B-1906-1(0)

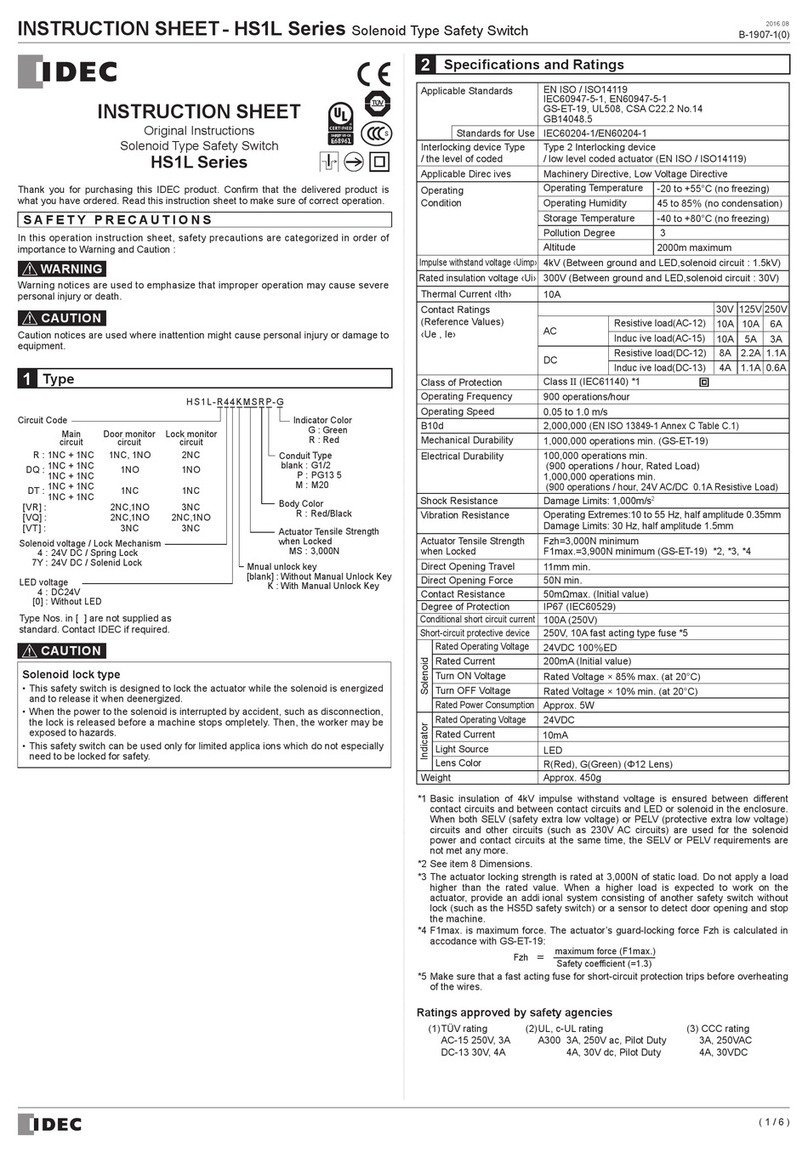

INSTRUCTION SHEET - HS6E Series Solenoid Type Safety Switch

( 2 / 6 )

2016.08

4Precautions for Operation

For Mounting

• Do not apply an excessive shock to the safety switch when opening or closing the

door.A shock to the safety switch exceeding 1,000m/s2may cause failure.

• Provide a door guide, and ensure that force is applied on the safety switch only in

the actuator insertion direction.

• Do not pull the actuator while it is locked. Also, regardless of door types, do not use

the safety switch as a door lock. Install a separate lock as shown in section 3.

• Entry of foreign objects in the actuator entry slot may affect the mechanism of the

switch and cause a breakdown. If the operating atmosphere is contaminated, use a

protective cover to prevent the entry of foreign objects into the switch through the

actuator entry slots.

• Make sure to install the product in a safe place out of reach. Make sure to conduct a

proper risk assessment evaluation before using the product, and use a shield or a

cover to protect the product if need be.

• While the solenoid is energized, the switch temperature rises approx-

imately 35°C above the ambient temperature (to approximately 85°C

while the ambient temperature is 50°C). Keep hands off to prevent

burns. If cables come into contact with the switch, use heat-resistant

cables.

The Adjustable (vertical/horizontal) Actuator

• Using the angle adjustment screw (M3 hexagon socket set screw), the actuator

angle can be adjusted up to 20°(refer to dimensions).

• The larger the actuator angle, the smaller the applicable radius of the door swing.

After installing the actuator, open the door. Then adjust the actuator angle so that he

actuator enters the entry slot of the safety switch properly.

• After adjusting the actuator angle, apply loctite or the like on the adjustment screw to

prevent loosening. Use screw locking agent that is compatible with the base

material.

Base : PA66 (66 nylon) of glass reinforced grade

Angle adjustment screws : stainless steel

Installing the Safety Switch and Actuator

• When installing the actuator, position the

actuator using the actuator stop (for

positioning the entry slot center and

mounting reference position).

• As shown on the right, the mounting

reference position of the actuator when

inserted in the safety switch is where the

actuator stop touches the actuator.

• Install a door stop as shown on the right

to protect the safety switch and actuator

against excessive force. Do not use the

safety switch as a door stop, otherewise

the safety switch will be damaged.

0.8mm

Safety Switch Latch

Actuator Stop

HS9Z-A61

Actuator Door Stop

Mounting

Reference

Door Stop

• After removing the actuator stop, ensure that the actuator is installed within the

tolerances shown below.

From he entry slot center of the safety switch (*5, 6) : ±1.0mm

The gap between the actuator shoulder and the safety switch surface (*7)

HS9Z-A61/-A62/-A65/-A66 : 1.9mm or shorter

HS9Z-A62S : 1.3mm or shorter

• To ensure correct operation, it is recommended to fasten the door using a latch to

achieve the above tolerance values.

• Make sure the actuator can be inserted into the entry slot without any issue.

• Perform operation test before starting operation in order to confirm the open/close

operation of contacts and locking/unlocking operation.

• When the actuator is pulled while locked in the safety switch, the actuator moves

within the range shown below.

HS9Z-A61/-A62/-A65/-A66 : 4.1mm maximum from the safety switch surface

HS9Z-A62S : 3.5mm maximum from the safety switch surface

The open/close status of the contacts are maintained within the range.When a gap is

caused because of actuator relocation, make sure that the gap does not lead to new

risks.

±1.0mm

(*6)

±1.0mm

(*5)

Entry

Direction

1.9mm(*7)

When using

HS9Z-A61

Safety Switch

Surface

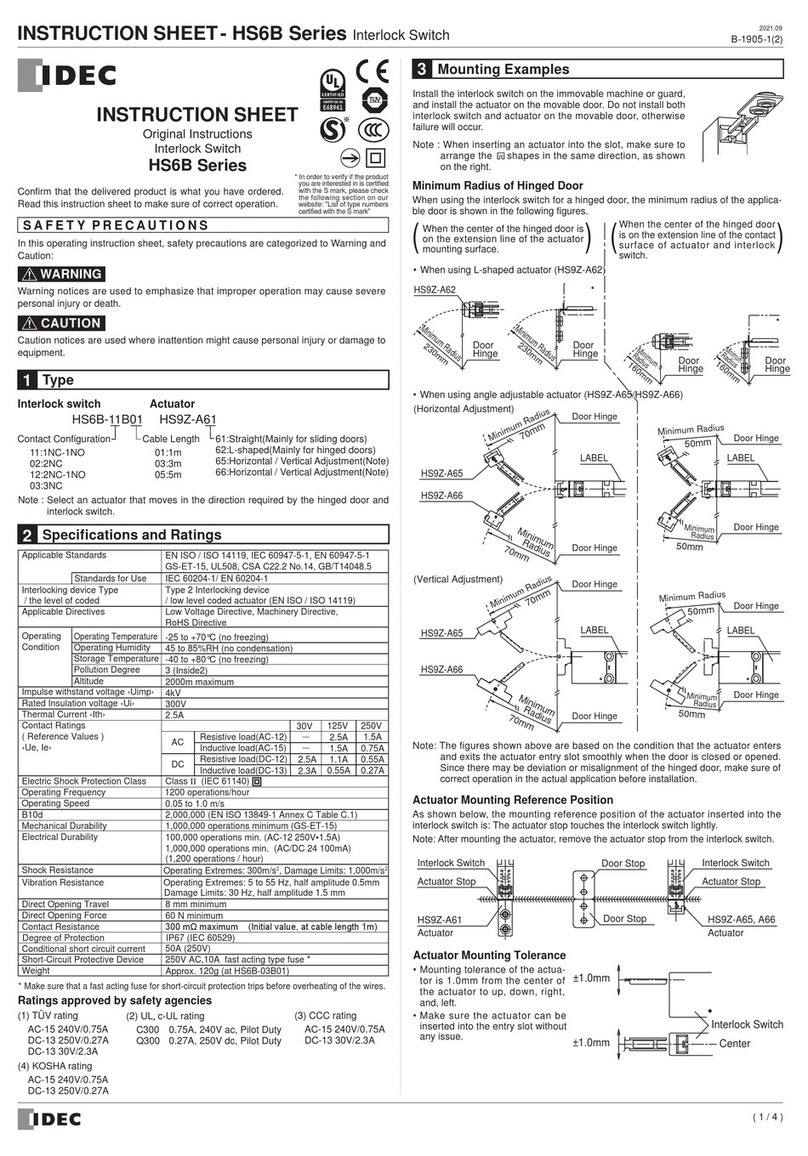

Minimum Radius of Hinged Door

• When using the safety switch for a hinged door, the minimum radius of the applica-

ble door is shown in the following figures.

When the center of the hinged

door ison the extension line of the

actuatormounting surfase.

When the center of the hinged

door ison he extension line of

the contact surfaceof actuator

and safety switch.

HS9Z-A62/-A62S

R1

230mm

70mm

(Horizontal Swing)

R2

230mm

70mm

(Vertical Swing)

R3

160mm

50mm

(Horizontal Swing)

R4

160mm

50mm

(Vertical Swing)

Minimum Radius

HS9Z-A65/-A66

The values shown above are based on the condition that the

actuator enters and exits the actuator entry slot smoothly

when the door is closed or opened.

Since there may be devia ion or dislocation of the hinged

door, make sure of correct operation in the actual applica-

tion before installation.

When inserting an actuator into the slot, make sure to

arrange the shapes in the same direction, as shown on

the right.

R3

Minimum

Radius

Door

Hinge

Door

Hinge

Door

Hinge

Door

Hinge

R4

Minimum

Radius

Minimum

Radius

R1

Minimum

Radius

R2

Recommended Screw Tightening Torque

Name or Use

For mounting the safety switch ( M4 screw ) *8

For mounting the actuator ( M4 screw ) *8

Screw Tightening Torque

1.0 to 1 5 N•m

1.0 to 1 5 N•m

HS9Z-A61, HS9Z-A62, HS9Z-A62S ACTUATOR

• When there is a displacement of safety switch and actuator, the actuator may hit the

entry lot of safety switch hardly, thus damaging the entry slot and actuator. The

rubber cushions on the HS9Z actuator prevent the actuator from damaging the entry

slit by absorbing the shock with movement flexibility. Do not, however, exert exces-

sive shocks, otherwise the failure of safety switch may be caused.

• The rubber cushions may deteriorate depending on the operatiing environment and

conditions. Immediately replace the deformed or crasked rubber cushions with new

ones.

*8 When he torque is not enough to recommended screw tightening torque, make

sure that he screw do not become loose by using adhesive sealants etc. to

keep right operation and mounting positioning.

Mounting HS9Z-A62S actuator

Using two M4 screws and plate, fasten the

actuator securely on the door.

Plate has directionality. Do not lose the

plate. The actuator may fall off from the

door if there is no plate, and the actuator

does not properly.

The tensile strength of the HS9Z-A62

actuator is 100N. If an excessive tensile

force is applied, the actuator may fall off

the door. When a tensile force exceeding 100N is expected, use the HS9S-A62S

actuator with a plate.

Rubber Cushion

Plate(supplied)

M4 Screw

Door

M4 Mountion holes

3Mounting Examples

(Examples of Mounting on Sliding Doors) (Examples of Mounting on Hinged Doors)

Door

Door Stop

HS9Z-A62S

Actuator

HS9Z-A61

Actuator

Latch

HS6E

Safety Switch

• Install the interlock switch on the immovable machine or guard, and install the

actuator on the movable door. Do not install both interlock switch and actuator on

themovable door, otherwise the angle of insertion of the actuator to the safety switch

may become inappropriate, and failure will occur.