Mounting

Protege DIN rail modules are designed to mount on standard DIN rail either in dedicated DIN cabinets or on

generic DIN rail mounting strip.

When installing a DIN rail module, ensure that there is adequate clearance around all sides of the device and

that air flow to the vents of the unit is not restricted. It is recommended that you install the module in a location

that will facilitate easy access for wiring. It is also recommended that the module is installed in an electrical

room, communication equipment room, secure cabinet, or in an accessible area of the ceiling.

1. Position the DIN rail module with the labeling in the correct orientation.

2. Hook the mounting tabs (opposite the tab clip) under the edge of the DIN rail.

3. Push the DIN rail module against the mount until the tab clips over the rail.

Removal

A Protege DIN rail module can be removed from the DIN rail mount using the following steps:

1. Insert a flat blade screwdriver into the hole in the module tab clip.

2. Lever the tab outwards and rotate the unit off the DIN rail mount.

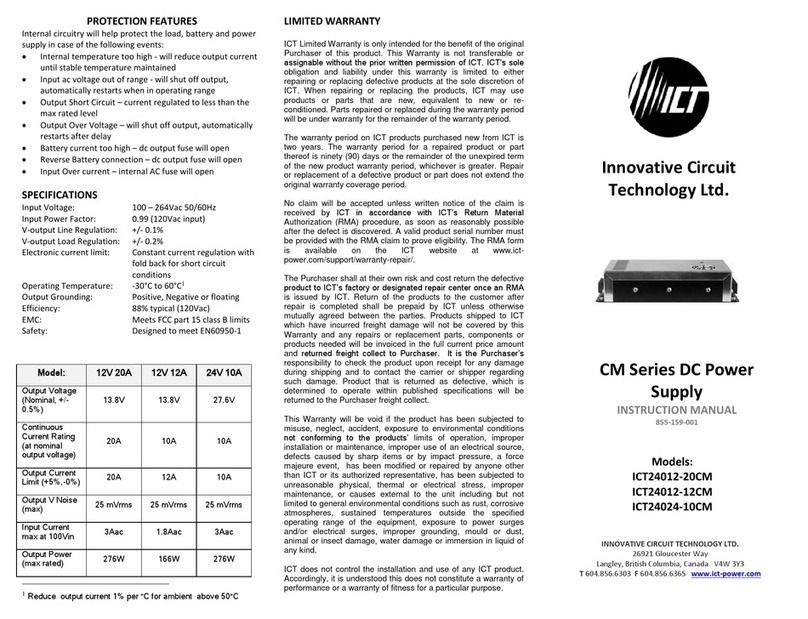

Cabinet Tamper Switch

The enclosure tamper input notifies the monitoring station or remote computer that the enclosure has been

opened. The tamper input switch and steel bracket provided should be correctly mounted into the enclosure

and secured to the wall. The tamper input switch terminals are connected in series with the tamper input (TP)

and the V- terminal of the power supply (or any other system input designated and programmed as a 24HR

tamper alarm input). When the tamper input is triggered, trouble input AExxx:01 on the power supply will be

opened.

Tamper Input Connection:

Bracket

C

TAMPER

NCNOCTP

BATT OK AC OK

FORM B CONTACTS (50mA max)

V2+ V- V1+ V-

12VDC OUTPUT 2 12VDC OUTPUT 1

Tamper Switch

PRT-PSU-DIN-2A | Protege DIN Rail 2A Intelligent Power Supply | Installation Manual 9