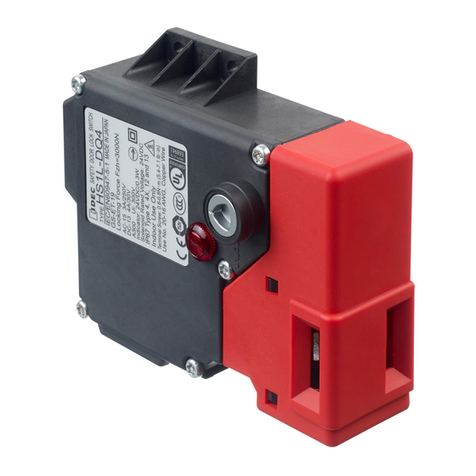

IDEC HS1E Series User manual

HS1E Series Safety Products

B1-30 www.idec.com USA: (800) 262-IDEC or (408) 747-0550, Canada: (888) 317-IDEC

B1

Safety Products

HS1E

Key features include:

• Basic unit and solenoid unit in one housing

• Plastic Housing: Light weight

• Ease of Wiring: All the terminal screws are M3.5.

• Available with a red or green indicator

• Choose from 4 circuit configurations

• When mounting the key on a movable door, and the switch on a machine body, the door can be

mechanically locked when closed.

• Greater Safety: The door is unlocked by a solenoid lock-release signal from a PLC or other source

after the machine has stopped.

• In the event of power failure or for machine maintenance, the door can be unlocked using a special

tool.

• Flexible Installation: The key can be accessed from two directions.

• Also available is a manual unlock key type.

HS1E Series Full Size Interlock Switch with Locking Solenoid

Direct Opening Action

GS-ET-15

BG standard in Germany

EN1088

EN60947-5-1

IEC60947-5-1

Double Insulation

Certificate No.

2005010305145656

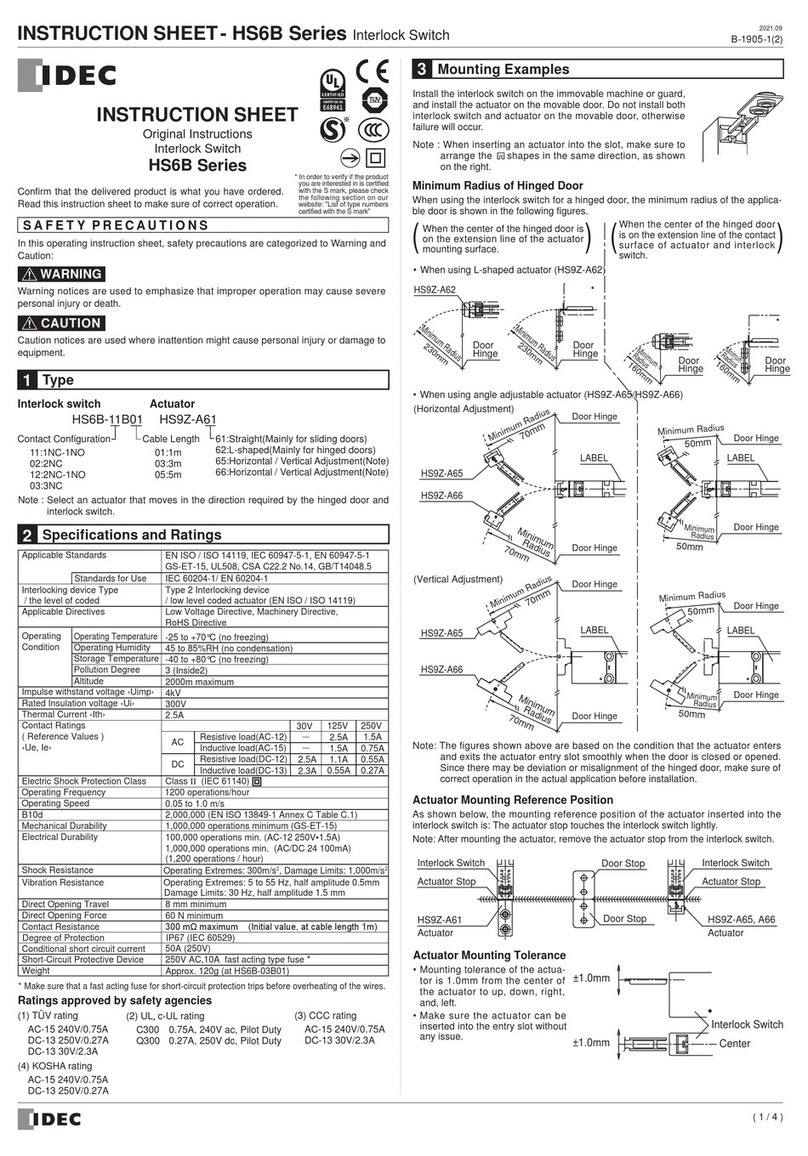

HS1E Series Functionality

Conduit Port: G1/2 Contact Mechanism

(Direct Opening Action)

LED Indicator

Terminal Block (M3.5)

L-shaped Key

(mainly for hinged doors)

Terminal Block for the

Indicator (M3.5)

Straight Key

(mainly for sliding

doors)

Two Key Entry Slots

Key wrench for TORX*

screws (included with

the switch)

TORX* screw

*TORX is a registered trademark of Camcar Textron.

Adjustable Key

(mainly for hinged doors)

Safety Products HS1E Series

www.idec.com USA: (800) 262-IDEC or (408) 747-0550, Canada: (888) 317-IDEC B1-31

B1

Safety Products

Ordering Information

Indicator Rated Voltage:

4 (24V DC)

0 (without indicator)

Circuit Diagram No.

Main Circuit Auxiliary Circuit

Blank: 1NC+1NC 1NO/1NO

1: 1NC+1NC 1NO

2: 1NC+1NC 1NC+1NC

3: 1NC+1NC 1NC

HS1E - 2 4 4 K R - R

Indicator Color:

R (Red)

G (Green)

Manual Unlock Key:

K (with key)

Blank (without key)

Specifications

Conforming to Standards EN1088, IEC60947-5-1, EN60947-5-1(TUV), IISO14119,

GS-ET-19 (BG), UL508, CSA C22.2 No. 14 (c-UL)

Applicable Use IEC60204-1, EN60204-1

Operating Temperature –20 to +40˚C (no freezing)

Storage Temperature –40 to +80˚C

Operating Humidity 40 - 85% (no condensation)

Altitude 2,000m maximum

Rated Insulation Voltage (Ui) 300V (between LED or solenoid and ground: 60V)

Impulse Withstand Voltage (Uimp) 4 kV (between LED or solenoid and ground: 2.5 kV)

Insulation Resistance

(measured with 500V DC megger)

Between live and dead metal parts: 100 MΩminimum

Between live metal part and ground: 100 MΩminimum

Between live metal parts: 100 MΩminimum

Between terminals of the same pole: 100 MΩminimum

Electric Shock Protection Class II (according to IEC61140)

Pollution Degree 3 (IEC60947-5-1)

Degree of Protection IP67 (IEC60529)

Vibration

Resistance

Operating Extremes 10 to 55 Hz, minimum (amplitude 0.35 mm)

Damage Limits 50 m/sec2 (approx. 5G)

Shock Resistance 1,000 m/sec2 (approx. 100G)

Actuator Tensile Strength when Locked 1,500N minimum (per GS-ET-19)

Actuator Operating Speed 1 m/sec maximum

Positive Opening Travel 11 mm minimum

Positive Opening Force 20N minimum

Thermal Current (Ith) Main circuit: 10A, Auxiliary circuit: 3A

Rated Operating Current (Ie)

Rated operating voltage (Ue) 30V 125V 250V

Main

Circuit

AC Resistive load (AC12)

Inductive load (AC15) 10A

10A 10A

5A 6A

3A

DC Resistive load (DC12)

Inductive load (DC13) 6A

3A –

0.9A –

–

Auxiliary

Circuit

AC Resistive load (AC12)

Inductive load (AC15) –

–3A

–3A

3A

DC Resistive load (DC12)

Inductive load (DC13) 3A

––

0.9A –

–

Contact Gap Main circuit: 1.7 mm min., Auxiliary circuit: 1.2 mm min.

Operating Frequency 900 operations/hour max.

Mechanical Life 1,000,000 operations min. (at full rated load)

900 ops/hr (AC-12/250V, 6A)

Electrical Life 100,000 operations (rated load)

Conditional Short-Circuit Current 100A (per IEC60947-5-1)

Recommended Short

Circuit Protection 250V, 10A fuse (Type D01 based on IEC60269-1, 60269-2)

Solenoid Unit

Rated Operating Voltage 24V DC

Rated Current 235 mA

Coil Resistance 102Ω(at 20°C)

Pickup Voltage 20.5V maximum (at 20°C)

DropOut Voltage 2.4 minimum (at 20°C)

Allowable Voltage 26.4V max (continuous)

Insulation Class Class B

Indicator

Rated Operating Voltage 24V DC

Rated Current 10 mA

Light Source LED lamp

Lens Color Red or Green (12 mm dia. Lens)

Weight Approx. 500g

Specifications

HS1E Series Safety Products

B1-32 www.idec.com USA: (800) 262-IDEC or (408) 747-0550, Canada: (888) 317-IDEC

B1

Safety Products

Circuit Diagrams

Circuit Diagram No. Blank Circuit Diagram No. 1 Circuit Diagram No. 2 Circuit Diagram No. 3

Part Numbers

Part Numbers: Keys, Wrench & Screwdriver

Item Part Number Description

HS9Z-A1 Straight Key

(Mainly for sliding

doors)

HS9Z-A2 L-shaped Key

(Mainly for rotating

doors)

HS9Z-A3 Adjustable Key

HS9Z-T1 Key Wrench (included

with switch)

HS9Z-P1 Conduit Opening Plug

Photo Not

Available HS9Z-KEY1 Replacement Manual

Unlocking Key

Part Numbers: Body

Part Number Indicator Key Conduit Port

HS1E-①40R Without Without G1/2

HS1E-①44R-∗With Without G1/2

HS1E-①40KR Without With G1/2

HS1E-①44KR-∗With With G1/2

1. Special key wrench (HS9Z-T1) for removing the cover and manual unlocking

is included with the switch.

2. Specify the circuit diagram No. in place of ①.

3. Specify the indicator color (R or G) in place of *.

4. Order the key separately (not included with the switch).

Circuit Diagram No.

Main Circuit Auxiliary Circuit

Blank: 1NC+1NC 1NO/1NO

1: 1NC+1NC 1NO

2: 1NC+1NC 1NC+1NC

3: 1NC+1NC 1NC

1. “/” indicates paralleled contacts.

2. “+” indicates series contacts.

Circuit Diagrams

Auxillary

Circuit

Main

Circuit

Soleoid

Power

Microswitch is linked to

solenoid mechanically

Auxillary

Circuit

Main

Circuit

Soleoid

Power

Microswitch is linked to

solenoid mechanically

Auxillary

Circuit

Main

Circuit

Soleoid

Power

Microswitch is linked to

solenoid mechanically

Auxillary

Circuit

Main

Circuit

Soleoid

Power

Microswitch is linked to

solenoid mechanically

Safety Products HS1E Series

www.idec.com USA: (800) 262-IDEC or (408) 747-0550, Canada: (888) 317-IDEC B1-33

B1

Safety Products

Circuit Diagram No. Blank (Main Circuit: 1NC-1NC, Auxiliary Circuit: 1NO/1NO)

Circuit Diagram No. 1 (Main Circuit: 1NC-1NC, Auxiliary Circuit: 1NO)

Status 1 Status 2 Status 3 Status 4 Unlocked Manually

Switch/

Door

Status

•Door closed

•Machine ready to operate

•Solenoid de-energized

•Door closed

•

Machine cannot be started

•Solenoid energized

•Door opened

•Machine cannot be started

•Solenoid energized

•Door opened

•

Machine cannot be started

•Solenoid de-energized

•Door closed

•Machine cannot be started

•Solenoid de-energized

Door

Circuit Diagram

Main Cir. 3-4: Closed 3-4: Open 3-4: Open 3-4: Closed 3-4: Open

Aux. Cir. 1-2: Open 1-2: Closed 1-2: Closed 1-2: Closed 1-2: Closed

Solenoid 5-6: Power OFF 5-6: Power ON 5-6: Power ON 5-6: Power OFF 5-6: Power OFF

Status 1 Status 2 Status 3 Status 4 Unlocked Manually

Switch/

Door

Status

•Door closed

•Machine ready to operate

•Solenoid de-energized

•Door closed

•

Machine cannot be started

•Solenoid energized

•Door open

•Machine cannot be started

•Solenoid energized

•Door opened

•

Machine cannot be started

•Solenoid de-energized

•Door closed

•Machine cannot be started

•Solenoid de-energized

Door

Circuit Diagram

Main Cir. 3-4: Closed 3-4: Open 3-4: Open 3-4: Open 3-4: Open

Aux. Cir. 1-2: Open 1-2: Open 1-2: Closed 1-2: Closed 1-2: Open

Solenoid 5-6: Power OFF 5-6: Power ON 5-6: Power ON 5-6: Power OFF 5-6: Power OFF

Application Examples and Circuit Diagrams

Auxillary

Circuit

Main

Circuit

Soleoid

Power

Microswitch is linked to

solenoid mechanically

Auxillary

Circuit

Main

Circuit

Soleoid

Power

Microswitch is linked to

solenoid mechanically

Auxillary

Circuit

Main

Circuit

Soleoid

Power

Microswitch is linked to

solenoid mechanically

Auxillary

Circuit

Main

Circuit

Soleoid

Power

Microswitch is linked to

solenoid mechanically

Auxillary

Circuit

Main

Circuit

Soleoid

Power

Microswitch is linked to

solenoid mechanically

Auxillary

Circuit

Main

Circuit

Soleoid

Power

Microswitch is linked to

solenoid mechanically

Auxillary

Circuit

Main

Circuit

Soleoid

Power

Microswitch is linked to

solenoid mechanically

Auxillary

Circuit

Main

Circuit

Soleoid

Power

Microswitch is linked to

solenoid mechanically

Auxillary

Circuit

Main

Circuit

Soleoid

Power

Microswitch is linked to

solenoid mechanically

Auxillary

Circuit

Main

Circuit

Soleoid

Power

Microswitch is linked to

solenoid mechanically

1. Main Circuit: used to enable the machine to start only when the

main circuit is closed.

2. Auxiliary Circuit: used to indicate whether the machine circuit or

door is open or closed.

3. Terminals 7 and 8 are used for the LED indicator, and are isolated

from solenoid and door status.

HS1E Series Safety Products

B1-34 www.idec.com USA: (800) 262-IDEC or (408) 747-0550, Canada: (888) 317-IDEC

B1

Safety Products

Circuit Diagram No. 2 (Main Circuit: 1NC+1NC, Auxiliary Circuit: 1NC+NC)

Circuit Diagram No. 3 (Main Circuit: 1NC+1NC, Auxiliary Circuit: 1NC)

Status 1 Status 2 Status 3 Status 4 Unlocked Manually

Switch/

Door

Status

•Door closed

•Machine ready to operate

•Solenoid de-energized

•Door close

•

Machine cannot be started

•Solenoid energized

•Door open

•Machine

cannot be started

•Solenoid energized

•Door opened

•

Machine cannot be started

•Solenoid de-energized

•Door closed

•Machine cannot be started

•Solenoid de-energized

Door

Circuit Diagram

Main Cir. 3-4: Closed 3-4: Open 3-4: Open 3-4: Open 3-4: Open

Aux. Cir. 1-2: Closed 1-2: Open 1-2: Open 1-2: Open 1-2: Open

Solenoid 5-6: Power OFF 5-6: Power ON 5-6: Power ON 5-6: Power OFF 5-6: Power OFF

Status 1 Status 2 Status 3 Status 4 Unlocked Manually

Switch/

Door

Status

•Door closed

•Machine ready to operate

•Solenoid de-energized

•Door closed

•

Machine cannot be started

•Solenoid energized

•Door opened

•Machine

cannot be started

•Solenoid energized

•Door opened

•

Machine cannot be started

•Solenoid de-energized

•Door closed

•Machine cannot be started

•Solenoid de-energized

Door

Circuit Diagram

Main Cir. 3-4: Closed 3-4: Open 3-4: Open 3-4: Open 3-4: Open

Aux. Cir. 1-2: Closed 1-2: Closed 1-2: Open 1-2: Open 1-2: Closed

Solenoid 5-6: Power OFF 5-6: Power ON 5-6: Power ON 5-6: Power OFF 5-6: Power OFF

Application Examples and Circuit Diagrams con’t

Auxillary

Circuit

Main

Circuit

Soleoid

Power

Microswitch is linked to

solenoid mechanically

Auxillary

Circuit

Main

Circuit

Soleoid

Power

Microswitch is linked to

solenoid mechanically

Auxillary

Circuit

Main

Circuit

Soleoid

Power

Microswitch is linked to

solenoid mechanically

Auxillary

Circuit

Main

Circuit

Soleoid

Power

Microswitch is linked to

solenoid mechanically

Auxillary

Circuit

Main

Circuit

Soleoid

Power

Microswitch is linked to

solenoid mechanically

Auxillary

Circuit

Main

Circuit

Soleoid

Power

Microswitch is linked to

solenoid mechanically

Auxillary

Circuit

Main

Circuit

Soleoid

Power

Microswitch is linked to

solenoid mechanically

Auxillary

Circuit

Main

Circuit

Soleoid

Power

Microswitch is linked to

solenoid mechanically

Auxillary

Circuit

Main

Circuit

Soleoid

Power

Microswitch is linked to

solenoid mechanically

Auxillary

Circuit

Main

Circuit

Soleoid

Power

Microswitch is linked to

solenoid mechanically

1. Main Circuit: used to enable the machine to start only when the

main circuit is closed.

2. Auxiliary Circuit: used to indicate whether the machine circuit or

door is open or closed.

3. Terminals 7 and 8 are used for the LED indicator, and are isolated

from solenoid or door status.

Safety Products HS1E Series

www.idec.com USA: (800) 262-IDEC or (408) 747-0550, Canada: (888) 317-IDEC B1-35

B1

Safety Products

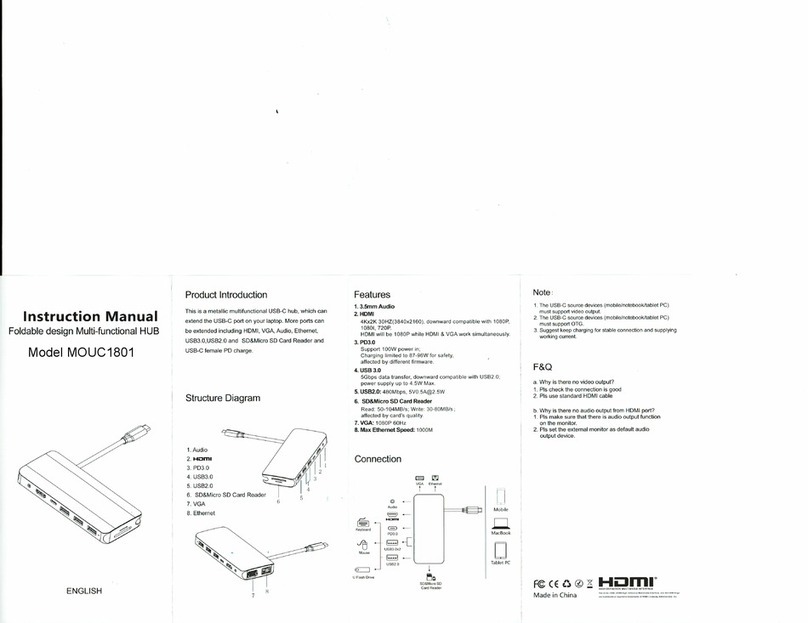

HS1E with indicator - using the straight key (HS9Z-A1)

HS1E with indicator - using the L-shaped key (HS9Z-A2)

Dimensions

23.523.5

RP

Actuator

Actuator Cover

Actuator

23.5

Mounting Hole Layout

3-M5 Screws

RP

210

49.5

129

121 26

ø5.4

R2.7

ø5.2

21

210

49.5

129

121

88 4

104

89

26

30 9

43

40

22

68.8

13.8

ø5.4

R2.7

ø5.2

30

9

43

40

22

13.8

54.3

35

39.7

6.5 ±1.0

35

39.7

8.5 ±1.0

26

89

45.4

33

45.4

21

89

33

88

104 4

RP: Actuator Mounting

Reference Position

Actuator Cover

23.523.5

23.5

Actuator

Actuator Cover

RP

Actuator Cover

Actuator

RP

Mounting Hole Layout

3-M5 Screws

210

49.5

129

121 26

ø5.4

R2.7

ø5.2

210

49.5

129

121 26

ø5.4

R2.7

ø5.2

35

39.7

35

39.7

26

89

22

40

43

30

6

61

11

17.5 ±1.0

40

43

30

6

46.5

22

11

19.5 ±1.0

45.4

21

89

33

88

104 4

45.4

21

89

33

88

104 4

RP: Actuator Mounting

Reference Position

All dimensions in mm.

HS1E Series Safety Products

B1-36 www.idec.com USA: (800) 262-IDEC or (408) 747-0550, Canada: (888) 317-IDEC

B1

Safety Products

Straight Key (mainly for sliding doors)

HS9Z-A1

L-Shaped Key (mainly for hinged doors)

HS9Z-A2

Adjustable Key

• The key angle is adjustable (0˚ to 20˚) for hinged doors.

• The minimum radius of the door opening can be as small as 100mm.

For HS1/HS2 Series (HS9Z-A3)

Accessories

2

7.4

Actuator Cover*

22 6.4

4-R3.2

30

49.3

22

2-M6

Tapped

Holes

Actuator

Mounting

Holes

weight: 22g

Key Cover*

Key

Mounting

Holes

2

4-R3.2

22

7.4

11

41.5

30

Actuator Cover*

*After installing the key, remove the key cover.

weight: 22g

Key Cover*

Stop Film

Angle Adjustment

(M3 Hexagon Socket Head Screw)

Door Hinge Side

20

5

30

R3.2

72

58

44

33 max.

12 (21)

1

20°

All dimensions in mm.

Safety Products HS1E Series

www.idec.com USA: (800) 262-IDEC or (408) 747-0550, Canada: (888) 317-IDEC B1-37

B1

Safety Products

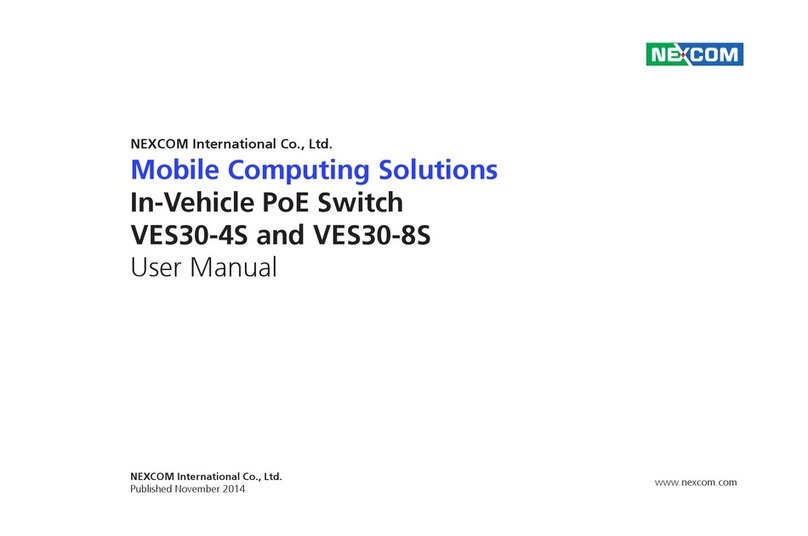

Comparison between Adjustable and Non-adjustable Keys

Key Angle Adjustment

•

Using the screw (M3 hex socket head screw), the actuator angle can

be adjusted (refer to the dimensional drawing). Adjustable angle:

(0˚) to 20˚

•

The larger the adjusted angle of the actuator, the smaller the appli-

cable radius of the door opening.

• After installing the actuator, open the door. Then adjust the actuator

so that its edge can be inserted properly into the entry slot of the

safety switch.

• Recommended tightening torque: 0.8 N-m (approx. 8.0 kgf-cm)

• After adjusting the actuator angle, apply loctite or the like to the

adjustment screw so as to prevent its loosening.

Accessories con’t

Door Hinge

MinimumRadius

500mm

MinimumRadius

600mm

HS9Z-A52

Actuator

Minimum Radius

400mm

Door Hinge

800mm

Minimum Radius

HS9Z-A2

Actuator

Non-adjustable Key HS9Z-A2

Non-adjustable Key HS9Z-A1

HS9Z-A53

Actuator

MinimumRadius

100mm

Adjustable Key HS9Z-A3

HS9Z-A3

Key HS9Z-A2

Key

HS9Z-A1

Key

Safety Products Precautions

www.idec.com USA: (800) 262-IDEC or (408) 747-0550, Canada: (888) 317-IDEC B1-43

B1

Safety Products

• In order to avoid electric shock or a fire, turn the power off before

installation, removal, wire connection, maintenance, or inspection

of the switch.

• If relays are used in the circuit between the safety switch and the

load, consider degrees of the danger and use safety relays, since

welded or sticking contacts of standard relays may invalidate the

functions of the safety switch.

• Do not place a PLC in the circuit between the safety switch and the

load. The safety security can be endangered in the event of a mal-

function of the PLC.

• Do not disassemble or modify the switch. It may cause a breakdown

or an accident.

• Regardless of door types, do not use the safety switch as a door

stop. Install a mechanical door stop at the end of the door to protect

the safety switch against excessive force.

• Do not apply an excessive shock to the switch when opening or

closing the door.

• A shock to the door exceeding 1,000 m/sec2(approx. 100G) may

cause the contacts of the switch to chatter, and a malfunction of the

switch may occur.

• For connection of wires, unscrew the cover. Unnecessary loosening

of other screws may cause a malfunction of the switch.

• Prevent foreign objects such as dust and liquids from entering the

switch while connecting a conduit or wiring.

• If the operating atmosphere is contaminated, use a protective cover

to prevent the entry of foreign objects into the switch through the

actuator entry slots.

• Entry of a considerable amount of foreign objects into the switch

may affect the mechanism of the switch and cause a breakdown.

• Do not store the switches in a dusty, humid, or organic-gas atmo-

sphere.

For Rotating Head Directions

• The head of the HS5B can be rotated in 90° increments after remov-

ing the 4 screws on the corners of the head. Prevent entry of foreign

objects into the switch during removal of the head. Tighten these

screws with torque designated in the instruction sheet. Improper

torque may cause errors.

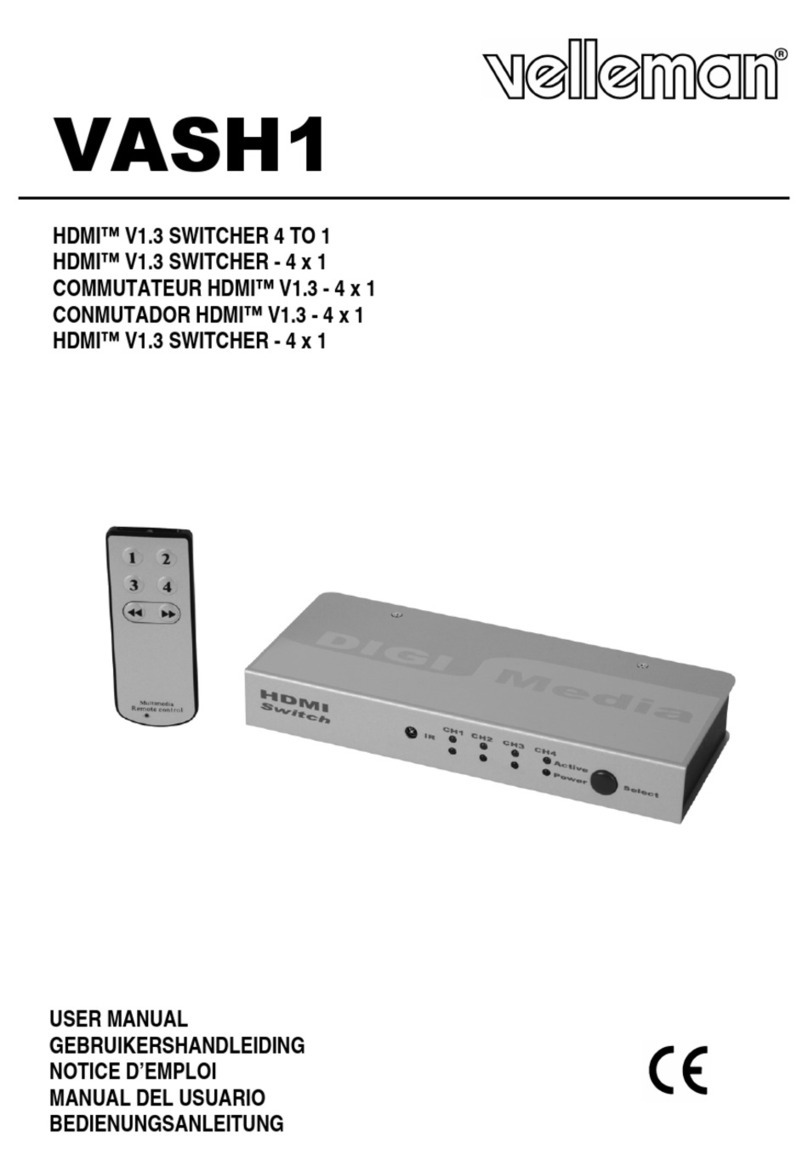

Minimum Radius of Hinged Doors

Wire Connection

• The HS2B has 3 conduit ports, which are closed as a part of the

molded switch housing.

• Make an opening for wire connection by breaking one of the con-

duit-port knockouts on the switch housing using a screwdriver.

• When breaking the conduit port, take care not to damage the con-

tact block or other parts inside the switch.

• Cracks or burrs on the conduit entry may deteriorate the housing

protection against water.

• When changing to another conduit port, close the unused opening

with an optional plug (Type No. HS9Z-P1).

Interlock Switch Safety Precautions

Operation Precautions - for all series

HS5B Precautions

Initial

Position Mounting in 3 Different Positions

Door Hinge

MinimumRadius

500mm

Minimum Radius

600mm

HS9Z-A52

Actuator

HS2B Precautions

Precautions Safety Products

B1-44 www.idec.com USA: (800) 262-IDEC or (408) 747-0550, Canada: (888) 317-IDEC

B1

Safety Products

Wire Connection

• Make an opening for wire connection by breaking one of the con-

duit-port knockouts on the switch housing using a screwdriver.

• Before breaking the knockout, temporarily remove the connector-fix-

ing lock nut from the switch.

• When breaking the knockout, take care not to damage the contact

block or other parts inside the switch.

• Cracks or burrs on the conduit entry may deteriorate the housing

protection.

• When changing to the other conduit port, close the unused opening

with an optional plug (accessory).

Manual Unlocking

• Remove the screw located on the unlocking entry at the side of the

switch using the key wrench included with the switch. Then insert a

small screwdriver into the switch to push the lever inside of the

switch toward the indicator until the actuator is unlocked (refer to

the diagram on the right).

• Insert a small screwdriver into the elliptical hole on the back of the

switch, then push the lever inside of the switch toward the indicator

until the key is unlocked (refer to the diagram on the right).

1. This unlocking method is intended for an escape from a

machine when a person is locked in. For access to the

unlocking entry, an access hole should be opened on the

mounting panel. When opening the hole, apply proper pro-

tection against water or other foreign objects.

2. Caution: After the unlocking operation, put the screw

back into the unlocking entry for safety.

• Regardless of door type, do not use the safety switch as a locking

device. Install a locking device independently, for example, using a

metal latch (also applicable to Type HS1E).

• The safety switch cover can be only removed with the special key

wrench supplied with the switch or with the optional screwdriver

(applicable to HS1B and HS1E).

• Remove the screw located on the unlocking entry at the side of the

switch using the key wrench included with the switch. Then insert a

small screwdriver into the switch to push the lever inside of the

switch toward the indicator until the actuator is unlocked (refer to

the diagram on the right).

Caution: After the unlocking operation, put the screw back

into the unlocking entry for safety.

HS1E Precautions

Type No.: HS9Z-P1

Plug (For G1/2)

Plug (For G1/2)

Type No. HS9Z-P1

Screwdriver

Lid

UNLOCK UNLOCK

Normal

Position Manual

Unlocking

Position

HS1C Precautions

Screwdriver

Safety Products Precautions

www.idec.com USA: (800) 262-IDEC or (408) 747-0550, Canada: (888) 317-IDEC B1-45

B1

Safety Products

Applicable Crimping Terminals

• (Refer to the Crimping Terminal 1 or 2 shown in the drawing below.)

• HS1C

Terminals No. 1 to 6: Use solid or stranded wires only (crimping ter-

minals not applicable).

Terminals No. 7 and 8: Crimping Terminal 1

Ground Terminal: Crimping Terminal 2

• HS1B

Ground Terminal: Crimping Terminal 2

Other Terminals: Crimping Terminal 1

HS2B, HS5B, and HS1E

Crimping Terminal 1

Use an insulation tube on the crimping terminal.

Installation Examples (see the diagrams below)

Applicable Connectors (As shown below)

• Use connectors which maintain the IP67 protection.

• Applicable Connector Dimensions

• Flex Conduit: VF03 (Japan Flex) www.nipolex.co.jp

• Steel Connector (G1/2): ALC-103

(PF13.5): RBC-103PG13.5

Recommended Screw Tightening Torque

• HS1C: 5.0±0.5 N-m (approx. 50±5 kgf-cm)

(4 or 6 pcs of M5 hex socket head cap screws)

• HS1B: 5.0±0.5 N-m (approx. 50±5 kgf-cm)

(2 or 4 pcs. of M5 hex socket head cap screws)

• HS2B: 5.0±0.5 N-m (approx. 50±5 kgf-cm)

(2 pcs of M5 hex socket head cap screws)

• HS5B: 4.0±0.4 N-m (approx. 40±4 kgf-cm)

(2 pcs of M4 hex socket head cap screws)

• HS1E: 5.0±0.5 N-m (approx. 50±5 kgf-cm)

(4 or 6 pcs of M5 hex socket head cap screws)

• Key (HS9Z-A1/A2)

5.0±0.5 N-m (approx. 50±5 kgf·cm)

• (2 pcs. of M6 hex socket head cap screws)

Key (HS9Z-A51/A52)

• 2.0±0.2 N-m (approx. 20±2 kgf·cm)

(2 pcs of M4 hex socket head cap screws)

• 1.0±0.2 N-m (approx. 10±2 kgf·cm)

(2 pcs of M4 Phillips screws)

The screws are supplied by the user.

Applicable Wire Size

• HS1C: 0.5 to 0.75 mm2 (Terminals No.1, 2, 5 to 8)

1.0 to 1.25 mm2 (Terminals No.3, 4, and

grounding terminal)

• HS5B: 0.5 to 1.25 mm2

• HS1E: 0.5 to 1.25 mm2

Operation Precautions

7.6 max.

3.5 min. 3.8 max.

ø4.1 min.

L1 (mm)

Crimping Terminal 2

Crimping Terminal 1

6.9 max.

3.6 min. 3.5 max.

ø3.6 min.

L1 (mm)

Approx. 4mm Crimping Terminal

Wire

Insulation Tube

Door Stop

HS9Z-A1 Actuator

Door

Mounting on Sliding Doors

Latch

HS9Z-A1 Actuator

HS9Z-A2 Actuator

Mounting on Hinged Doors

G1/2 or PG13.5

9 mm max.

30 mm max.

This manual suits for next models

4

Table of contents

Other IDEC Switch manuals

IDEC

IDEC HS1C Series User manual

IDEC

IDEC HS5L Series User manual

IDEC

IDEC HS5E Series User manual

IDEC

IDEC HS3A Series User guide

IDEC

IDEC SA1E Series User manual

IDEC

IDEC HS5E Series User manual

IDEC

IDEC HS5L Series User manual

IDEC

IDEC HS1C Series User manual

IDEC

IDEC HS5E Series User manual

IDEC

IDEC SA1E Series User manual

IDEC

IDEC HS1L Series User manual

IDEC

IDEC SX5E Series User manual

IDEC

IDEC SA1U Series User manual

IDEC

IDEC HS5D-11 User manual

IDEC

IDEC SA1E Series User manual

IDEC

IDEC HE1B Series User manual

IDEC

IDEC HS5E-K User manual

IDEC

IDEC HS1T Series User manual

IDEC

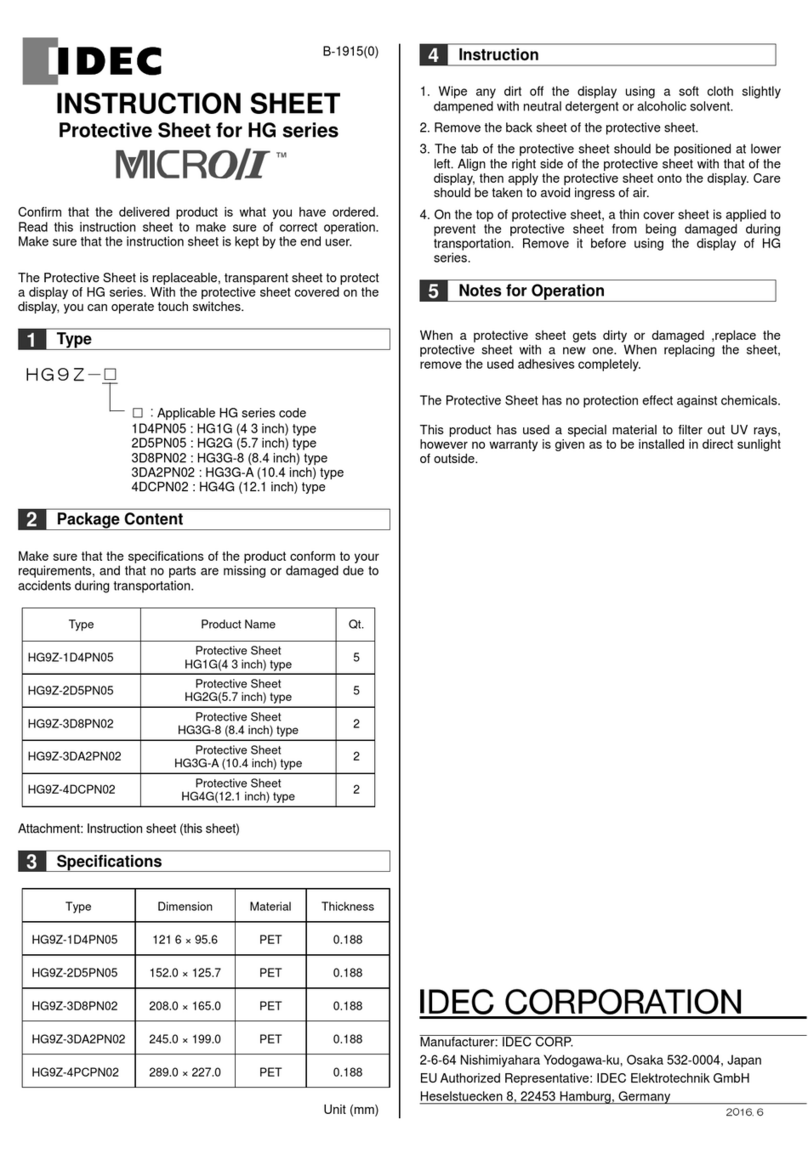

IDEC MICRO/I HG9Z-1D4PN05 User manual

IDEC

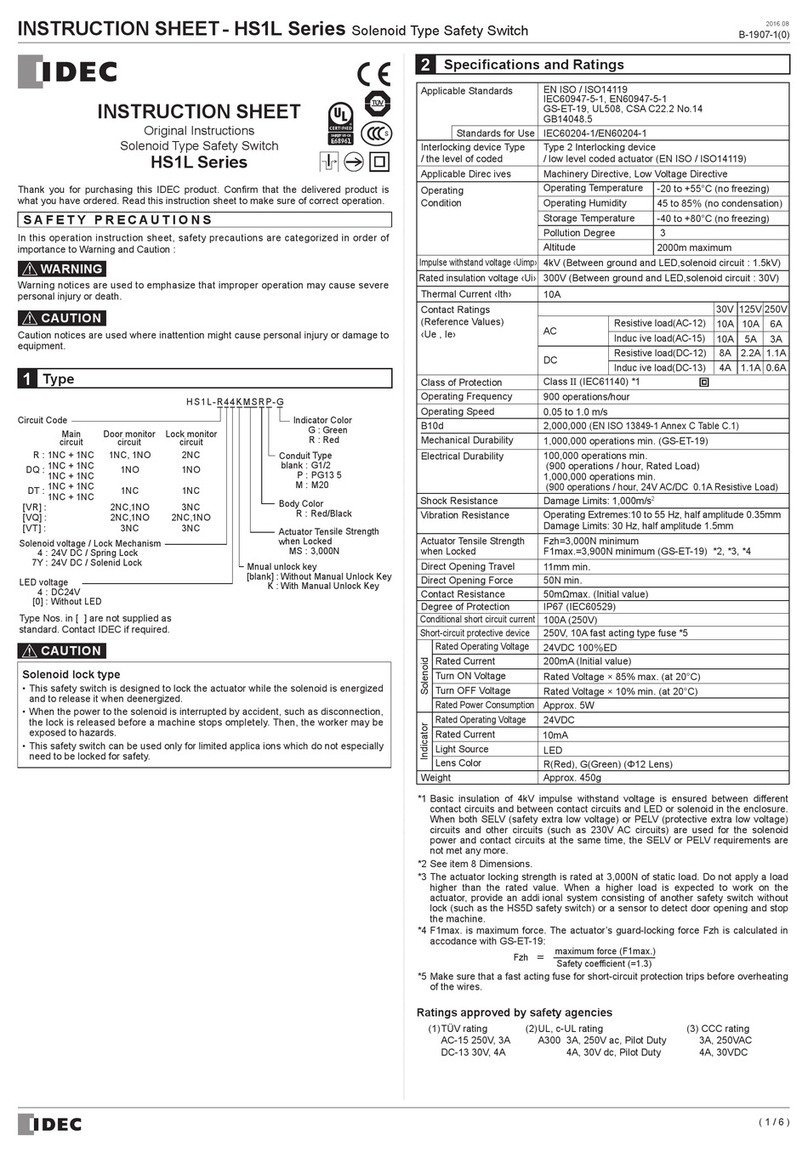

IDEC HS1L Series User manual