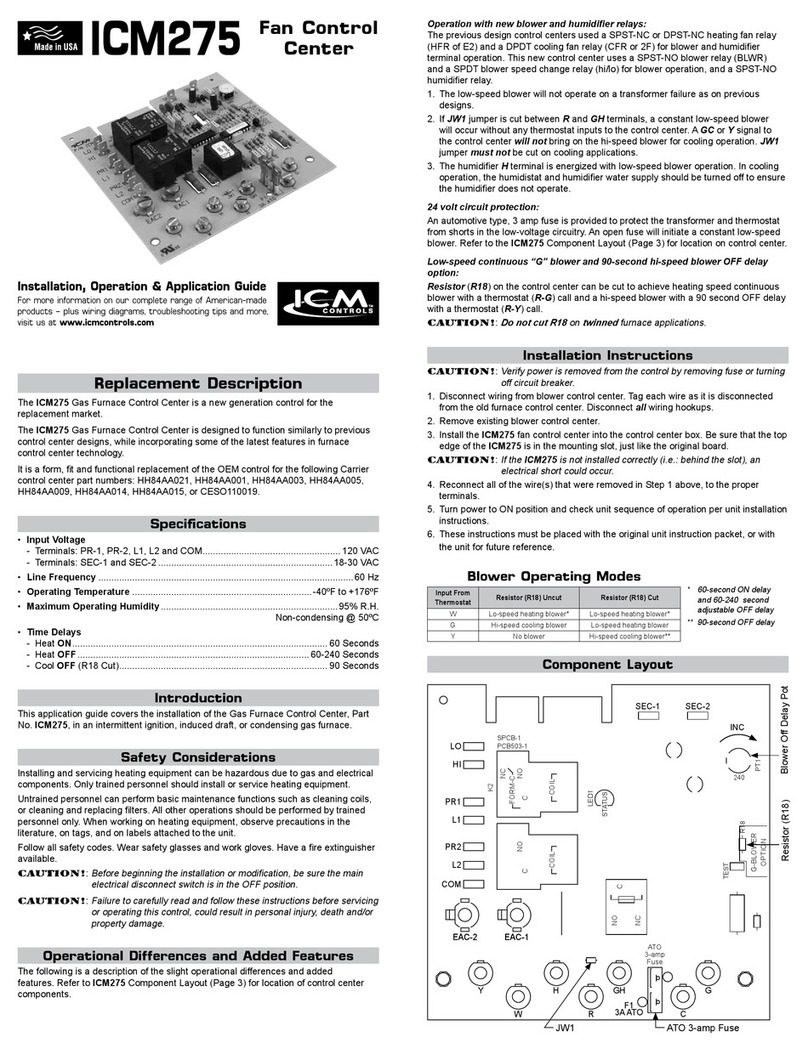

LEDS Flashes Fault condition

GREEN ON Normaloperation

1Flash Ignitionfailure(4trials)

2Flashes Pressureswitchstuckopen

3Flashes Limitswitchesopen

4Flashes Pressureswitchstuckclosed

5Flashes Twinfault

6Flashes Brownoutvoltage

7Flashes Hotandneutralreversedornoground

Continuous Gasvalverelayshort

YELLOW RapidBlink Flameoutofsequence

SlowBlink Lowameornoame

ON Flamepresent

CAUTION!

To service control, and prior to disconnection, label all wires. Failure to do so may result in wiring

errors that can cause dangerous operation.

Remove Existing Control

1. TurnthermostattoOFFpositionorsetittothelowestpossiblesetting.

2. TurnOFFelectricalsupplytofurnace.

3. TurnOFFgassupplytofurnace.

CAUTION:Failure to turn off gas and electric supplies can result in explosion, re, death, or

personal injury.

4. Removefurnaceblowerandcontrolaccessdoors.

5. Disconnectthermostatwiresandhumidierwires(ifequippedwithahumidier).

6. Disconnectlinevoltage,blower,electronicaircleanerwires(ifequipped),andtransformerwires.

7. Removescrewsandanyotherfasteners,andtheoldcircuitboard.

8. Examinecontrolandcontrolboxtocheckforwaterstains.

9. Makerepairsifanysourcesofwaterleakagearefound.Besuretocheckhumidiers,evaporator

coils,andventsystemsintheareaofthecontrol.