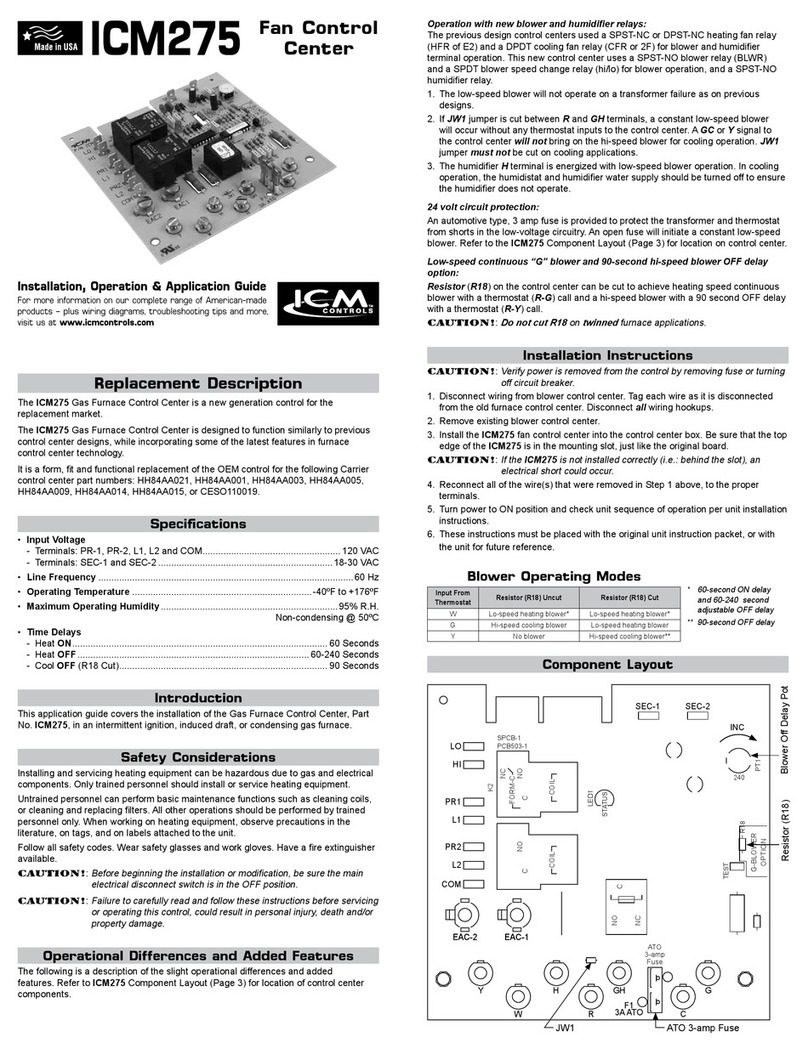

Installation, Operation & Application Guide

For more information on our complete range of American-made

products – plus wiring diagrams, troubleshooting tips and more, visit

us at www.icmcontrols.com

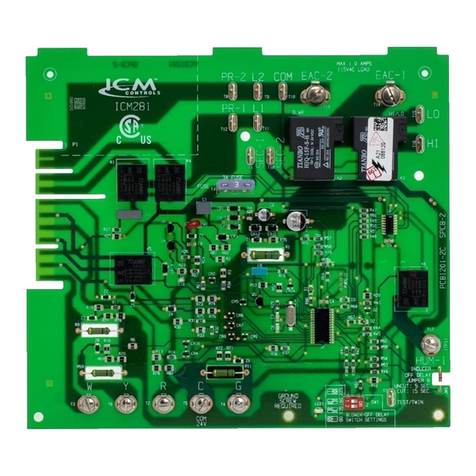

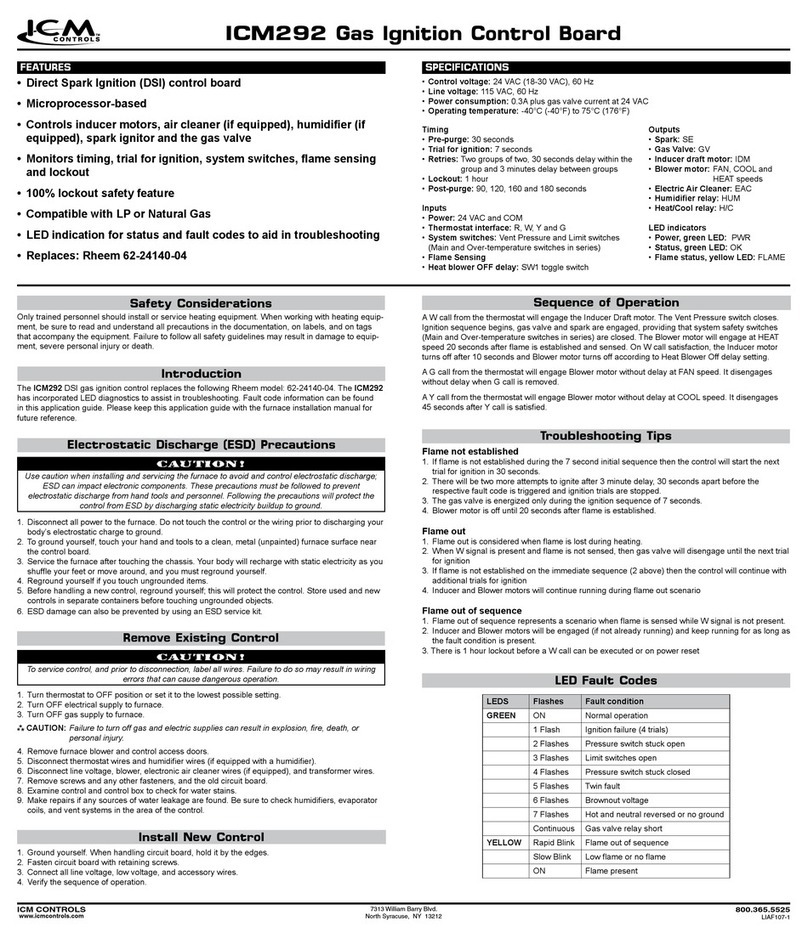

ICM2910

Ignition Control Board

Features

• Direct Spark Ignition (DSI) control board

• Microprocessor-based

• Controls spark ignitor and gas valve

•Monitorstiming,trialforignition,amesensingand

lockout

• Compatible with LP or natural gas

Only trained personnel should install or service heating

equipment. When working with heating equipment, be sure

to read and understand all precautions in the documentation,

on labels, and on tags that accompany the equipment.

Failure to follow all safety guidelines may result in damage to

equipment, severe personal injury or death.

Safety Considerations

Failure to turn off gas and electric supplies can result in

explosion, re, death, or personal injury.

! CAUTION !

Use caution when installing and servicing the furnace

to avoid and control electrostatic discharge; ESD can

impact electronic components. These precautions

must be followed to prevent electrostatic discharge

from hand tools and personnel. Following the

precautions will protect the control from ESD by

discharging static electricity buildup to ground.

Electrostatic Discharge (ESD) Precautions

1. Disconnect all power to the furnace. Do not touch the

control or the wiring prior to discharging your body’s

electrostatic charge to ground.

2. To ground yourself, touch your hand and tools to a clean,

metal (unpainted) furnace surface near the control board.

3. Service the furnace after touching the chassis. Your body

will recharge with static electricity as you shufe your feet

or move around, and you must reground yourself.

4. Reground yourself if you touch ungrounded items.

5. Before handling a new control, reground yourself, this

will protect the control. Store used and new controls in

separate containers before touching ungrounded objects.

6. ESD damage can also be prevented by using an ESD

service kit.

Specifications

• Control Voltage: 102-138 VAC

• Flame Current: 1uA minimum

• Current Draw: 50mA maximum

• Gas Valve: 1.5A@120VAC

• Flame Failure Response Time: 0.8 seconds max

• Operating temperature: -40˚F to 175˚F (-40˚C to 80˚C)

• Pre-purge: 7 seconds

• Inter-purge: 7 seconds

• Trial for Ignition: 15 seconds

• Trials: 3

Replaces

Fenwal: 35-725903-997

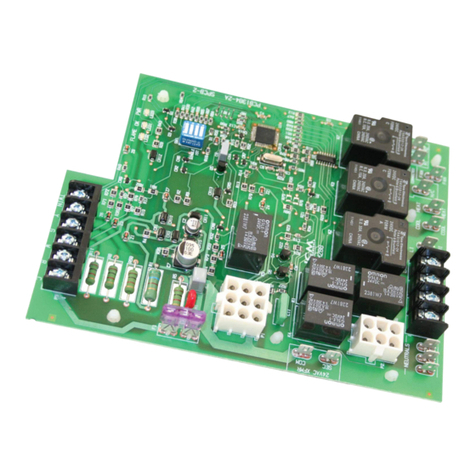

When the thermostat initiates a “Call for Heat”, the ICM2910

will perform a hardware check, after the hardware check the

ICM2910 will start a 7 second pre-purge. Once the pre-purge

has ended, the spark source and the gas valve relay are

energized simultaneously for 15 seconds. A ame rectication

circuit conrms the presence of the ame, upon ame

detection; the spark source turns off, while the gas valve

remains open for the duration of the heat call.

If ame is not sensed the control will turn off the spark source

and gas valve and start the 7 second inter-purge before the

next trial for ignition. If ame is not detected after 3 trials for

ignition, the control will enter a hard lockout. To remove the

hard lockout: either the input voltage to the control or the

thermostat’s heat call will have to be recycled.

Mode of Operation