IECHO 1.8KW Router User manual

1.8KW Router User Manual

1.8KW Router

User Manual

Hangzhou IECHO Science & Technology Co., Ltd.

1.8KW Router User Manual

1

Directory

1. Summary....................................................................................................................................1

2. Caution....................................................................................................................................... 1

3. Mandatory list for 1.8KW debugging.....................................................................................1

4. Inspection before test running................................................................................................1

4.1. Brush......................................................................................................... 1

4.2. Collet......................................................................................................... 1

4.3. Electric and air circuit............................................................................... 2

4.4. Check router cable.....................................................................................2

4.5. Check control cable...................................................................................2

4.6. Check air circuit........................................................................................ 2

4.7. Test run for 1.8kw spindle.........................................................................3

5. Parameter setting..................................................................................................................... 3

6. Manual change router bit (4041)........................................................................................... 6

7. Software setting........................................................................................................................ 6

7.1. Extension parameter..................................................................................6

7.2. Button........................................................................................................6

8. Manual change router bit (4040)........................................................................................... 7

9. Router bit library shifting correction.......................................................................................7

9.1. Component................................................................................................ 7

9.2. Stick & paper to correction router bit library offset................................10

9.3. Read left coordinate of positioning slot A...............................................10

9.4. Read right coordinate of positioning slot A............................................ 10

9.5. Read front coordinate of positioning slot A............................................ 11

9.6. Read back coordinate of positioning slot A.............................................11

9.7. Read coordinate positioning slot B......................................................... 11

9.8. Transfer value from positioning slot to hole........................................... 12

9.9. Positioning hole A/B correction.............................................................. 12

10. Auto change bit test........................................................................................................... 13

Cutterserver setting........................................................................................................................13

10.1. Speed selection........................................................................................13

10.2. Router bit library initialization................................................................13

11. Automatic adjust depth, router bit and pen coincide setting.......................................15

11.1. Reading the coordinates of the initialization point................................. 15

11.2. Router bit and pen coincide.....................................................................16

12. Automatic Tool Changer....................................................................................................17

13. Dust cleaner........................................................................................................................ 18

13.1. Dust cleaner and Router linkage............................................................. 18

13.2. Dust cleaner operation test...................................................................... 19

13.3. Others...................................................................................................... 19

14. Software............................................................................................................................... 20

14.1. Material library........................................................................................20

14.2. Material................................................................................................... 20

1.8KW Router User Manual

2

14.3. Solution................................................................................................... 21

15. IBrightCut............................................................................................................................ 22

16. Export cutting file................................................................................................................26

17. Blade.....................................................................................................................................26

18. Troubleshooting.................................................................................................................. 27

18.1. Emergency stop....................................................................................... 27

18.2. Router cannot be started..........................................................................27

18.3. Router cannot start.................................................................................. 27

18.4. Software serial port in dark status...........................................................27

18.5. The tool library cover is not smooth....................................................... 28

18.6. Blade fall in the tool library.................................................................... 28

19. Software Update.................................................................................................................28

19.1. Serial port connection............................................................................. 28

19.2. Interface configuration............................................................................ 28

Statement....................................................................................................................................... 29

1.8KW Router User Manual

1

1. Summary

This instruction is for R&D testers, factory testers, and engineer. The main

content is 1.8KW milling cutter automatic router bit changer debugging

instructions

2. Caution

Press E-stop button when a security risk appeared.

3. Mandatory list for 1.8KW debugging

Model

List

1

1.8KW router

2

Router bit library

3

TK3S AKI

4

DSP version:2.2.8-6A180903M

5

CutterServer version:V4 - 2019.9.4.51

6

IBrightCut version:V3 - 2019.9.10.194

7

D 9+10mm Stick for initialization

8

9 router bit with rings

9

Test file and configuration.

4. Inspection before test running

4.1. Brush

No brush on spindle when test run.

4.2. Collet

There must be router bit or stick on spindle, run spindle without stick or router

bit is not allowed.

1.8KW Router User Manual

2

4.3.Electric and air circuit

Make sure correct router cable, control cable, air tube connect before test run.

Water cooler: Circulate cooling water inside 1.8kw through inlet and outlet

pipes

4.4.Check router cable

Check router power, controller,( shown in image 1)

(image 1)

4.5.Check control cable

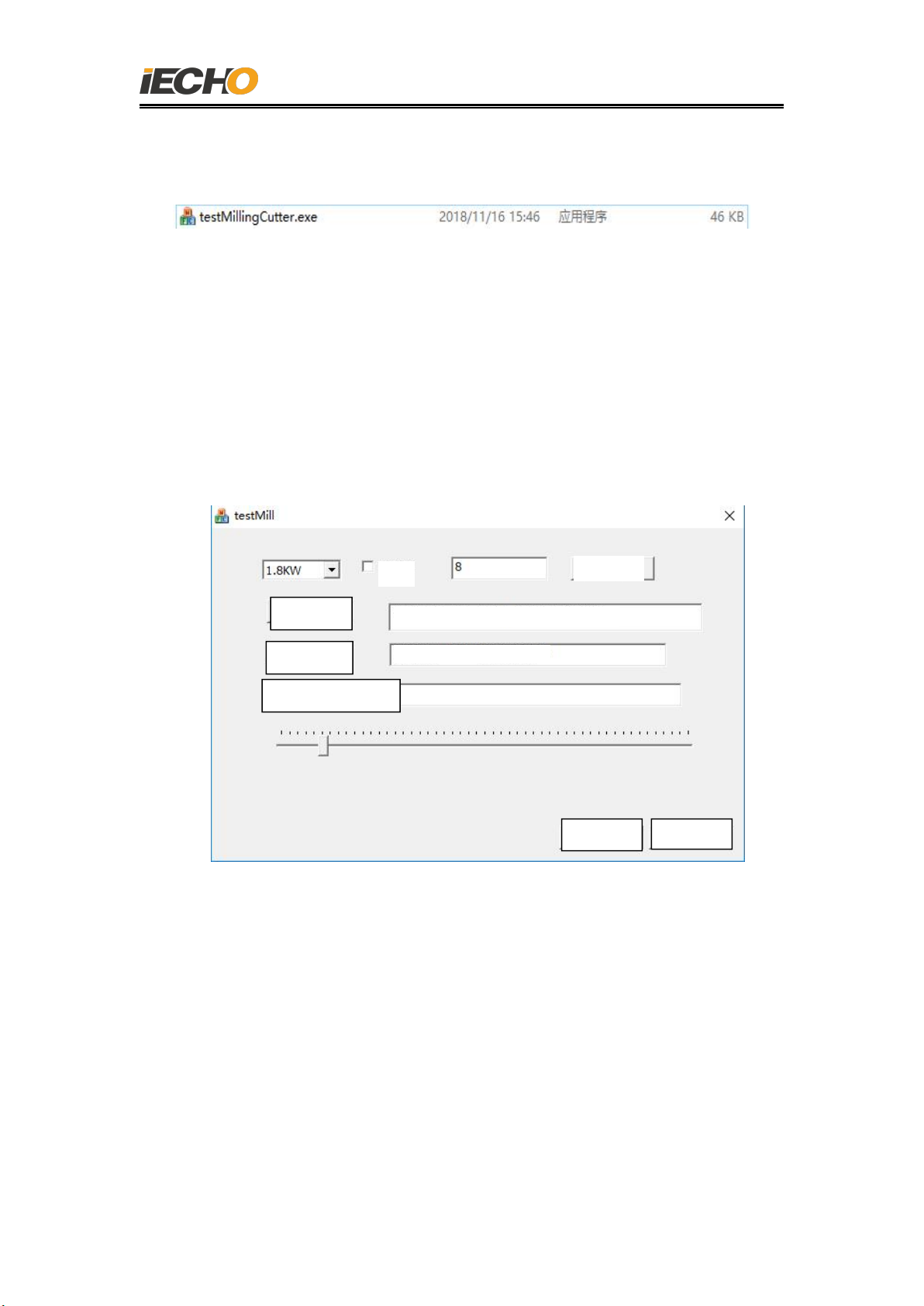

Run testmillingcutter.exe, click START button. Control cable is good if spindle

running, if not, check the connectors.

4.6.Check air circuit.

Main air pressure: 0.8Mpa.

Air pressure for spindle collet: 0.8Mpa

Air pressure for Router bit library: 0.6Mpa

Air pressure for cooling: 0.1Mpa

1.8KW Router User Manual

3

4.7.Test run for 1.8kw spindle.

Run testmillingcutter.exe, (shown in Image 2)

(Image 2)

Parameter setting for software

1. Choose 1.8kw router and select correct serial port.

2. Set the parameter in testmill page, click ON button, spindle run; click

OFF button, spindle closed, set the rotation speed in software, then

spindle rotation speed changed accordingly. (shown in image 3)

3. Do not stop during test run, click Close button to finish test run.

(image 3)

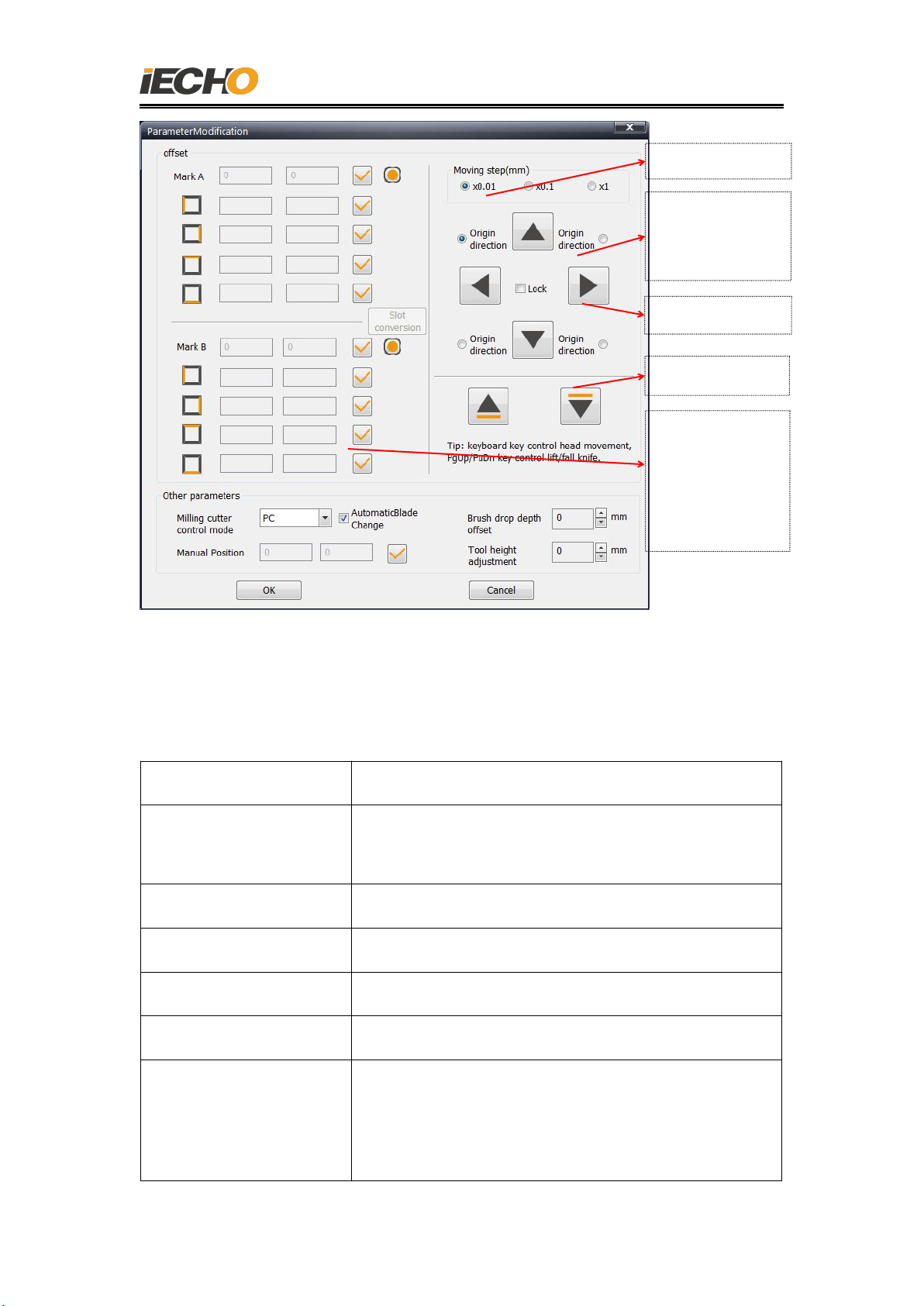

5. Parameter setting

Find extension parameter in Cutterserver (shown in image4)

Start

Close

MILL speed

Sure

Cancel

1.8KW Router User Manual

4

(image 4)

1. IO Function Redefine: define the function of buttons on table.

Change the knife(4 steps: 1. Brush rise; 2. Loose the bit;3. Install router bit;

4. Finish, Brush down)

2. The IO function redefines 1: define the function of buttons on table.

Material thickness detection: After define this function, brush will detect

material thickness once when press the button on table.

3. 2 AKI mode: TK model must be set 2 AKI model(2+2 model), BK model

should be set 2 AKI model (1+1model)

4. Enable tool changing speed: Control cleaning, speed during tool change.

Tick it means select working speed, use for normal running speed.

Untick it means select testing speed, use for testing, all speed is much

lower than working speed.

5. Turn on automatic tool change: Confirm if this model have automatic tool

change or not( select accordingly), after turn on automatic tool change function,

1.8KW Router User Manual

5

machine will go AKI automatically after initialization( Current cutting head no

allowed to be empty)

6. Brush down again depth: this configuration control brush down depth when

cutting, it will affect cutting, dust collection a lot. (The configuration could be

modify by cutter material thickness detect -B MTD)

7. Fine-tune height of brush when cleaning cover: control brush down

compensation when cleaning the cover.

8. Milling blade control way: 1.8KW router use PC, 350W router use C board.

9. Change tool way: 4041 (auto change)/4040(manual change)/4064 (3.6KW

router.)

1kw router/1.8kw router/3.6kw router

For change the router bit, correction shifting.

4040 (Manual change)

make manual change, material thickness detect

3060 (350w): No icon shown.

10. Brush re-depth: After the material thickness is detected, the height of the

brush is compensated (range 0-12.7mm).

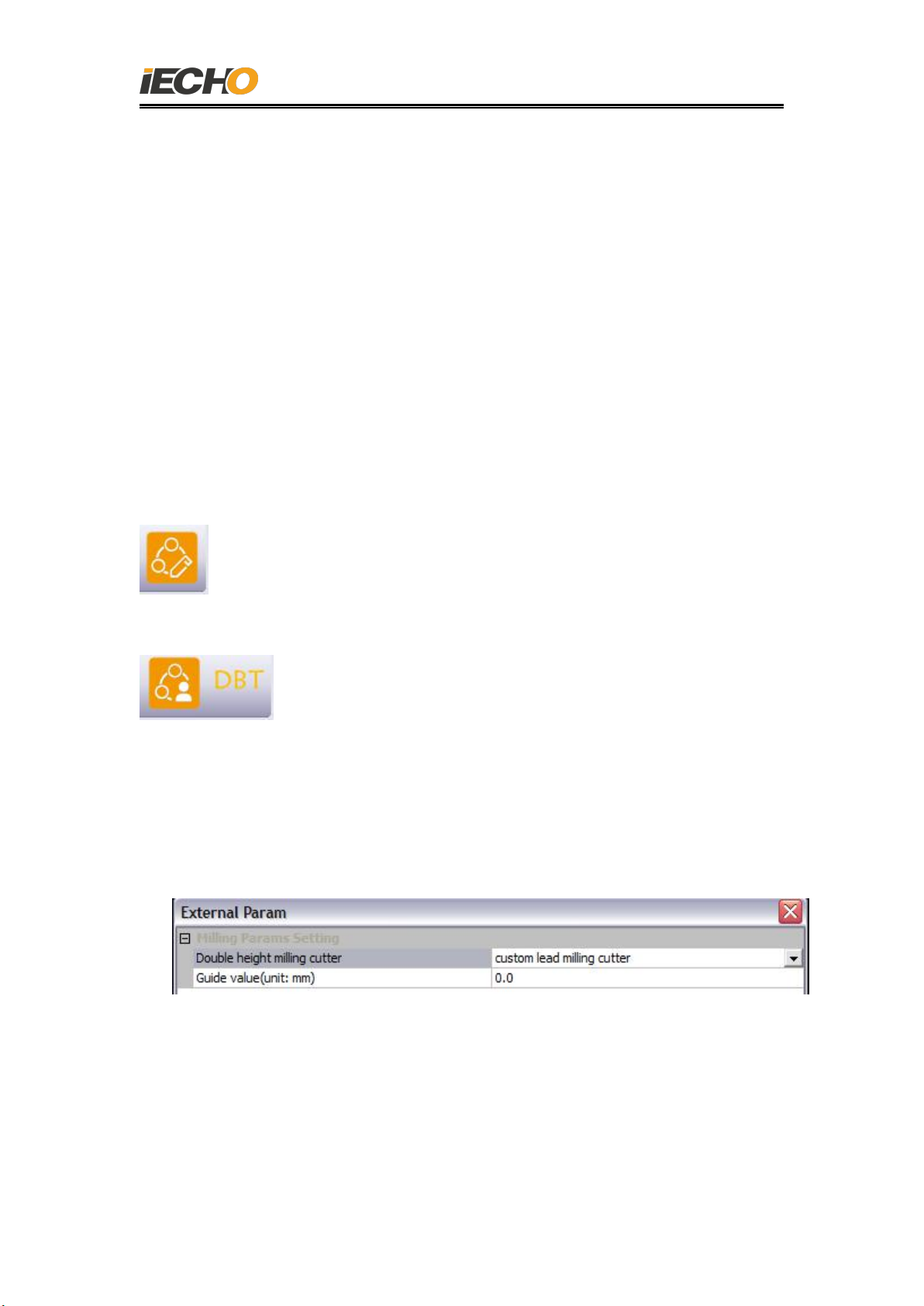

External parameter settings (Image 5)

(image 5)

1.8KW Router User Manual

6

6. Manual change router bit (4041)

Move the tool head to manual change position (Shown in image 6):

(image 6)

7. Software setting

7.1.Extension parameter

Modify as follow

Caution: Make sure current head is milling head before manual change.

(image 7)

7.2.Button

TC SLC

Press TC SLC button on table, S: Start;L: Loose; C: Clamp

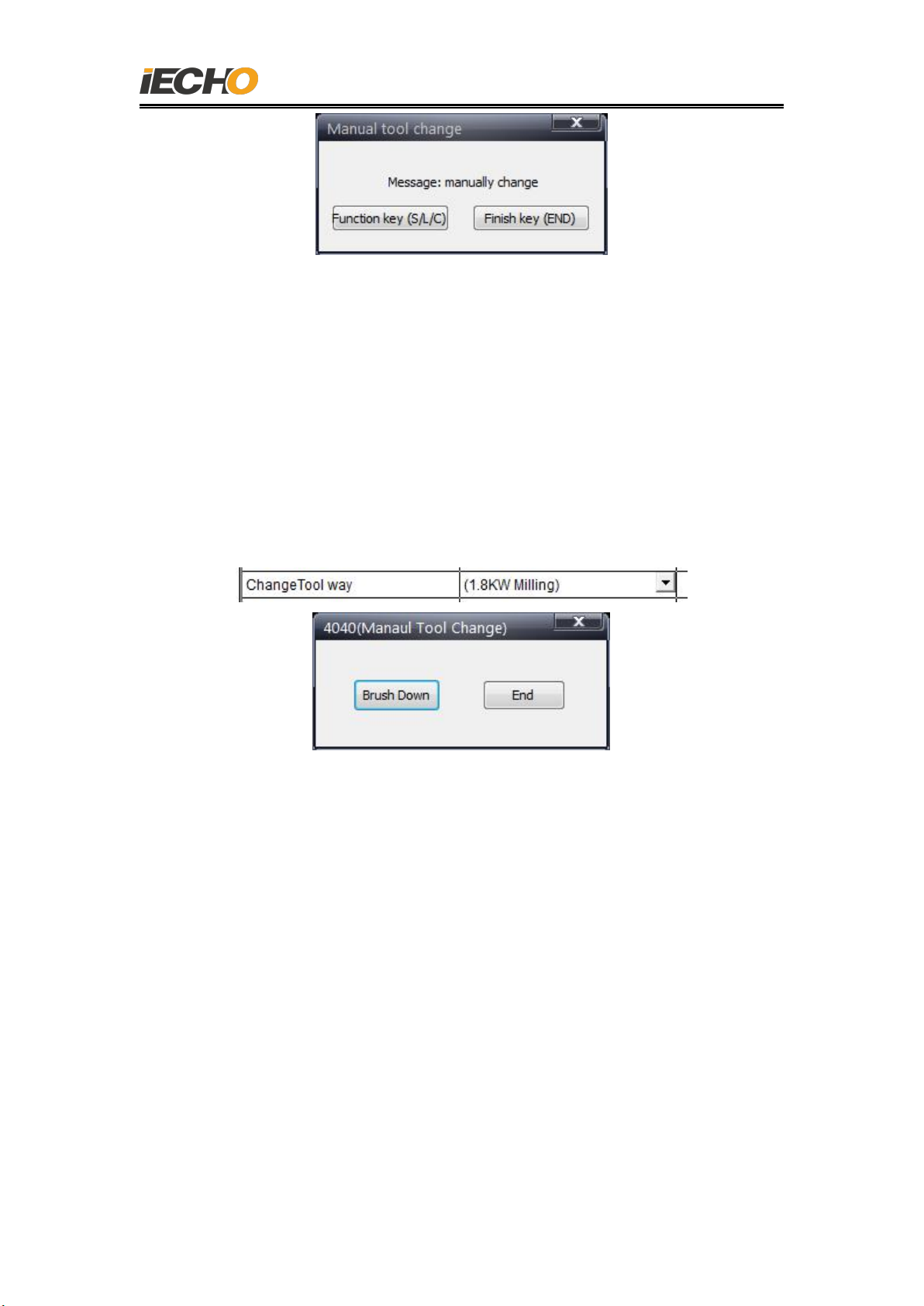

1. One press, brush down, manual change page pop-up in

cutterserver(shown in image 8).

Remark: The button here have same function as button on table.

2. Two press: The collet loose, take router bit out.

3. Three press: Change router bit, push to bottom, release when clamp.

Click END in cutterserver page after change bit, then brush move on.

Button for manual change:

TC S/L/C

Manual change: Take off the router bit

and change another one.

1.8KW Router User Manual

7

(image 8)

8. Manual change router bit (4040)

Set parameter: modify extension parameter

Click manual change ICON, the following window pop-up.

1. Click【Down brush】, the brush will go down, use wrench to disassembly the

bit.

2. Click END in cutterserver page after change bit, then brush move on.

Caution: DO NOT use software during manual change router bit.

(image 9)

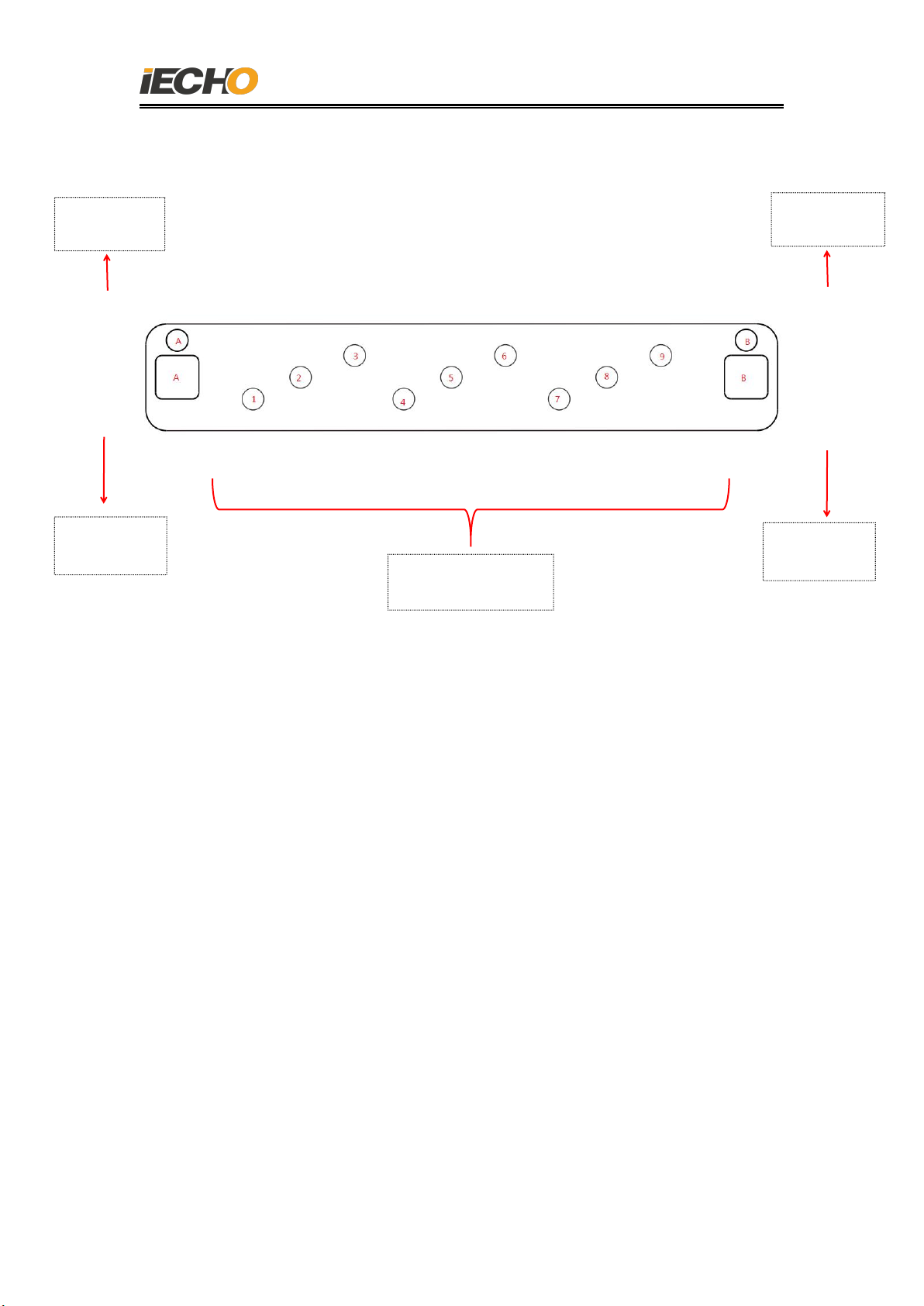

9. Router bit library shifting correction

9.1.Component

Router bit distribution as follow:

1.8KW Router User Manual

8

(Image 10)

CutterServer Auto changer bit page, select shifting correction(router bit library

will open automatically).

9 bit position

Positionin

g Slot A

Positionin

g Slot B

Positioning

hole A

Positioning

hole B

1.8KW Router User Manual

9

(Image 11)

Function parameters

Meaning

Positioning hole A,

positioning hole B

Coordinate of current saved positioning hole on

table.

Movement step

distance

Tool head movement distance each click.

Coordinate direction

Relationship between movement button and tools

movement.

Router control method

1.8KW router must select”PC control”

Start auto change

Select for current model if with auto changing.

Position for manual

change

If user find the bit not in router bit library when

cutting, move to this position and do manual

change

offset correction

coordinate:

1. left

2. right

3. up

down 边

Up and down

move step distance

Front, back, left, right

Select original position

according to direction of

pc desk and machine

1.8KW Router User Manual

10

Brush down

compensation

After the brush detect material thickness, it will

make down compensation (range 0-12.7mm)

Router bit change

fine-tune

Spindle down compensation when change router

bit (to make extra 2mm down)

9.2.Stick & paper to correction router bit library offset

Preparation

1. Put stick on spindle

2. Cut some 10*40CM paper sheet.

9.3.Read left coordinate of positioning slot A

Set stick to the central position of slot, make sure it fully touch with each side of

slot except bottom side.

Select step distance “x 1mm”, move the stick approach to left side of slot;

change to step distance”x0.1mm”, put paper between stick and left side of slot,

keep moving stick till paper can’t move up and down, then back 0.1mm,

change to step distance”x0.01mm”, keep moving when paper can’t be move

up and down, read the coordinate.

Read the coordinate and click

9.4. Read right coordinate of positioning slot A

Set stick to the central position of slot, make sure it fully touch with each

side of slot except bottom side.

Select step distance “x 1mm”, move the stick approach to right side of slot;

change to step distance”x0.1mm”, put paper between stick and right side of

slot, keep moving stick till paper can’t move up and down, then back 0.1mm,

change to step distance”x0.01mm”, keep moving when paper can’t be move

up and down, read the coordinate.

1.8KW Router User Manual

11

Read the coordinate and click

9.5. Read front coordinate of positioning slot A

Set stick to the central position of slot, make sure it fully touch with each

side of slot except bottom side.

Select step distance “x 1mm”, move the stick approach to front side of slot;

change to step distance”x0.1mm”, put paper between stick and front side of

slot, keep moving stick till paper can’t move up and down, then back 0.1mm,

change to step distance”x0.01mm”, keep moving when paper can’t be move

up and down, read the coordinate.

Read the coordinate and click

9.6. Read back coordinate of positioning slot A

Set stick to the central position of slot, make sure it fully touches with each side of slot

except bottom side.

Select step distance “x 1mm”, move the stick approach to back side of slot; change to

step distance”x0.1mm”, put paper between stick and back side of slot, keep moving stick

till paper can’t move up and down, then back 0.1mm, change to step distance”x0.01mm”,

keep moving when paper can’t be move up and down, read the coordinate.

Read the coordinate and click

9.7.Read coordinate positioning slot B

After read coordinate of four side, click “W”to lift the stick to top, move tool

head to positioning B slot, read coordinate of four side with same way, lift the

stick to the top(shown in image 12)

1.8KW Router User Manual

12

(image 12)

9.8.Transfer value from positioning slot to hole.

After read coordinate of 8 side of two slot, click OK, the software will

calculator and transfer value from positioning slot to hole, click OK save to

DSP.

9.9.Positioning hole A/B correction

Open offset correction page again, click the ICON behind of positioning hole A,

tool head will move to the top of positioning hole A and down slowly, check if

the 10mm stick could fit the hole completely, if yes, lift the tool head and

correct positioning hole B offset. After correct offset of AB coordinate then do

auto change test. (If any offset during correction, need to correct A and B slot

coordinate or fine-tune hole coordinate)

1.8KW Router User Manual

13

10.Auto change bit test.

Cutterserver setting

10.1. Speed selection

There are two speed in auto change setting, normal running speed and

test speed; untick working speed in extension parameter, then it will be test

speed.

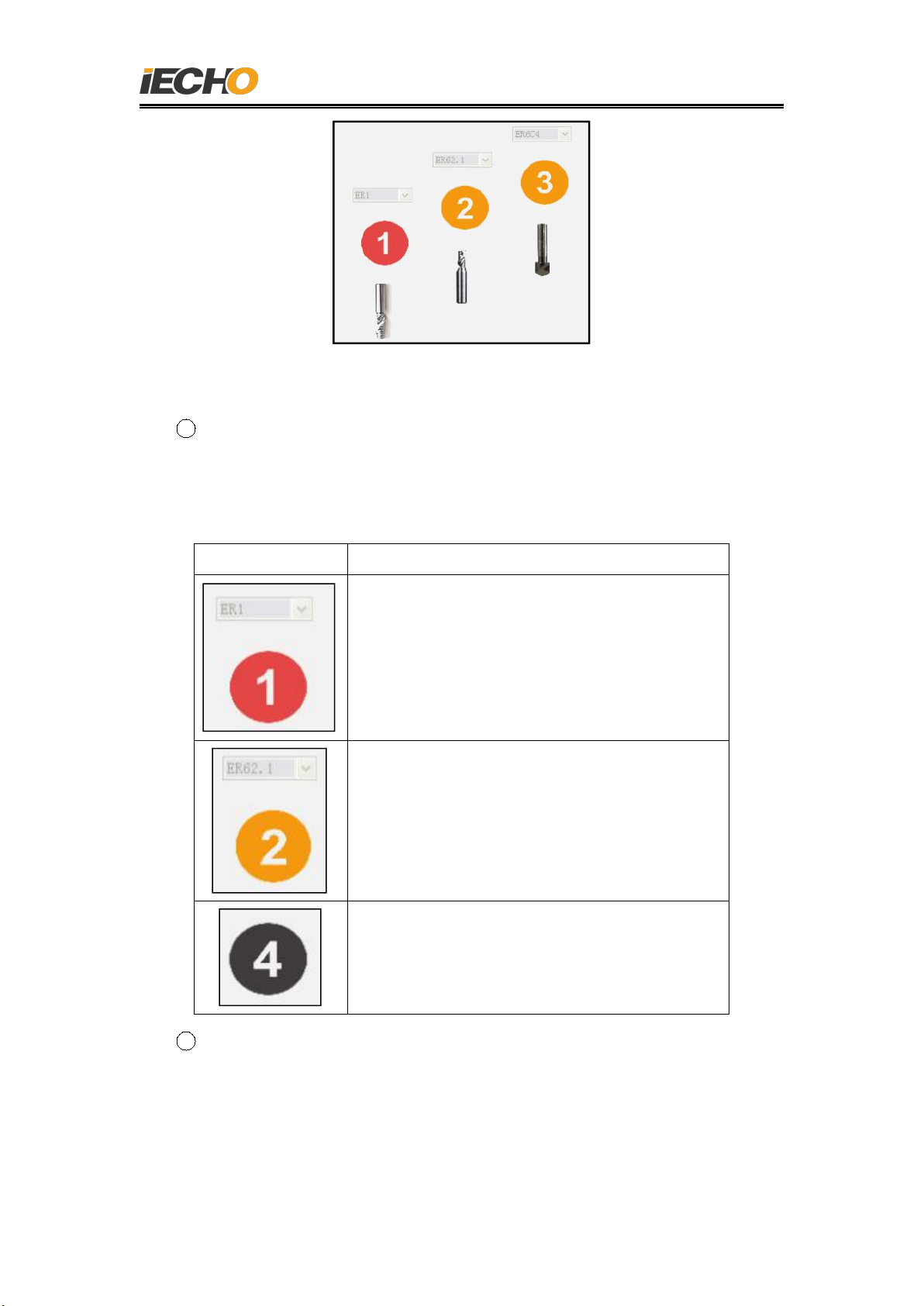

10.2. Router bit library initialization.

1. Select router head and click CT ICON, select modify router bit page

(router bit library will open)

2. Put router bit into library, select right bit number in software with

accordingly.

(image 13)

2Other operation

1.8KW Router User Manual

14

(image 14)

3Instruction for image in library

Image

Meaning

Means no.1 holder is current holder, and

ER1 blade on current holder, new router bit

not allowed to put on this holder.

Means No.2 holder is not empty, with router

bit ER62.1

Means No.4 holder is empty and could set

any router bit.

4Click SAVE after configure finished, click OK to finish router bit library

initialization after make sure all configuration correct.

1.8KW Router User Manual

15

(image 15)

11. Automatic adjust depth, router bit and pen coincide

setting.

11.1. Reading the coordinates of the initialization point

1. Select router head, open CT to offset correction page.

2. Move tool head to AKI position, and down router bit to confirm.

3. Write down current coordinate (X,Y), then quit CT page.

4. Choose system configuration-AKI-first AKI point, move router head to

(X, Y) position.

5. After click SAVE, use AKI testing, start adjust the cutting depth after

confirm the position.(Tick”Check sensor before adjustment “when first

adjustment) . Use finger to shade the AKI back and forth after tick it.

1.8KW Router User Manual

16

(image 16)

(image 17)

11.2. Router bit and pen coincide

1. Use chamfering bit when test coincide of router bit and pen.

2. Open coincide test file(shown in image 18)

3. Output the file and cut, modify the offset parameter to correct

position(shown in image 19).

Remarks: Do not modify router head offset because it will affect the AKI

position, router change position etc.)

1.8KW Router User Manual

17

(image 18)

(image 19)

12.Automatic Tool Changer

Send file, click the start button, perform automatic tool change, observe

whether each milling cutter blade is changing normally. If it is dangerous, press

the emergency stop button immediately.

Testing method:

Open the test data in IBrightCut, including 9 blade automatic tool change data,

use manual to start cutting, such as (image 20):

Table of contents

Other IECHO Wood Router manuals

Popular Wood Router manuals by other brands

Mafell

Mafell LO 65 Ec Translation of the original operating instructions

Festool

Festool Plunge Router I instruction manual

Far Tools

Far Tools ER 700 manual

Scheppach

Scheppach WRT1200 Translation of original instruction manual

Westfalia

Westfalia WOF 1600 Original instructions

EINHELL

EINHELL TC-RO 850 Original operating instructions