Enabling Switches

General Information

Safety Precautions

General Information

•

In order to avoid electric shock or fire, turn power off before installation,

removal, wire connection, maintenance or inspection of switch.

•

Follow specification when installing. Improper electrical load may damage

switch, cause electric shock, or fire.

•

Use proper wire diameter to meet voltage and current requirements. Using

improper wires or incomplete soldering may cause fire due to abnormal heat

generation.

InstallationPrecautions

HE2B

•

M3 nut is inside the rubber cover.

•

If the panel is not level when mounting an enabling switch, the waterproof

featurecannot beguaranteed.

HE3B

•

The rubber boot has a tab to be used for orientation. When making a position-

ing hole in a panel, do not make a hole in the rubber boot, or the waterproof

feature cannot be guaranteed. When the positioning hole is not on the panel,

remove the tab, but do not make a hole in the rubber boot.

•

When tightening the locking ring, secure the flange to prevent the enabling

switch from rotating. In applications where the enabling switch is to be

rotated, mount the switch in a recess on the panel as shown.

HE2B/HE3B

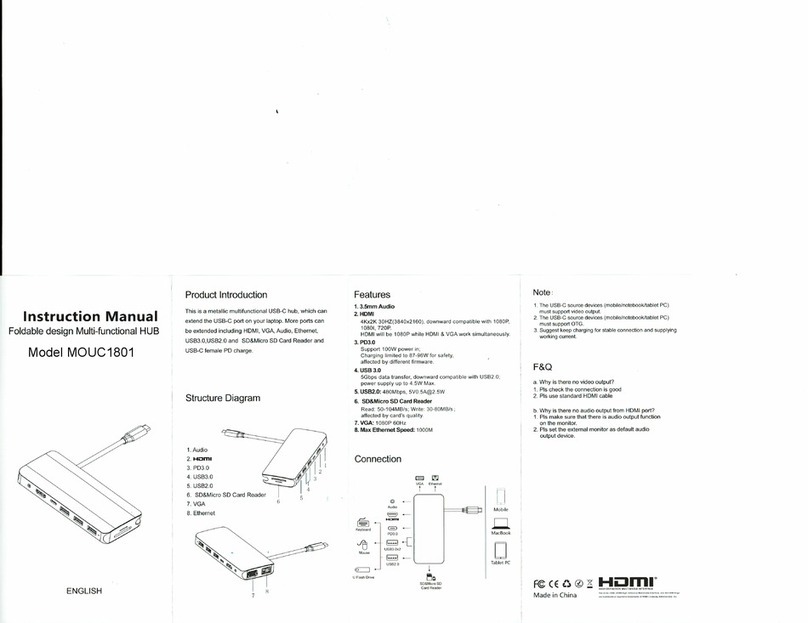

Mounting Panel Positioning

Projection

•

A change in internal air pressure may cause the rubber boot to expand and

shrink on an enabling switch that has the rubber boot sealed. This may affect

the performance of the switch. Periodically check to ensure that the enabling

switch is operating correctly.

Anti-rotation Ring

Locking Ring

Wiring Precautions

HE1B/HE2B/HE3B

•

Applicable wire size is 0.5mm

2

(20AWG) (maximum) / 1 line.

•

When soldering the terminal, solder at a temperature of 260°C within 3

seconds. Use non-corrosive liquid rosin as soldering flux.

HE1G

•

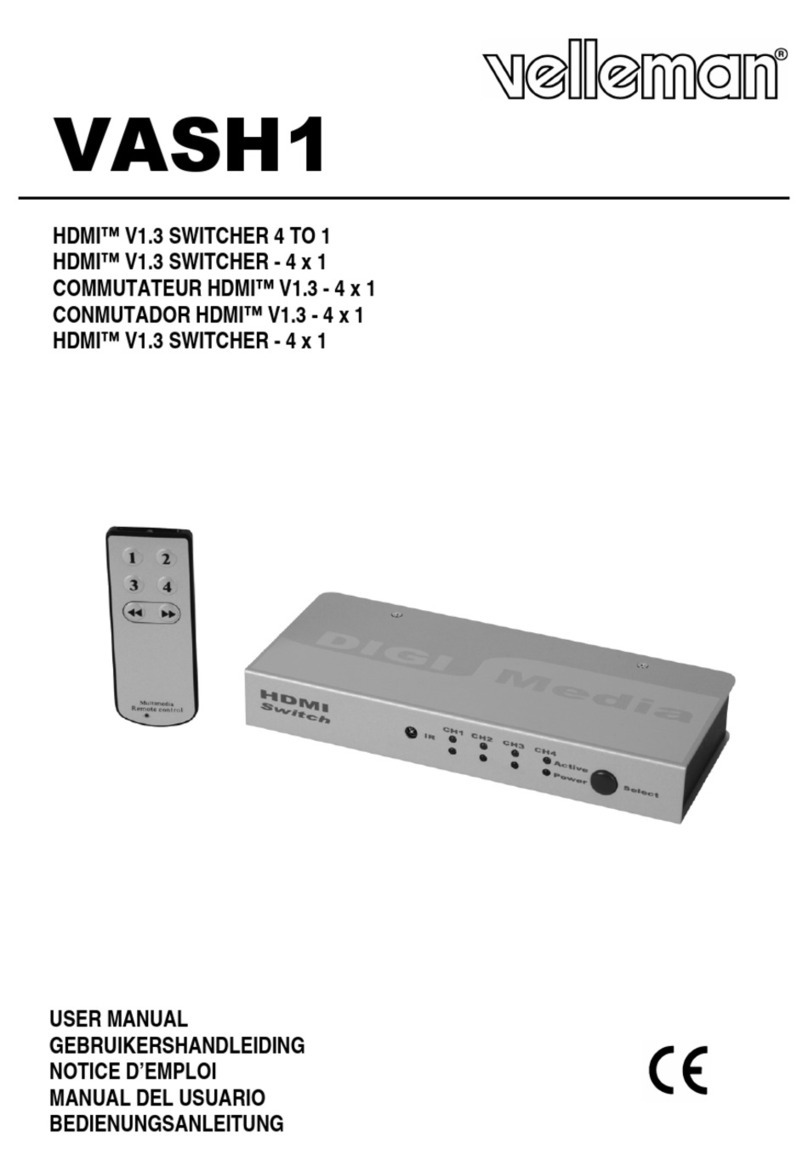

WireStrippingInformation

•

Recommended Torque

cover

base

base

cover

base

(M4 screw x 3)

Rubber Boot & Base

A1.2±0.1Nm

Connector & Grip Switch

B4.0±0.3Nm

Connector

C4.0±0.3Nm

Terminal Screw

D0.5±0.6Nm

Do Not Remove

E

•

Applicable Wire Size:0.14 to 1.5mm

2

(24 - 16AWG, one wire per terminal)

Use Precautions

HE2B/HE3B/HE1G

•

To ensure the highest level of reliability connect both contacts to a monitoring

devicesuch as a safety relay.

HE1B/HE2B/HE3B

•

When installing the enabling switch ensure that it cannot be accidently

activated. For example, a protrusion from a teaching pendant could cause the

enabling switch to be activated by the weight of the teaching pendant.

See Drawing Above

Recommended Torque

AS-Interface

Safety

at

W

ork

WireLength

Terminal Number 1-4 Terminal Number 5-8

L1, L2 (mm)

L1=40mm

L2=27mm

L3 (mm)

L3=6mm

Phone:

800.894.0412

-

Fax:

888.723.4773

-

Web:

www.clrwtr.com

-

Email:

[email protected]