http://www.icpdas.com DN-8368MB User Manual V 1.0 7

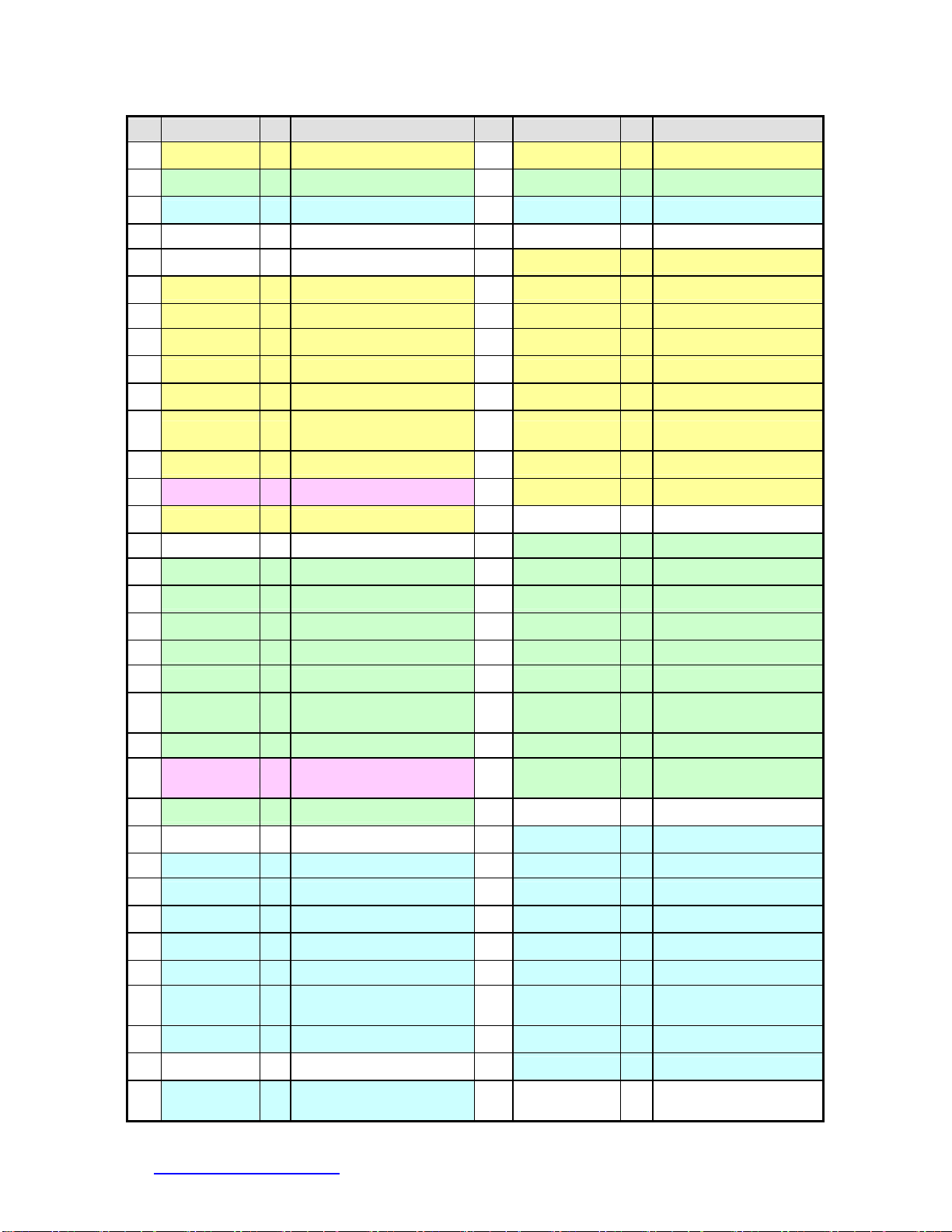

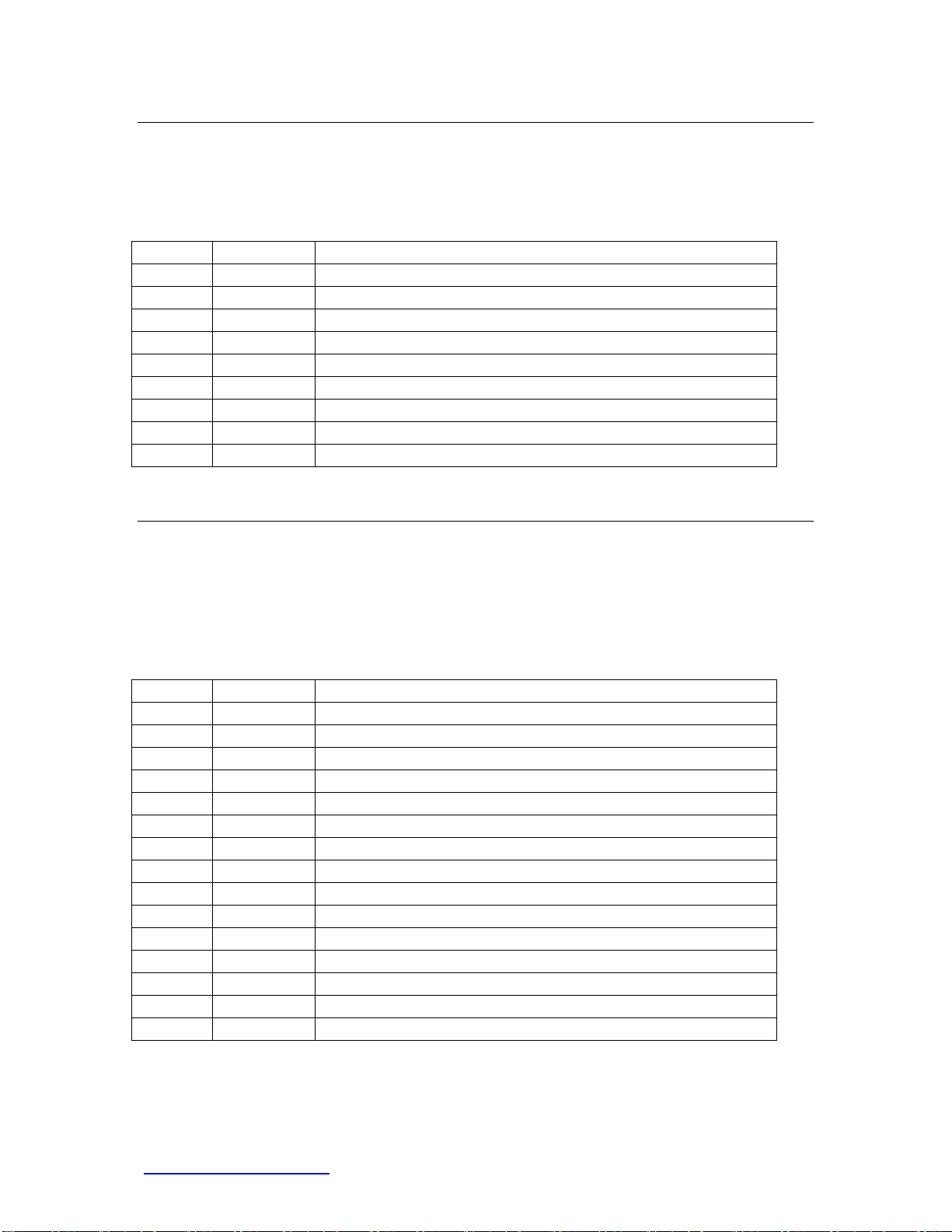

Table 1-2 CN1B (be distances from PCB)

No. Name I/O Function Axis No. Name I/O Function Axis

1 AOUT3 O Analog Output 35 AIN3 IAnalog Input

2 AOUT4 O Analog Output 36 AIN4 IAnalog Input

3 AOUT5 O Analog Output 37 AIN5 IAnalog Input

4 AGND - Analog Ground 38 AGND - Analog Ground

5 DGND - Digital Ground 39 ERC3 OError Counter Clear

6 LTC3 I Position Latch 40 SVON3 OServo On

7 EA3 I Encoder A-Phase 41 RDY3 IServo Ready

8 EB3 I Encoder B-Phase 42 INP3 IServo In-Position

9 EZ3 I Encoder Z-Phase 43 ALM3 IServo Alarm

10 CW3 O Clockwise pulse 44 SLD3 ISlow Down

11 CCW3 O Counter-Clockwise

pulse 45 ORG3 IOrigin Signal

12 CMP3 O Compare Trigger 46 MEL3 IMinus End Limit

13 GDI11 I Generic Digital Input 47 PEL3 IPositive End Limit

14 ALMRST3 O Servo Alarm Reset 48 DGND - Digital Ground

15 DGND - Digital Ground 49 ERC4 OError Counter Clear

16 LTC4 I Position Latch 50 SVON4 OServo On

17 EA4 I Encoder A-Phase 51 RDY4 IServo Ready

18 EB4 I Encoder B-Phase 52 INP4 IServo In-Position

19 EZ4 I Encoder Z-Phase 53 ALM4 IServo Alarm

20 CW4 O Clockwise pulse 54 SLD4 ISlow Down

21 CCW4 O Counter-Clockwise

pulse 55 ORG4 IOrigin Signal

22 CMP4 O Compare Trigger 56 MEL4 IMinus End Limit

23 GDO2 O Generic Digital

Output 57 PEL4 IPositive End Limit

24 ALMRST4 O Servo Alarm Reset 58 DGND - Digital Ground

25 DGND - Digital Ground 59 ERC5 OError Counter Clear

26 LTC5 I Position Latch 60 SVON5 OServo On

27 EA5 I Encoder A-Phase 61 RDY5 IServo Ready

28 EB5 I Encoder B-Phase 62 INP5 IServo In-Position

29 EZ5 I Encoder Z-Phase 63 ALM5 IServo Alarm

30 CW5 O Clockwise pulse 64 SLD5 ISlow Down

31 CCW5 O Counter-Clockwise

pulse 65 ORG5 IOrigin Signal

32 CMP5 O Compare Trigger 66 MEL5 IMinus End Limit

33 DGND - Digital Ground 67 PEL5 IPositive End Limit

34 ALMRST5 O Servo Alarm Reset 68 VCC - 5V Digital Power

from Bus