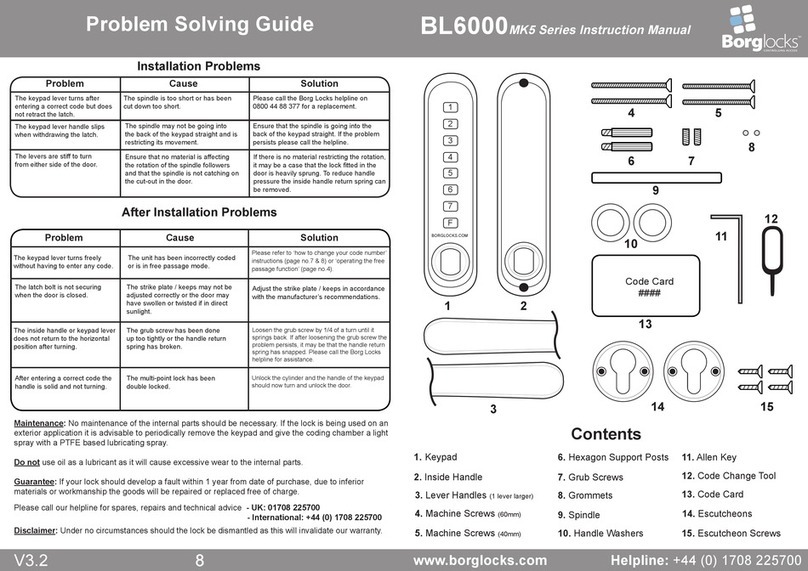

2

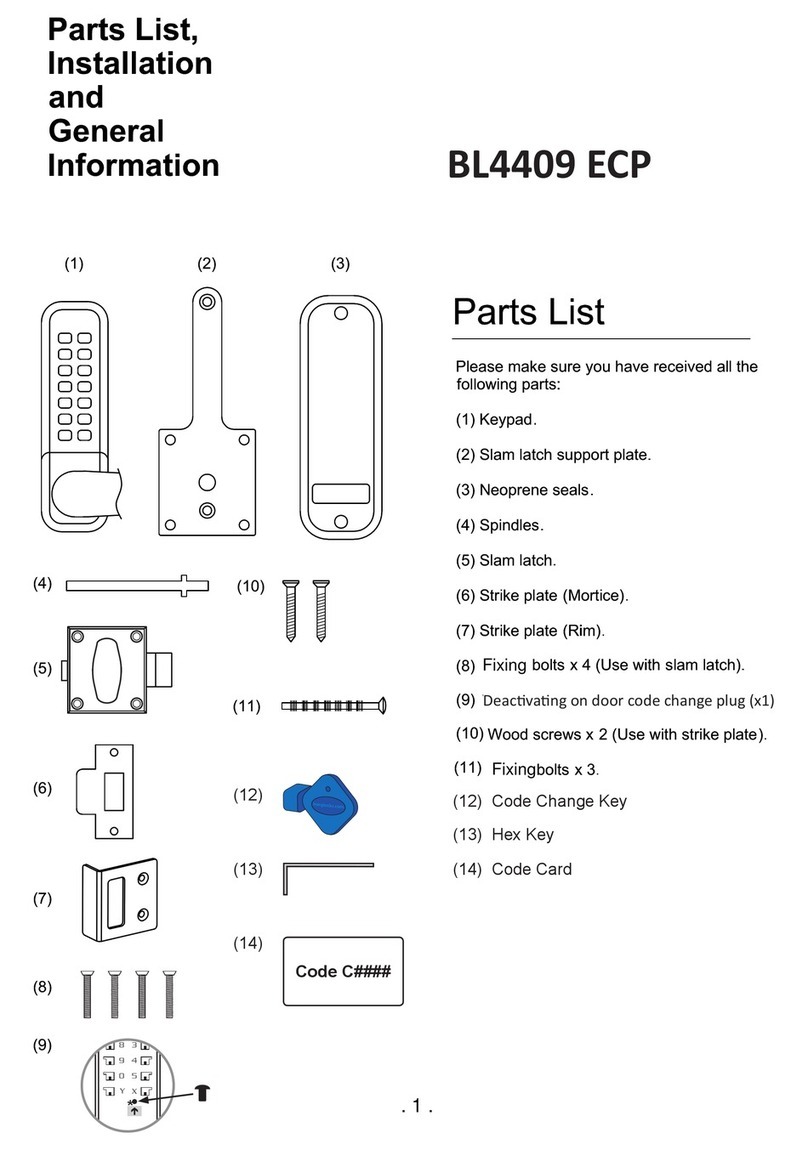

Please check that all the parts are working correctly. Enter the factory preset code as on the code card (part

no.15), rotate the knob on the keypad one turn clockwise, re-enter the code and turn the knob anti-clockwise ensur-

ing that the follower on the back of the keypad rotates each time. The knob should return easily under its spring

pressure. If you intend to change the code please refer to ‘how to change your code number’ instructions (page

no.7) prior to tting.

Make sure that the Inside handle device (part no.2) rotates freely and returns under its spring pressure.

Check that the latch bolt on the tubular latch (part no. 4) moves freely by pressing the latchbolt at the end, and also

turning the spindle (part no. 10 or 11) in the hour glassed shaped follower on the tubular latch.

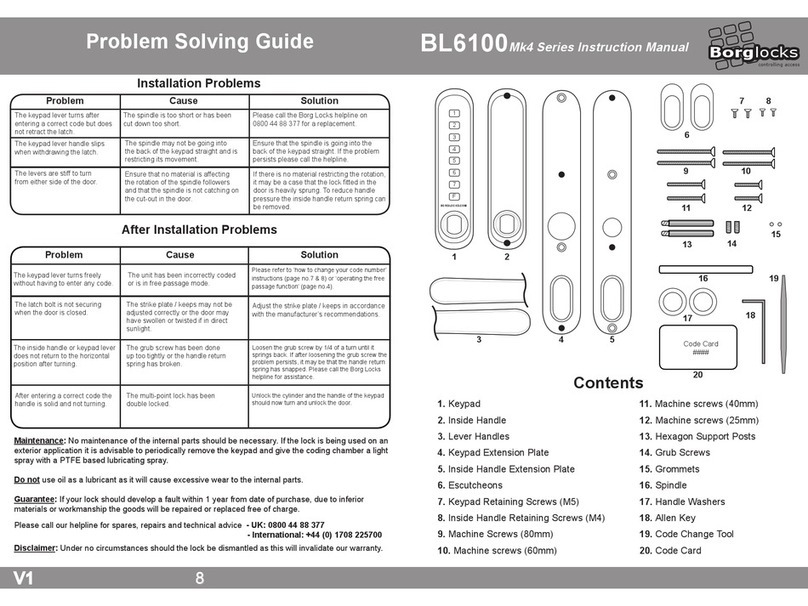

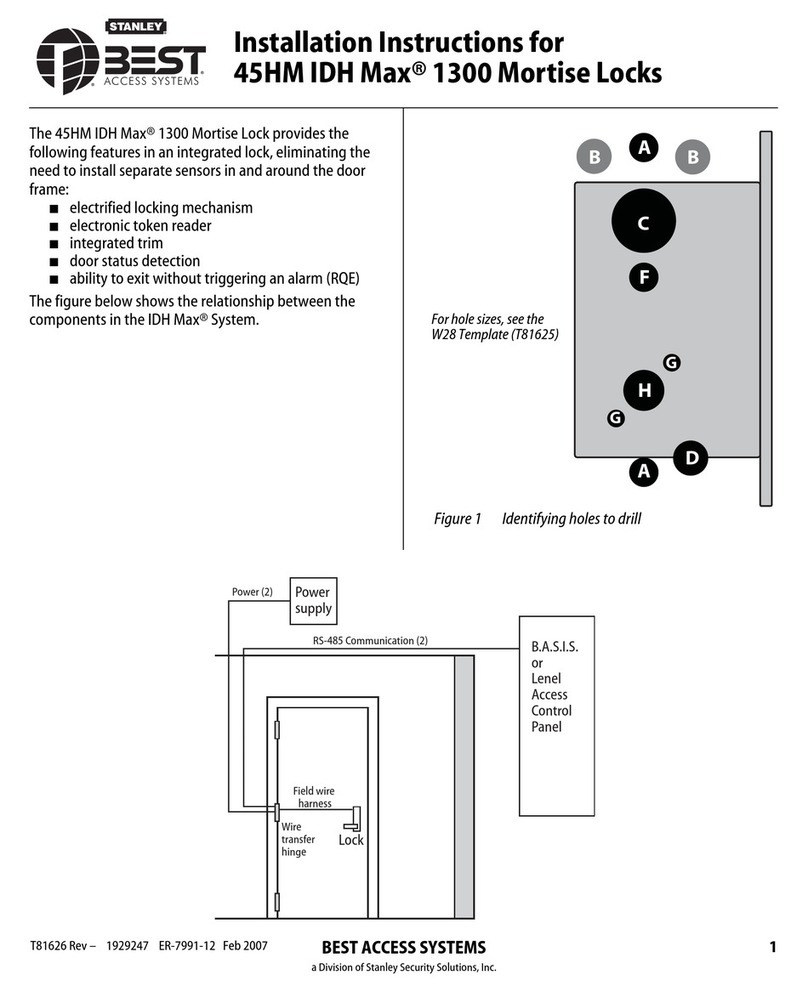

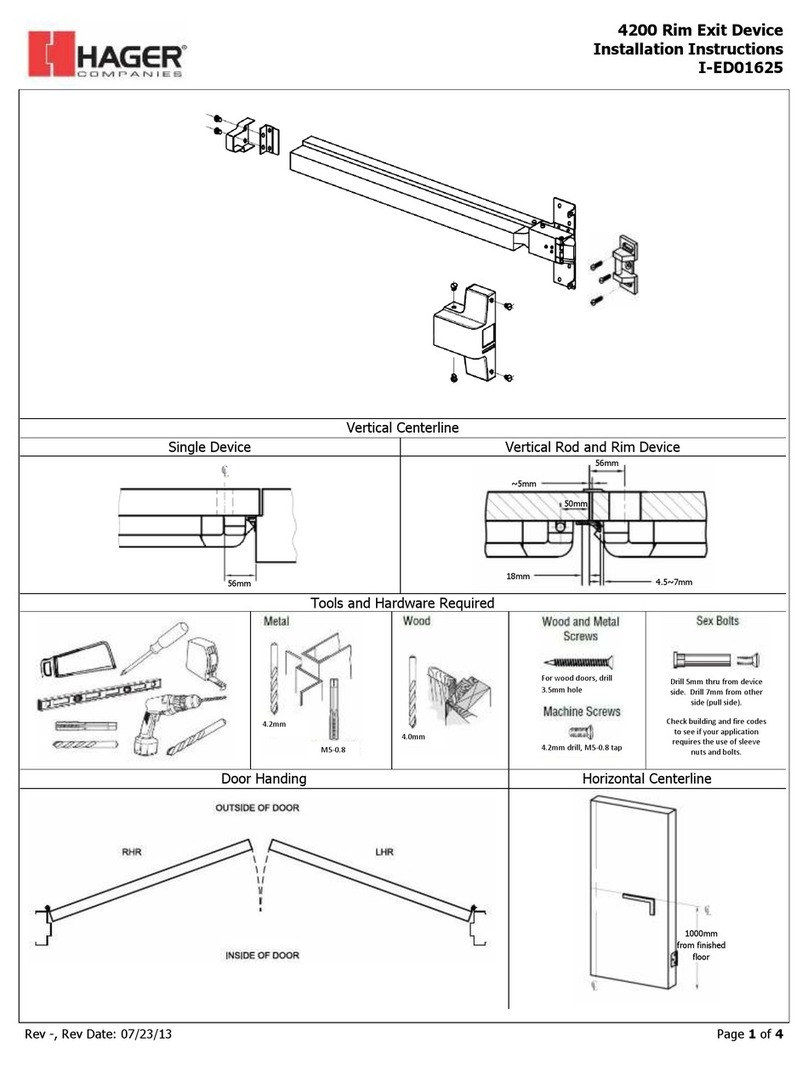

Determining the hand of the door

Many of the installation instructions refer to the handing

of the door. The hand of the door is determined with the

door in its closed position from the exterior or keypad

side of the door.

A) Right hand door – door opens inward (push), hinged

on the right side.

B) Left hand door – door opens inward (push), hinged

on the left side.

C) Right hand inward opening – door opens outward

(pull), hinged on the right side.

D) Left hand inward opening – door opens outward

(pull), hinged on the left side

Inside

Outside

A B

CD

V3

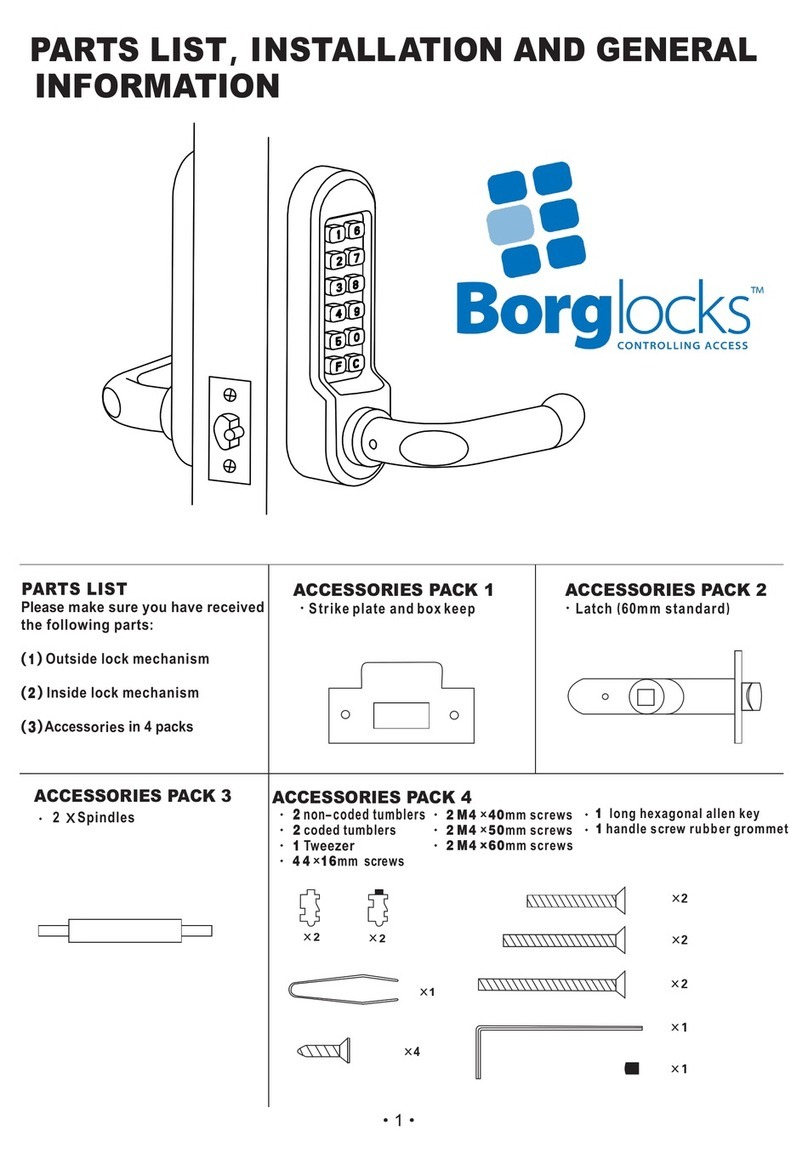

Preparation

A B

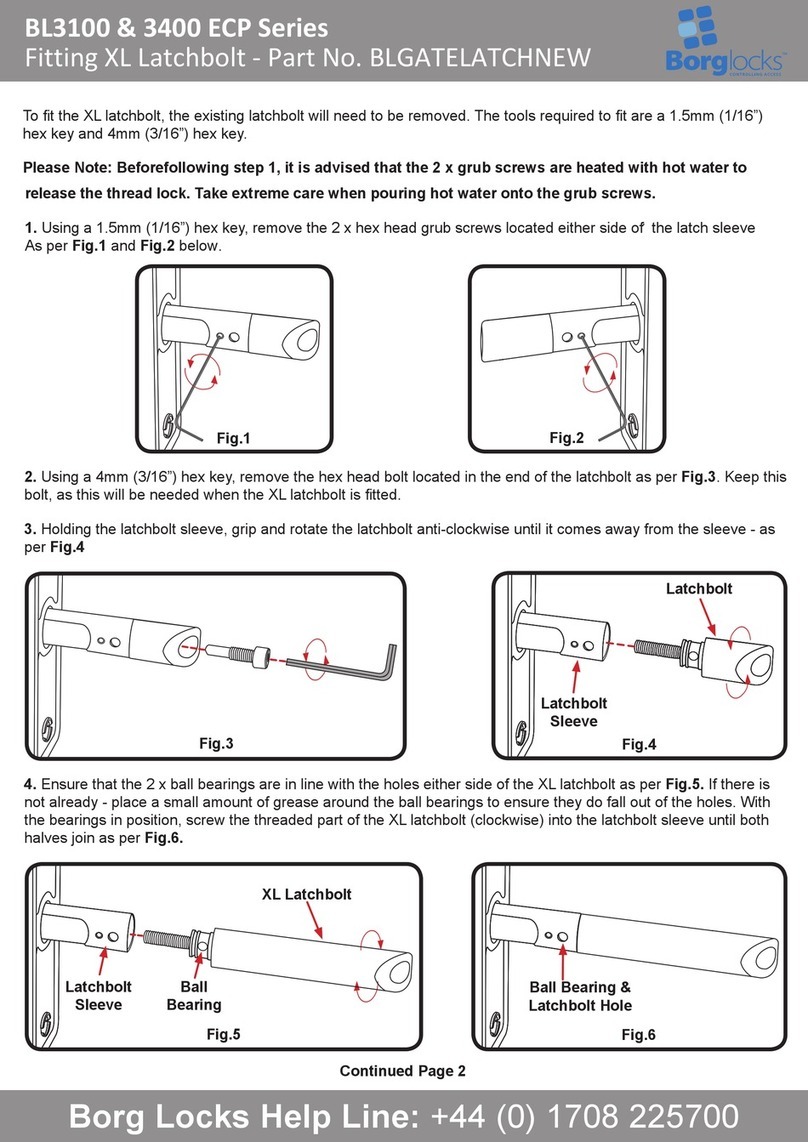

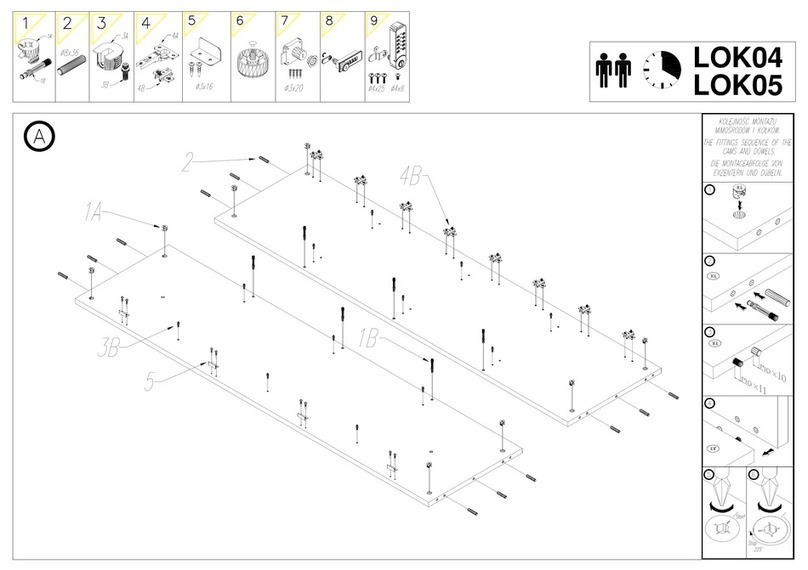

Fitting the Latch Support Post

Fit the latch support post (part no.8) in hole A for a right hand hung door or

Bfor a left hand hung door. Please refer to the ‘determining the hand of the

door’ if you are unsure what hand of door you have.

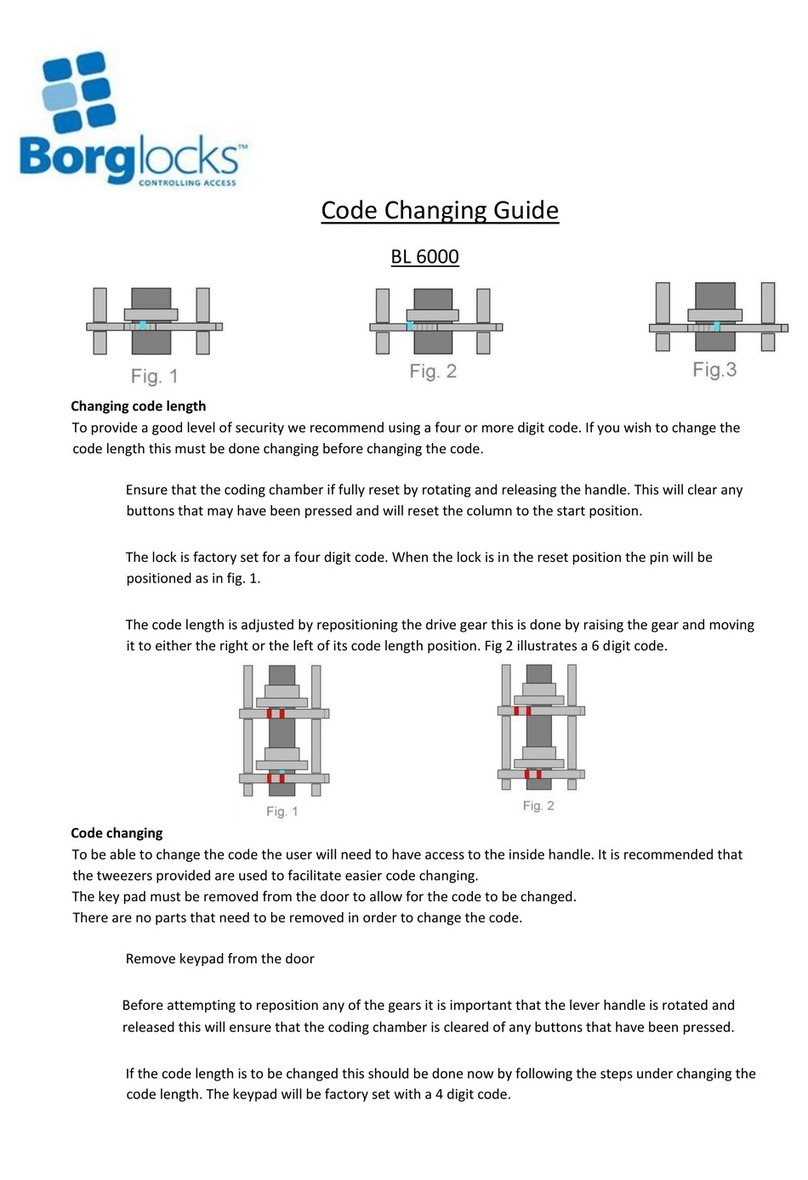

How To Change Your Code Number

Changing the Handing of the Unit

If the unit is being tted to a right hand hung door as per the ‘determining

the hand of the door’ nothing will need to be changed on the unit.

If the unit is being tted to a left hand hung door the only part that will

need to be changed would be the blue handing screw on the back of the

inside handle from point Ato point Bas per the diagram.

AB

V3

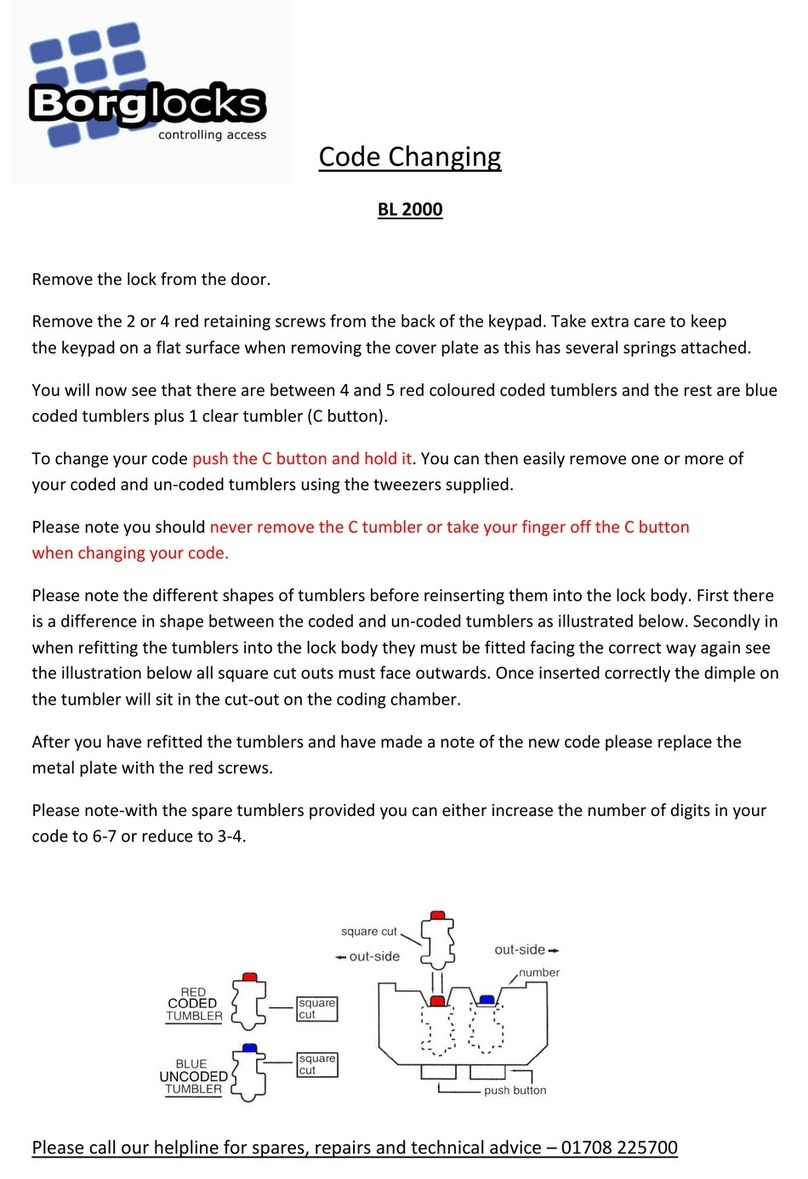

1. Remove the lock from the door, which is done by removing the two screws at the very top and bottom of the

inside handle.

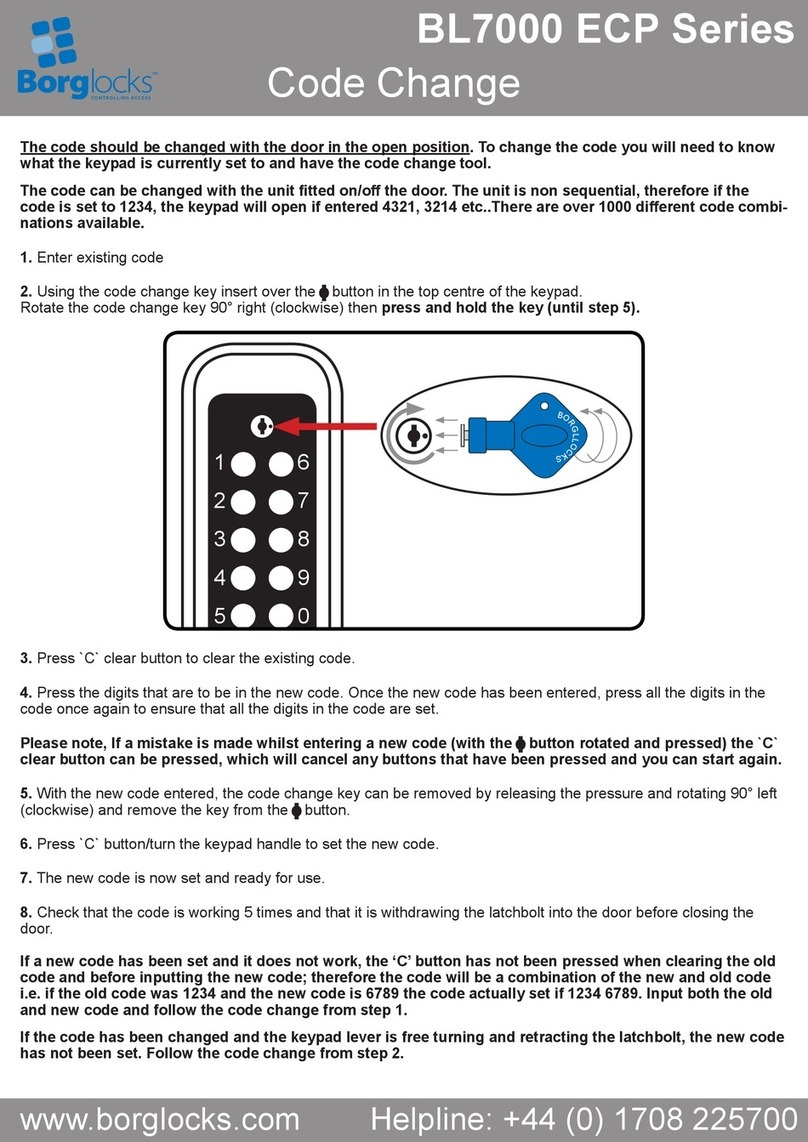

2. With the keypad o the door turn the keypad over and on the reverse you will see two red screws and if from

an earlier model four red screws. Remove the two or four red screws which are securing a plate on with 14

small holes. Take care when removing the red screws as behind the plate are fourteen small springs.

3. With the plate removed you will now see that there are ve red tipped (coded) tumblers, eight blue (non-

coded) tumblers and one uncoloured tumbler (‘C’ button).

4. To change the code, push and hold the ‘C’ button. Do not turn the keypad over as this will result in all

of the coloured tipped tumblers falling out. With the ‘C’ button held in the red tipped (coded) tumblers and

blue tipped (non-coded) tumblers can easily be lifted out using the tweezers supplied (part no. 5).

Please remember that the C tumbler should never be removed and should always be pressed in when

removing or replacing the coded or non-coded tumblers. Failing to hold the ‘C’ button in when chang-

ing the code may result in a damaged lock.

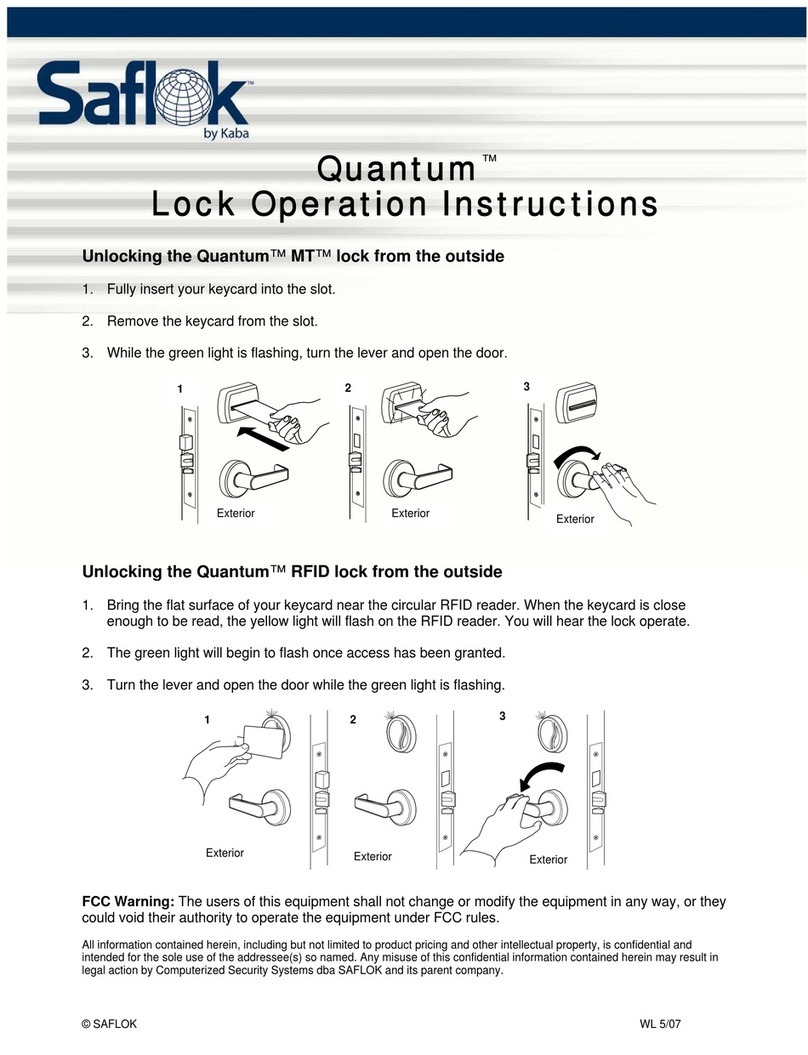

5. Please note the dierent shapes of tumblers before reinserting them into the lock body. Firstly there is a

dierence in shape between the red tipped (coded) and blue tipped (non-coded) tumblers, as illustrated below.

When inserting the tumblers into the lock body they must be tted facing the correct way, again see the illustra-

tions below. All square cut-outs must face outwards, regardless of whether they are coded or non-coded.

If you are inserting a tumbler into the 6, 7, 8, 9, 0, or Z positions the square cut-out of the tumbler need

to be facing towards the left and the dimple on the tumbler facing downwards. If you are inserting a

tumbler into the 1, 2, 3, 4, 5, X or Y positions the square cut-out of the tumbler need to be facing to-

wards the right and the dimple facing upwards.

6. If for instance the keypad needed to be coded to 1, 2, 3, 4, 5 you would hold the ‘C’ button down and using

the tweezers supplied (part no. 5) arrange the red tumblers so that they are in the 1, 2, 3, 4 and 5 positions

and in the remaining 8 positions blue tumblers will need to be inserted.

Please note that the code is not sequential and if for instance the unit was coded to 1, 2, 3, 4, 5 the

code can be entered 5, 4, 3, 2, 1 or any sequence as long as all of the digits in the code have been

pressed.

7. After you have retted the tumblers and made a note of the new code, replace the plate with the 14 small

springs on and secure in place with the two or four red screws.

8. With the lock coded and the plate on the back retted, ensure that the new code works 3 - 4 times before

retting it to the door. Once tted to the door check the code once more before closing.

Square

cut-out

Square

cut-out

Red Coded

Tumbler

Blue Non-Coded

Tumbler

Buttons

Outwards

Square

cut-out

Square

cut-out

Outwards

7