IECHO 450W User manual

Hangzhou IECHO Science & Technology Co., Ltd.

1

450W Router User Manual

Hangzhou IECHO Science & Technology Co.,Ltd

Hangzhou IECHO Science & Technology Co., Ltd.

1

Catalog

1. Summary.....................................................................................................................2

2. Risk control warning...................................................................................................2

3. Milling system composition and working principle................................................... 3

4. Technical parameter...................................................................................................4

5. Essential of Router installation...................................................................................4

5.1. Installation of the suction pipe bracket of the cutting head.......................... 4

5.2. Connection of router spindle with cable and air pipe.................................... 5

5.3. Emergency stop cable connection.................................................................. 6

5.4. Gas source connection.................................................................................... 6

5.5. USB communication cable connection........................................................... 7

6. Router debugging....................................................................................................... 7

6.1. Driver initialization.......................................................................................... 7

6.2. Spindle running-in......................................................................................... 10

6.3. Communication settings between Router and computer............................ 11

6.4. Spindle rotating direction confirmation........................................................13

7. Router operation...................................................................................................... 13

7.1. Power on....................................................................................................... 14

7.2. Cooling air pressure inspection.....................................................................14

7.3. Blade installation...........................................................................................15

7.4. Router parameter setting..............................................................................15

7.5. Communication serial port settings.............................................................. 16

7.6. Knife cutting depth setting............................................................................16

7.7. Router rotating speed setting....................................................................... 17

8. Precautions for spindle use...................................................................................... 17

9. Daily maintenance of Router....................................................................................18

10. Router driver alarm and troubleshooting.............................................................. 19

10.1. Warning light ............................................................................................. 19

10.2. Warning codes and error codes.................................................................. 20

10.3. Common faults and solution to Router.......................................................25

Statement.....................................................................................................................27

Hangzhou IECHO Science & Technology Co., Ltd.

2

1. Summary

The 450 Router adopts German imported electric spindle as the core body of

the milling tool, with stable speed and superior performance. It is suitable for

engraving and engraving of non-metallic hard materials, such as acrylic board, MDF

board, aluminum-plastic board, Foam board and other materials. The operation is

simple and it can be widely used in industries such as advertising and composite

materials.

2. Risk control warning

If there is a safety hazard, please immediately press the

emergency stop button!

Do not touch the router bit with your hands when it is

rotating!

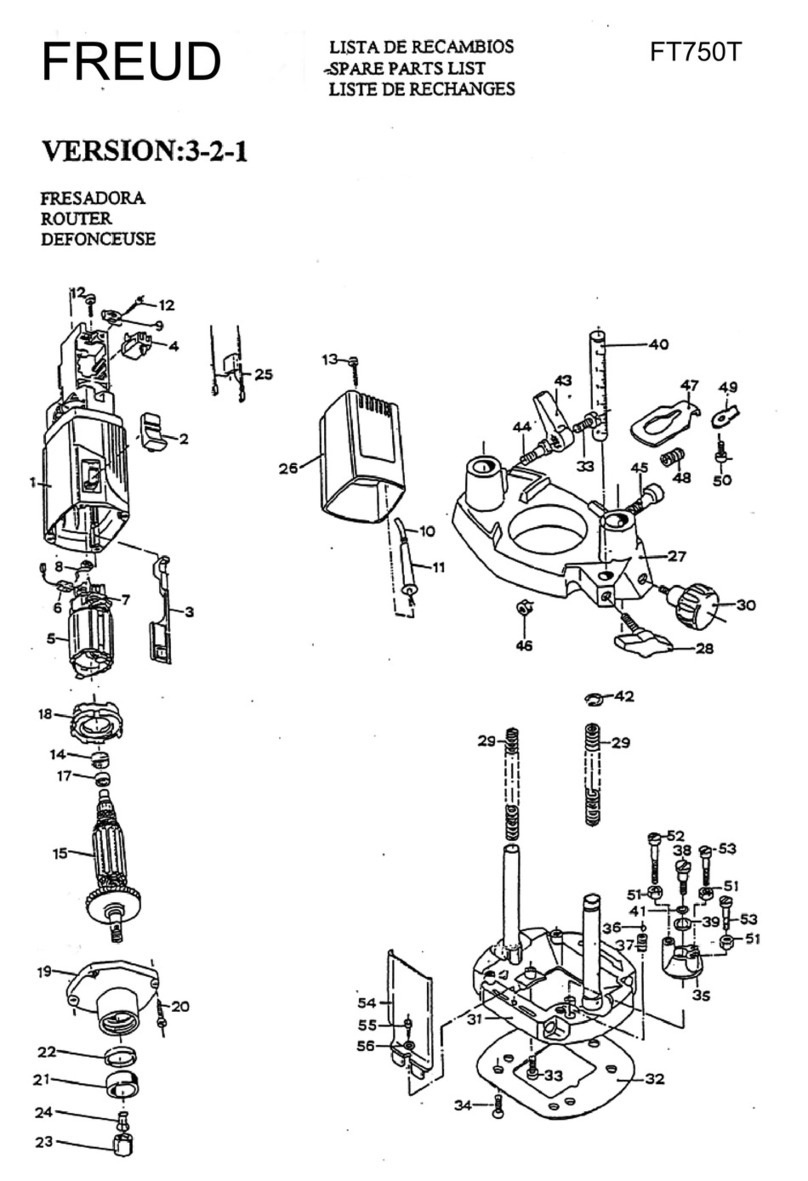

3. Milling system composition and working principle

450 milling system is composed of 450 milling tool (including spindle), Router

controller, vacuum cleaner, dust suction pipeline, air cooling pipeline and other

components. As shown in Figure 1 for the connection diagram of the main parts of

the milling system, the milling tool is installed on the universal head, and it is

connected with the driver in the router control box through a flexible cable. A milling

system suction device is installed on the universal head, and the suction device is

directly connected with an external vacuum cleaner through a vacuum hose.

In the system, when the milling tool is running, the external driver provides the

required power, and then the cutting head controls the height of the router to

engrave and mill the material to be cut. During the working process, the milling

system suction component sucks the waste and dust cut by the milling tool. With the

vacuum cleaner, it generates a negative pressure suction to the vacuum cleaner, to

achieve the purpose of clean production table.

Hangzhou IECHO Science & Technology Co., Ltd.

3

Figure -1 · Connection Diagram of Router Parts

1- Cutting head 6- Router hose holder

2- Milling tool 7- Router controlling box

3- Dust suction pipeline 8- Dust cleaner

4- Driver cable 9- Power Indicator

5- Air cooling pipeline 10- Power switch

9

1

2

6

7

8

10

3、4、5

Hangzhou IECHO Science & Technology Co., Ltd.

4

4. Technical Parameter

Items

Parameters

Output Power

S1:420W,max.500W

Range of rotation

6000-60000rpm

Motor type

Three-phase asynchronous motor

Motor protection level

IP55

frequency

100-1999Hz

Voltage

49V

Current

S1:6.6A,max.8A

Torque

S1:8.4Ncm,max.8.4Ncm

Air pressure requirement

min0.04MPa

Collet

maxɸ5.0mm

5. Essential of Router Installation

5.1. Installation of the suction pipe bracket of the cutting head

Remove the two original M3×3 countersunk head screws on the side of the cutting

head cover, and use M3×6 countersunk screws to fix the suction tube bracket on the

cutting head.

Replace the two M3×3 countersunk head screws of the

cutting head cover with M3 ×6 countersunk head

screws, to fix the milling tool suction tube holder.

Note: Please select the correct screws type to avoid

damage to the cutting head.

Hangzhou IECHO Science & Technology Co., Ltd.

5

Pic 2 Installation of the suction pipe bracket of the cutting head

5.2. Connection of router spindle with cable and air pipe

Before connecting the milling spindle and the drive cable, please check whether

there is anything in the plug and clean, then insert the plug straight to the end after

aligning the position. When you hear a "click" sound, it means that the plug is locked.

Then insert a 4.0mm air pipe and connect with the milling spindle.

Figure 3 The connection between the milling spindle and the cable & air pipe

Hangzhou IECHO Science & Technology Co., Ltd.

6

5.3. Connection of emergency stop cable

The three-pin plug of the emergency stop cable is connected with the

emergency stop control interface on the outside of the milling tool control box, and

the two-pin plug is connected with the emergency stop control interface of the

milling tool on the electrical box of the cutting machine.

Figure 4 · plug Emergency stop cable into milling tool control box connection

Figure 5 · Connect the emergency stop cable to the electrical box of the machine

5.4. Gas source connection

Use a 6mm intake pipe to connect the intake end of the filter. The cooling air is

controlled by a solenoid valve. When the milling tool is powered on, the solenoid

valve opens automatically. The output interface is on the outside of the milling tool

control box, and the spindle cooling air is connected through this. (Note: The pipe

connected to the electric spindle is 4mm.)

Gas path:①→②→③→④→⑤→⑥ Figure 6 Air connection

6mm pipe④

6mm pipe①

4mm pipe⑤

6mm pipe②

6mm pipe③

4mm pipe⑥

Hangzhou IECHO Science & Technology Co., Ltd.

7

5.5. USB communication cable connection

Pass one end of the mini USB data cable through the wire hole of the milling

tool control box and connect it to the milling driver. Connect the USB plug of the data

cable to the USB port of the computer.

Figure 7 ·USB communication cable connection

6. Milling tool debugging

Note: The 0.04MPa clean air source must be connected before the spindle runs.

6.1. Driver initialization

The driver initialization is completed when the device is debugged first time in

the factory, and SycoDrive software must be installed before the operation.

(Https://www.sycotec.eu/en/about-sycotec/downloads2/)

======================================

USB 2.0 to mini

5P data cable

Hangzhou IECHO Science & Technology Co., Ltd.

8

(Figure. 8)

Start the SycoDrive software, as shown in Pic 9, a green light is displayed in the

lower left corner of the page, indicating that the drive is successfully connected to

the computer.

(Figure. 9)

Green

means

connected

System status display

Hangzhou IECHO Science & Technology Co., Ltd.

9

(1) In the Motor Parameter Sets column, set the spindle model according to Pic 10.

(Figure. 10)

The 450 milling spindle model is 4033-AC, and the maximum speed is set to

100000rpm. Click the [Load motor type] button on the page. The following prompt

pops up, indicating that the import was successful.

(Figure. 11)

(2) After setting the above parameters, click the [Save on inverter] button at the

bottom right corner of the main page.

(Figure. 12)

Hangzhou IECHO Science & Technology Co., Ltd.

10

The following prompt pops up, indicating that the save is successful.

(Figure. 13)

6.2. Spindle running-in

To start the milling tool for the first time, the spindle must be run-in. The spindle

manufacturer has done the initial run-in before the product leaves the factory.

However, if the spindle is out of service for a long time (more than 3 months), it must

be re-run-in before using it again.

Operation method:

Start the Sycodrive software, on the SPINDLE RUN-IN page, first set the spindle

model 4033-AC-100000rpm in the Spindle run-in control column, then select the

running-in method as Downtime>3 months, and click [START] to start running-in.

(Figure. 14)

Hangzhou IECHO Science & Technology Co., Ltd.

11

During the running-in process, you can view the progress bar to display the

running-in progress, as shown in the picture.

(Figure. 15)

Until the following window pops up, indicating that the running-in is complete.

(Figure. 16)

6.3. Communication settings between milling tool and computer

After the USB communication line is connected, WINDOWS will automatically

discover the hardware and automatically generate a serial port, as shown in the

picture, USB Serial Port (COM3) will appear in the device manager, and the serial port

number will be randomly generated.

Hangzhou IECHO Science & Technology Co., Ltd.

12

(Figure. 17)

Note: Normally, WINDOWS 7/10 system can automatically recognize

and install the driver. If the driver cannot be installed automatically,

you need to install the serial port driver manually, and the serial port

number will be generated after installation.

There is no need to set the serial port number when connecting the

milling tool, it can be automatically connected after startup. When using

the CutterServer software, the milling tool communication serial port

must be set first. Note: Sycodrive software and CutterServer software

cannot be connected at the same time. Before running one of them,

you need to close the other program.

Hangzhou IECHO Science & Technology Co., Ltd.

13

(Figure. 18)

6.4. Confirm spindle rotation direction

When first time using, please make sure whether the spindle direction is correct

(as shown in the figure). If it is not correct, please check if the cable connected

properly. The software can not change the rotation direction setting.

(Figure. 19)

7.The use of router

450W Router software version requirements:

DSP program version: DSP2.2.8-6A180903M and above

CutterServer software version: V4 (2019.9.4.511) and above

iBrightCut software version: V4 (2020.4.3.2373) and above

Router rotation direction

Hangzhou IECHO Science & Technology Co., Ltd.

14

Steps for usage:

(1) Preparation (including installing the blade, setting the spindle speed, cutting

speed and other parameters);

(2) Edit cutting data in iBrightcut software and send it to Cutterserver.

(3) Place the material, turn on the suction and fix it;

(4) Turn on the power of the vacuum cleaner and start cutting.

7.1. Power ON

When the knob switch is turned ON, the power of the router is turned on, and

the power indicator light is on.

(Figure. 20)

Note: when using emergency stop function, before turning on router power,

please turn on machine power firstly, otherwise the drive will report an error.

7.2. Cooling air pressure checking

Before starting the machine, please turn on the air source and check the air

pressure. The minimum air pressure required for router 0.04MPa. Too low or too

high air pressure will damage the spindle.

(Figure. 21)

Hangzhou IECHO Science & Technology Co., Ltd.

15

7.3. Blade installation

The 450W router is equipped with 3.5mm or 4mm blade collet, corresponding to the

blade ER1 or ER2 respectively. Please select it correctly when using it.

Blade installation steps:

(1) Place the blade collet into the spindle nut;

(2) Manually screw the blade collet and spindle nut onto the spindle (no need to

tighten);

(3) Insert the router blade into the blade collet (keep a distance of about 1mm

between the cutting edge and the collet);

(4) Use 8mm and 12mm wrenches to tighten the nuts.

(Figure. 22)

Note: Please follow the blade installation steps above. The wrong installation

sequence may cause damage to the collet.

7.4. Router parameter setting

In the Cutterserver software parameter table, the tool name is selected as

MILL450, the tool lifting angle is set to 180, and the rotating direction should not be

chosen.

Set appropriate cutting parameters: such as XY motion speed, knife drop speed,

motion acceleration, etc.

Hangzhou IECHO Science & Technology Co., Ltd.

16

(Figure. 23)

7.5. Communication serial port settings

With Cutterserver software, open [System Configuration]-[Serial Configuration]

to set the milling router serial port.

(Figure. 24)

7.6. Set knife depth

Select the milling router icon and click the manual tool setting icon to open the

manual tool setting window. Press the down arrow on the keyboard and the milling

router will start to fall. Stop when it is adjusted to the upper surface of the cutting

mat, click [OK] to complete the knife setting.

Hangzhou IECHO Science & Technology Co., Ltd.

17

(Figure. 25)

Note: The knife must be adjusted again after each blade change. Hold down

the Ctrl key of the computer keyboard during manual tool setting to speed up

the cutting speed

7.7. Set milling router speed

Drag the slider of [Milling Router Setting] up and down, the

speed will change in the range of 6000rpm-60000rpm.

8. Precautions for using spindle

The main shaft is self-closed and dustproof when working, and is permanently

lubricated. Any act of adding grease and using cleaning solvents will damage the

spindle.

The tapered surface of the chuck must be kept clean and free from scratches,

otherwise the accuracy of the tapered surface of the front end of the spindle

rotor will be changed, resulting in the inability to lock the tool, resulting in

failures such as tool drop or tool breakage. The chuck must be cleaned before

installing.

After the spindle is ventilated, the sealed state can be reached, and the sealing

air flow rate is 25L/min (the sealing air pressure must be strictly controlled at

Hangzhou IECHO Science & Technology Co., Ltd.

18

0.04MPa). Excessive air pressure can damage the grease or lubrication system of

the bearing. If the bearing loses lubrication, the bearing will be damaged under

the high-speed state of the spindle; if the air pressure is too small, the sealing

effect cannot be achieved.

The air source of the spindle must be filtered. Using an unqualified air source will

seriously damage the spindle stator coil and bearings, and affect the spindle life.

The main shaft cannot be hit by any kind of impact in any direction. After the

main shaft is hit, the dynamic balance will be destroyed, and even the bearing

will be damaged, affecting the service life of the main shaft.

Please use the matching professional tools for disassembly and assembly of the

chuck; if the bearing is damaged due to man-made reasons, no warranty

treatment will be done; if there is any problem with the spindle, please do not

disassemble and install it privately.

9. Daily maintenance of milling router

Check item

Check content

Require

Water

separator

1. Check the installation

2. Check the standing water

3. Check the air pressure

1. Must be installed vertically

2. Check whether the automatic

drainage is normal every day

3. Keep the normal pressure at

0.04Mpa

Milling router

body

1. Check whether the position

limiter is installed

2. Check the bottom of the

cutter body

3. Check the position of the

milling cutter chuck

1. The position limiter must be

installed before use

2. Clean the bottom with a brush

or wire every day

Residue

3. Frequently clean up debris

from the milling cutter chuck

Hangzhou IECHO Science & Technology Co., Ltd.

19

Router bit

1. Check whether the router is

installed correctly

2. Check for nicks or residues on

the router

1. When installing the bit, it is

necessary to leave a row groove

Bit exposed length = Bit flute

length + 1mm

2. If the bit is notched, please

replace the bit; if there is debris,

blow with an air gun or clean it

with a brush

Milling router

cable

Check whether the cable is

twisted

No wire entanglement

Suction line

1. Check whether the pipeline is

loose

2. Check whether the pipeline is

flattened

3. Check whether the pipeline is

blocked

4. Check whether the debris in

the vacuum cleaner bucket is

full

1. Confirm that the pipeline is

installed in place

2. Straighten out the pipeline, do

not flatten

3. Do not block, the blockage can

be taken out by shaking the

suction tube

4. Clean up in time when the

vacuum cleaner bucket is full

10. Milling router driver alarm and troubleshooting

10.1 The meaning of warning lights

Red

light(LED1)

Green

light(LED2)

Meaning

Remarks

OFF

OFF

No power

OFF

ON

Ready to work

OFF

Blink

Spindle work

Blink

On or Blink

Warning:the code is less than 6

(the number of flashes is the

code number)

Can continue to

use in warning

state

Table of contents

Other IECHO Wood Router manuals