7313 William Barry Blvd.

North Syracuse, NY 13212

ICM CONTROLS 800.365.5525

www.icmcontrols.com LIAF098-1

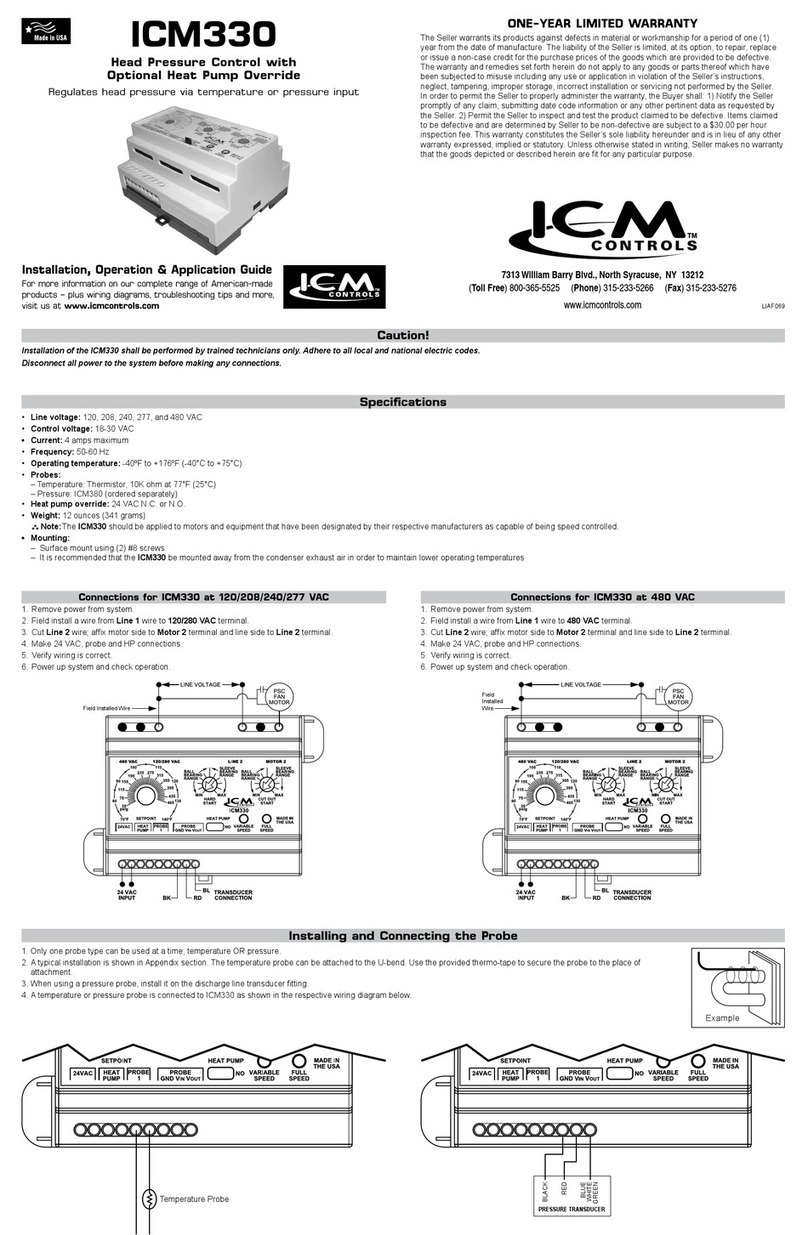

Install New Control

1. Groundyourself.Whenhandlingcircuitboard,holditbytheedges.

2. Fastencircuitboardwithretainingscrews.

3. Connectalllinevoltage,lowvoltage,andaccessorywires.

4. Verifythesequenceofoperation.

Safety Considerations

Onlytrainedpersonnelshouldinstallorserviceheatingequipment.Whenworkingwithheating

equipment,besuretoreadandunderstandallprecautionsinthedocumentation,onlabels,andon

tagsthataccompanytheequipment.Failuretofollowallsafetyguidelinesmayresultindamageto

equipment,severepersonalinjuryordeath.

Introduction

TheICM291DSIgasignitioncontrolreplacesthefollowingCarriermodel:LH33WP003A.The

ICM291hasincorporatedLEDdiagnosticstoassistintroubleshooting.Faultcodeinformationcanbe

foundinthisapplicationguide.Pleasekeepthisapplicationguidewiththefurnaceinstallationmanual

forfuturereference.

Electrostatic Discharge (ESD) Precautions

CAUTION!

Use caution when installing and servicing the furnace to avoid and control electrostatic discharge;

ESD can impact electronic components. These precautions must be followed to prevent

electrostatic discharge from hand tools and personnel. Following the precautions will protect the

control from ESD by discharging static electricity buildup to ground.

1. Disconnectallpowertothefurnace.Donottouchthecontrolorthewiringpriortodischargingyour

body’selectrostaticchargetoground.

2. Togroundyourself,touchyourhandandtoolstoaclean,metal(unpainted)furnacesurfacenear

thecontrolboard.

3. Servicethefurnaceaftertouchingthechassis.Yourbodywillrechargewithstaticelectricityasyou

shufeyourfeetormovearound,andyoumustregroundyourself.

4. Regroundyourselfifyoutouchungroundeditems.

5. Beforehandlinganewcontrol,regroundyourself;thiswillprotectthecontrol.Storeusedandnew

controlsinseparatecontainersbeforetouchingungroundedobjects.

6. ESDdamagecanalsobepreventedbyusinganESDservicekit.

CAUTION!

To service control, and prior to disconnection, label all wires. Failure to do so may result in wiring

errors that can cause dangerous operation.

1. TurnthermostattoOFFpositionorsetittothelowestpossiblesetting.

2. TurnOFFelectricalsupplytofurnace.

3. TurnOFFgassupplytofurnace.

CAUTION:Failuretoturnoffgasandelectricsuppliescanresultinexplosion,re,death,or

personalinjury.

4. Removefurnaceblowerandcontrolaccessdoors.

5. Disconnectthermostatwiresandhumidierwires(ifequippedwithahumidier).

6. Disconnectlinevoltage,blower,electronicaircleanerwires(ifequipped),andtransformerwires.

7. Removescrewsandanyotherfasteners,andtheoldcircuitboard.

8. Examinecontrolandcontrolboxtocheckforwaterstains.

9. Makerepairsifanysourcesofwaterleakagearefound.Besuretocheckhumidiers,evaporator

coils,andventsystemsintheareaofthecontrol.

Remove Existing Control

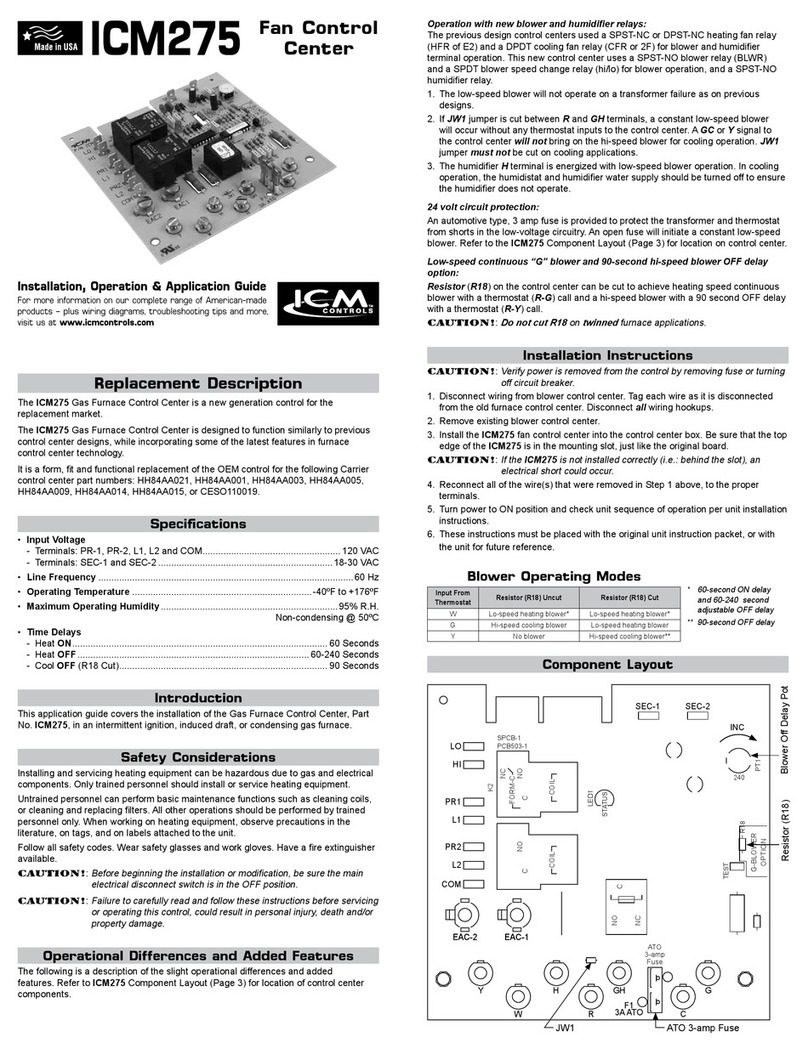

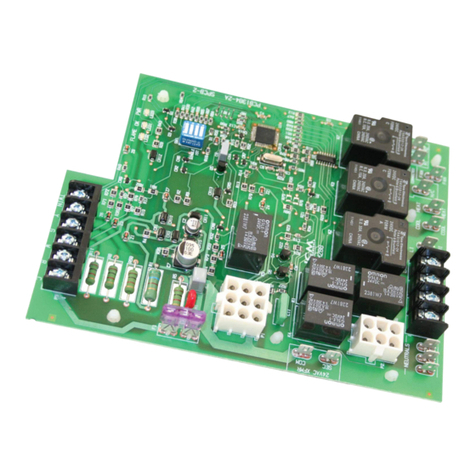

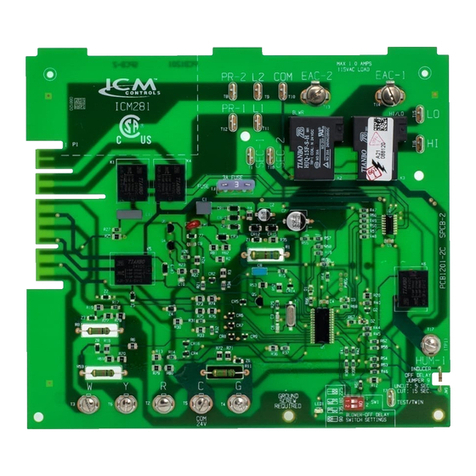

ICM291

Gas Ignition Control Board

AWcallfromtheT’statwillengagethecombustionmotor.Ignitionsequencebegins,gasvalveand

sparkareengaged,providingthatsystemsafetyswitches(RS,LS,andCS)areclosedandthereis

feedbackfromthecombustionmotorHallEffectsensor.Theblowerandindoormotorswillengage45

secondsafterameisestablishedandsensed.Theydisengage45secondsafterWcallissatised.

AGcallfromtheT’statwillengageblowerandindoormotorsrightaway.Theydisengage25seconds

afterGcallisremoved.

Sequence of Operation

Flame not established

1. Ifameisnotestablishedduringthe5+2initialsequencethenthecontrolwillstartthenexttrialfor

ignitionin20seconds.

2. Theattempttoignitewillcontinuefor15minutesbeforetherespectivefaultcodeistriggeredand

ignitiontrialsarestopped.

3.Thegasvalveisenergizedonlyduringtheignitionsequenceof5+2seconds.

4. Blowerandindoorfanmotorsareoffuntilameisestablishedand45secondslater.

Flame out

1. Flameoutisconsideredwhenameislostduringheating.

2. WhenWsignalispresentandameissensedoutthenthesparkwillstartrightaway.

3. Ifameisnotestablishedontheimmediatesequence(2above)thenthecontrolwillcontinue

attemptsevery20secondsfor15minutesbeforetherespectivefaultcodeistriggeredandignition

trialsarestopped.

4. Blower&indoorfanmotorswillcontinuerunningduringameoutscenariofor15mins.+45secs.

5.Combustionmotorremainsonthroughouttheameoutscenario.

Flame out of sequence

1. FlameoutofsequencerepresentsascenariowhenameissensedwhileWsignalisnotpresent.

2. Combustion,blowerandindoorfanmotorswillbeengaged(ifnotalreadyrunning)rightawayand

keeprunningforaslongasthefaultconditionispresent.

3. Theunitisoperablebutwilldisplaythefaultcodeconstantlyuntilreplacedbyanotherfaultcodeor

powerreset.

No signal from the Hall affect sensor

1. OnaWcall,iftheinputfromtheHallaffectsensor(RA0)isnotpresentformorethanaminute,

thenthecombustionmotorwillcontinuerunningendlesslyandtherespectivefaultisashed.

2. DuringrunningstateiftheinputfromtheHallaffectsensorisnotsensedthenthegasvalvewill

shutoffrightaway,blowerandindoorfanmotorswillcontinuerunningfor30secondsandthen

turnoff,combustionmotorrunscontinuously.

Troubleshooting Tips

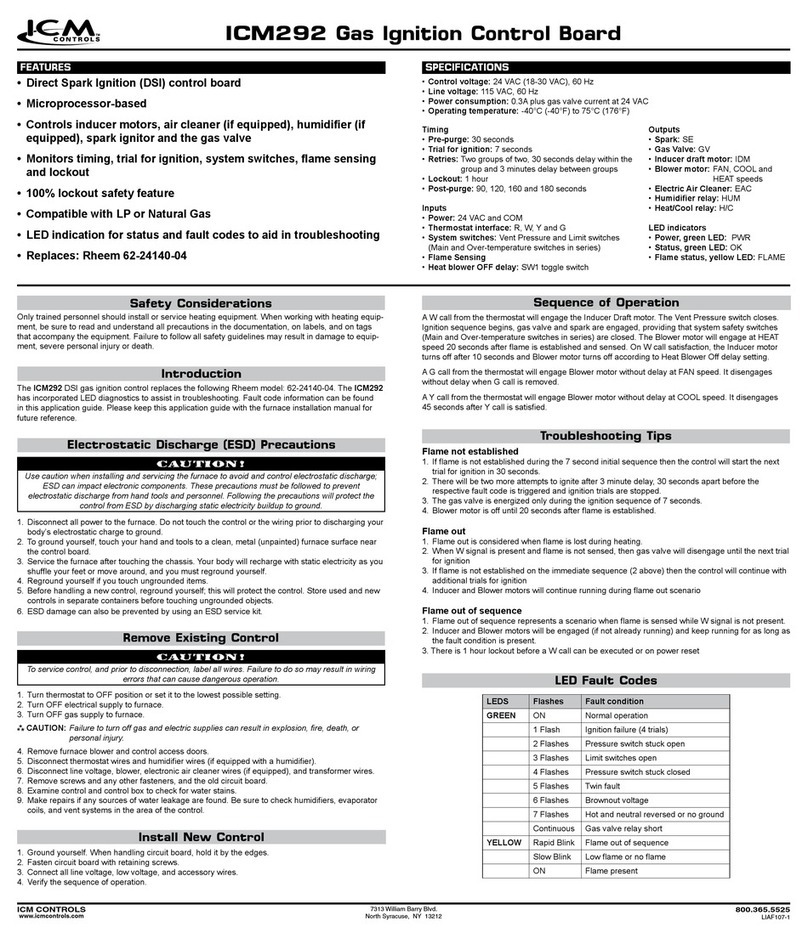

LED Fault Codes

# Of Flashes

represents Constant

ON Normal operation

Results

1Thecontrolhasmodiedthefanondelayto0andoffdelayto3mins.

duetosensingLStripwithin10minutesofacall

2a) LSisopenduetohightemperature(fanisn’tworkingscenario)

b) Theunitwillnotstartatrialforignitionuntiltheswitchclosesback

3

a) Flamesensedoutofsequence.

b) Theunitisoperable,howeverwilldisplaythisfaultcodeuntilpower

resetoranothercode

4a) LSopened4consecutivetimesduringacallforheating

b) ThefaultcodeisresetonthenextWcall

5a) Ignitionlockout.Thecontroltriedunsuccessfullytoignitefor15mins.

b) Theunitwillnotoperate.Requirespowerreset

6a) ThecombustionmotorisnotsensedrunningORCSopen

b) Theunitwillnotoperate.Requirespowerreset

7a) RStripped

b) Theunitwillnotoperate.Requirespowerreset

8a) Unusualgasvalveresponse

FEATURES

• Direct Spark Ignition (DSI) control board

• Microprocessor-based

• Controls combustion, blower and indoor motors; spark ignitor; and the gas valve

• Monitors timing, trial for ignition, ame sensing and lockout

• 100% lockout safety feature

• Compatible with LP or Natural Gas

• Status LED for fault codes to aid in troubleshooting

• Replaces: Carrier LH33WP003A

SPECIFICATIONS

• Control voltage:24VAC(18-30VAC),60Hz

• Line voltage:208/230VAC,60Hz

• Power consumption:0.3Aplusgasvalvecurrentat24VAC

• Operating Temperature:-40°C(-40°F)to75°C(176°F)

LED indicators

• Red LED: SteadyON-normaloperation

Flashing-faultcodes

Timing

• Pre-purge:45seconds

• Trial for Ignition:5+2seconds

• Retry period:every20sec.for15min.

• Lockout:manualreset

• Post-purge:45seconds

Inputs

• Power:RTandC

• Thermostat interface:R,WandG

• Safety switches:RS,LS,andCS

• CombustionmotorHallEffectsensor

• FlameSensing

Outputs

• Spark

• Gas Valve:GV

• Combustion motor:CM

• Blower motor:BM

• Indoor fan motor:IFO