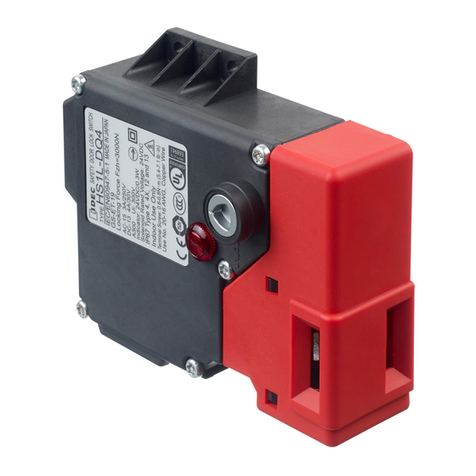

IDEC HS1T Series User manual

B-2048-1(1)

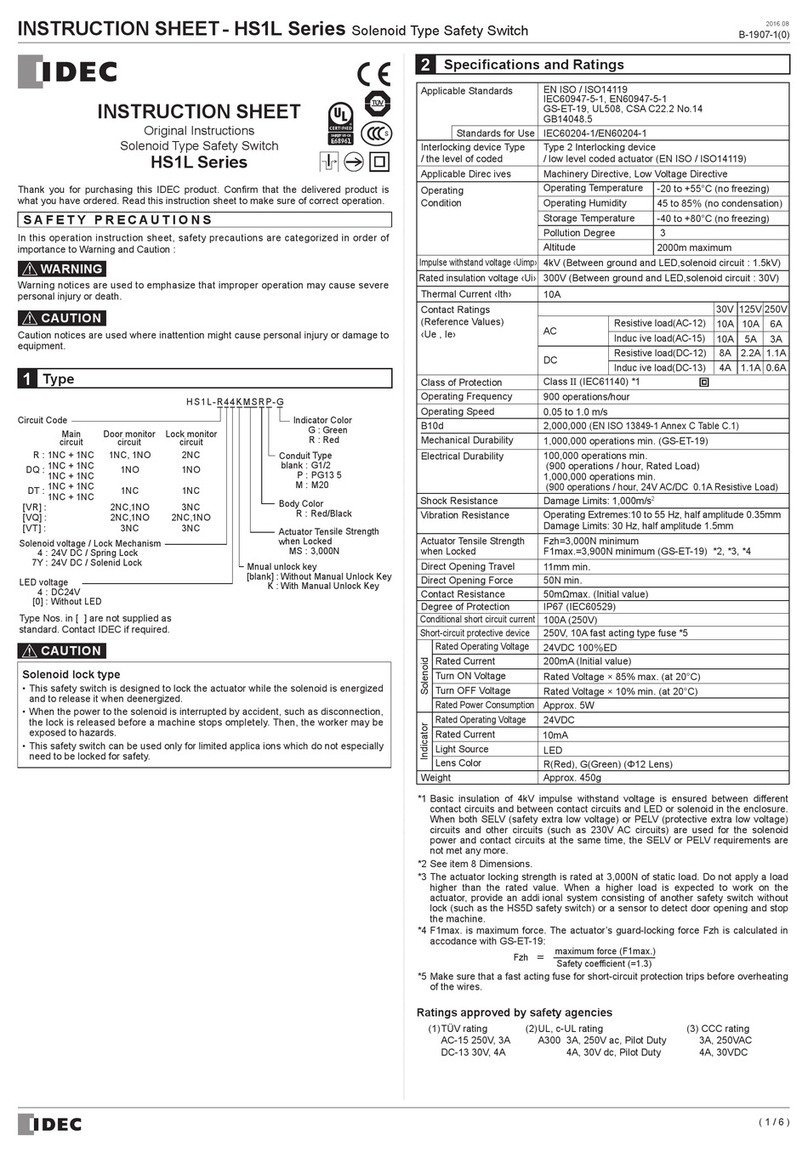

INSTRUCTION SHEET - HS1T Series Solenoid Type Safety Switch

( 1 / 9 )

2019.07

2Specifications and Ratings

*2 Ratings approved by safety agencies

(1)TÜV/CCC rating AC-15 250V/0.75A

DC-13 30V/1.0A

(2)UL , c-UL rating 0.75A, 250V ac, Pilot Duty

1A, 30V dc, Pilot Duty

The M20 threaded opening must be filled by a Listed or

Recognized Component Liquid-Tight Flexible Cord Fitting

in order to maintain the Tye 4X Indoor use only rating.

*3 Basic insulation of 2.5kV impuise withstand circuits and between contact circuit

SELV(safety extra low voltage) or circuits (such as 230V AC circuits) at the same

time, the SELV or PELV arequirements are met any more.

*4 The actuator locking strength is rated at 5000N of static load. Do not apply a load

higher than the rated value. When a higher load is expected to work on the

actuator, provide an additional system consisting of another safety switch without

lock (such as the HS5D safety switch) or a sensor to detect door opening and stop

the machine.

1Type

HS1T-VD44ZLM-G

Solenoid Voltage / Lock Mechanism

4 : 24V DC / Spring Lock

7Y : 24V DC / Solenoid Lock

Pilot Light Rated Voltage

4 : 24V DC

Indicator Color

G : Green

Circuit Code

Rear Unlock Button

Blank : Without Rear Unlock Button

L : Rear Unlock Button

Head material

Z:Metal

CAUTION

Solenoid lock type

•

This safety switch is designed to lock the actuator while the solenoid is energized

and to release it when deenergized.

•

When the power to the solenoid is interrupted by accident, such as disconnection,

the lock is released before a machine stops ompletely. Then, the worker may be

exposed to hazards.

•

This safety switch can be used only for limited applications which do not especially

need to be locked for safety.

Applicable Standards

Applicable Directives

Thermal Current ‹ h›

Contact Ratings

(Reference Values)

‹Ue, Ie›*2

Rated Operating Voltage

Rated Current

Turn ON Voltage

Turn OFF Voltage

Rated Power Consumption

Rated Operating Voltage

Rated Current

Light Source

Illumination Color

Standards for Use

SolenoidIndicator

Operating Condition

Inpulse withstand voltage

‹Uimp›

Raed Insulation voltage‹Ui›

Interlocking device Type

/ the level of coded

Device

Short-circuit Protective

current

Condi ional short circuit

Degree of Protection

Contact Resistance

Direct Opening Force

Direct Opening Travel

when Locked

Actuator Tensile Streng h

Electrical Durability

Mechanical durability

B10d

Operating Speed

Operating Frequency

Class of Protection

DC24V 100% duty cycle

200 mA (initial value)

Rated voltage x 85% maximum (at 20°C)

Rated voltage x 10% minimum (at 20°C)

Approx. 5W

DC24V 100% duty cycle

10 mA

LED

Green

Type 2 Interlocking device

/ low level coded actuator (EN ISO / ISO14119)

EN ISO / ISO14119, IEC60947-5-1, EN60947-5-1,

GS-ET-19,UL508, CSA C22.2 No.14, GB/T 14048. 5

IEC60204-1/EN60204-1

Low Voltage Directive, Machinery Directive

2.5A

AC Resistive load (AC12)

Inductive load (AC15)

DC Resistive load (DC12)

Inductive load (DC13)

30V 125V 250V

- 2.5A 1.5A

- 1.5A 0.75A

2.0A 0.4A 0.2A

1.0A 0.22A 0.1A

Class II (IEC61140) *3

900 opera ions/hour

0.05 to 1.0 m/s

2,000,000 (ISO 13849-1 Annex C Table C.1)

2,000,000 operations minimum (GS-ET-19)

The Rear Unlock Button: 3000 operations

minimum (Type HS1T-□L)

100,000 operations min. (AC-15 250V/0.75A)

2,000,000 operations min. (AC/DC 24V 100mA)

(900 operations / hour)

Fzh=5,000N minimum

F1max=6500N minimum (GS-ET-19) *4, *5

12 mm minimum

120N minimum

50 mΩ maximum (initial value)

IP67 (IEC60529) , Type 4X Indoor Use Only

50A(250V)

Use 250V / 10A fast acting type fuse *6

Operating Temperature

Operating Humidity

Pollution Degree

Altitude

2.5kV

(Between ground and LED, solenoid circuit : 0.5kV)

250V (Between ground and LED, solenoid circuit : 30V)

-25 to +55

°C (no freezing)

20 to 95%RH

(no condensation)

3 (Inside 2)

2000m maximum

Thank you for purchasing this IDEC product. Confirm that the delivered product is

what you have ordered. Read his instruction sheet to make sure of correct operation.

In this operation instruction sheet, safety precautions are categorized in order of

importance to Warning and Caution :

Warning notices are used to emphasize that improper operation may cause severe

personal injury or death.

Caution notices are used where inattention might cause personal injury or damage to

equipment.

INSTRUCTION SHEET

Original Instructions

Solenoid Type Safety Switch

HS1T Series

S A F E T Y P R E C A U T I O N S

CAUTION

WARNING

Shock Resistance

Vibration Resistance

Operating Extremes: 100m/s2, Damage Limits: 1000m/s2

Operating Extremes:10 to 55 Hz, half amplitude 0.35mm

Damage Limits: 30 Hz, half amplitude 1.5mm

Conduit Cover

M : Standard type (M20)

SM : Cable side-routed type (M20)

Standard typeContact Congifiguration

*1 Only type No. on √ mark are supplied

as standard.

Contact IDEC for the other if required. Spring Lock Type Solenoid Lock Type

Main

circuit

-

-

-

-

-

-

-

-

-

-

-

-

-

-

1NC+1NC

1NC+1NC

-

-

1NC+1NC

1NC+1NC

1NC+1NC

1NC+1NC

1NC+1NC

1NC+1NC

1NC+1NC

1NC+1NC

-

-

-

-

-

-

-

-

HS1T-□

7Y4ZM-G

√

-

-

√

√

-

-

√

√

√

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

HS1T-□

44ZLM-G

-

-

-

√

√

-

-

√

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

HS1T-□

44ZM-G

√

-

-

√

√

-

√

√

-

-

√

√

√

√

√

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Door monitor

circuit

1NC

2NC

1NC,1NO

-

1NC,1NO

1NC,1NO

2NC

2NC

3NC

2NC,1NO

1NC

1NC

1NO

1NO

-

1NO

-

1NO

1NO

1NC

1NC

2NC

1NC,1NO

-

-

1NO

1NO

1NC

1NC

2NC

1NC,1NO

-

-

Lock monitor

circuit

1NC

-

-

2NC

1NC,1NO

2NC

1NC,1NO

2NC

1NC

1NC

3NC

2NC,1NO

3NC

2NC,1NO

-

1NC

1NC,1NO

1NO

1NC

1NO

1NC

-

-

2NC

1NC,1NO

1NC,1NO

2NC

1NC,1NO

2NC

1NC

1NC

3NC

2NC,1NO

XD

XF

XG

XH

VA

VB

VC

VD

VF

VG

VH

VJ

VW

VX

DD

XB

XJ

A

B

C

D

F

G

H

J

TA

TB

TC

TD

TF

TG

TH

TJ

Rear Unlock Button

Weight Approx. 450g

Thermal Current‹lth›

B-2048-1(1)

INSTRUCTION SHEET - HS1T Series Solenoid Type Safety Switch

( 2 / 9 )

2019.07

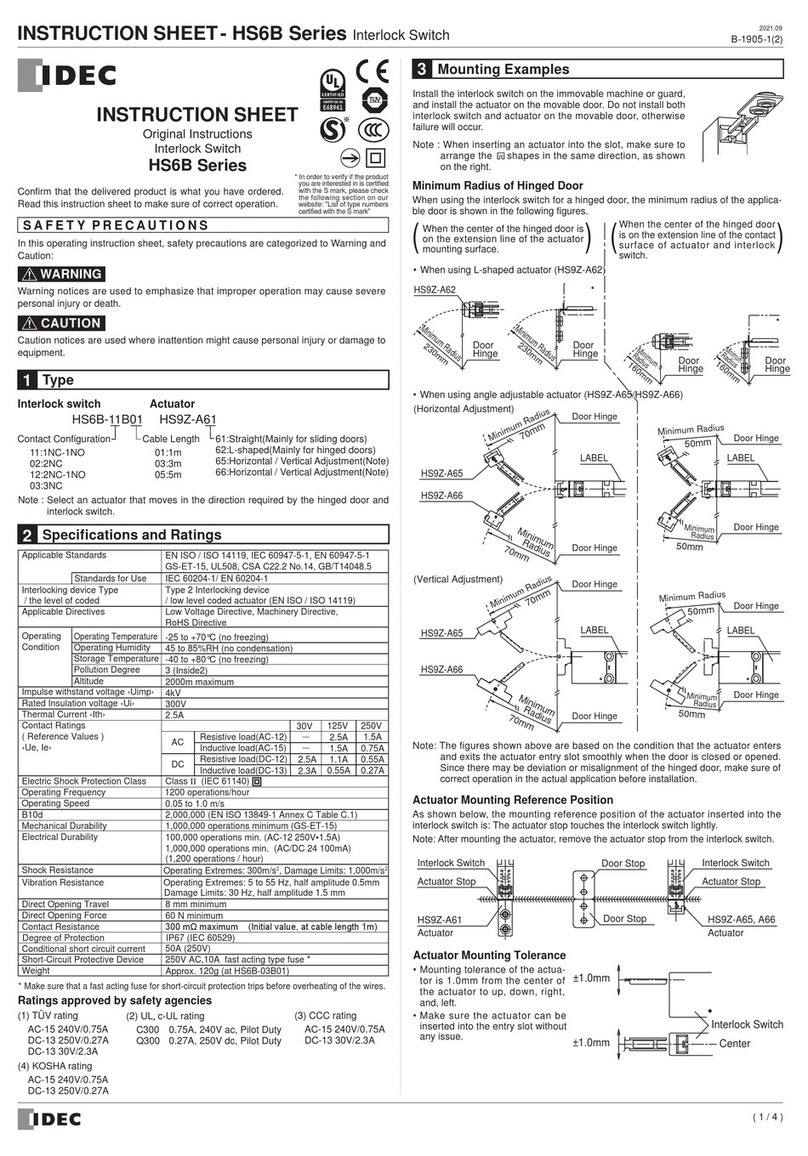

3Mounting Examples

• Install the interlock switch on the immovable machine or guard, and install the

actuator on the movable door. Do not install both interlock switch and actuator on

the movable door, otherwise the angle of insertion of the actuator to the safety switch

may become inappropriate, and failure will occur.

(Examples of Mounting on Sliding Doors)

HS9Z-A11T

Actuator

Door Stop

Latch

HS1T

Safety Switch

Door

(Examples of Mounting on Hinged Doors)

HS9Z-A12T

Actuator

HS1T

Safety Switch

HS9Z-A12T

Actuator

Door

●The HS1T Head

•Changing the Mounting Directions of the HS1T Head

The head of the HS1T can be changed in four directions by pulling up the rota-

tion stopper screw of the HS1T head with a minus driver.

The head rotates in the range of movement as in the diagram below, based on

the mounting direction at the time of shipment.

When

Shipped

Alternative Mounting Direc ions

Range of Movement

of the Head

Attachment Direction

at the Time of Shipment

Rotation Stopper Screw

●How to Change the Mounting Direction

①Rotate the minus driver in he direction

of the arrow and pull up the rotation

stopper screw.

②Once you've pulled up the rotation stopper

screw to its stopping point, rotate the head

to your desired direction.

③When the head has been rotated to your desired mounting direction, align

the △marks of the head and case, and then tighten the rotation stopper screw.

Head

R1

R2

R4

R3

Rotation Stopper Screw

○×

Latch

Fzh

=

maximum force (F1max.)

Safety coefficient (=1.3)

CAUTION

• After installing the rear unlock button, apply Loctite to the screw so that the screw

does not become loose. The lod is made of stainless steel.The rear unlock button

is glass-reinforced PA66 (66 nylon). The mounting screw is iron. Take the

compatibility of plastic material and Loctite into considera ion.

HS9Z-A12T

R1

510 mm

R2

840 mm

R3

270 mm

R4

450 mm

Minimum Radius

CAUTION

• The values shown above are based on the condition that the actuator enters and

exits the actuator entry slot smoothly when the door is closed or opened. Since

there may be deviation or dislocation of the hinged door, make sure of correct

operation in the actual applica ion before installation.

Actuator Mounting Reference Position

As shown below, the mounting reference position of the actuator inserted into the

safety switch is:

(After mounting the actuator, remove the actuator stop from the safety switch.)

• When using the safety switch for a hinged door, the minimum radius of the applicable

door is shown in the following figures.

Minimum Radius of Hinged Door

• Insert the rear unlock indicator

(supplied) in the indicator guide hole on

either the left or right side of the safety

switch and attach the ring part to the

rod on the rear side. After installing the

safety switch on the panel, put the rear

unlock button (supplied) on the rod,

and fasten using the mounting screw

(supplied).

When installing on the aluminum frame

with a thickness of 6mm or more, use

the rear unlock button for the frame kit

(HS9Z-FL5□) sold separately.

The Rear Unlock

Button

Mounting

Screw

(M3 sems screw)

Panel

Rod

When the center of the hinged door is

on the extension line of the actuator

mounting surfase.

When the center of the hinged door is

on the extension line of the contact surface

of actuator and safety switch.

Door Hinge Door Hinge

Minimum

Radius

Minimum Radius

Door Hinge Door Hinge

Minimum Radius

Minimum

Radius

ActuatorCover

Door StopSafety Switch Safety Switch

HS9Z-A11T

Actuator

HS9Z-A12T

Actuator

Door Stop

ActuatorCover

*5 F1max is maximum force. The actuator’s guard-locking force Fzh is calculated in

accodance with GS-ET-19:

*6 Make sure that a fast acting fuse for short-circuit protection trips before

overheating of the wires.

●

Mounting Directions of the HS1T Head

•There is a range of movement to the head. Do not forcibly rotate the head

over its range of movement. There is a risk of damage.

•

There is a risk of damage if the rotation stopper screw is forcibly tightened

without aligning the

△

marks of the head and case.

•

Apply loctite or the like to on the rotation stopper screw to prevent loosening.

•When replacing the HS1T head, make sure that no foreign object enters

into the safety switch.

•Tighten the rotation stopper screw of the head tightly, otherwise the safety

switch may malfunction.

•Don't loosen the rotation stopper screw of the head except when the

mounting directions of the head is changed.

Rear Unlock

Indicator

Indicator Guide Hole

WARNING

Installing the Rear Unlock Button and Indicator

(Type HS1T-□L)

B-2048-1(1)

INSTRUCTION SHEET - HS1T Series Solenoid Type Safety Switch

( 3 / 9 )

2019.07

4Precautions for Operation

(Actuator deviation)+(Door movement)

≤ 3.8mm

≤ 3.8mm

HS9Z-A11T

HS9Z-A12T

For Mounting

• Do not apply an excessive shock to the safety switch when opening or closing the

door. A shock to the safety switch exceeding 1,000 m/s2may cause failure.

• Provide a door guide, and ensure that force is applied on the safety switch only in

the actuator insertion direction.

• Do not pull the actuator while it is locked. Also, regardless of door types, do not use

the safety switch as a door lock. Install a separate lock as shown in section 3.

• Ensure that the safety switch is installed on a flatmounting surface, and provide

sufficient strengthto the mounting surface so that it will not be distorted during

operation. Make sure that no foreign objects are caught between the safety switch

and mounting surface. Uneven surface, distorted surface, or foreign objects may

result in the malfunction of safety switch.

• Entry of foreign objects in the actuator entry slot may affect the mechanism of the

switch and cause a breakdown. If the operating atmosphere is contaminated, use a

protective cover to prevent the entry of foreign objects into the switch

through the actuator entry slots.

• Make sure to install the product in a place where it cannot be damaged.

Make sure to conduct a proper risk assessment evalua ion before using

the product, and use a shield or a cover to protect the product if need be.

• While the solenoid is energized, the switch temperature rises approximately 40°C

above the ambient temperature (to approximately 95°C while the ambient tempera-

ture is 55°C). Keep hands off to prevent burns. If cables come into contact with the

switch, use heat-resistant cables.

• Solenoid has polarity. Be sure to wire correc ly. Do not apply voltage that exceed the

rated voltage, otherwise the solenoid will be burnt out.

• Do not fasten and loosen the conduit at he bottom of the safety switch.

• Use the dedicated actuators only. Other actuators will cause damage to the switch.

• Be careful not to injure yourself with the screwdriver tip when wiring the terminals.

• Be careful not to damage the square-shaped screwdriver port when inserting the

driver into it in order to wire the terminals. Inserting the screwdriver with too much

strength may damage the product.

• Before using the following accessories, be sure to refer to the instruc ion manual for

the respective accessory and follow the instructions in the manual to ensure correct

use. HS9Z-FL5

CAUTION

• HS1T Series Safety Switches are Type 2 low-level coded interlocking devices (EN

ISO / ISO14119). The following system installation & mounting instructions are EN

ISO / ISO14119 requirements to prevent function failure from the interlock switch.

1. Using permanent fixing methods (e.g. welding, rivets, special screws...etc) to

prevent dismantling or de-positioning of the interlock device. However, perma-

nent fixing methods are not an adequate solution if you expect the interlock

device to fail during the machinery lifetime, or if you need to replace the prod-

uct in quick manner. In these situations, other measures (see 2.) should be put

in place to reduce the risks of function failure.

2. At least one of the following measures should be applied to prevent function

failure.

(1) Mounting the interlock device in a place out of reach from workers

(2) Using shielding protection to prevent physical obstruction of the device

(3) Mounting the interlock device in a hidden position

(4) Integrate status monitoring & cycling testing of the device to the control

system to prevent product failure.

• Regardless of door types, do not use the safety switch as a door stop. Install a

mechanical door stop to the end of the door to protect the safety switch against

excessive force.

• Mount the actuator so that it will not hit the operator when the door is open, other-

wise injury may be caused.

• Pay attention to the management of spare actuator. Safety function of door inter-

lock switch will be lost in case the spare actuator is inserted into the interlock

switch. Ensure that the actuator is firmly fastened to the door (welding, rivet, special

screw) in the appropriate location, so that the actuator cannot be removed easily.

• Do not cut or remodel the actuator, otherwise failure will occur.

• If multiple safety components are wired in series, the Performance Level to

ISO13849-1 will be reduced due to the restricted error detection under certain

circumstance.

• The insulation of the cable has to withstand environmental influences.

• The entire concept of the control system, in which the safety component is

integrated, must be validated to ISO13849-2.

• When there is a displacement of safety switch and actuateor, the actuator may hit the

entry slot of safety switch hardly, thus damaging the entry slot and acutuator. The

rubber cushions on the HS9Z actuator prevent the actuator from damaging the entry

slot by absorbing the shock with movement flexibility. Do not, however, exert

excessive shocks, otherwise the failure of safety switch may be caused.

• The rubber cushions may deteriorate depending on the operating enviroment and

conditions. Immediately replace the deformed or cracked rubber cushions with new

ones.

For Type HS9Z-A11T/A12T actuator

Name or Use

For mounting the safety switch (M5 screw) *7

For mounting the cover(M3screw)

For Rotation Stopper Screw of the Head (M4screw)

For mounting the rear unlock button

(M3 sems screw)

For mounting the actuator

(HS9Z-A11T/A12T : two M5 screws) *8

Screw Tightening Torque

3.2 to 3 8 N•m

0.5 to 0.7 N•m

0.1 to 0.3 N•m

0.5 to 0.7 N•m

2.7 to 3.3 N•m

Recommended Screw Tightening Torque

Safety

Switch

Center Center

*7 When the torque is not enough to recommended screw tightening torque, make

sure that the screw do not become loose by using adhesive sealants etc. to

keep right operation and mounting posi ioning.

CAUTION

WARNING

• Turn off the power to the safety switch before starting installation, removal, wiring,

maintenance, and inspection on the safety switch. Failure to turn power off may

cause electrical shocks or fire hazard.

• Do not disassemble or modify the switch. Also do not attempt to disable the

interlock switch function, otherwise a breakdown or an accident will result.

Actuator Mounting Tolerance

• Mounting tolerance of the actuator is 0.5 mm in the four lateral directions.

• Make sure the actuator can be inserted into he entry slot without any issue.

Actuator Mou ting Tolerance

M unting t leran e f the a tuat r is 1 0 mm in the four lateral dire ti ns

• Make sure he actuator can be inserted into he entry slot without any issue

• When closing the door, the actuator is inserted and locked within a certain distance

from the reference position. After the actuator has been locked, the contact operation

is not affected by the actuator movement in the locked state.

HS9Z-A12T

HS9Z-A11T

3.8mm

3.8mm

±0.5mm ±0.5mm

Slot plug

・When not in use, close up the safety switch

actuator entry slots with slot plugs to prevent

dust from entering.

・Actuator entry slots on the front come closed up

wi h slot plugs at time of shipment. When replacing,

please use the tool as shown.

●Installing the slot plug

Rubber Cushions

*8: When rubber cushions (and spacers) are not used, use M6 screws and tighten to a

torque of 4.5 to 5.5 N・m.

B-2048-1(1)

INSTRUCTION SHEET - HS1T Series Solenoid Type Safety Switch

( 4 / 9 )

2019.07

5Contact Operation

(Actuator

Completely Inserted) (Actuator

Pulled Out)

:Contact Closed :Contact Open

Approx. 4 2 (Lock)

0

(Actuator Mounting Reference Position)

Approx.

28.5

Approx

.9.8 Approx.

11.6

(Travel: mm)

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

(Type HS1T-□4)

The HS1T allows manual unlocking of the actuator to precheck proper door opera-

tion before wiring or turning power on, as well as for emergency use such as a power

failure.

(Type HS1T-□7Y)

If the actuator is not unlocked althoug the solenoid is deenergized, the actuator can

be unlocked manually.

CAUTION

• Before manually unlocking the safety switch, make sure the machine has come to a

complete stop. Manual unlocking during operation may unlock the switch before the

machine stops, and the function of safety switch with solenoid is lost.

• While the solenoid is energized, do not unlock the actuator manually (solenoid lock

type).

• Do not apply excessive force (0.45 N•m or more) to he manual unlock key. Otherwise

the manual unlock switch will be damaged. Do not attach the key to the switch

intentionally (the key is designed to fall off when the operator's hand is off the key).

• Do not leave the manual unlock key attached to the switch during operation. This is

dangerous because the switch can always be unlocked while the machine is in

opera ion.

CAUTION

• Install the HS1T to ensure that a worker can operate the rear unlock button from

inside the safety hedge (the dangerous area). It is dangerous to install the HS5L in

the position where the rear unlock button can be operated from outside the the

safety hedge (the dangerous area), because it is possible to unlock while the

machine is opera ing.

• Use hand to press the button, and do not use a tool. Do not apply excessive force

to the rear unlock button.

• To change the normal position to the

manual unlocking position as shown

above, turn the key fully (90 degrees)

using the special key included with the

switch.

• Using the switch with the key being not

fully turned(less than 90 degrees) may

cause damage to the switch or errors.

• When manually unlocked, the switch will

keep the main and lock monitor circuit

disconnected and the door unlocked.

For Manual Unlocking

Normal

Position Manual

Unlocking

Position

Manual Unlock Key

attached to the

safety switch

Manual Unlock Key Hole

For the Rear Unlock Button and Indicator

(Type HS1T-□L)

• The rear unlock button is used for an emergency escape when he worker is confined in he

safety hedge (the dangerous area).

(The rear unlock button is according to EN ISO / ISO14119, GS-ET-19)

• The lock is released when the rear unlock button is pressed, and the door can be opened.

• To return to the locked status, pull back the button. While the rear unlock button is

depressed, the main circuit remains open and the door is unlocked.

• Each time the rear unlock button is pressed, the indicator is displayed on the side of he

safety switch.

Enables checking of the unlock status from outside he safety hedge.

• Use the rear unlock indicator by attaching it to the display area on either side of the safety

switch.

The Rear Unlock Button

Lock

Release

Rear Unlock StatusNormal Status

●Contact Configuration and Operation

Contact Congifiguration *11

※

9

[

HS1T-TJ

□]

[

HS1T-TG

□]

[

HS1T-TF

□]

[

HS1T-TD

□]

[

HS1T-TC

□]

[

HS1T-TB

□]

[

HS1T-TA

□]

[

HS1T-J

□]

[

HS1T-G

□]

[

HS1T-F

□]

[

HS1T-D

□]

[

HS1T-C

□]

[

HS1T-B

□]

[

HS1T-A

□]

[

HS1T-XB

□]

HS1T-DD

□

HS1T-VG

□

HS1T-VH

□

HS1T-VF

□

HS1T-VD

□

HS1T-VC

□

[

HS1T-VB

□]

HS1T-VA

□

HS1T-XH

□

[

HS1T-XG

□]

[

HS1T-XF

□]

HS1T-XD

□

11

23 24 53 54

42 11-42

23-24

53-54

23

11 24 51 52

42 11-42

23-24

51-52

11

21 22 53

42

54

11-42

21-22

53-54

11

21 22 51

42

52

11-42

21-22

51-52

11

21

33 22

34

42 11-42

21-22

33-34

11

21

31 22

32

42 11-42

21-22

31-32

11

63

51 64

52

42 11-42

51-52

63-64

21

11 42

52 11-42

21-52

23

11 12

24 41

53

42

54

11-12

23-24

41-42

53-54

11

23 24

12 41

51

42

52

11-12

23-24

41-42

51-52

21

11 12

22 53

41

54

42

11-12

21-22

41-42

53-54

21

11 22

12

51

41

52

42

11-12

21-22

41-42

51-52

31

21

11

32

22

12 41 42

11-12

21-22

31-32

41-42

33

21

11

34

22

12 41 42

11-12

21-22

33-34

41-42

11

21 12

22

11-12

21-22

11

23 12

24

11-12

23-24

51

41 52

42 41-42

51-52

11 12 41 42

11-12

41-42

13 14 41 42

13-14

41-42

13 14 53 54

41-42

13-14

53-54

41 42

11 12 51 52

41-42

11-12

51-52

41 42

21

11 22

12 41-42

11-12

21-22

41 42

63

51 64

52 41-42

51-52

63-64

41 42

23

11 24

12 41-42

11-12

23-24

41 42

14 51 52

41-42

13-14

51-52

41 42

13

11 12 53 54

41-42

11-12

53-54

41 42

HS1T-VJ

□

HS1T-VW

□

HS1T-VX

□

11 12

63

51

41

64

52

42

11-12

41-42

51-52

63-64

[

HS1T-XJ

□]

53

41 54

42 41-42

53-54

A1A2

(+) (

-

)

11 12

61

51

41

62

52

42

61

51

41

62

52

42

13 14

13 14

63

51

41

64

52

42

13-14

41-42

51-52

63-64

13-14

41-42

51-52

61-62

11-12

41-42

51-52

61-62

[

HS1T-H

□]

[

HS1T-TH

□]

11 42

51 52

61 62

11-42

51-52

61-62

41 42

51 52

61 62

41-42

51-52

61-62

Type *10 Contact Operation (reference)

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Main Circuit:

Monitor Circuit:

Monitor Circuit:

Main Circuit:

Monitor Circuit:

Monitor Circuit:

Main Circuit:

Monitor Circuit:

Monitor Circuit:

Main Circuit:

Monitor Circuit:

Monitor Circuit:

Main Circuit:

Monitor Circuit:

Monitor Circuit:

Main Circuit:

Monitor Circuit:

Monitor Circuit:

Main Circuit:

Monitor Circuit:

Monitor Circuit:

Main Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Main Circuit:

Main Circuit:

B-2048-1(1)

INSTRUCTION SHEET - HS1T Series Solenoid Type Safety Switch

( 5 / 9 )

2019.07

• In applications using ferrules for stranded wires, choose the ferrule listed in the table.

mm2

AI0.5-6WH

AI0.75-6GY

AI1-6RD

TE0.5-8

TE0.75-8

TE1.0-8

0.5

0.75

1

0.5

0.75

1

AWG

AI0.34-6TQ

0.34 20

18

18

20

18

18

22 Phoenix

Contact

Nichifu

Part No. Manufacturer

Applicable wire

(stranded)

6Wiring

Terminal wiring method

• Terminal NO.

‹4 contact type› ‹2 contact type›

• Wire insertion positions, screwdriver insertion positions, and the directions of

screwdriver tip are shown below.

The round-shaped Wire Port

The square-shaped Screwdriver

Port Direction of Screwdriver Tip

Screwdriver Tip

• Contact operation is based on the condition that the actuator is inserted into the

center of the safety switch slot.

• Contact operation shows the HS9Z-A11T/A12T actuator.

• Use main circuit or monitor circuit with for the input to safety circuit.

• Indicator turns on when solenoid is energized.

Note :

• The following type circuits are shipped with jumpers connecting the indicated terminals.

A,B,C,D,F,G,J type circuits: Jumper connecting 12-41

DD type circuit: Jumpers connecting 12-41 and 22-51

• When the NC contacts (11-12)/(21-22) of the door monitor circuit and NC contacts

(41-42)/(51-52) of the lock monitor circuit are connected in series as inputs to the safety

circuit, connect 12-41 or 22-51 before use.

• Wire length and example of layout

• Recommended Wire Core Size : 0.3 to 1.5 mm2(AWG22 to 16)

Routing direction

Wire Length: L1

Type

HS1T-□△*4LM-G

HS1T-□△*4M-G

HS1T-□△*4LSM-G

HS1T-□△*4SM-G

Straight orientation

Straight orientation

Horizontal orientation

30 to 35mm

50 to 55mm

40 to 45mm 8 to 9mm L1

• For wiring, use the following applicable screwdriver.

(Tip shape of the driver is according to the standard of

DIN5264)

0.4

7° to 13°

Φ2.5

2.5

A1

A2

CAUTION

*12 Do not attempt manual unlocking when the solenoid is energized.

*13 Do not energize the solenoid for a long time while the door is open or when the

door is unlocked manually.

CAUTION

*9 This locking monitoring marking has been newly described in section 9.2.1 of

EN ISO / ISO14119. It indicates that any devices with this marking meet the

following EN ISO / ISO 14119 requirements:

- General (- General requirements for guard locking devices) (Section 5.7.1) *

- Locking monitoring (- Locking monitoring for guard locking devices) (Section

5.7.2.2)

When a lock monitor circuit (contact) has the locking monitoring marking, it

means that one circuit (contact) can monitor the position and the locking

function of the protective door. (The locking monitoring circuit (contact) turns

ON only when the protective door is closed and locked.)

*note Both types of HS1T safety switches - spring lock type switches and solenoid

lock type switches - have obtained the locking monitoring certifica ion marking.

Based on risk assessment results, solenoid lock type switches can be used

only for limited applications which do not especially need to be locked for

safety.

*10 Type No. in [ ] are not supplied as standard. See 1. Type for standard.

*11 These are the image of locking position with actuator inserted.

• Solenoid Lock Type (HS1T-□7Y)

Main Circuit

11-42

21-52

Monitor Circuit

11-12

21-22

31-32

Monitor Circuit

13-14

23-24

33-34

Monitor Circuit

41-42

51-52

Monitor Circuit

53-54

63-64

Door is

locked.

The machine

can be

operated.

Door is

unlocked.

The machine

can not be

operated.

The machine

can not be

operated.

Door is

unlocked.

The machine

can not be

operated.

Open

OFF/ON

*13

Closed

Turn the

key to unlock

position

Turn he

key to lock

position

Returned

status

When

operating

the Button

Closed

Closed Closed Closed

Closed

Closed

Closed Closed Closed

Open Open Open

Open

Open Open Open

Open Open Open

Open

OFF

*12 *13

Manual

Unlock Key

Rear Unlock

Button

Closed

OFFON

Closed

Turn the

key to lock

position

Turn the

key to lock

posi ion

Returned

status Returned

status

Door States

Solenoid

Power

A1-A2

Operation Cycle

• Spring Lock Type (HS1T-□4)

Manual

Unlock Key

Rear Unlock

Button

Main Circuit

11-42

21-52

Monitor Circuit

11-12

21-22

31-32

Monitor Circuit

13-14

23-24

33-34

Monitor Circuit

41-42

51-52

Monitor Circuit

53-54

63-64

Door is

locked.

The machine

can be

operated.

Door is

unlocked.

The machine

can not be

operated.

The machine

can not be

operated.

Door is

unlocked.

The machine

can not be

operated.

Closed Open

OFF ON ON/OFF

Closed Closed

OFF

Turn the

key to lock

position

Turn the

key to unlock

position

Turn the

key to lock

posi ion

Turn he

key to lock

position

Returned

status Returned

status Returned

status

When

operating

the Button

Closed

Closed Closed Closed

Closed

Closed

Closed Closed Closed

Open Open Open

Open

Open Open Open

Open Open Open

Open

Door States

Solenoid

Power

A1-A2

21/23/

41/43

22/24/

42/44

11/13/

51/53 12/14/

52/54

31/33/

51/53

32/34/

52/54

21/23/

63 22/24/

64

1211 4241

A1

A2 A1

A2

( 6 / 9 )

B-2048-1(1)

INSTRUCTION SHEET - HS1T Series Solenoid Type Safety Switch 2019.07

Note : Confirm the outside diameter of the multi-core cable, the connector type

depends on the outside diameter of multi-core cable.

Note : When using ST-M20×1.5, use with gasket GP-M (Type No: GPM20, made by

LAPP).

Note : If you use HS1T as Type 4X Indoor Use Only, please use M20 connectors that are

certified the following.

Plastic connector: Type 4,4X, 6 or 6P

Metal connector: Type 4X or 6P

Note : To unwire the terminals, disassemble the product in the following order:

turn off the power → loosen connecter B → remove the terminal cover →

remove the waterproof gasket from connecter A* → loosen connecter A

* Please remove the water-proof gasket carefully with tools such as tweezers.

Be careful when removing the gasket as damages may affect its waterproof

properties. Also, loosening connecter A without removing the gasket first may

damage the cable and provoke connection issues. Please make sure you

re-insert the waterproof gasket properly into connector A when re-assembling

the product.

• Wiring Instructions

1. Insert the applicable screwdriver into

the square-shaped port as shown,until

the screwdriver tip touches the bottom

of the spring.

3. While the screwdriver is retained in

the port, insert the wire or ferrule into

the round-shaped wire port. Each wire

port can accommodate one wire or

ferrule.

Bottom of the Port

Safety Switch

Terminal Cover

Gasket

Connecter

(To buy separately)

How to open conduit port (cable side-routed type)

• Before use, knock in the conduit port where the connector is to be connected, using

a tool such as screwdriver as shown in the figures.

• Before opening the conduit port, remove the terminal cover from the HS1T Safety

Switch main unit, and remove the locking ring for the cable gland installed in the

terminal cover.

• Be sure to remove any crack or burrs on the conduit port, as it will impair waterproof

performance.

Safety switch

Straight orientation Horizontal orientation

Locking ring

for cable gland

Terminal cover

AB

4. Pull out the screwdriver.

The connection is now complete.

2. Push in the screwdriver until it touches

the bottom of the port. The wire port is

now open, and the screwdriver is held

in place. The screwdriver will not come

off even if you release your hand.

The waterproof

gasket is completely

tightening the cable

The waterproof

gasket is not

properly tightening

the cable

Spring Force

Terminal

Spring Force

Terminal

Safety

Switch

A

Gasket

Sheath

B

Terminal

Cover

CAUTION

• Make sure not to lose any screw when

removing the terminal cover from the

switch.

• Please make sure the cable is insterted

deep enough into the terminal cover so

that the waterproof gasket can tighten

he cable sheath completely and ensure

its waterproof functions.

• Make sure you always tighten connecter

A before connecter B, otherwise the

wires which connect the terminals might

get twisted or might break, and this

might also damage the terminal ports.

• When tightening the connecters, only

use a tightening torque that is approved by the connecters' manufacturer to

ensure waterproof properties of the product.

• Do not pull or twist the cable with excessive force, otherwise you might damage the

wires inside of it.

Use a connector with a degree of protection IP67.

Applicable connector dimensions : See the figure on the right.

• When using flexible conduit and metal connector

Applicable Flexible Conduit Example:

Type VF-03 (made by Nihon Flex)

(M20) Applicable Metal Connector Example:

Type RLC-103EC20 (made by Nihon Flex)

• When using plastic connector, metal connector and multi-core cable

(M20) Applicable Plastic Connector Example:

Type ST-M20×1.5 (made by LAPP)

Applicable Metal Connector Example:

Type ALS-□□EC20 (made by Nihon Flex)

9mm max.

Conduit Thread

30mm max.

Applicable Connectors

AB

Connecter (To buy separately)

Gasket

1. Loosen connecter A and connecter B, and insert the cable into these pieces in the

following order :

connecter B → waterproof gasket → connecter A.

Do not tighten the connecters yet.

2. Remove the terminal cover from the switch

and insert the cable into the cover.

3. Wire the terminals.

4. Tighten connecter A into the terminal cover.

Fix the terminal cover back into its original

position. Tighten connector B.

Connecters' mounting method

Correct

The wire is inserted

deep enough

between the clamps

Incorrect

The wire insula ion

sheath is in contact

with the clamps

CAUTION

• When using wire with insulation

diameter of Φ2.0mm or less, do not

insert the wire too deep where the

insulation inserts into the spring clamp

opening. Otherwise conductive failure

will be caused. Make sure that the

wire insulation is stripped 8 to 9 mm

and the wire is inserted to the bottom.

• Please only connect one wire per

terminal port (according to the general

requirements section (13.1.1) of

IEC60204).

B-2048-1(1)

INSTRUCTION SHEET - HS1T Series Solenoid Type Safety Switch 2019.07

( 7 / 9 )

7

Example of wiring Diagram realizing Safety Category

S1: HS1T-VB4 Safety Switch with Solenoid

S2: Starting Switch (HW Series Momentary)

S3: Unlocking Enabling Switch

S4: Safety limit Switch

ESC: Outside start condition

K3, 4: Safety Contactor

F1: Outside fuse of safety relay module at power supply line

Note: Use the monitoring device(Safety relay module) provided the capavility to

detect a cross short circuit. The insulation of the cable has to withstand

environmental influences. If a control device other than the one shown in the

draft is used, the used control device has to be equipped with a cross short

circuit monitor.

Example of a circuit diagram for Safety Category 4

(attainable PL = e)

Output Circuit

HR1S-AF Safety relay module

One of the example of

the circuit ; Safety

relay module, HR1S-AF

series manufactured

by IDEC CORPORATION

HS9Z-A11T Actuator

HS1T-VB4

Safety Switch with Solenoid

Used as open/close

monitor of guard Guard Open

Output Circuit

HR1S-AF Safety relay module

One of the example of

the circuit ; Safety

relay module, HR1S-AF

series manufactured

by IDEC CORPORATION

HS9Z-A11T Actuator

HS1T-VB4

Safety Switch with Solenoid

Used as open/close

monitor of guard Guard Open

Example of a circuit diagram for Safety Category 3

(attainable PL = d)

(Condition 1: To apply the fault exclusion of mechanical structural parts including the actuator

→ Make sure to use the product wi hin the product specification range described in this

manual and he version of the manual provided with he product.)

(Condition 2: Documenta ion of the reason for the machine/equipment manufacturer to have

applied he fault exclusion based on ISO13849-1, ISO13849-2 or IEC62061.)

L1(+)

DC24V

S3

F1

K4

K3

N(−)

DC0V

A1(−)

A2(+)

52

S1

13

14

ESC

K4

K3 S2

51

42

41

S4

1

2

S33 S34 13 23A1

S11 S22

14 24

A2

S12 S21

12

11

24

23

L1(+)

DC24V

S3

F1

K4

K3

N(−)

DC0V

A1(-)

A2(+)

52

S1

12

11

13

14

ESC

K4

K3 S2

51

42

41

24

23

S33 S34 13 23A1

S11 S22

14 24

A2

S12 S21

( 8 / 9 )

B-2048-1(1)

INSTRUCTION SHEET - HS1T Series Solenoid Type Safety Switch 2019.07

Dimensions (mm)

3-M5 Safety Switch

Mounting Holes

Type :HS1T-□4ZSM

Type :HS1T-□4ZM

Type :HS1T-□4ZLM

(For L-type actuators)

8

●Safety Switch dimensions

φ10

(24)

6 5

24 5)

18

3

15 9

Slot Plug

30

40

20

7

45

22

54.9

52.3

(19.1 ±0.5)※

11.5

(16.6 ±0.5)※

22.5

104.6

17.5

104.6

47.1

40

7 1

170

125.540.1

56.2

59.49 20.8

30

φ5.2

4.6 4

61.6

2.5

(5.1±0.5)※

35

(2.6±0.5)※

56.8

(8)

Slot Plug※14

7~8

30

97.8

φ20

20.8

30

40

143

97.840.1

56 2

7 1

59.49 20.8

30

φ5.2

61.6

2 5

(5.1±0.5)※

17.8

35

(2.6±0.5)※

56.8

47.1

(8)

4.6 4

22

φ

5.1

7.7

27

Rear Unlock Indicator

Rear Unlock Button

Rear Unlock Button

(RP)

(RP)

7~8

30

125.5

Main body moun ing hole layout

HS9Z-A12T

Actuator

HS9Z-A11T

Actuator

Slot Plug

(取付基準)

※Actuator center position

30

40

143

97.840.1

56 2

59.49 20.8

30

40

20

6.5

61.6

2.5

17.8

35

56.8

47.1

22

54.9

52.3

(19.1±0.5 )※

11 5

(16.6 ±0.5)※

7 1

(5.1±0.5)※

(2.6±0.5)※

(8)

4.6 4

φ5.2

φ

5.1

φ

5.1

7~8

30

97.8

HS9Z-A11T

Actuator

HS9Z-A12T

Actuator

HS9Z-A11T

Actuator

Main body mounting hole layout

Manual Unlock Key (Supplied)

Main body mounting hole layout

3-M5 Safety Switch

Mounting Holes

(For straight actuators )

3-M5 Safety Switch

Mounting Holes

(RP)

(RP)

(RP)

(RP)

(RP)

(RP)

(RP)

*14 When not in use, close up he safety switch actuator entry slots with slot plugs

to prevent dust from entering.

(Actuator entry slots on the front come closed up with slot plugs at time of shipment.)

( 9 / 9 )

B-2048-1(1)

INSTRUCTION SHEET - HS1T Series Solenoid Type Safety Switch 2019.07

9Precaution for Disposal

Dispose of the HS1T safety switch as an industrial waste.

http://www.idec.com

Manufacturer: IDEC CORP.

2-6-64 Nishimiyahara Yodogawa-ku, Osaka 532-0004, Japan

EU Authorized Representative:APEM SAS

55, Avenue Edouard Herriot BP1, 82303 Caussade Cedex, France

DECLARATION OF CONFORMITY

We, IDEC CORPORATION 2-6-64, Nishimiyahara Yodogawa-ku,Osaka 532-0004, Japan declare

under our sole responsibility that the product:

Description: Safety Switch

Model No: HS1T

to which this declaration relates is in conformity with the EU Directive on the following standard(s)

or other normative document(s). In case of alteration of the product, not agreed upon by us, this

declaration will lose its validity.

Applicable EU Directive : Low Voltage Directive (2014/35/EU)

Machinery Directive (2006/42/EC)

RoHS Directive (2011/65/EU)

Applicable Standard(s) : EN 60947-5-1,GS-ET-19,EN 50581

20.5

11.5

22

40

40

(42.5)

12.3

0.8

43

18.6

3

5.1

φ

5.1

φ

15

90°

22

40

22

43

18.6

479

19.3

0.8

φ5.1

φ

15

When installed on

3

5.1

Actuator Stop

(Supplied with actuator)

When installed on

Actuator dimensions

Type : HS9Z-A11T

(To be sold by separately)

Type : HS9Z-A12T

HS9Z-A11T/A12T Actuator mounting hole layout

2-M5

(Φ5.2 or M5 tapped)

Type :HS1T-□4LSM

(For straight actuators) (For L-type actuators)

Rear Unlock Button

(取付基準)

Slot Plug

(取付基準)

52.3

(19.1 ±0.5)※

11 5

(16.6 ±0.5)※

22.5

104.6

7 1

4.6 4

(5.1±0.5)※

(2.6±0.5)※

47.1

30

22

40

170

125.540.1

56.2

59.49 20.8

30

φ5.2

40

20

7

45

17.5

104.6

61.6

2.535

56 8

(8)

54.9

7~8

30

125.5

φ

20

20.8

Main body mounting hole layout

3-M5 Safety Switch

Mounting Holes

φ

5.1

HS9Z-A12T

Actuator

HS9Z-A11T

Actuator

Rear Unlock Indicator

Rear Unlock Button Rear Unlock Button

(RP)

(RP)

Table of contents

Other IDEC Switch manuals

IDEC

IDEC HS5E Series User manual

IDEC

IDEC HS5L Series User manual

IDEC

IDEC HS1L Series User manual

IDEC

IDEC HS5E Series User manual

IDEC

IDEC HS1C Series User manual

IDEC

IDEC MICRO/I HG9Z-1D4PN05 User manual

IDEC

IDEC HS1E Series User manual

IDEC

IDEC SA1E Series User manual

IDEC

IDEC HS3A Series User guide

IDEC

IDEC HS1C Series User manual

IDEC

IDEC HE1B Series User manual

IDEC

IDEC HS5L Series User manual

IDEC

IDEC HS6B Series User manual

IDEC

IDEC HS5D-11 User manual

IDEC

IDEC SA1U Series User manual

IDEC

IDEC SA1E-L Series User manual

IDEC

IDEC SA1E Series User manual

IDEC

IDEC HS5E-K User manual

IDEC

IDEC SX5E Series User manual

IDEC

IDEC HS5E Series User manual