Borglocks MK5 Series User manual

BL6000

MK5 Series Instruction

Manual

Helpline: +44 (0) 1708 225700

Problem Solving Guide

Maintenance: No maintenance of the internal parts should be necessary. If the lock is being used on an

exterior application it is advisable to periodically remove the keypad and give the coding chamber a light

spray with a PTFE based lubricating spray.

Do not use oil as a lubricant as it will cause excessive wear to the internal parts.

Guarantee: If your lock should develop a fault within 1 year from date of purchase, due to inferior

materials or workmanship the goods will be repaired or replaced free of charge.

Please call our helpline for spares, repairs and technical advice - UK: 01708 225700

- International: +44 (0) 1708 225700

Disclaimer: Under no circumstances should the lock be dismantled as this will invalidate our warranty.

Problem Cause Solution

V3.2

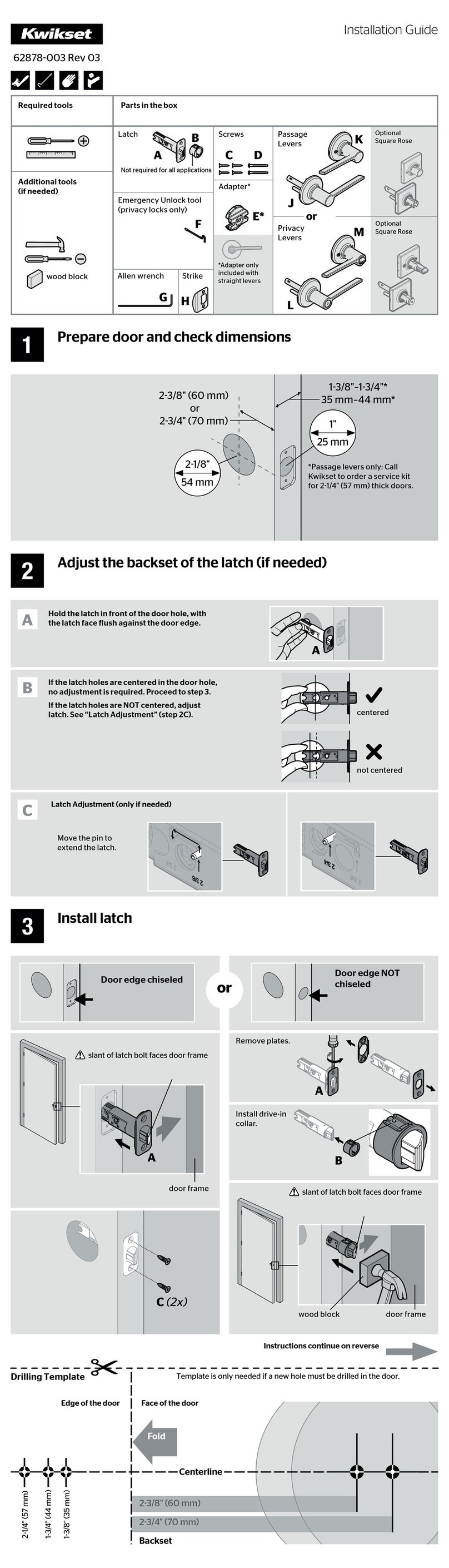

Installation Problems

www.borglocks.com

8

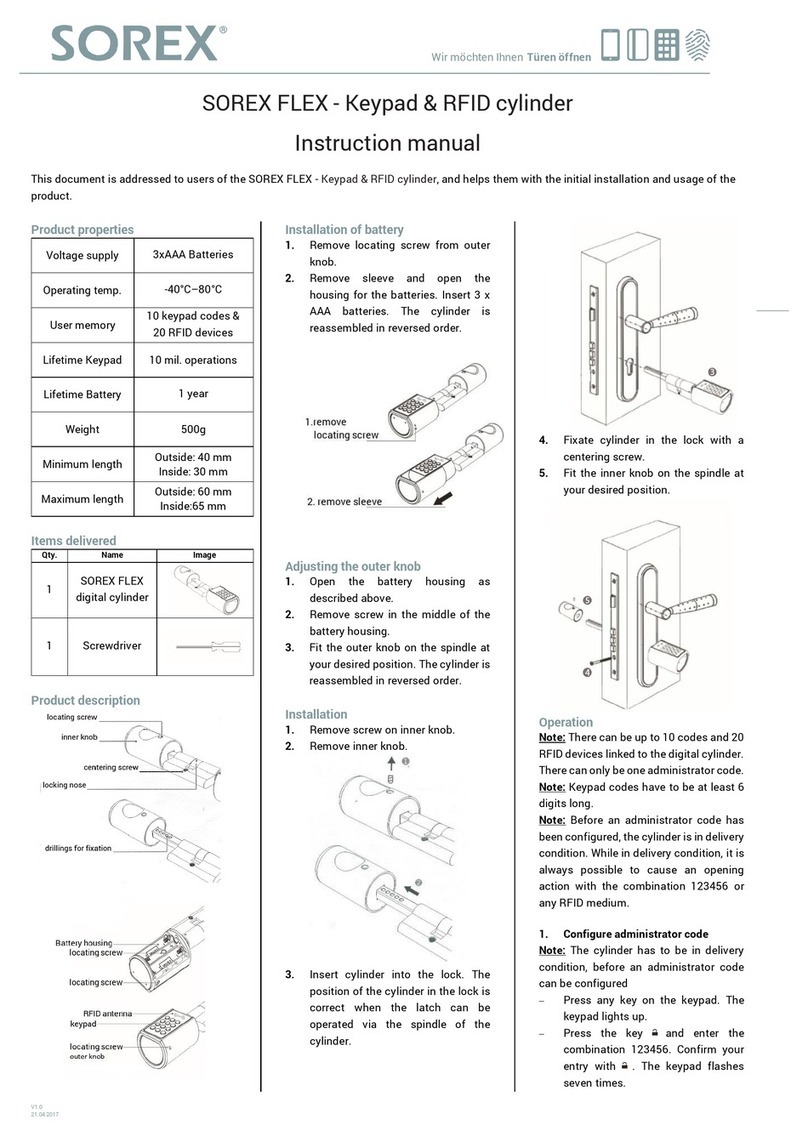

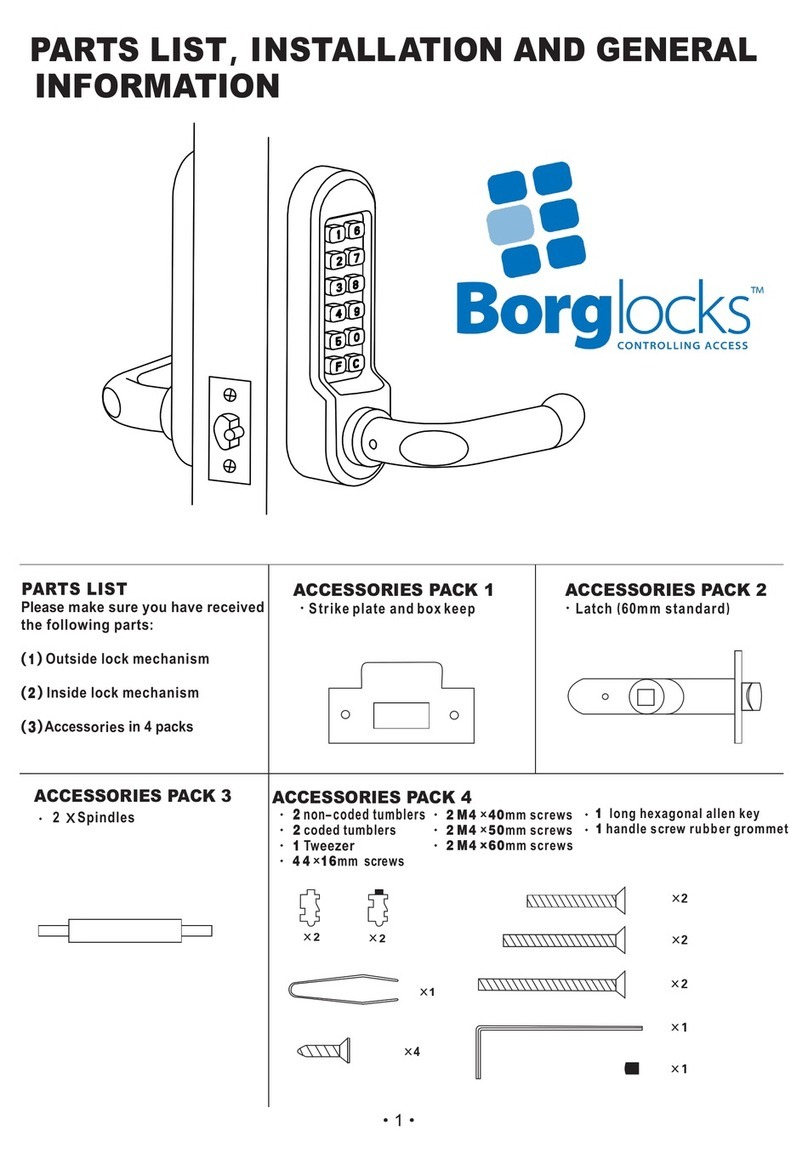

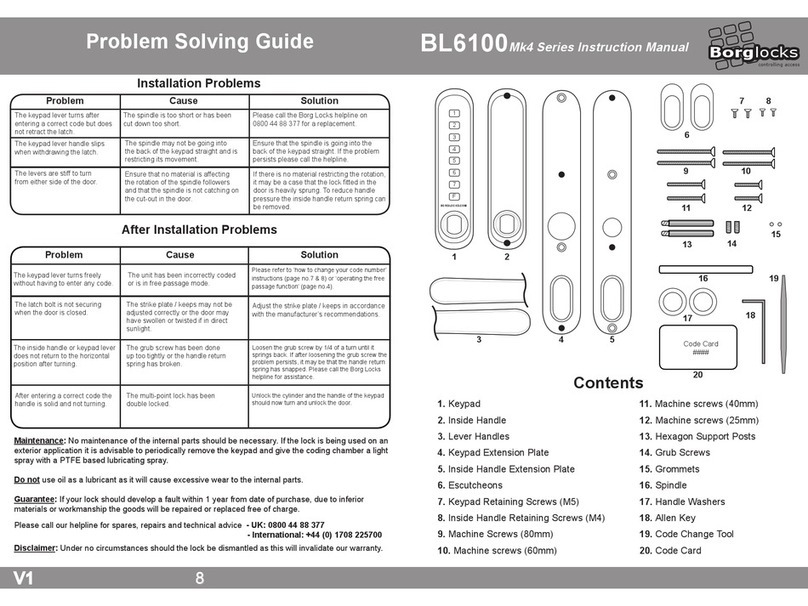

Contents

1. Keypad

2. Inside Handle

4. Machine Screws (60mm)

5. Machine Screws (40mm)

6. Hexagon Support Posts

7. Grub Screws

8. Grommets

9. Spindle

10. Handle Washers

11. Allen Key

12. Code Change Tool

13. Code Card

14. Escutcheons

15. Escutcheon Screws

3. Lever Handles (1 lever larger)

1

2

3

4

5

6

7

F

BORGLOCKS.COM

Code Card

####

4 5

6 7

8

9

10 11

12

13

14 15

1 2

3

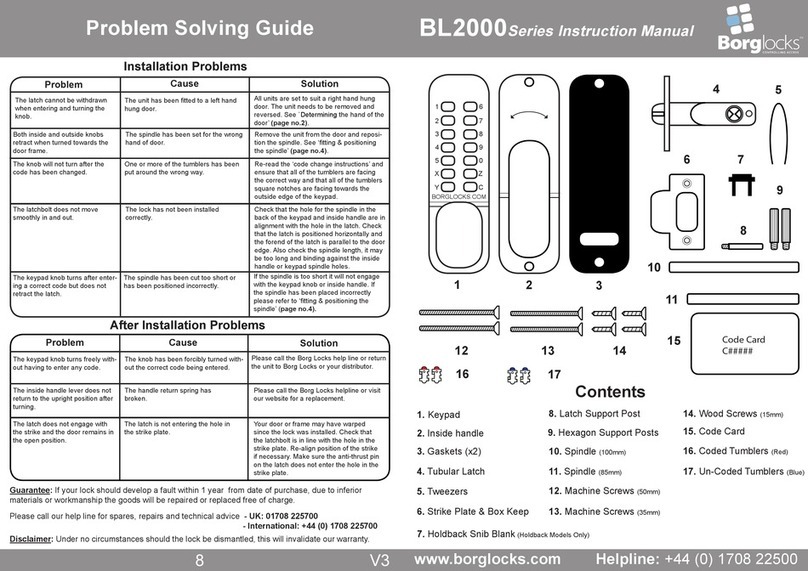

After Installation Problems

Problem Cause Solution

The keypad lever turns freely

without having to enter any code.

The unit has been incorrectly coded

or is in free passage mode.

Please refer to ‘how to change your code number’

instructions (page no.7 & 8) or ‘operating the free

passage function’ (page no.4).

The inside handle or keypad lever

does not return to the horizontal

position after turning.

The grub screw has been done

up too tightly or the handle return

spring has broken.

Loosen the grub screw by 1/4 of a turn until it

springs back. If after loosening the grub screw the

problem persists, it may be that the handle return

spring has snapped. Please call the Borg Locks

helpline for assistance.

The latch bolt is not securing

when the door is closed.

The strike plate / keeps may not be

adjusted correctly or the door may

have swollen or twisted if in direct

sunlight.

Adjust the strike plate / keeps in accordance

with the manufacturer’s recommendations.

The keypad lever turns after

entering a correct code but does

not retract the latch.

The spindle is too short or has been

cut down too short.

Please call the Borg Locks helpline on

0800 44 88 377 for a replacement.

After entering a correct code the

handle is solid and not turning.

The multi-point lock has been

double locked.

Unlock the cylinder and the handle of the keypad

should now turn and unlock the door.

The keypad lever handle slips

when withdrawing the latch.

The spindle may not be going into

the back of the keypad straight and is

restricting its movement.

Ensure that the spindle is going into the

back of the keypad straight. If the problem

persists please call the helpline.

The levers are stiff to turn

from either side of the door.

Ensure that no material is affecting

the rotation of the spindle followers

and that the spindle is not catching on

the cut-out in the door.

If there is no material restricting the rotation,

it may be a case that the lock tted in the

door is heavily sprung. To reduce handle

pressure the inside handle return spring can

be removed.

2V3.2

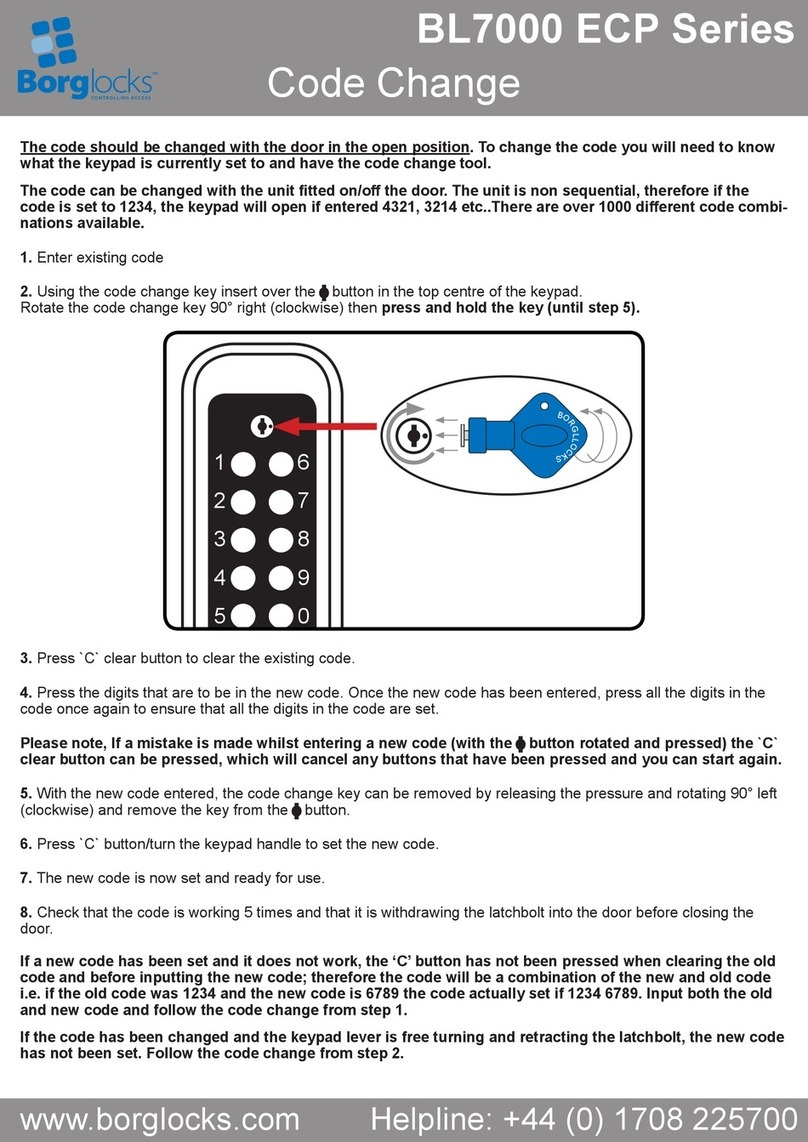

Preparation How To Change Your Code Number

7

V3.2

Please check that all parts are working correctly. Once the lever handles have been tted to the keypad and inside

handle, enter the factory preset code as printed on the code card (part no.13), rotate the lever handle on the

keypad downwards, re-enter the code and turn the handle upwards ensuring that the spindle follower on the back of

the keypad rotates each time - an audible click should be heard every time a correct code is entered and the lever

handle is turned. Both lever handles on the keypad and inside handle should return easily under their own spring

pressure. Please refer to ‘tting the lever handles’ below.

If you intend to change the code please refer to ‘how to change your code number’ instructions

(page no.7 & 8) prior to tting.

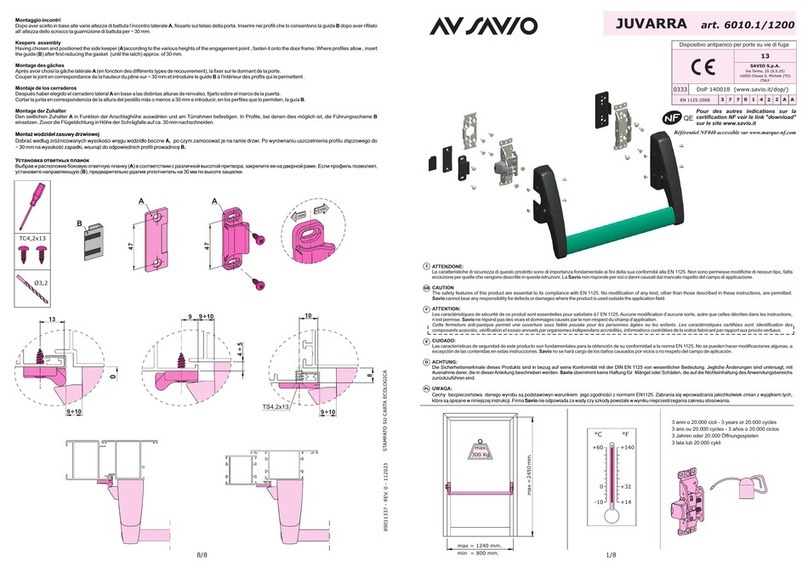

Determining the Hand of the Door

Many of the installation instructions refer to the handing

of the door. The hand of the door is

determined with the door in its closed position

from the exterior or keypad side of the door, as shown in

the diagram on the right.

A) Right hand door – door opens inward (push), hinged

on the right side.

B) Left hand door – door opens inward (push), hinged

on the left side.

C) Right hand inward opening – door opens outward

(pull), hinged on the right side.

D) Left hand inward opening – door opens outward

(pull), hinged on the left side.

Fitting the Lever Handles

The unit is non-handed and the lever handles (part no.3) are not supplied tted. Once you have determined what

handing of door you have, the lever handles can be tted to the keypad and inside handle. The larger lever handle is

tted to the keypad side and the smaller handle to the inside handle - This is done as follows:

Ensure that one of the handle washers (part no.10) is placed around the handle holder before the handle is secured

in place with one of the grub screws (part no.7) and tightened using the allen key (part no.11).

With the lever handles secured to the keypad and inside handle turn the lever handle upwards and downwards to

ensure that they return under their own spring pressure to the horizontal position. If both lever handles return under

their own spring pressure cover the grub screw holes with the grommets (part no.8).

If the handle does not return under it own spring pressure loosen the grub screw by 1/4 of a turn until it springs back.

Inside

Outside

A B

CD

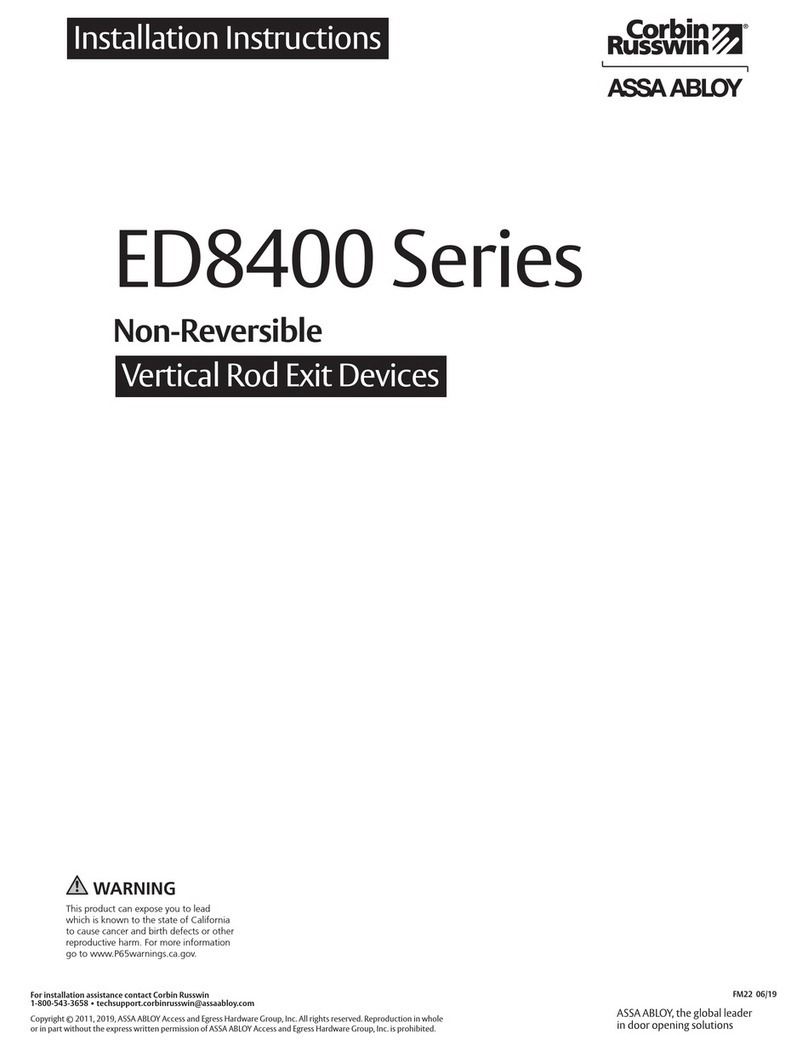

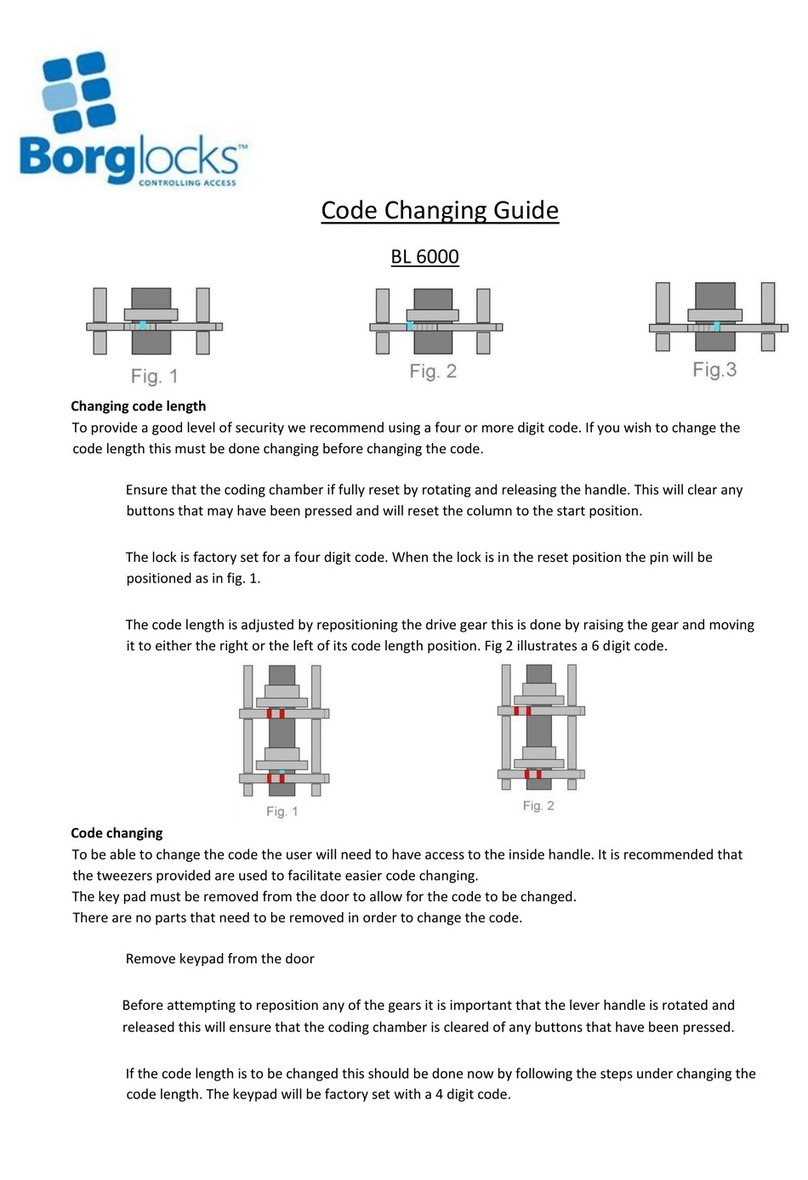

7. Once the rst digit has been set, the principle is the same for any other button that you want to set in the code.

Once you have programmed all the required digits in your code, turn the handle to reset the coding chamber and

ensure that all the buttons that are in the code have the coloured markers in alignment with the centre line arrow

on the keypad cover plate. Make sure that any digit that is not in the code has the blue marker of the coding disk in

alignment with the centre line arrow.

8. When the new code has been set, check that the code is working correctly. Enter the code and rotate the handle

and you should see the spindle follower rotate on the back of the keypad rotate. Test 2-3 times before tting onto

the door.

5. Whilst holding the inner gear the coding disk can be rotated using your nger. If you want that button in the code

as a single press, align the red marker of the coding disk with red line of the inner tab (as per g.6). If you want

that button as a double press align the green marker of the coding disk with the red line of the inner gear (as per

g.7) and if you do not want that button in the code align the blue line of the coding disk with the red line of the

inner gear (as per g.8).

6. With the selected marker in position the inner gear can be released and it should drop into position. The inner

gear and tab should no longer be visible. If the inner gear is still exposed after releasing the pressure, rotate the

coding disc with your nger to the left until the inner gear drops into position.

Set as single press

Red Marker

Fig.6

1

2

3

4

↓↓

Not in the code

Blue Marker

Fig.8

1

2

3

4

↓↓

Fig.7

Set as double press

Green Marker

1

2

3

4

↓↓

V3.2 3V3.2

Preparation

6

How To Change Your Code Number

Fitting the Hexagonal Support Posts

Fit both of the hexagonal support posts (part no.6) into the top and

bottom threaded holes of the keypad, as shown in arrows A and Bin the

diagram on the right.

Without the hexagonal support posts tted the machine screws will not be

able to be screwed into place, as they are different thread sizes.

Do not over tighten the hexagonal support posts as this may strip the

thread on either the post itself or the thread in the back of the keypad.

How To Change Your Code Number Preparation

1

2

3

4

5

6

7

F

B

A

↓ ↓

↓ ↓

Please note: The keypad has a double button press function and you are able to have the same digit twice. When

the unit is being coded, if the green marker of the coding disk is in alignment with the centre line arrow on the cover

plate it denotes that the button is set as a double press. If the red marker of the coding disk is inalignment with the

centre line arrow it is set for a single press and if blue marker of the coding disk is in alignment with the centre line

arrow it is not part of the code.

The coding chamber is non-sequential so the code can be entered in any order. If for instance the unit was coded

to 11234 (as per g.4 below), the unit can be opened by entering 11432, 43211, 12314 etc...

1. To change the code the unit will need to be removed from the door or done prior to tting.

2. Turn the keypad over and remove the extension plate (if tted) so that the back of the coding chamber is visible.

The extension plate is secured to the keypad by 2 x retaining screws. Turn the lever handle of the keypad to ensure

that the coding chamber is reset before a new code is to be programmed.

3. With the coding chamber reset you will see that the coding disks are set to what the keypad is currently coded

to. If for instance the unit is coded to 11234; the number 1 disk will have the green marker of the coding disk lined

up with the centre line arrow on the cover plate. The number 2, 3 and 4 will have the red marker of the coding disks

lined up with the centre line arrow (as per g.4). All the other coding disks will have the blue line in alignment with

the centre line arrow.

4. Choose what the unit wants to be coded to. To change how a button is set in the code – insert the code change

tool (part no.12) into the small hole in the top of the inner gear and then it can be lifted upwards, this will expose a

red line on the inner gear (as per g.5).

Fig.4

↓↓

Centre Line

Arrow 1

2

3

4

↓↓

Coding

Disk

Code Change

Tool

Inner

Gear

1

2

3

4

Fig.5

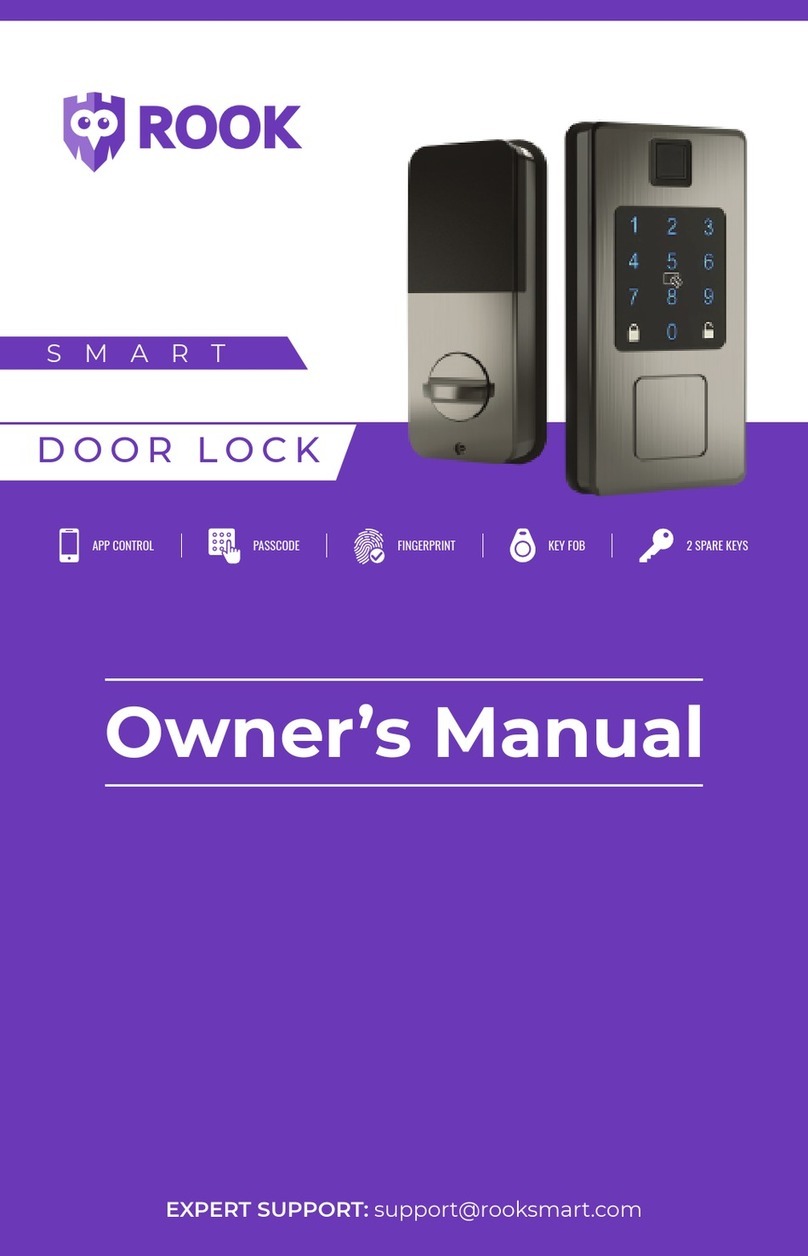

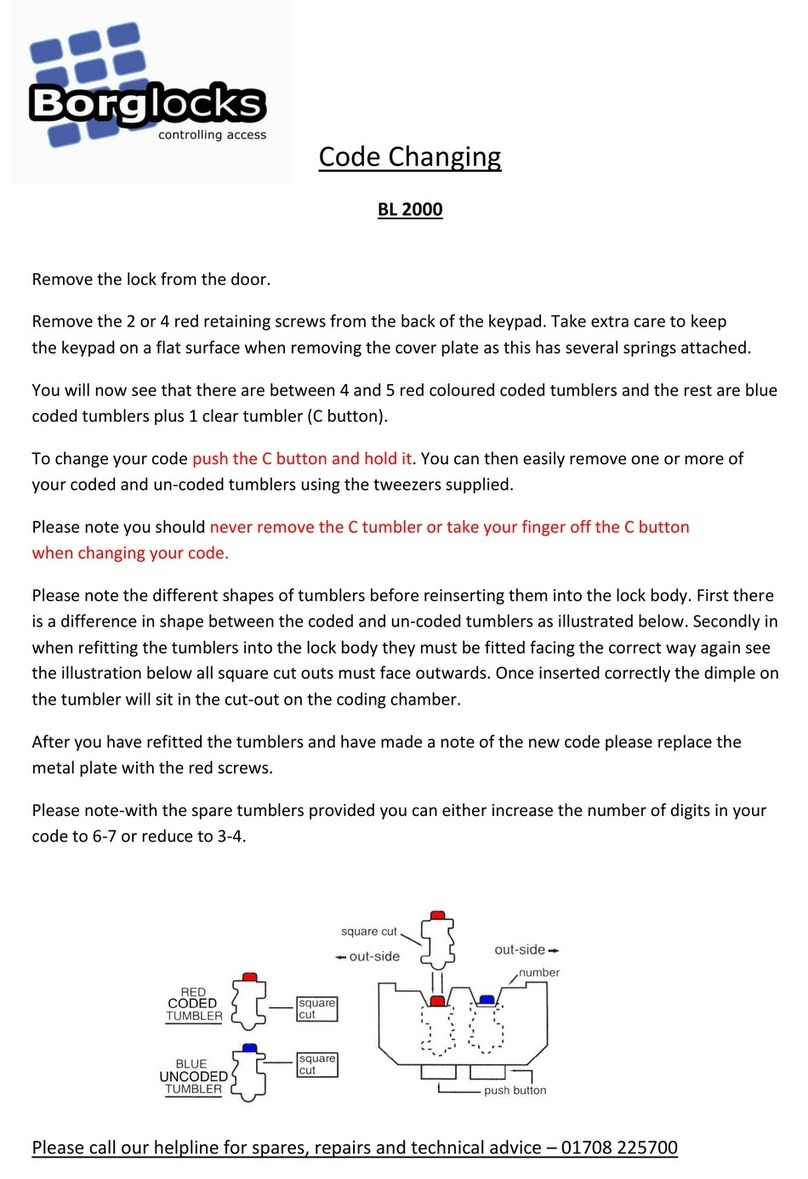

Turning off the Free Passage Function

All units are supplied with the free passage function ready to be used, unless you have specically ordered with the

function turned off. If you do not require the free passage function this feature can be turned off, this should be done

before the unit is tted to the door.

If your unit has the free passage function turned on, the white line of the ‘F’ coding disk will be in alignment with the

centre line arrow (as per g.1). If it is turned off the blue line of ‘F’ coding disk will be in alignment with the centre

line arrow.

1. To turn off the free passage function – insert the code change tool (part no.12) into the small hole in the top of the

inner gear and then it can be lifted upwards, this will expose a red line on the inner gear (as per g.2).

2. Whilst holding the inner gear the coding disk can be rotated using your nger. Rotate the disk until the blue line of

the coding disk is in alignment with the red line of the inner gear (as per g.3).

3. With the blue line in position, the inner gear can be released and it should drop into position. The inner gear and

tab should no longer be visible. If the inner gear is still exposed after releasing, rotate the coding disc with your nger

to the left until the inner gear drops into position.

If at a later date you wish to turn back on the free passage function, follow the above steps but instead of setting the

blue line of the coding disk set the white line.

F

↓ ↓

Fig.1

Coding

Disk

77

F

↓ ↓

Code

Change

Tool

Inner

Gear

Fig.2

F

↓ ↓

7

Fig.3

Centre Line

Arrow

4V3.2

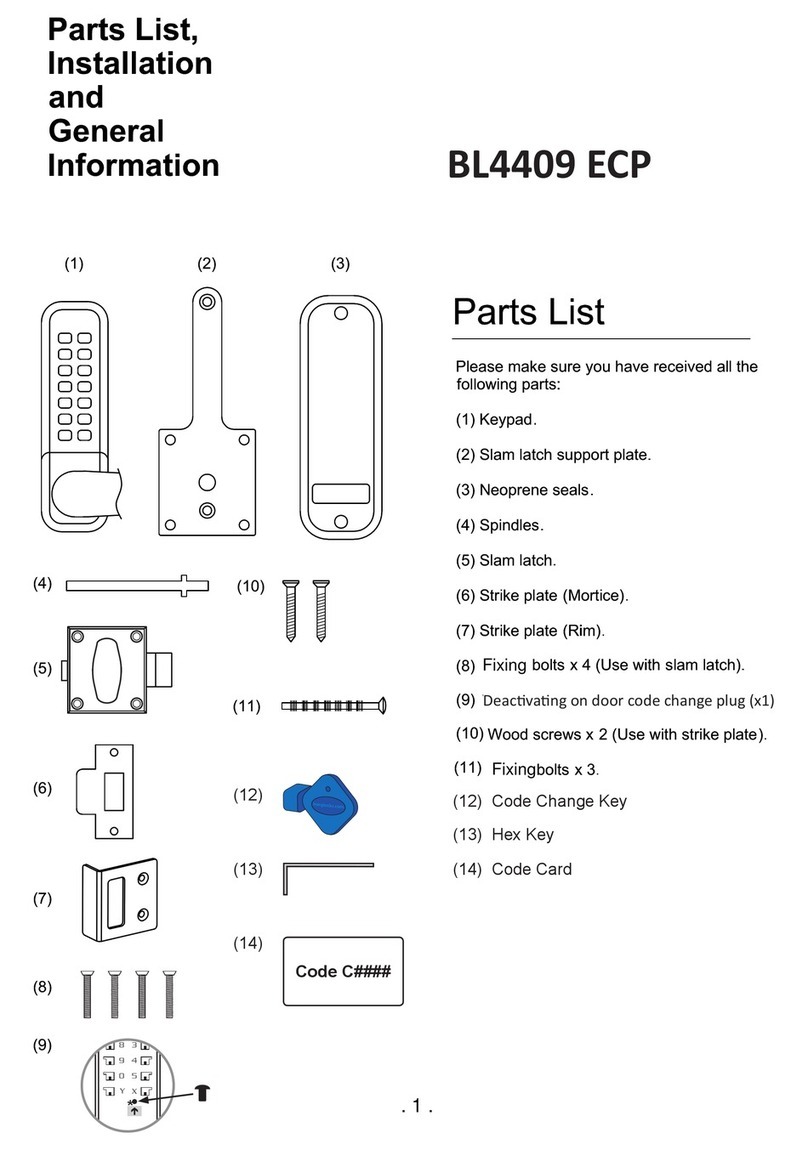

Preparation & Installation

5V3.2

Installation & Operation

Fitting Illustration

Apply the Drilling Template

If the unit is to be tted onto a UPVC door then the door section is likely to have

already been drilled out to accept a standard set of lever handles. In this case

please align our drilling template from the spindle centre with the spindle centre in

the door.

1. Apply the supplied template to the outside of the door so that the centre line of

the keypad matches the backset of the latch taking into account that most UPVC

doors have a rebated edge.

2. Mark the centres points for the top and bottom xing holes and the hole for the

spindle and drill to the correct size holes as specied on the drilling template.

Operating the Free Passage Function

When the keypad is set in the free passage function the handle will be free turning until the function is deactivated.

This function is designed for high trafc / low security situations and allows users to pass through the door by

turning the handle without having to enter the code each time.

The ‘F’ button activates the free passage function, if you want to set this function the steps are as follows:

1. Enter the code into the keypad along with the ‘F’ button and turn the handle.

2. The user will now be able to rotate the handle freely without having to enter the code.

3. To cancel the free passage function, press the ‘F’ button and rotate the keypad handle once and the keypad will

return to being in the locked state.

Escutcheons

(part no.14)

Door

Hexagon Support Posts

(part no.6)

Spindle

(part no.9) Machine Screws

(part no.4/5)

Lever Handle

(part no.3)

Larger Lever

Handle

(part no.3)

Escutcheon Screws

(part no.15)

Escutcheon Screws

(part no.15)

Handle Washer

(part no.10)

Handle Washer

(part no.10)

Keypad

(part no.1)

Inside Handle

(part no.2)

Door

Operating the Unit

The 6000 series model has been designed to work with a variety of multi-point locks and how they work varies

between different manufacturers. In the majority of cases, if the door is double locked via a key, the keypad or

inside handle will not operate until it has been unlocked.

Before entering a code turn the handle to ensure the coding chamber is clear of any buttons that may have been

pressed. Enter the code and turn the handle, the latchbolt and any other secondary bolts will disengage and the

door will open. After the handle is turned the unit will reset and the code will need to be entered again in order to

access. If there is going to be constant trafc through the door you may want to put the unit in free passage mode,

please refer to ‘operating the free passage function’ on page 4.

If tted to a multi-point lock and the door needs to be double locked, enter the code and lift the handle upwards this

will throw any secondary bolts and the key can be turned to double lock.

Fitting & Positioning the Spindle

If the spindle needs to be cut to length, offer the keypad up to the

door and put the spindle into the back of the keypad.

The ideal length of spindle protruding to go into the back of the inside

handle wants to be between 10-15mm.

There is a spring located in the spindle follower of the inside handle

to avoid any movement of the spindle when tted to the door.

If the spindle is cut too short there is a chance the spindle could

slip out of position and result in the user being locked out.

Back of Keypad

Spindle

(part no.9)

Spindle

Follower

The dot on the

keypad spindle

follower to

always be facing

at the top/12

o’clock position

when tting.

When placing the spindle into the spindle follower on the back of the

keypad, it is essential that the dot on the spindle follower is facing at

the top/12 o’clock position.

If the spindle follower is out of position when tted, there will be

no spindle drive even if the correct code is entered.

This manual suits for next models

1

Other Borglocks Door Lock manuals

Borglocks

Borglocks BL2000 Series User manual

Borglocks

Borglocks BL5000 ECP User manual

Borglocks

Borglocks BL7000 ECP Series Administrator guide

Borglocks

Borglocks BL5001 Service manual

Borglocks

Borglocks BL 6000 Administrator guide

Borglocks

Borglocks BL 2000 User manual

Borglocks

Borglocks BL4409 ECP Configuration guide

Borglocks

Borglocks BL3100 ECP Series User manual

Borglocks

Borglocks BL5000 Configuration guide

Borglocks

Borglocks BL6100Mk4 Series User manual