Notes on the operating instr ctions

- The operating instr ctions are in-

tended for specialist workers and

trained personnel.

- Before each stage of work, read the

relevant notes and warnings care-

f lly, and keep to the seq ence as

stated.

- Pay partic lar attention to the sec-

tion on ”General safety warnings”.

If yo have any problems or q estions,

please contact yo r s pplier or

cons lt the company MARIANNE

MAYER, ELECTRONISCHE SCHAL-

TUNGEN directly.

1.

Description of the device

General description

The high press re calibrator enables

press re to be generated by means of

the integrated press re p mp, p to

700 bar relative.

The meas rement technology incor-

porated into this device allows ac-

c rate meas rement and doc men-

tation of the characteristic of a test

object that is connected to it. The

meas red press re progression can

be displayed, eval ated and saved

with a comp ter monitoring program

(CCS30).

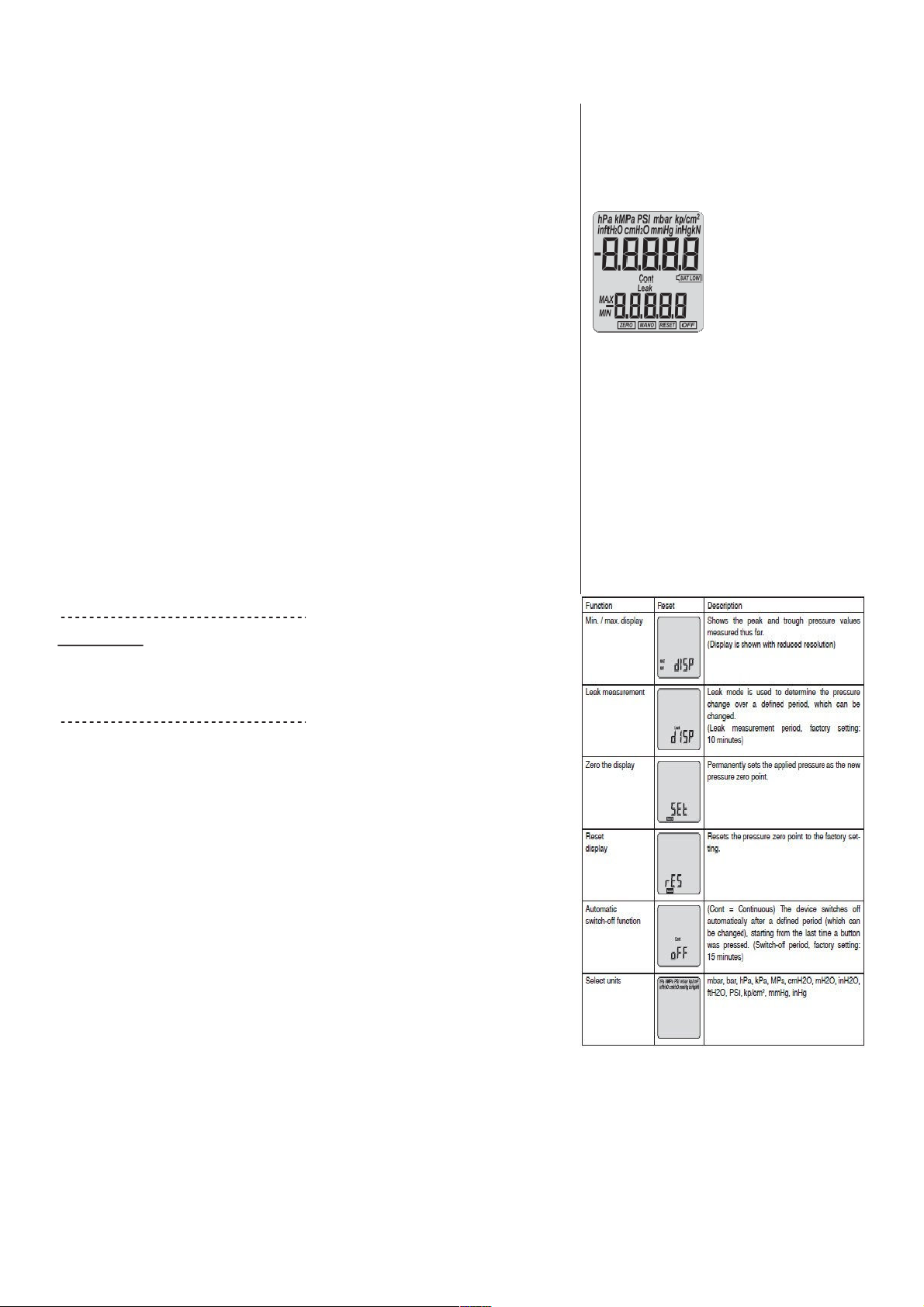

The calibrator is operated with the

two f nction b ttons SELECT and

ENTER, located directly below

the display. The calibrator itself is

powered by a 3,0 V battery.

Copyright

For copyright reaons this operating

man al may only be sed for inho se

p rposes.

Any reprod ction, even in part and for

inho se p rposes, req ires the assent

by Messrs

Also, any distrib tion to third parties is

prohibited for competitive reasons.

Commissioning

A press re-resistant connection for

the test object is req ired in order to

se the high press re calibrator. The

press re connection for the test object

is already screwed to the press re

distrib tor of the high press re calibra-

tor so that it is press re resistant when

it leaves the factory, and it m st not be

dismantled.

Recommended torq e for the test

object press re connection: 30 Nm

IMPORTANT!

Nothing m st adhere to the s rface of

the test object (no oil, grease, water,

etc). Imp rities co ld pass tro gh the

adapter to reach the high press re

calibrator and damage it.

Overpress re

If the press re exceeds the meas ring

range by more than 20%, the meas r-

ing cell or the mechanism of the high

press re calibrator may be destroyed

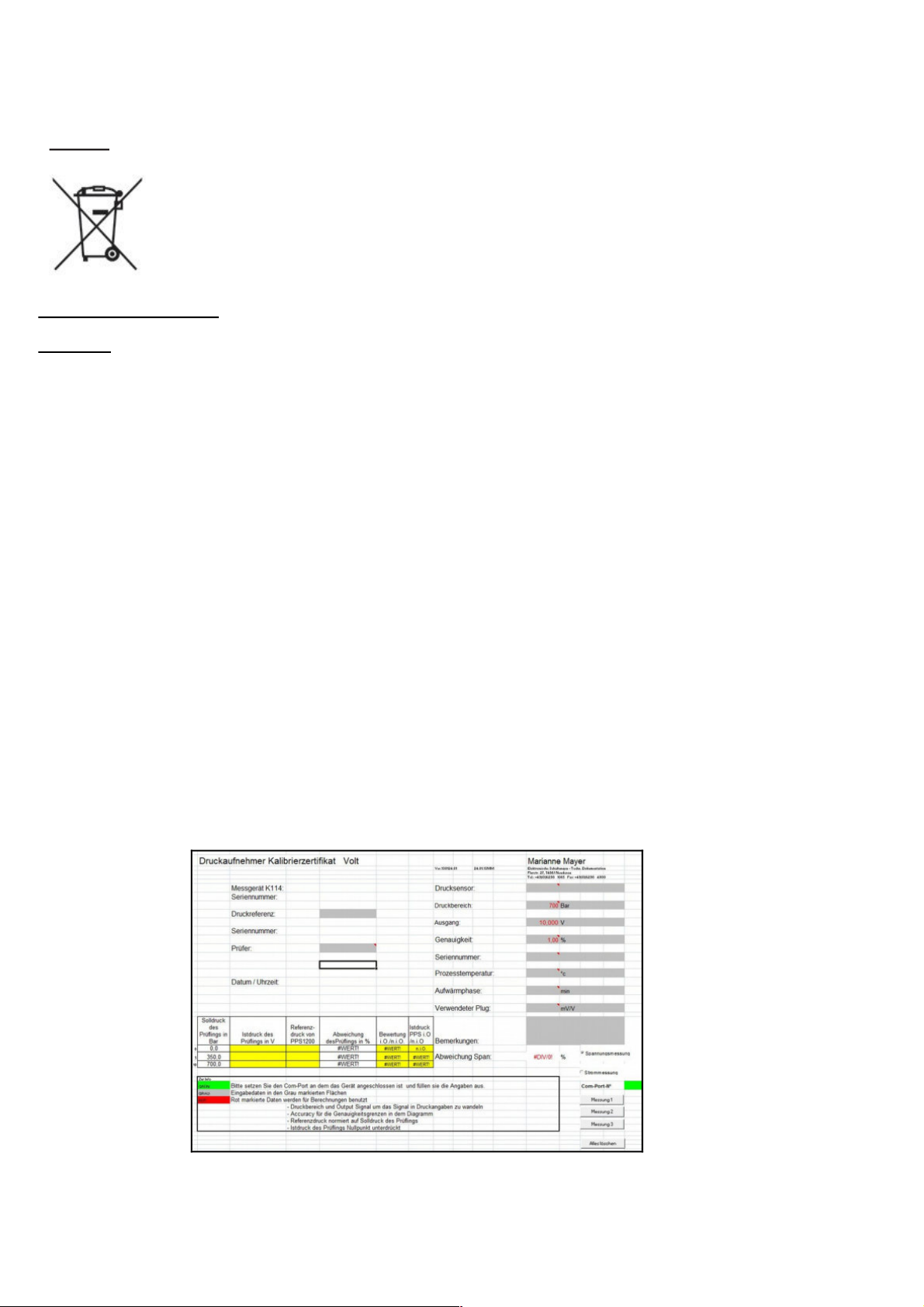

Recalibration

The recalibration cycle depends on

the conditions of se. Recommended

recalibration cycle: 1 year.

Intended se

The high press re calibrator may

only be sed to generate press re

with the type HLP 22 BP hydra lic oil

that is s pplied with the prod ct. Use

of the calibrator with other media will

damage it. The operational safety

of the device s pplied is g aranteed

only if it is sed as intended. The limit

val es as stated (see page 9: ”Tech-

nical data”) m st never be exceeded.

Before installing the high press re

calibrator, check that it is s itable for

yo r applications

2.

General safety warnings

The c rrent national reg lations on

accident prevention and

workplacesafety m st be followed

whenever work is carried o t.

Internal reg lations iss ed by the

operator m st

be followed, even if

they are not mentioned in these

instr ctions.

Never se the high press re calibra-

tor together with an external press re

so rce.

Do not remove any connected compo-

nents (e.g. test objects) when the high

press re calibrator is nder press re.

Open the screwed sealing pl g before

removing parts.

Do se Teflon tape to seal the

press re connection caref l. Resid es

of

Teflon tape co ld penetrate the

high- press re calibrator and damage

it.

Only se the adapters and seals that

are available as accessories.

Do not store the calibrator nder pres-

s re: only store the high press re cali-

brator with the drain valve open.

Avoid the action of force of any kind

on the high press re calibrator and its

operating controls.

Do not se high press re calibrators if

they are damaged or fa lty.

4