IDEC HS5B User manual

HS5B/HS5E

Door Handle Actuator

Sliding Actuator

(08/03/12)

2

Easy and Secure Pushbutton Operation

Pressing a red mushroom pushbutton in an

emergency situation—the established safety measure.

Simply press the red mushroom

pushbutton.

Imagine you are in an emergency situ-

ation and you need to escape from a

hazardous area immediately. If getting

out requires multiple actions, it is likely

you will be trapped within the hazard-

ous area!

A system should require only simple

measures which can be performed

without much thinking—such as press-

ing a pushbutton!

Press the pushbutton.

Machine will stop.

Turn the rear handle. Escape.

Press

(08/03/12)

Push

Tu r n

3

Rotational handle actuator can be inserted/removed smoothly on

rattling doors.

The door can be locked and unlocked by pushing and turning the handle.

Padlockable tab ensures operator’s safety.

When padlocks are installed on the padlock tab, the machine cannot

be started because the actuator entry slot is blocked and the actuator

cannot enter the interlock switch. By requiring all operators to have

their own padlock and installing them on the door handle actuator be-

fore entering the hazardous area, the door will not be closed unless

all padlocks are removed—i.e. all operators have left the hazardous

area.

Note: Operators must observe rules in the workplace in order to ensure safety.

Residual risk such as failure to install padlocks must be taken into con-

sideration.

Interlock switch with/without

solenoid locking can be selected.

LED shows solenoid status

(when using the HS5E interlock switch)

Conventional Sliding Actuator IDEC's Door Handle Actuator

The actuator can be inserted

into the interlock switch by push-

ing and turning the front handle.

The actuator can be removed

from the interlock switch by turn-

ing the front handle.

HS5E HS5B

Rattling doors can be locked

smoothly and securely.

Because the handle can be

turned only while it is pushed,

the actuator is prevented from

hitting the switch cover unit.

The rear handle

can remove the

actuator, but

cannot insert the

actuator.

Sliding doors can also

be locked securely.

(HS5E-∗44L∗∗-G) (HS5B-∗∗Z)

Using a hasp

Padlock Knob

Padlock Knob

Padlock Tab

Padlock Tab

(08/03/12)

4

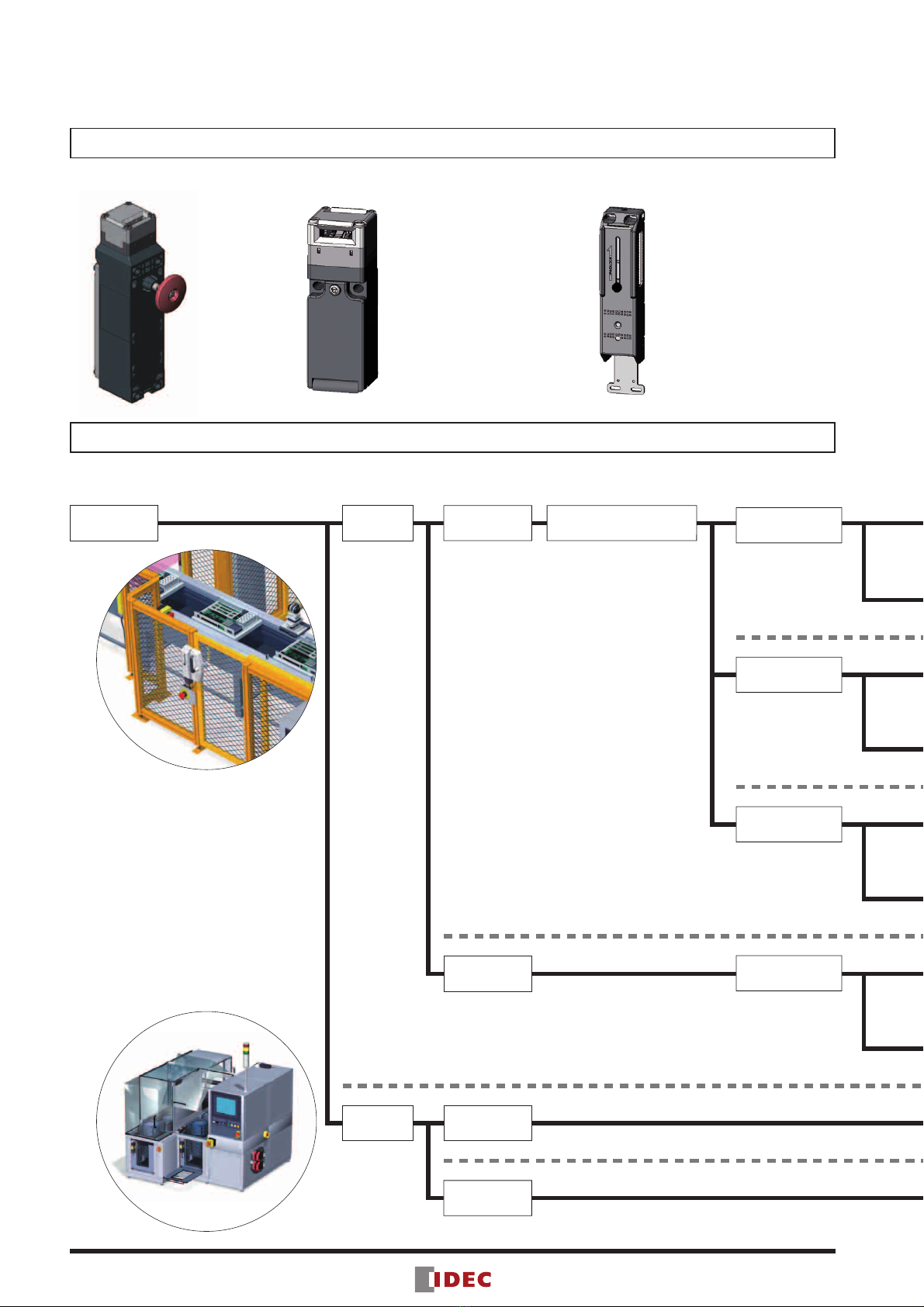

Rear Unlocking

Required

Mounting Panel Thickness (X)

With Lock

Without Lock

Large

Small

Door Size

20 ≤ X ≤ 30 mm

X ≤ 3 mm

30 < X ≤ 40 mm

X ≤ 70 mm

With Lock

Without Lock

Door Handle Actuator Configuration

Selection Chart

HS5E-∗44L∗∗-G

Rear Unlocking

Button Type

HS5B-∗∗Z

Metal Head Type HS9Z-DH5C

Interlock Switches

•Switch Cover Unit

•

(08/03/12)

5

Right-hand Door

Left-hand Door

Right-hand Door

Left-hand Door

Right-hand Door

Left-hand Door

Handle Unit Switch Cover Unit Accessories Interlock Switch

HS5E-∗44L∗∗-G

(Rear Unlocking

Button Type)

HS9Z-DH5C

HS9Z-DH5RH

HS9Z-DH5LH

Right-hand Door

Left-hand Door

HS9Z-DH5LH

HS9Z-DH5RH

HS5B-∗∗Z

(Metal Head Type)

HS5E

(All types)

HS5B-∗∗Z

(Metal

Head Type)

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

HS9Z-DH5LH

HS9Z-DH5LH

+++

HS9Z-DH5RH

+++

Sliding Actuator

HS9Z-SH5

+

+

HS5B Installation Kit

HS9Z-DH5B

Rear Unlocking Button Kit

HS9Z-FL54

Rear Unlocking Button Kit

HS9Z-FL53

HS9Z-DH5RH

HS9Z-DH5RH

Right-hand Door Left-hand Door

HS9Z-DH5LH HS9Z-FL53

HS9Z-FL54 HS9Z-DH5B

Handle Unit

•Accessories

Rear Unlocking

•

Button Kit

HS5B

•

Installation Kit

(08/03/12)

6

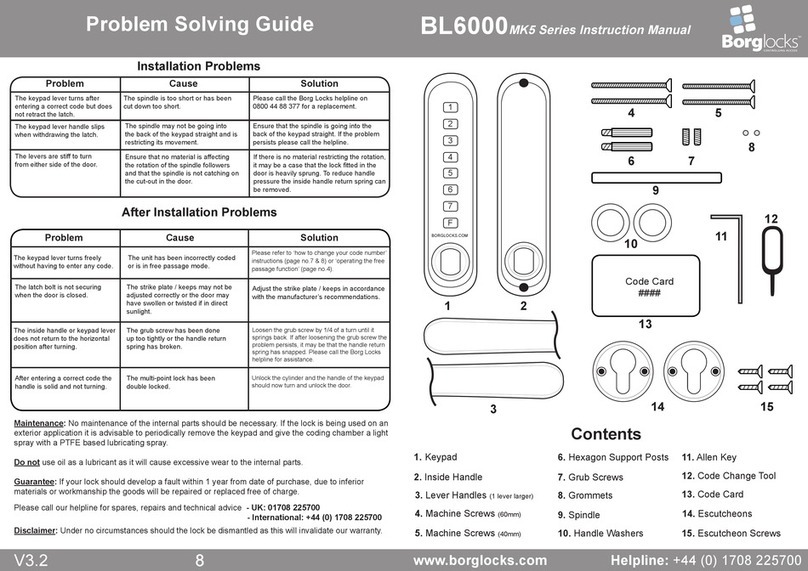

Easy and secure operation.

Rattling doors can be locked smoothly and securely.•

A door can be locked with an actuator by pushing and•

turning the handle.

Padlock tab is provided to ensure operator safety.•

Interlock switch with or without solenoid lock can be•

installed.

LED shows solenoid status•

(when using HS5E-∗44L∗∗-G).

HS5B/HS5E Door Handle Actuator

Specifications

Applicable Interlock

Switch

HS5B Metal Head Interlock Switch (Note 1)

HS5E Rear Unlocking Button Type Interlock

Switch with Solenoid (Note 2)

Operating Temperature –25 to +70°C (no freezing)

Mechanical Durability 100,000 operations minimum

Applicable Shackle

Diameter of Padlock ø6 to 7.5 mm

Withstand Load of

Padlock Tab 30N maximum

Handle Operation Angle 77° (removed position ↔ inserted position)

Weight

HS9Z-DH5LH/RH: 1000g

HS9Z-DH5C: 900g

HS9Z-DH5B: 30g

Note 1: HS5B-∗∗ZB, HS5B-∗∗ZBM

Note 2: HS5E-∗44L∗∗-G

Interlock switch is not supplied with the actuator and must be ordered separately.

•

For the specifications of interlock switches, see Cat No. EP1199-0.

•

Types

Description Ordering Type No. Remarks

Handle Unit For right-hand door HS9Z-DH5RH Choose according to the required opening side.

For left-hand door HS9Z-DH5LH

Switch Cover Unit HS9Z-DH5C Used for installing the interlock switch inside.

HS5B Installation Kit HS9Z-DH5B Contains a mounting plate and two spacers.

Rear Unlocking Button Kit (Note 1)

HS9Z-FL53 Contains a button with base

plate and a connecting rod

Mounting panel thickness (X): 20 ≤X ≤30 mm

(Note 2)

HS9Z-FL54 Mounting panel thickness (X): 30 < X ≤40 mm

(Note 2)

Note 1: Use the kit in combination with the HS5E-∗44L∗∗-G rear unlocking button type interlock switch.

Note 2: Mounting panel is a frame or a panel.

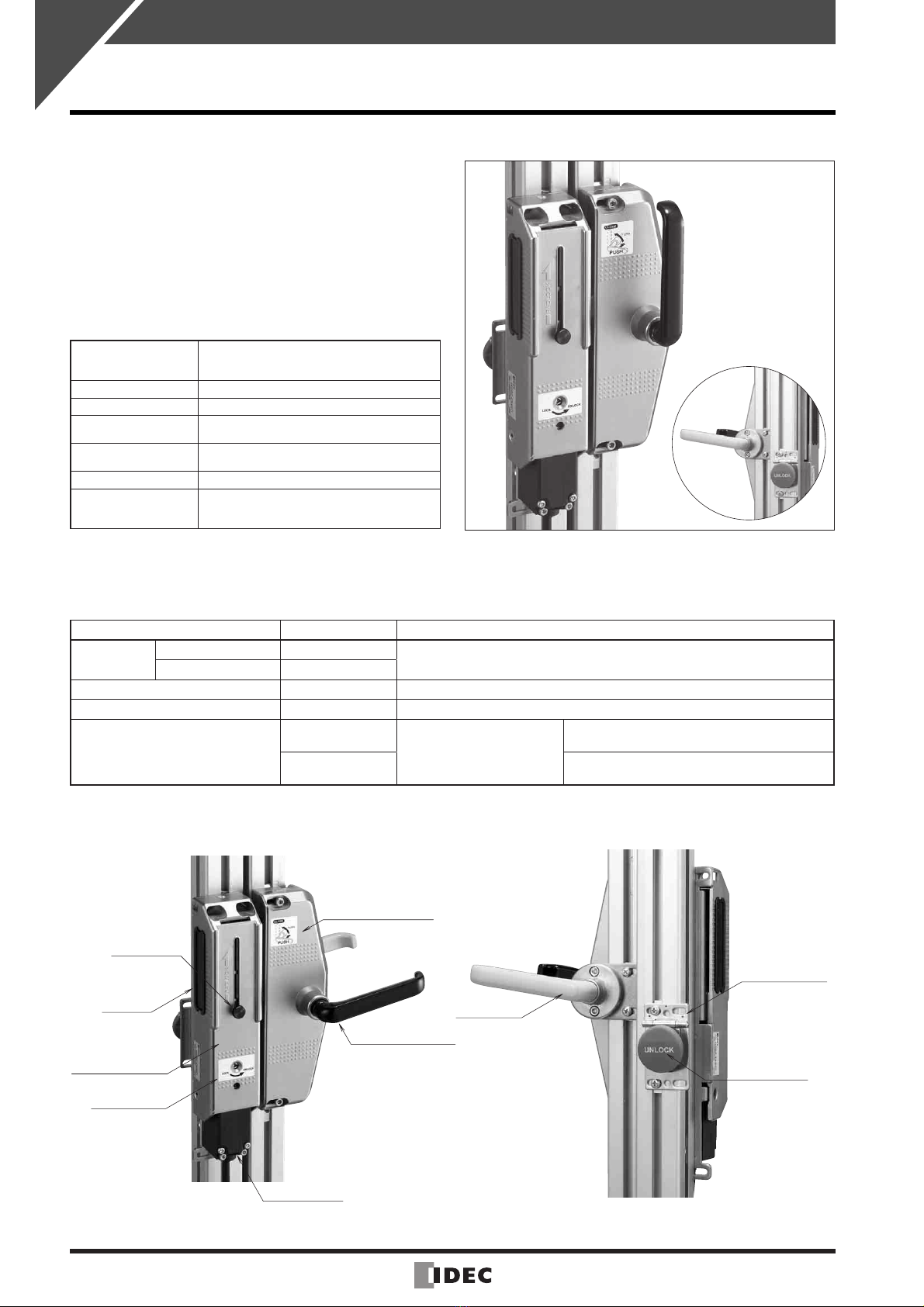

Parts Description

Rear Handle

(yellow)

Rear Unlocking

Button Kit

Rear Unlocking

Button

Padlock Knob

Blind Cap

Handle Unit

(for right-hand door)

Manual Unlock

Label

Interlock Switch

Front Handle (black)

Switch Cover Unit

Front View Rear View

(08/03/12)

7

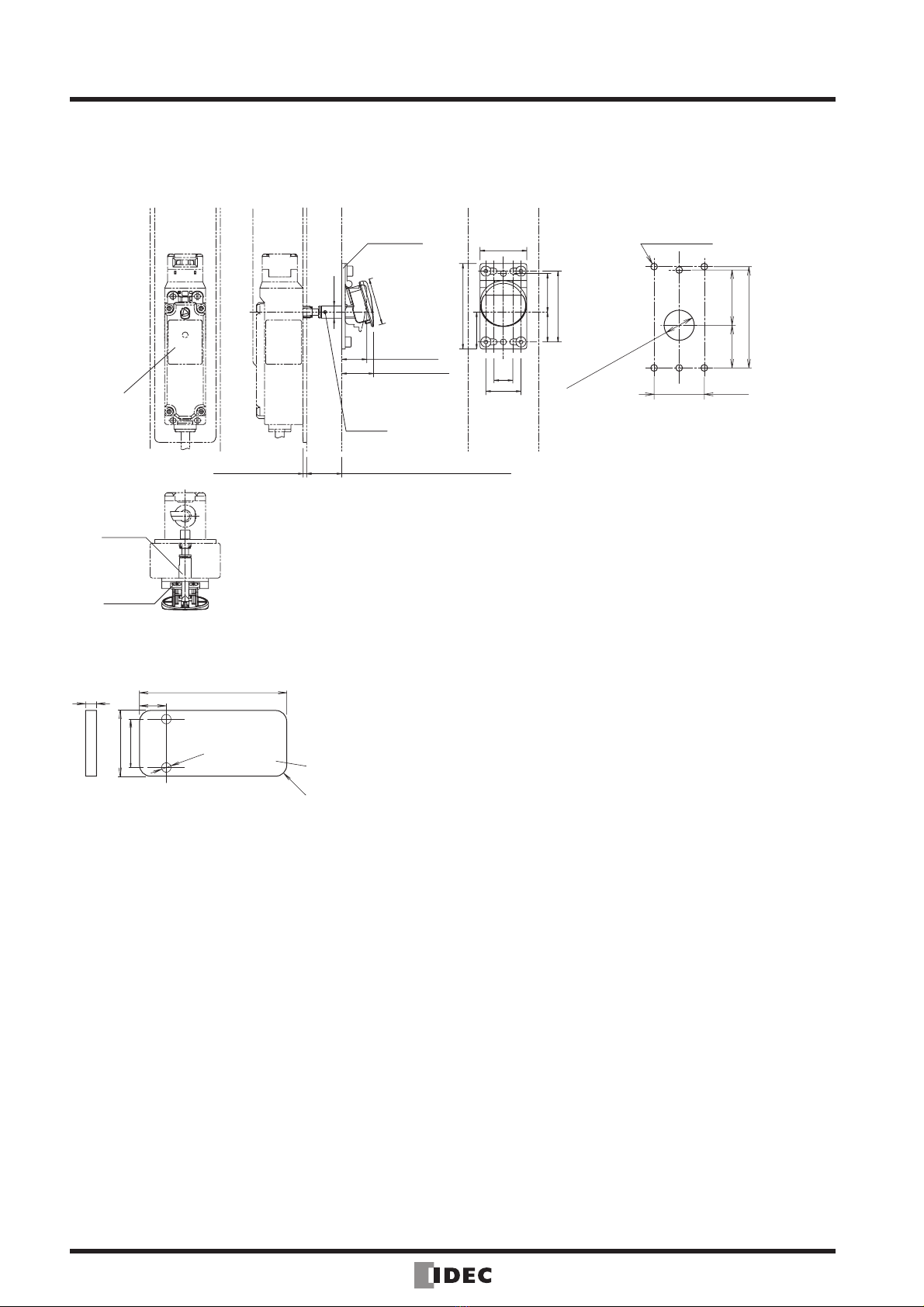

HS5B/HS5E Door Handle Actuator

77°

49.5

271

256

8

8

47.5

220

220

204

102

52

73

49

46

49.8

6

10

7 to 9

12

836 10

Locked: 81

Unlocked: 84

49.8

35

Mounting Panel Thickness:

20 to 40

PADLOCK

3

LOCK UNLOCK

4

Rear Unlocking Button

Connecting Rod (SUS)

Handle Link

Shaft 8

Polyacetal (black)

SUS

(free-cutting

steel)

SUS

ø10.4

1

2

110

77°

13

7

7

11

347

35

116.5

177

Rear Unlocking Button

(Nylon 66) (red)

Rear Handle

(diecast aluminum)

(yellow)

Rear Handle

(diecast aluminum)

(black)

Diecast Aluminum

(plated) (silver)

Diecast Aluminum (plated)

(silver)

110

77°

49.5

271

256

8

8

47.5

220

220

204

102

52

73

49

46

49.8

77°

6

10

7 to 9

13

7

7

11

34 7

12

8

3610

35

116.5

177

49.8

35

Locked: 81

Unlocked: 84

Mounting Panel Thickness:

20 to 40

3

Handle Link Shaft 8

(free-cutting steel)

LOCK UNLCOK

4

SUS

SUS

ø10.4

Front Handle (diecast aluminum)

(black)

Rear Handle (diecast aluminum)

(yellow)

Rear Unlocking

Button Connecting Rod (SUS)

Diecast Aluminum (plated)

Diecast Aluminum (plated)

Rear Unlocking Button

(Nylon 66) (red)

Polyacetal (black)

PADLOCK

Dimensions

HS9Z-DH5RH (right-hand door) and HS5E-

•∗44L∗∗-G Interlock Switch with Solenoid

HS9Z-DH5LH (left-hand door) and HS5E-

•∗44L∗∗-G Interlock Switch with Solenoid

Legend Description

1 Right-hand Door Handle Unit HS9Z-DH5RH

2 Switch Cover Unit HS9Z-DH5C

3 Rear Unlocking Button Kit HS9Z-FL5∗

4 Interlock Switch HS5E-∗44L∗∗-G

Legend Description

1 Left-hand Door Handle Unit HS9Z-DH5LH

2 Switch Cover Unit HS9Z-DH5C

3 Rear Unlocking Button Kit HS9Z-FL5∗

4 Interlock Switch HS5E-∗44L∗∗-G

All dimensions in mm.

(08/03/12)

8

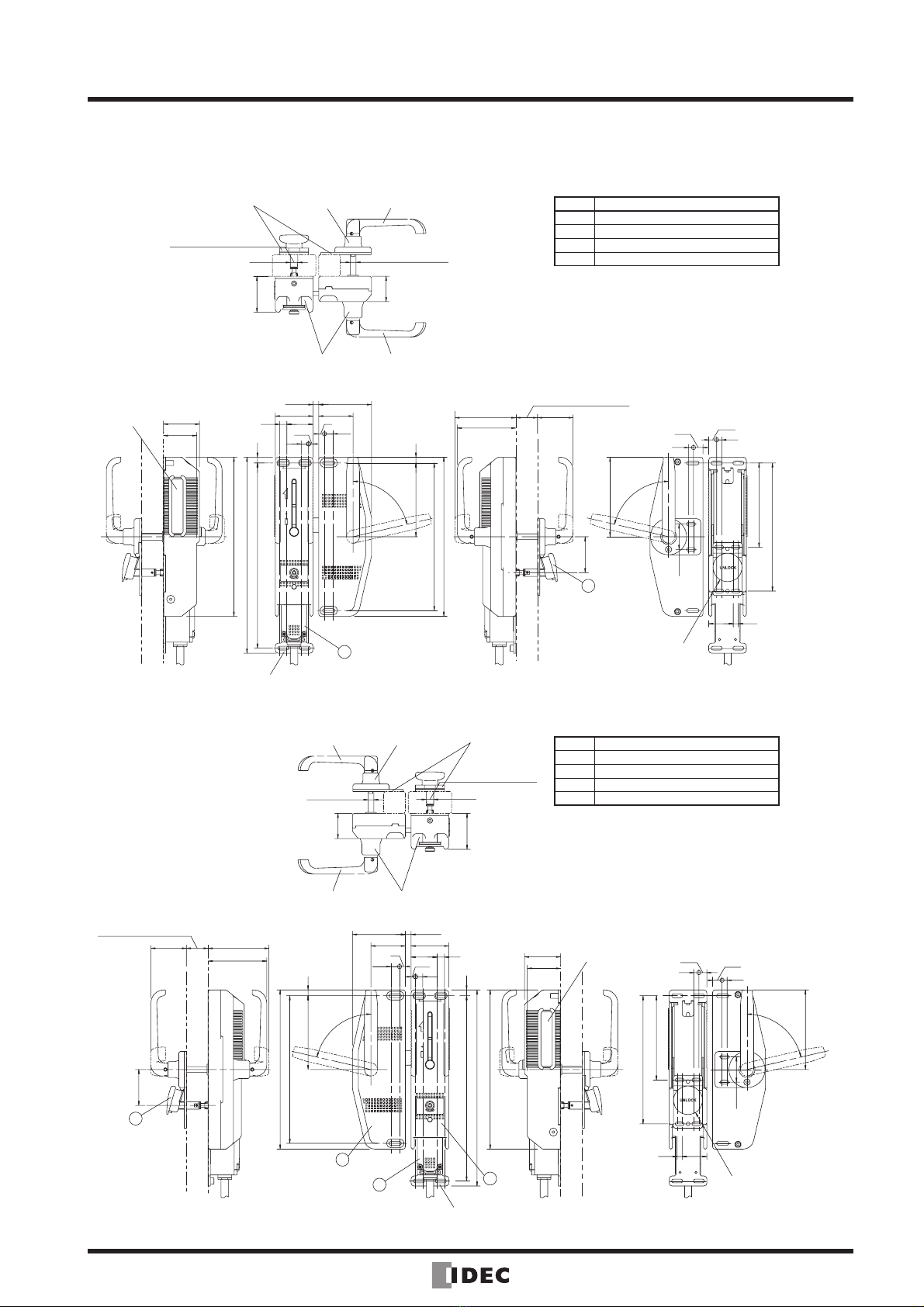

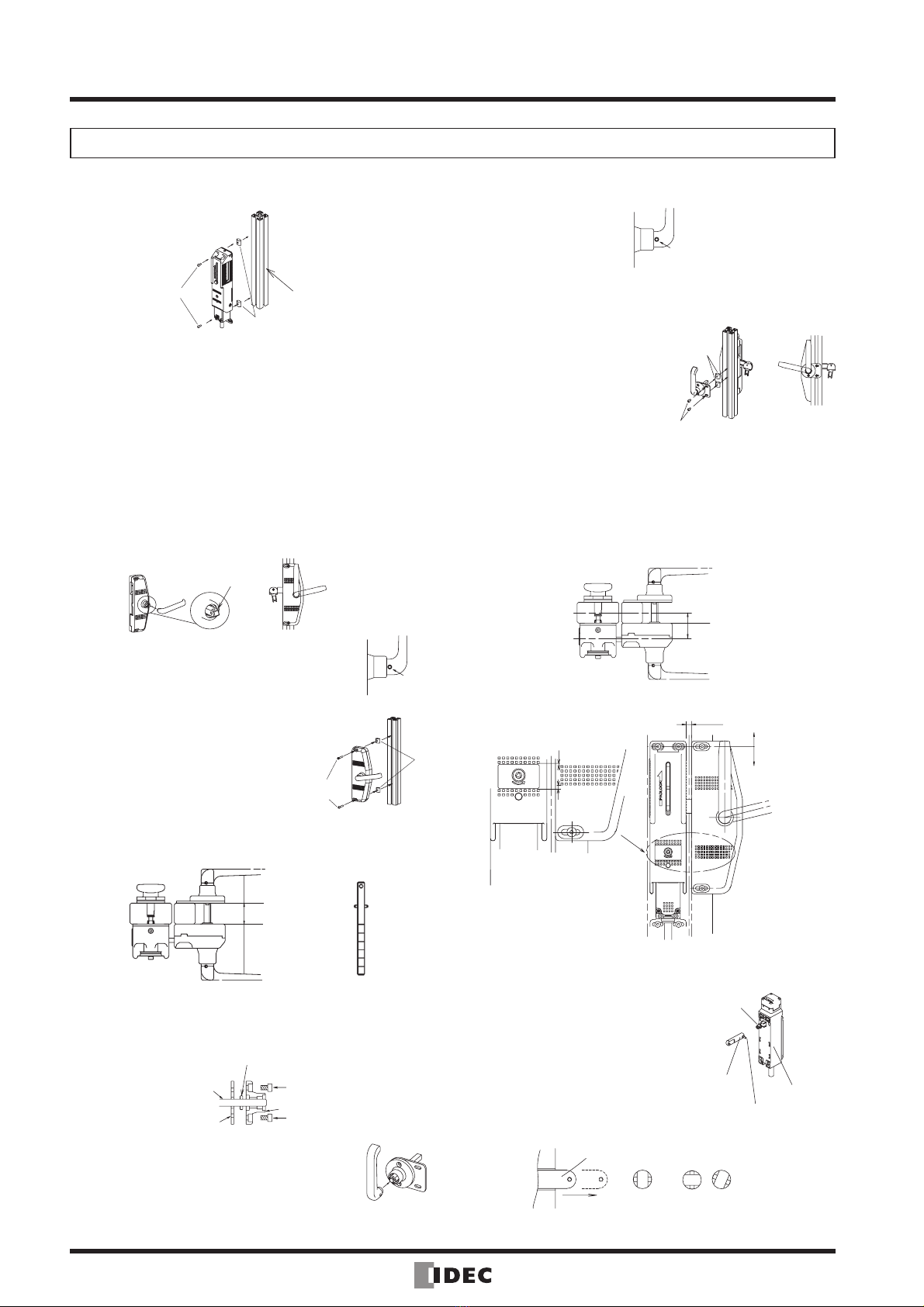

HS5B/HS5E Door Handle Actuator

49.8

35

35

49

77°

271

256

8

8

47.5

220

204

102

52

73

6

10

7 to 9

12

8

36

10

220

46

49.8

13

7

110

77°

(49.5)

1

2

4

3

LOCK

UNLOCK

PADLOCK

Locked: 81

Unlocked: 84

Mounting Panel

Thickness:

70mm or less

Handle Link Shaft 8

(free-cutting steel)

SUS

SUS

Front Handle

(diecast aluminum)

(black)

Rear Handle (diecast aluminum)

(yellow)

Diecast Aluminum

(plated) (silver)

Diecast Aluminum

(plated) (silver)

Polyacetal (black)

35

49.8

35

49

77°

271

256

8

8

47.5

220

204

102

52

73

6

10

7 to 9

12

836 10

220

46

49.8

13

7

110

77°

(49.5)

2

1

LOCK

UNLOCK

4

3

PADLOCK

Locked: 81

Unlocked: 84

Mounting Panel Thickness:

70 mm or less

Polyacetal

(black)

Handle Link Shaft 8

(free-cutting steel)

SUS

SUS

Rear Handle

(diecast aluminum)

(yellow)

Rear Handle

(diecast aluminum)

(black)

Diecast Aluminum

(plated) (silver)

Diecast Aluminum

(plated) (silver)

HS9Z-DH5RH (right-hand door) and HS5B-

•∗∗Z Interlock Switch

HS9Z-DH5LH (left-hand door) and HS5B-

•∗∗Z Interlock Switch

Legend Description

1 Left-hand Door Handle Unit HS9Z-DH5LH

2 Switch Cover Unit HS9Z-DH5C

3 HS5B Installation Kit HS9Z-DH5B

4 Interlock Switch HS5B-∗∗Z

Legend Description

1 Right-hand Door Handle Unit HS9Z-DH5RH

2 Switch Cover Unit HS9Z-DH5C

3 HS5B Installation Kit HS9Z-DH5B

4 Interlock Switch HS5B-∗∗Z

All dimensions in mm.

(08/03/12)

9

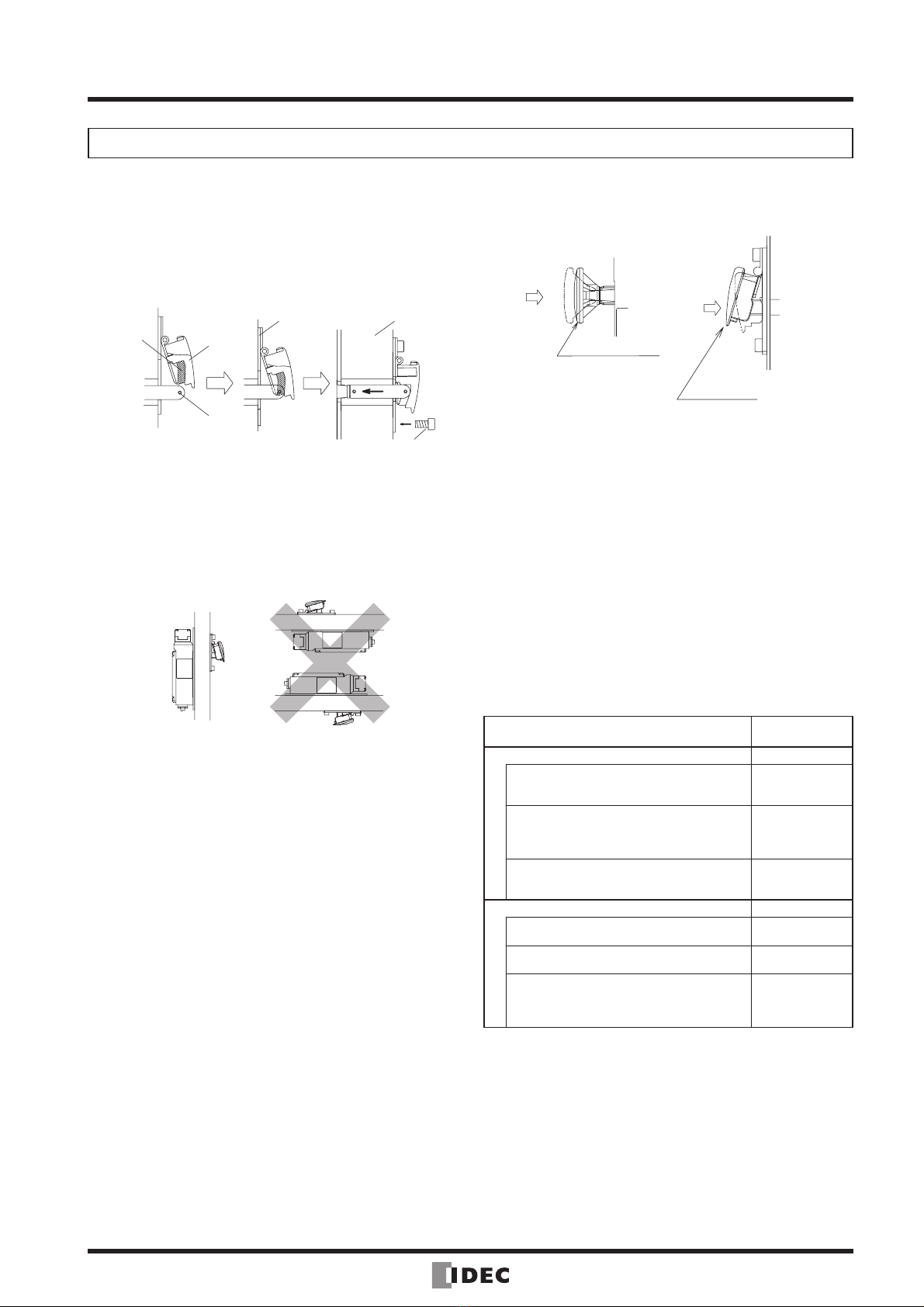

HS5B/HS5E Door Handle Actuator

Panel Cut-out

HS9Z-DH5RH right-hand door handle unit

•

HS9Z-DH5LH left-hand door handle unit

•

Note 1:

Required when using the HS5E-∗44L-∗∗−G.

Not required when using the HS5B-∗∗Z

(without locking function).

Note 2:

Ensure that the hole in the mounting panel

does not interfere with the rear handle shaft.

All dimensions in mm.

Rear Handle Hole

ø26 to 30 (Note 2)

Rear Handle Hole

ø26 to 30 (Note 2)

(34 to 41)

11 to 18

26

(102)

(47.5)

(26)

47.5

35

102

204

256

(7 to 9)

13 to 20

6 to 16

36 to 46

8 to 20

7 to 9

Rear Unlocking

Button Hole ø22 to 30

(Note 1)

Rear Unlocking

Button Hole ø22 to 30

(Note 1)

7 to 9

8 to 20

36 to 46

6 to 16 13 to 20

Door gap Door gap

(7 to 9)

256

204

10249.5

35

47.5

(26)

(47.5)

7 to 9

(102)

26

4040

4040

49.5

Door Gap

Door Gap

UNLOCK

LOCK

4(6)-M5

4(6)-M5

2-M5

6-M5

Reference

3

2

4

Reference

Mounting Position Tolerance

0.8

<Rear View><Front View>

<Front View> <Rear View>

PADLOCK

When using the HS5E-∗44L∗∗-G on the

mounting panel of 3 mm or less in thick-

ness (use the rear unlocking button).

When using the HS5B-∗Z

(mounting panel thickness X ≤70mm).

When using the HS5E-∗44L∗∗-G on

the mounting panel of 20 to 40 mm

in thickness.

Use the rear unlocking button kit•

(HS9Z-FL5∗).

In the figure shown on the right,•

40mm frame is used.

When using the HS5E-∗44L∗∗-G on

the mounting panel of 20 to 40 mm

in thickness.

Use the rear unlocking button kit•

(HS9Z-FL5∗).

In the figure shown on the right,•

40mm frame is used.

Rear Handle Hole

ø26 to 30 (Note 2)

7 to 9

8 to 20

36 to 46

6 to 16 13 to 20

Door gap

(7 to 9)

256

204

10249.5

35

47.5

(26)

(47.5)

(102)

26

Door gap

2-M5

6-M5

<Rear View>

<Front View>

Rear Handle Hole

ø26 to 30 (Note 2)

(34 to 41)

11 to 18

26

(102)

(47.5)

(26)

47.5

35

102

204

256

(7 to 9)

13 to 20

6 to 16

36 to 46

8 to 20

7 to 9

Rear Unlocking

Button Hole ø22 to 30

(Note 1)

Rear Unlocking

Button Hole ø22 to 30

(Note 1)

Door gap

49.5

Door gap

4040

4040

4(6)-M5

4(6)-M5

<Front View> <Rear View>

When using the HS5E-∗44L∗∗-G on

the mounting panel of 3 mm or less

in thickness (use the rear unlocking

button).

When using the HS5B-∗Z

(08/03/12)

10

HS5B/HS5E Door Handle Actuator

ø22 to 30 Rear Unlocking

Button Hole

16 to 30

3325.5

60.5

Rear Unlocking Button Kit

Mounting Hole Layout

2 or 4-M4 Screws

Button unpressed

Button pressed

(unlocked)

ø10.4

ø40

25.5

40

31.5

30

16

33

60.5

73

Total thickness of mountingpanel: 20 to 40

Pin (SUS)

Screws (iron)

Connecting

Rod (SUS)

Hinge + Plate

(SUS)

HS5E-∗44L∗∗-G

Interlock Switch

(sold separetely)

Mounting Bracket (3)

67

12.2

4-R5

22

5

30

2-ø4.4

A6063 Anonized

Dimensions

Rear Unlocking Button Kit

•

(HS9Z-FL53/HS9Z-FL54) (Use with the HS5E-∗44L∗∗-G Interlock Switch)

HS5B Installation Kit (HS9Z-DH5B)

•

Note: The illustration kit contains the aluminum mounting

plate shown above and two spacers.

All dimensions in mm.

(08/03/12)

11

HS5B/HS5E Door Handle Actuator

Instructions

The door handle actuator can be used with the HS5B-• ∗∗Z

(metal head type) and HS5E-∗44L∗∗-G (rear unlocking button

type) only. Do not use with other interlock switches.

When using the door handle actuator in the safety-related part•

of the system, make sure of proper operation while observing

the safety standards and regulations of the relevant country

or region where the actual machine/system is used. Also, per-

form a risk assessment before operation.

Read the instruction sheet of interlock switch before installing•

the door handle actuator.

Install the switch cover unit and handle unit on the outside of•

the door. Do not install them inside the door, otherwise the

door cannot be opened or closed by the operator, affecting

the operation and causing danger to the operator.

Install the door handle actuator in the direction•

as shown on the right, so that the cable faces

downward. Do not install in any other direction,

otherwise malfunction will be caused.

Do not modify or disassemble the door handle•

actuator.

Padlocking

When padlocking the HS9Z-DH5, lift the•

knob on the front of the HS9Z-DH5. A tab

will appear. Install padlock(s) or a hasp on

the tab.

Make sure that the total load by the pad-•

locks and hasp does not exceed 30N. Oth-

erwise the door handle actuator will be-

come deformed or damaged.

The applicable shackle diameter of padlock is ø6.0 to 7.5 mm.•

Manual Unlocking

When using the HS5E-•

∗44L∗∗-G interlock switch, at-

tach the manual unlock label

on the front of the switch cover

unit.

For manual unlocking, refer•

to the catalog for the HS5E

interlock switch with solenoid

(EP1199).

Handle Operation

Push the handle, and turn the handle to insert the actuator.•

Note: Do not force to turn the handle without pushing in the

handle, otherwise damage will occur.

Do not close the door when the actuator is in the locked sta-•

tus, otherwise the actuator will hit the door, resulting in defor-

mation or damage.

When turning the handle, make sure that your hands or fin-•

gers are not caught by the door.

Cable

Padlock Knob

Padlock Tab

Shackle Diamete

Normal Status Unlocked Status

LOCK UNLOCK

LOCK UNLOCK

LOCK

UNLOCK

Manual Unlock

Label

➀Push the handle

➁ Turn the handle

Handle Operation

Installation

Check wether the following parts are included.•

Unit Type Part Quantity

Switch Cover Unit

HS9Z-DH5C

Mounting Bracket 1

Switch Cover 1

Blind Cap 1

Screw A ∗1

Screw B ∗2

Screw C 4

Handle Unit

HS9Z-DH5RH

HS9Z-DH5LH

Actuator Cover 1

Front Handle (black) 1

Rear handle (yellow) 1

Rear handle Shaft 1

Rear handle Plate 1

Rear handle Base 1

Screw D ∗2

Screw E 2

HS5B Installation Kit

HS9Z-DH5B

Mounting Plate 1

Spacer 2

∗Screws A and B are loosely attached to the switch cover.

Screws D are loosely attached to the handles.

Installing the Switch Cover Unit (HS9Z-DH5C)

Remove one Screw A and two1.

Screws B from the switch cover

and remove the switch cover

from the mounting bracket.

[HS5E-2. ∗44L∗∗-G Interlock Switch]

Using four Screws C, install the

interlockswitch on the mounting

bracket (panel thickness 3 mm or

less). When installing on a mounting

panel (X) of 20 ≤X ≤40 mm, install

the connecting rod onto the push

rod and press the pin into the hole in the push rod as de-

scribed in the “Installing the Rear Unlocking Button Kit” on page

12, before installing the switch on the mounting bracket.

[HS5B-∗∗Z Interlock Switch]

Install the interlock switch using the

HS5B Installation Kit (HS9Z-DH5B)

and two Screws C.

3. Plug the unused actuator entry

slot using the blind cap. To do

so, attach the tab on one end to

the switch cover, and bending

the blind cap, attach the other

end on the switch cover.

Install the switch cover on the mounting4.

Screw A

Screws B

plate using one Screw A and two

Screws B.

Switch Cover

Mounting

Bracket

Screw A

Screws B

Screw C

HS5E-∗44L∗∗-G

Interlock Switch

Screws C

Spacers

HS5B-∗∗Z

Interlock Switch

Mounting Plate

Switch Cover

Blind Cap

Outside

Blind Cap

Inside

(08/03/12)

12

HS5B/HS5E Door Handle Actuator

Instructions

Install the switch cover unit on the mounting frame and5.

panel. Mounting screws or nuts are not supplied and must

be provided by the user.

Installing the rear unlocking button

When the total thickness of mounting panel is 3.0 mm or

less: Install the rear unlocking button on the rod on the back

of the switch. For details, see the instruction sheet or catalog

(EP1199) for the HS5E.

When the total thickness of mounting frame or panel is 20

mm or more: Install the rear unlocking button kit (HS9Z-

FL5∗) sold separately. For installation, see the instruction

sheet for the HS9Z-FL5 or catalog (EP1199) for the HS5E.

Installing the Handle Unit HS9Z-DH5RH

Install the front handle (black) on the shaft on the actuator1.

cover as shown below.

Tighten Screw D attached to the handle2.

using a hexagonal wrench (size: 2.5).

Apply Loctite to the screw so that it does not

become loose.

Install the handle unit on the3. mounting frame

and panel, aligning the handle unit and

switch cover unit as illustrated under

“Actuator Mounting Reference Posi-

tion.” Mounting screws and nuts are

not supplied and must be provided by

the user.

Cut the rear handle shaft according to the thickness of the4.

mounting frame and panel.

Cut at →

Cut at →

Cut at →

Cut at →

Cut at →

Cut at →

No cut →

1

2

3

4

5

6

Mounting panel

thickness (X)

0 < X ≤ 10mm:

10 < X ≤ 20mm:

20 < X ≤ 30mm:

30 < X ≤ 40mm:

40 < X ≤ 50mm:

50 < X ≤ 60mm:

60 < X ≤ 70mm:

Align the rear handle plate, rear handle shaft, and the rear5.

handle base as shown below, and fasten them using two

Screws E. Apply Loctite to the screws so that they do not

become loose.

Shaft Positioning Pin

Rear Handle Base

Screw E

Screw E

Rear Handle

Plate

Rear Handle

Shaft

Install the rear handle (yellow) on the rear6.

handle shaft.

Mounting holes required

in the frame. See Dimensions

on page 10.

Mounting Screws

Nuts

Handle Position

Locked

Unlocked

Shaft

Screw D

Mounting

Screws

Nuts

Tighten S7. crew D attached to the handle using a hexagonal

wrench (size: 2.5). Apply Loctite to the screw so that it does

not become loose.

Screw D

Turn the handle to the locked position, and insert the rear8.

handle shaft into the actuator cover. The rear handle should

be in the locked position.

While adjusting to ensure9.

smooth operation of the rear

handle, fasten the rear handle

unit on the mounting frame and

panel.

∗Install the HS9Z-DH5LH in a

similar fashion as the HS9Z-

DH5RH. Note that the handle

direction becomes opposite.

∗Mounting screws and nuts are not supplied and must be pro-

vided by the user.

Actuator Mounting Reference Position

The mounting reference position and allowable mounting•

range are as shown below.

0.8

3

Reference Position

Use the square dot pattern as a guide of the allowable mount-•

ing range.

Installing the Rear Unlocking Button Kit

1. Install the connecting rod onto the

push rod on the HS5E-∗44L∗∗-G rear

unlocking button type interlock

switch.

2. A pin is attached to the connecting

rod. Using pliers, press the pin into

the hole in the push rod.

3. Pull out the connecting rod from the

hole in the mounting frame, and turn

the button operating pin to the horizontal position.

Unlocked

Mounting

Screws

Nuts

Locked

Reference

Position

4

2

7 to 9

LOCK UNLOCK

LOCK UNLOCK

4

2

Connecting

Rod

Push Rod

HS5E-∗44L-∗∗-G

Interlock Switch

Pin

Correct Incorrect

Connecting Rod Orientation

Pull

Connecting

Rod

(08/03/12)

13

HS5B/HS5E Door Handle Actuator

Instructions

Safety Precautions

Ensure that the connecting rod is pulled out completely and it is

horizontal to the interlock switch, otherwise the unlocking but-

ton cannot be installed.

4. Install the unlocking button on the connecting rod by fitting

the pin to the grooves on the back of the button, and fasten

the base plate on the mounting frame using the screws.

Button Operating

Pin

Button

Groove

Screw

Unlocking

Button

Base Plate Mounting Frame

5. After tightening the mounting screws to a torque of 4.8 to

5.2 N·m, check if locking and unlocking operations can be

performed. Apply Loctite to the screws so that they do not

become loose.

Safety Precautions

Install the rear unlocking button kit in the correct direction as

shown below. Do not install the kit in incorrect directions, other-

wise malfunction will be caused.

Correct Incorrect

Do not apply strong force exceeding 100 m/s2to the rear un-

locking button kit, otherwise malfunction will be caused.

Manual Unlocking Using the Rear

Unlocking Button

The rear unlocking button is used by the operator confined in•

a hazardous area for emergent escape.

Unlock

Rear Unlocking Button

Unlock

Rear Unlocking

Button Kit

How to operate

When the rear unlocking button is pressed, the interlock switch•

is unlocked and the door can be opened.

To lock the interlock switch, pull back the button.•

While the button remains pressed, the interlock switch can-•

not be locked even if the door is closed, and the main circuit

remains open.

Safety Precautions

Install the rear unlocking button in the place where only the•

operator inside the hazardous area can use it. Do not install

the button in the place which can be reached by an opera-

tor outside the hazardous area, otherwise the interlock switch

may be unlocked during machine operation, causing danger.

Operate the rear unlocking button by hand only. Do not oper-•

ate using a tool or with excessive force. Do not apply force to

the button from the direction other than the proper direction,

otherwise the button will be damaged.

Recommended Tightening Torque

Screw Recommended

Tightening Torque

HS9Z-DH5C Switch Cover Unit

One Screw A (M4) and two Screws B (M5)

to install the switch cover on the mounting

bracket

1.0 to 1.2 N·m

Four Screws C (M4) to install the HS5E-

44L∗∗-G on the mounting bracket

Two Screws C (M4) to install the HS5B-∗∗Z on

the mounting bracket

1.5 to 1.8 N·m

Four M5 screws to install the switch cover unit

on the mounting frame and panel (not supplied

and must be provided by the user)

4.5 to 5.0 N·m

HS9Z-DH5∗H Handle Unit

Two Screws D (M5) to fasten handles

(one each on front and rear handles) 2.5 to 3.0 N·m

Two Screws E (M5) to install the rear handle

base on the rear handle plate 4.5 to 5.0 N·m

Two M5 screws each to install the front and

rear handles on the mounting frame and panel

(not supplied and must be provided by the

user)

4.5 to 5.0 N·m

Note: The above recommended tightening torques of the mounting screws

are the values with hex socket head bolts. When other screws are

used and tightened to a smaller torque, make sure that the screws do

not become loose after mounting.

(08/03/12)

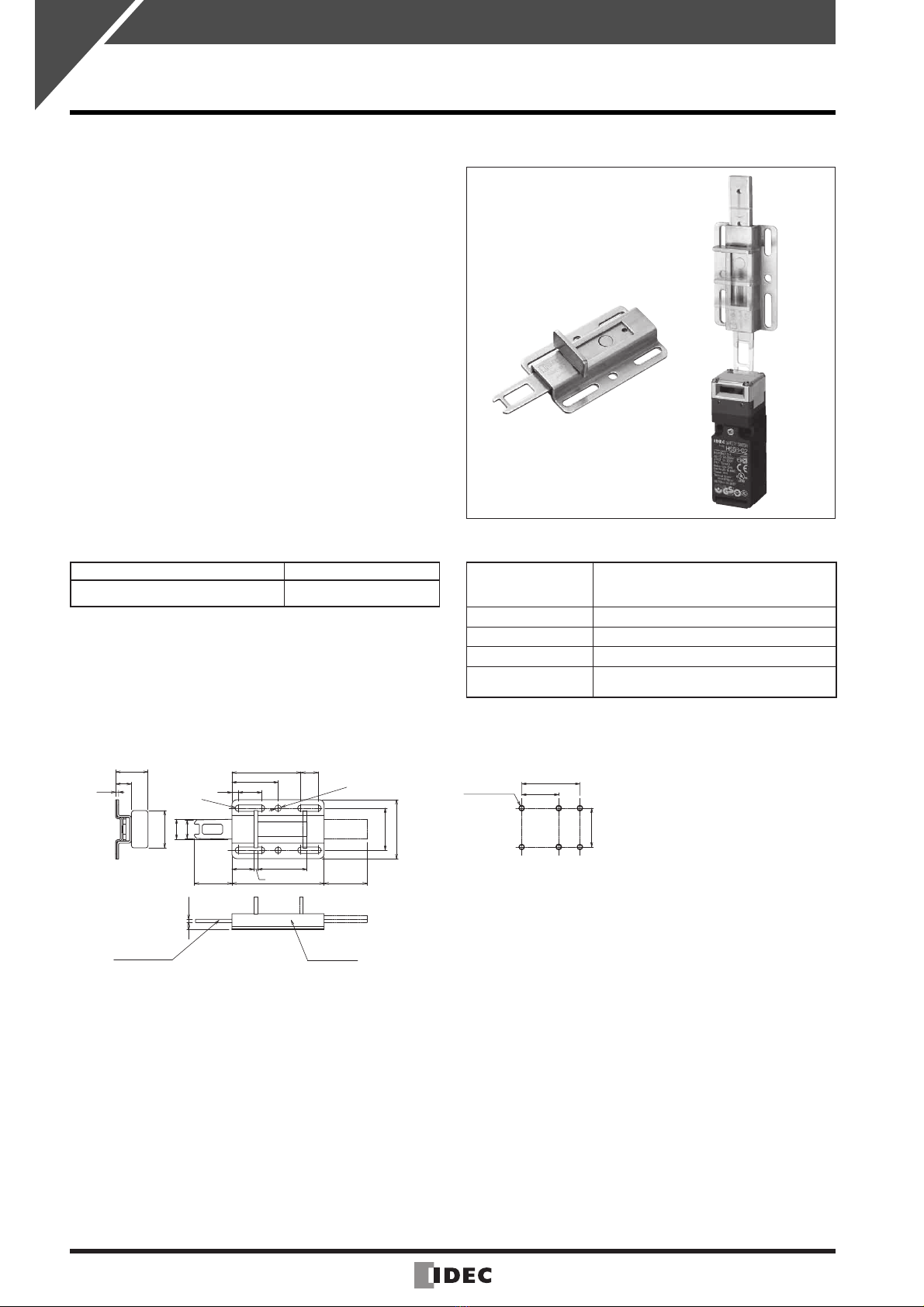

Types

Description Ordering Type No.

HS5B/5E Sliding Actuator HS9Z-SH5

Note: HS5B and HS5E interlock switches are not supplied with the

sliding actuators and must be ordered separately.

Specifications

Applicable Type

HS5B-∗∗Z Metal Head Type Interlock

Switches

HS5E Interlock Switches

Weight 125g

Mechanical Durability 100,000 operations minimum

Operation Stroke 40 mm

Direct Opening Force HS5B: 80N minimum

HS5E: 90N minimum

14

Sliding Actuator

Dimensions

1456

37.5

19

5

34

48.5

(40)18

75

30.7

15

16

3

8-R2.6

13

26.5

51

32.5

34

6-M5 Screws

2.5

30.5

2.5

6

35

2-ø5.2

Actuator (SUS)

Thickness: 2.5 Cover (SUS)

HS5B/HS5E Sliding Actuator

Sliding actuators allow for easy installation and adjustment.

Angle adjustment is not required, enabling easy position-•

ing.

Installation is possible both vertically and horizontally, and•

also on any type of doors.

Can be used on the HS5B metal head type and HS5E in-•

terlock switches.

Safety measures can be provided easily on existing facili-•

ties.

Mounting Hole Layout

All dimensions in mm.

(08/03/12)

15

Installation

When using with HS5B-∗∗Z interlock switch When using with HS5E interlock switch

Fasten the actuator cover on at least two rectangular holes

and two round mounting holes using mounting screws.

The thickness adjustment plate requires mounting holes.

5

4

36.2

34

106

20 to 22

HS5E

Interlock

Switch

Thickness Adjustment Plate

(to be provided by the user)

Recommended thickness:

Two Round

Mounting Holes

Two Oblong

Mounting Holes

50

-1

5mm

0

-1

HS5B/5E Sliding Actuator

4

5

36.2

34

20 to 22

Fasten the actuator cover on at least two

oblong holes using mounting screws.

HS5B

Interlock Switch

Two Oblong

Mounting Holes

Instructions

Operating Instructions

When using the sliding actuator in a safety-related part of the•

system, make sure of proper operation while observing the

safety standards and regulations of the relevant country or re-

gion where the actual machine/system is used. Also, perform

a risk assessment before operation.

Read the instruction sheet of the interlock switch carefully be-•

fore installation or operation.

The actuator has projections on the end. Take care not to in-•

jure hands.

Regardless of door types, do not use the sliding actuator as a•

door stop.

When the actuator is inserted to an interlock switch in the dif-•

ferent direction from the open/close direction of the door, do

not open the door with excessive force, otherwise failure or

damage will be caused.

When an operator enters the hazardous zone, take a safety•

measure such as using padlock hasp HS9Z-PH5 so that the

operator is not trapped inside and the machine is not operated

while the operator is in the hazardous zone.

Do not install the sliding actuator as shown below, otherwise•

the actuator may be removed from the interlock switch due to

shocks.

Ensure to slide the sliding actuator completely. Incomplete in-•

sertion of the actuator may cause unstable contact operation

of the interlock switch. Also, door may not be opened, damag-

ing the actuator.

Do not close the door when the actuator is slid out of the cov-•

er, otherwise the actuator may damaged.

When using the sliding actuator, take care so that fingers•

or hands are not caught between the actuator and interlock

switch.

When installing the sliding actuator over•

the interlock switch as shown below, do

not apply a shock exceeding 100 m/s2

to the actuator, otherwise the actuator

may be inserted to the interlock switch

and cause unintended machine opera-

tion.

Use the sliding actuator with HS5B and•

HS5E interlock switches only. Do not

use with other products.

Do not modify or disassemble the slid-•

ing actuator.

Adjustment

Mounting Reference Position1.

The mounting reference position of sliding actuator is shown•

below.

Recommended Tightening Torque of Mounting Screws2.

M5 screws for mounting the sliding actuator: 4.5 to 5.5 N·m•

M4 screws for mounting the interlock switch: 1.8 to 2.2 N·m•

Note: The above recommended tightening torque of the mounting screws are

the values with hex socket head bolts. When other screws are used

and tightened to a smaller torque, make sure that the screws do not

become loose after mounting.

Interlock

Switch

HS9Z-SH5

HS5B Interlock Switch

Mounting

Position

Tolerance: ±2.5

26.7 21 4

Mounring

Reference

(Mounting position tolerance 4 )

+3

-1

(08/03/12)

HS5E Miniature Interlock Switch with Solenoid

HS5B Miniature Interlock Switches

Ideal for applications in small spaces.

Available with a robust and durable metal head.

Choice of three conduit port sizes: G1/2, PG13.5,

and M20

Compact body. 35 × 40 × 146 mm•

Rear unlocking button type for emergency escape available.•

Also available is a rear unlocking button kit.

A variety of circuit types—dual safety circuit and four-circuit independent•

output type available.

Spring lock and solenoid lock are available.•

The head orientation can be rotated, allowing for 8 different actuator entries.•

A metal entry slot ensures high durability of head.•

The actuator retention force is 1000N minimum (GS-ET-19).•

Rear Unlocking Button

Actuators are interchangeable with the HS5E interlock switches.•

Actuators with rubber bushings are ideal for rattling doors.•

The head orientation can be changed, allowing for 8 different actuator entries.•

Compact body (30 × 30 × 90mm)•

IDEC CORPORATION (USA)

1175 Elko Drive, Sunnyvale, CA 94089-2209, USA

Tel: +1-408-747-0550 / (800) 262-IDEC (4332)

Fax: +1-408-744-9055 / (800) 635-6246

E-mail: [email protected]

IDEC CANADA LIMITED

3155 Pepper Mill Court, Unit 4, Mississauga,

Ontario, L5L 4X7, Canada

Tel: +1-905-890-8561, Toll Free: (888) 317-4332

Fax: +1-905-890-8562

E-mail: [email protected]

IDEC AUSTRALIA PTY. LTD.

2/3 Macro Court, Rowville, Victoria 3178, Australia

Tel: +61-3-9763-3244, Toll Free: 1800-68-4332

Fax: +61-3-9763-3255

E-mail: [email protected]

IDEC ELECTRONICS LIMITED

Unit 2, Beechwood, Chineham Business Park,

Basingstoke, Hampshire RG24 8WA, UK

Tel: +44-1256-321000, Fax: +44-1256-327755

E-mail: [email protected]

7-31, Nishi-Miyahara 1-Chome, Yodogawa-ku, Osaka 532-8550, Japan

Tel: +81-6-6398-2571, Fax: +81-6-6392-9731

E-mail: [email protected]

Specifications and other descriptions in this catalog are subject to change without notice.

Cat. No. EP1210-0 MARCH 2008 7.2T PRINTED IN JAPAN

IDEC ELEKTROTECHNIK GmbH

Wendenstrasse 331, 20537 Hamburg, Germany

Tel: +49-40-25 30 54 - 0, Fax: +49-40-25 30 54 - 24

E-mail: [email protected]

IDEC (SHANGHAI) CORPORATION

Room 608-609, 6F, Gangtai Plaza, No. 700,

Yan'an East Road, Shanghai 200001, PRC

Tel: +86-21-5353-1000, Fax: +86-21-5353-1263

E-mail: [email protected]

IDEC (BEIJING) CORPORATION

Room 211B, Tower B, The Grand Pacific Building,

8A Guanghua Road, Chaoyang District,

Beijing 100026, PRC

Tel: +86-10-6581-6131, Fax: +86-10-6581-5119

IDEC (SHENZHEN) CORPORATION

Unit AB-3B2, Tian Xiang Building, Tian’an Cyber Park,

Fu Tian District, Shenzhen, Guang Dong 518040, PRC

Tel: +86-755-8356-2977, Fax: +86-755-8356-2944

IDEC IZUMI (H.K.) CO., LTD.

Units 11-15, Level 27, Tower 1,

Millennium City 1, 388 Kwun Tong Road,

Kwun Tong, Kowloon, Hong Kong

Tel: +852-2803-8989, Fax: +852-2565-0171

E-mail: [email protected]

IDEC TAIWAN CORPORATION

8F-1, No. 79, Hsin Tai Wu Road, Sec. 1,

Hsi-Chih, Taipei County, Taiwan

Tel: +886-2-2698-3929, Fax: +886-2-2698-3931

E-mail: service@tw.idec.com

IDEC IZUMI ASIA PTE. LTD.

No. 31, Tannery Lane #05-01,

HB Centre 2, Singapore 347788

Tel: +65-6746-1155, Fax: +65-6844-5995

E-mail: [email protected]

www.idec.com

(08/03/12)

This manual suits for next models

7

Table of contents

Popular Door Lock manuals by other brands

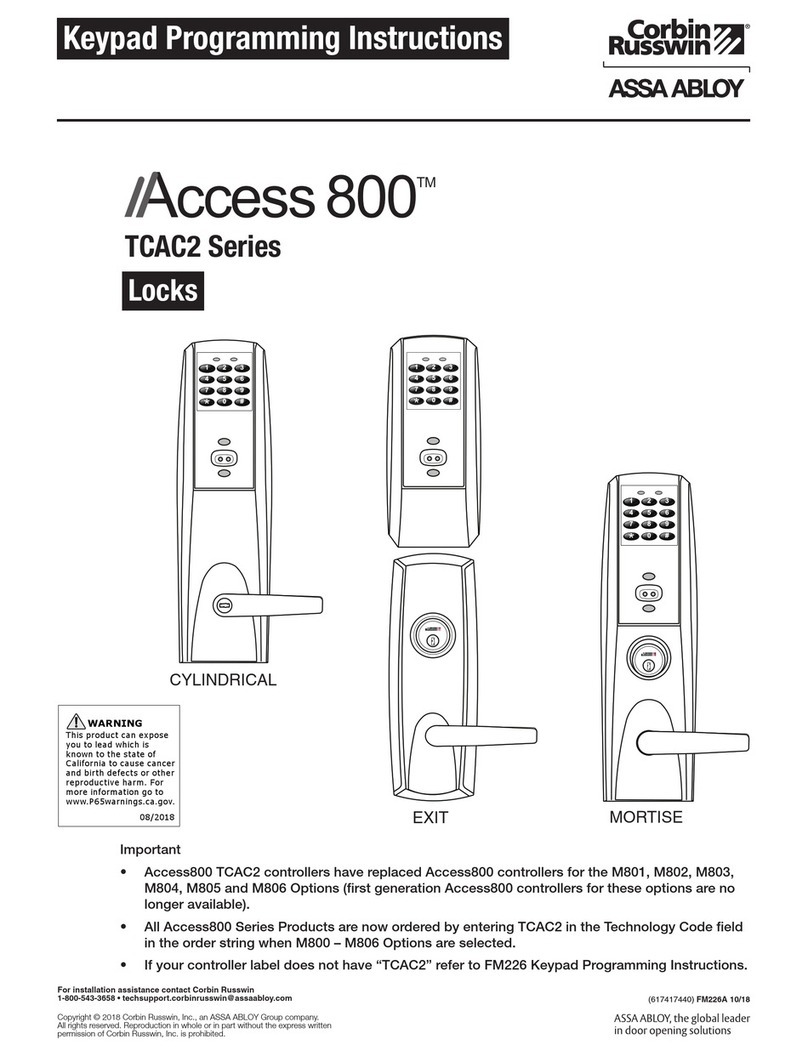

Assa Abloy

Assa Abloy Corbin Russwin Access 800 TCAC2 Series Programming instructions

Assa Abloy

Assa Abloy Abloy EL648 manual

Hafele

Hafele DT 100 FH installation instructions

BANKSTON

BANKSTON Edition Office Pull 02 installation instructions

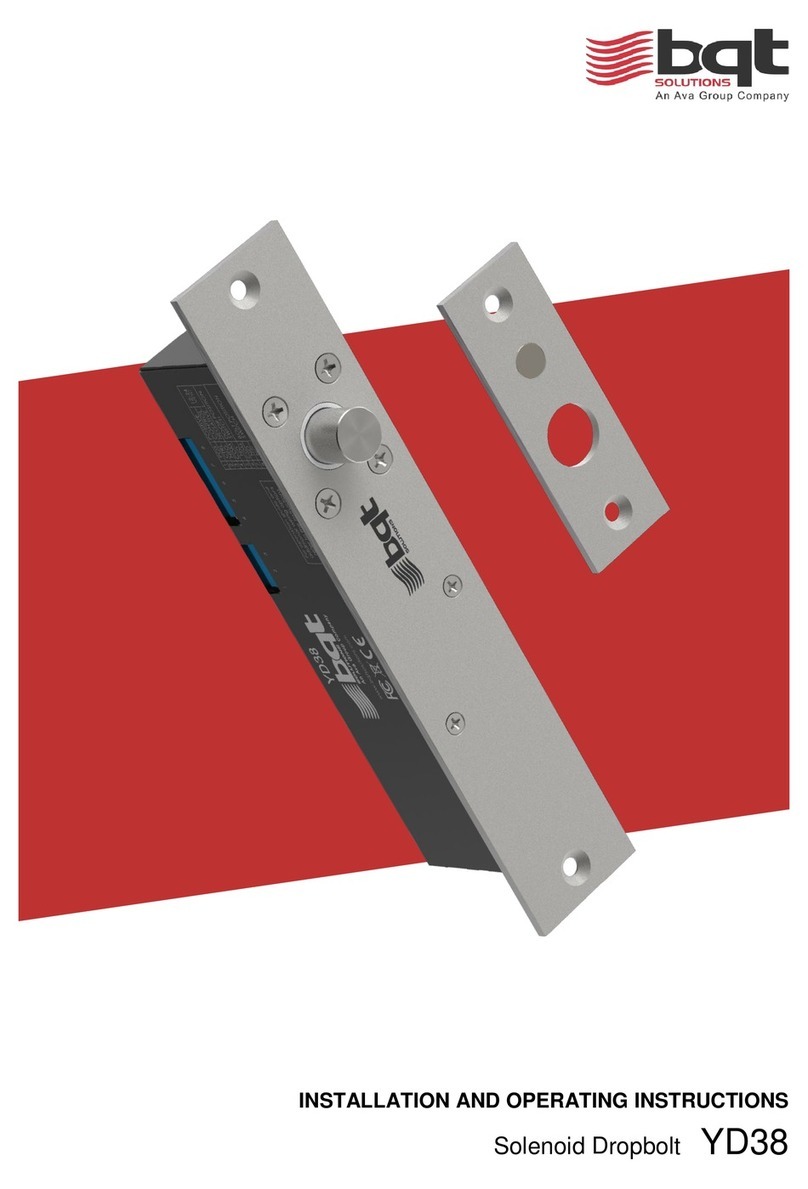

Ava

Ava BQT Solutions YD38 Installation and operating instructions

Avent Security

Avent Security VN168 manual