IEMAI HIGH-TEMPERATURE Series User manual

Print More Materials, All For Application

HIGH-TEMPERATURE SERIES

3D PRINTER

MAGIC-HT-MAX

Operating Instructions

www.iemai3d.com

* Please read this manual carefully before starting to operate.

This device is a Class A product. Use in a general indoor environment

may cause radio interference and therefore requires the user to take

appropriate protective measures.

Print More Materials, All For Application

- 3 -

Content

1. Overview.........................................................................................................................................................................................- 4 -

1.1 Printer Overview............................................................................................................................................................... - 4 -

1.2 Precautions.........................................................................................................................................................................- 5 -

1.3 Safety....................................................................................................................................................................................- 6 -

2. Detailed Parameter.....................................................................................................................................................................- 7 -

2.1 Specification.......................................................................................................................................................................- 7 -

2.2 Device Layout.................................................................................................................................................................... - 9 -

2.3 Interactive Interface.......................................................................................................................................................- 13 -

2.3.1 System Interface.................................................................................................................................................- 14 -

2.3.2 Tool Interface......................................................................................................................................................- 15 -

2.3.3 Print Interface..................................................................................................................................................... - 16 -

3. Device Usage..............................................................................................................................................................................- 17 -

3.1 Unpacking........................................................................................................................................................................ - 17 -

3.2 Check Equipment Motion........................................................................................................................................... - 18 -

4. Print Operation.......................................................................................................................................................................... - 19 -

4.1 Install Print Platform And Leveling...........................................................................................................................- 19 -

4.1.1 Use Auto Leveling To Print.............................................................................................................................- 20 -

4.1.2 Use Mechanical and electronic limit to Print............................................................................................- 23 -

4.2 Load/Unload Filament..................................................................................................................................................- 24 -

4.3 Start Printing....................................................................................................................................................................- 26 -

4.4 Disassembly Model....................................................................................................................................................... - 27 -

4.5 PEEK Material Printing Precautions..........................................................................................................................- 27 -

4.6 PC-Based WIFI LAN control....................................................................................................................................... - 28 -

5. Function Introduction.............................................................................................................................................................. - 29 -

5.1 Power Failure Recovery................................................................................................................................................- 29 -

5.2 Filament Absent Warning............................................................................................................................................- 29 -

5.3 Chamber Temperature Setting..................................................................................................................................- 30 -

5.4 Moisture Proof Cabinet Setting.................................................................................................................................- 31 -

6. Maintenance and Care............................................................................................................................................................- 32 -

6.1 Maintenance of Linear Guide and Ball Screw.......................................................................................................- 32 -

6.2 Dust Removal from Electrical Box Fans.................................................................................................................. - 33 -

6.3 Nozzle Maintenance..................................................................................................................................................... - 34 -

6.4 Height Adjustment for Dual Nozzle........................................................................................................................ - 35 -

6.5 Dual Nozzle Spacing Adjustment Method............................................................................................................- 36 -

6.6 Print Head Disassembly............................................................................................................................................... - 37 -

7. Common Problems and Their Solutions........................................................................................................................... - 38 -

7.1 Movement........................................................................................................................................................................- 38 -

7.2 Temperature....................................................................................................................................................................- 38 -

7.3 Print.................................................................................................................................................................................... - 39 -

7.4 Clean Up Carbon Blockage.........................................................................................................................................- 40 -

Appendix A:..................................................................................................................................................................................- 41 -

Appendix B:..................................................................................................................................................................................- 42 -

Print More Materials, All For Application

- 4 -

1. Overview

1.1 Printer Overview

IEMAI high-performance material 3D printer, the Magic-HT-MAX, is a 3D printing equipment

based on the principle of fused filament fabrication (FFF) technology. It has a printing temperature of

up to 500℃, a hot bed temperature of 200℃, and a chamber temperature of 150℃, which supports

most polymer 3D printing materials in the market, including PEEK, PEKK, PPSU, PEI 1010/9085 and

other high performance materials, nylon, PC, ABS, PETG, ASA, TPU, PLA and other general engineering

materials, and composite reinforcement materials of the above materials (carbon fiber, glass fiber,

flame retardant, anti-static, etc.).

The MAGIC-HT-MAX comes with individual lifting dual print head that supports the printing of

support materials, including water-soluble PVA, limonene soluble HIPS, easy remove support

materials and high temperature resistant support materials. We use a modular design, for example,

the print head and the platform can be quickly disassembled, thus creating conditions for easy

maintenance.

Print More Materials, All For Application

- 5 -

1.2 Precautions

First of all, thank you for choosing IEMAI 3D Printer!

This device is a Professional equipment, please read this manual carefully before starting to use,

this manual contains important information about the installation, operation, maintenance, and

common problems of the 3D printer, the company is not responsible for all losses caused by violation

of the cautions and operating procedures given in this manual。

Consumables: Please use the filament provided by our company or the third-party filament of

official authorized brand or choose the high-quality filament provided by other regular filament

manufacturers, and users should be responsible for the loss caused by using low-quality filament.

Please keep the consumables sealed and moisture-proof if not in use for a long time; please bake and

dry them in advance before using them again.

Software: Please use a 64-bit system with Windows 7 or above to run the software, more than

4G of RAM and more than 1G of GPU, please use a computer with a higher configuration if possible.

Installation Site Requirements: Installation Site≥2010*2300*2700mm (L*W*H)。

Installation Power Requirements:200~250 V, 50~60 Hz, 6500w,Electric cable 6 m2or more.

Operating Environment: 15-30°C, 10-85% Relative Humidity, non-condensation

Storage Environment: 25-55°C, 10-85% Relative Humidity, non-condensation

Print More Materials, All For Application

- 6 -

1.3 Safety

The device has a specialized motion structure, control system and electrical control parts, users

need to pay careful attention to the safety label when using it to prevent burns, pinching, electric

shock or other safety problems.

The maximum temperature of the print head of this equipment can reach 500 °

C, its heating is strictly prohibited to touch

The maximum temperature of the printing platform of this equipment can reach

200°C, its heating is strictly prohibited to touch

The maximum temperature of the chamber of this equipment can reach 150°C,

and it is strictly forbidden to touch it when it is heated.

Ensure that the power supply grounding terminal is well grounded to prevent the

printer from not working properly or posing a risk of electric shock

Do not disassemble the case without permission, be careful of electric shock

When the printer is working, it is forbidden to move in the printing area to

prevent collision, belt turning in, etc.

Print More Materials, All For Application

- 7 -

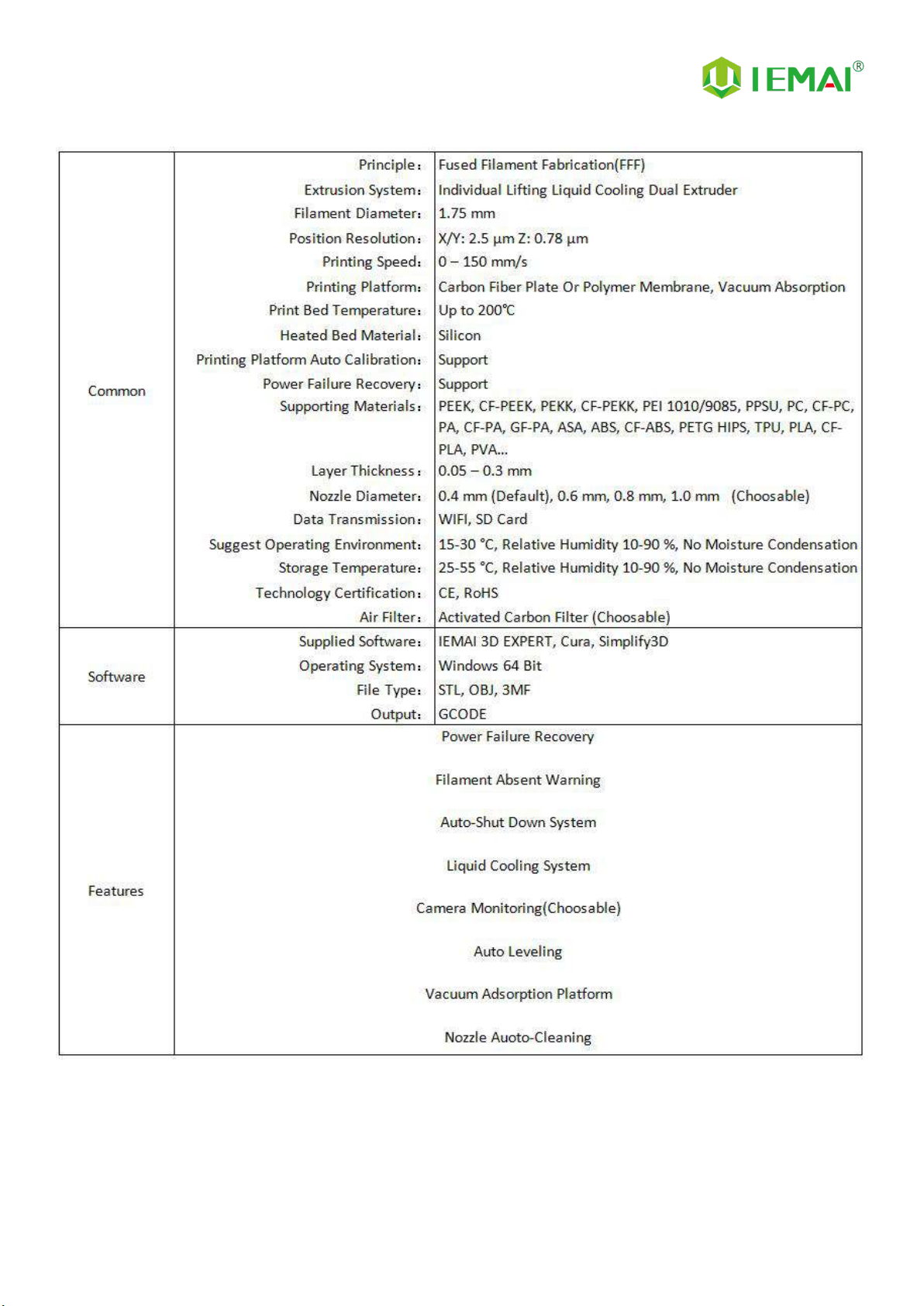

2. Detailed Parameter

2.1 Specification

Print More Materials, All For Application

- 8 -

Print More Materials, All For Application

- 9 -

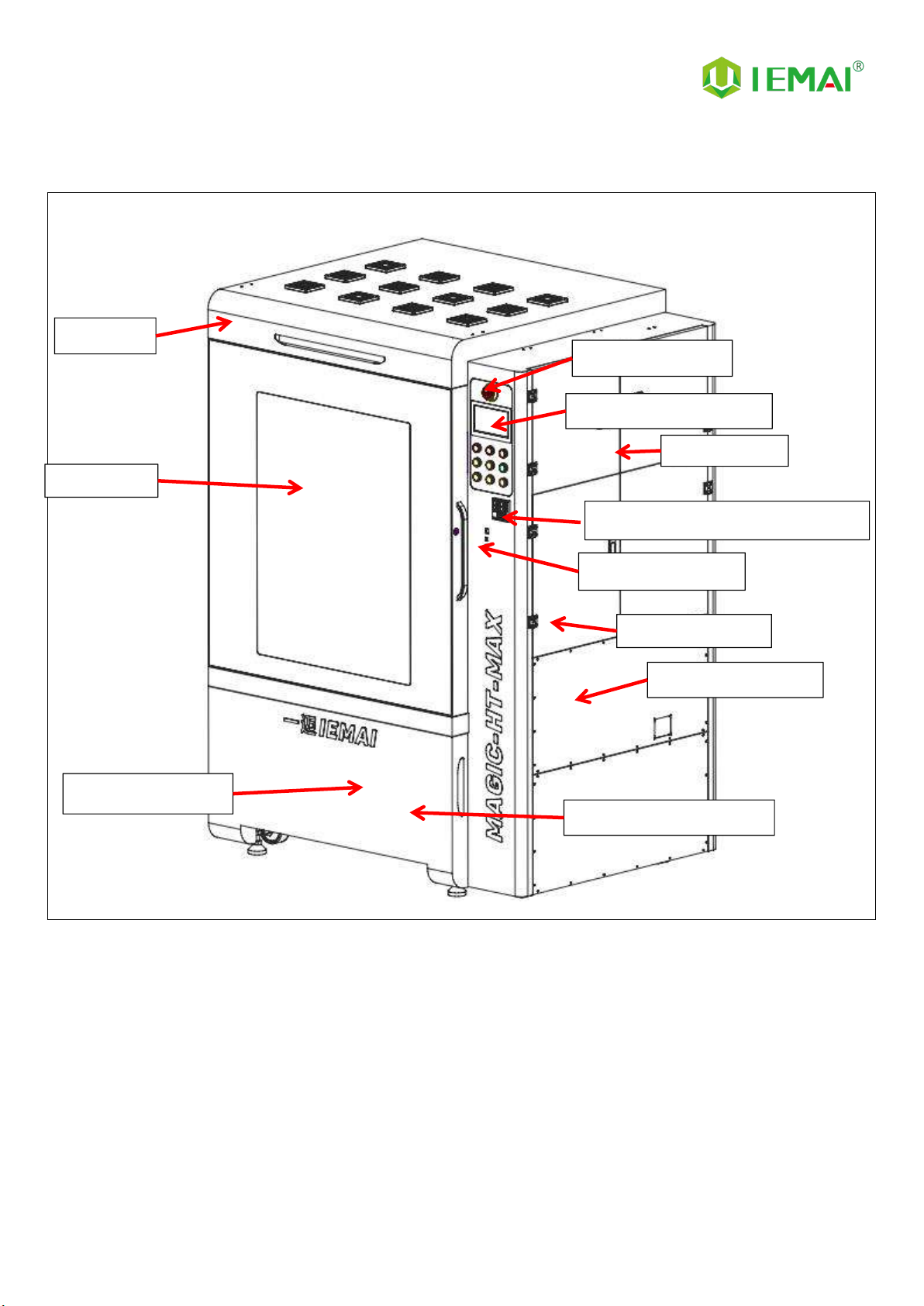

2.2 Device Layout

Filament Box

Emergency Stop

7-Inch Touch Screen

Chamber Temperature Controller

Main Electric Box

Date Transfer Area

Vacuum Pump Box

Moisture-Proof Storage

Material Box Door

Front Door

Top Cover

Print More Materials, All For Application

- 10 -

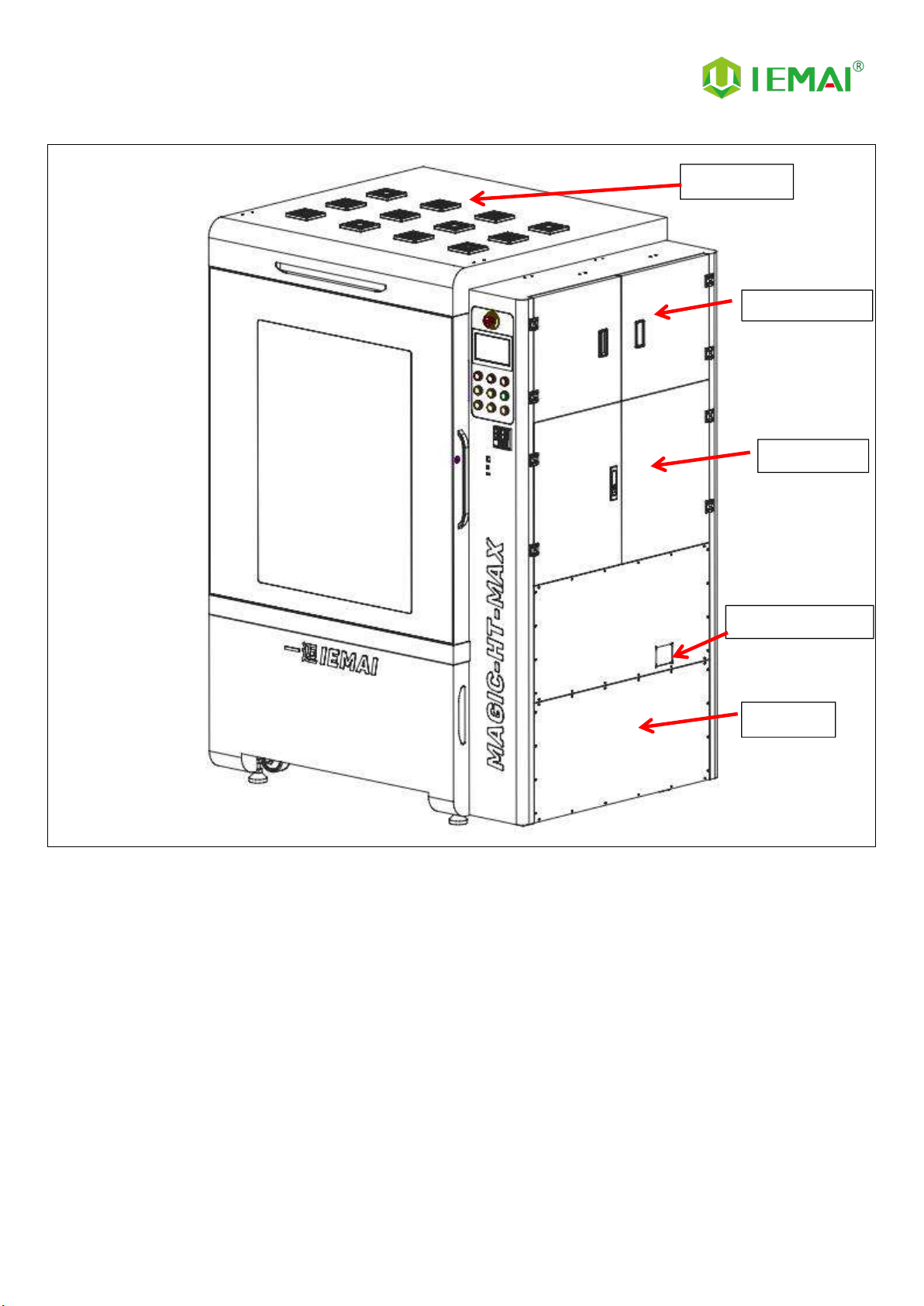

Internal Chamber

Print More Materials, All For Application

- 11 -

Filament Box

Electric Box

Pressure Gauge

Air Pump

Cooling Fan

Print More Materials, All For Application

- 12 -

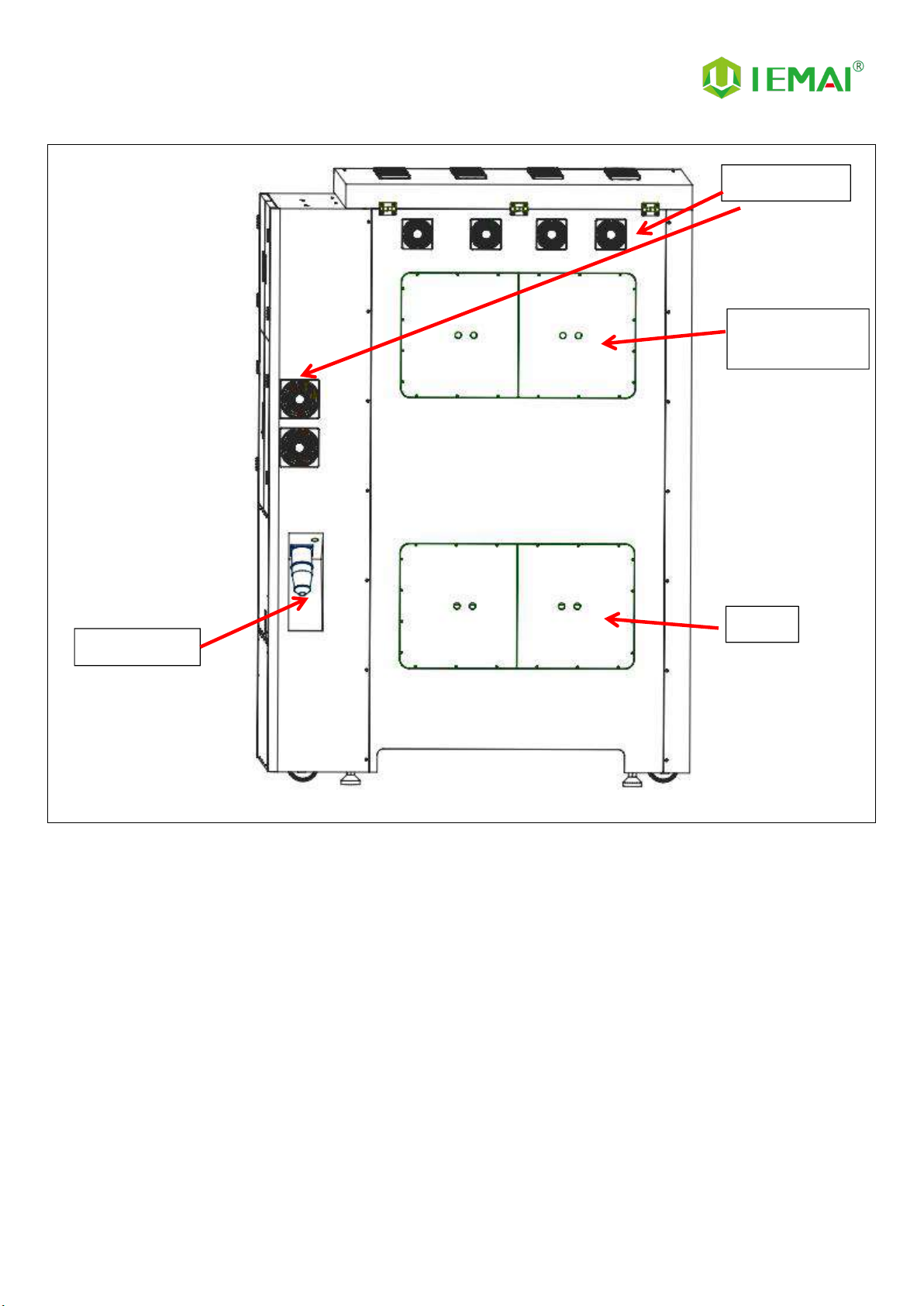

Cooling Fan

Built-In Light

Built-In Camera

Motor

Power Outlet

Print More Materials, All For Application

- 13 -

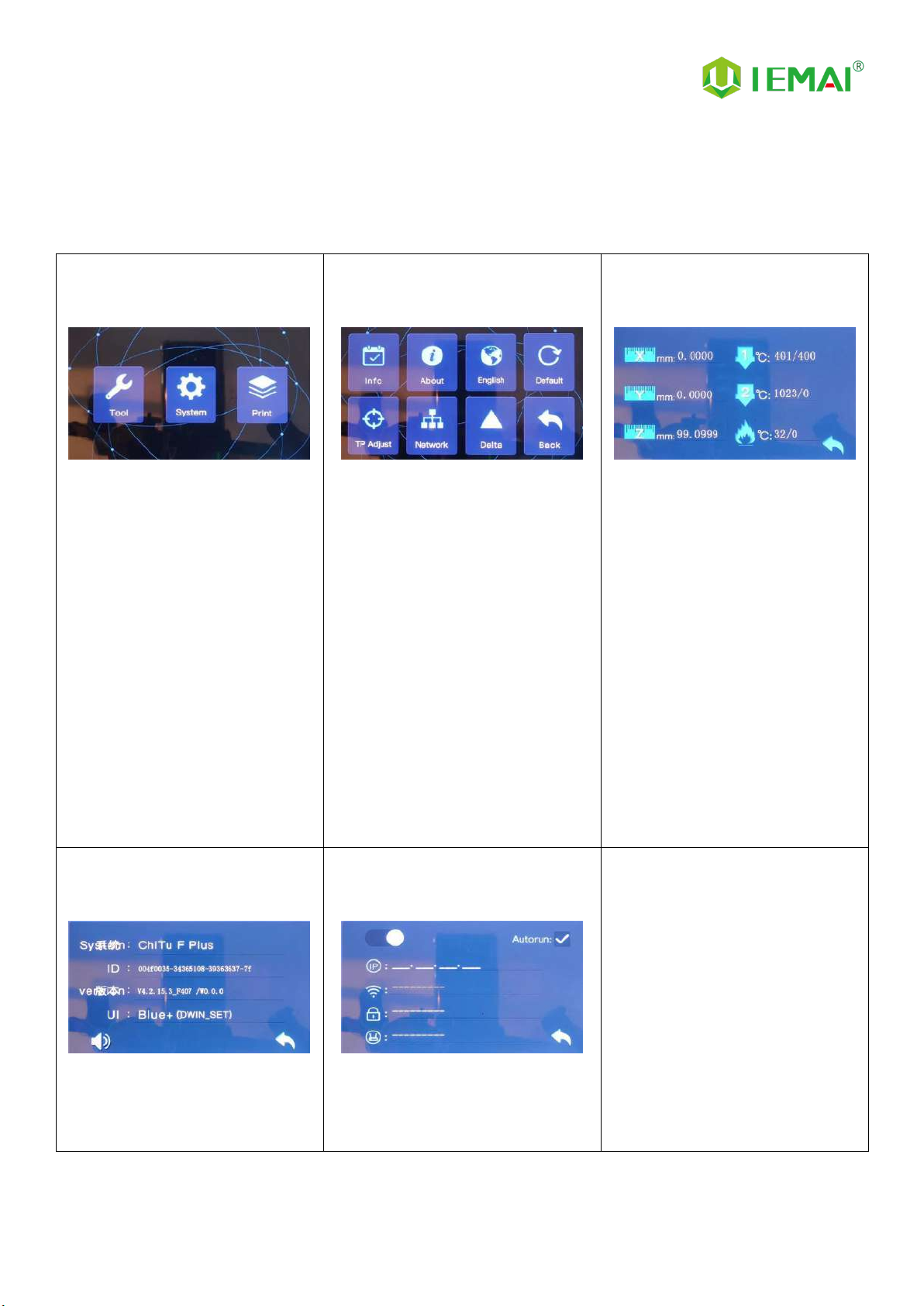

2.3 Interactive Interface

The interactive interface of the device adopts a 7-inch Chinese-English color touch

screen (resistive). Please read the following interface instructions carefully before first

use.

Logic diagram of interactive interface

Print More Materials, All For Application

- 14 -

2.3.1 System Interface

Figure 1: Main interface

Click "System" to go to Figure 2

Figure 2: System interface

1. Click "Info" to go to Figure 3

2. Click "About" to go to Figure

4

3. Click "English" to switch to other

Language

4. Click "Default" to restore the

original factory settings

5. Tap TPAAdjustment to correct

the touch offset

6. Click "WIFI" to go to Figure 5

Figure 3: Info interface

1. This interface allows you to

view the current coordinates of

the XYZ axis

2. The current temperature of the

left nozzle, and right nozzle,

and hot bed

Figure 4: About interface

This interface allows you to view the

name, ID, system version, UI

version, and Power On/Off sounds

Figure 5: WiFi Setup Interface

This interface allows you to view

information about Wi-Fi

Print More Materials, All For Application

- 15 -

2.3.2 Tool Interface

Figure 1: Main interface

Click "Tool" to go to Figure 2

Figure 2: Tool Interface

1. Click "Manual" to go to Figure 3

2. Click "Preheat" to go to Figure 4

3. Click "Filament” to go to Figure 5

4. Click "Level" to perform

automatic leveling

5. Click "Fan" to go to Figure 6

6. Click "Stop" to stop all execution

commands

7. Click "More" to view the

after-sales contact information

Figure 3:Manual

Here can do the following

1. Select the moving unit of

0.1-10mm

2. Controls the XYZ axis for unit

movement

3. Click “ ” to go back to the

original point"

4. Select E1 or E2 for unit

extrusion

Figure 4: Pre-Heat interface

1. This interface allows you to

set the preheat temperature

of the hot bed, left nozzle

and Right nozzle

Figure 5: Filament interface

1. Loading material “ ”

2. Unload material “ ”

3. E1- Left Nozzle,E2-Right Nozzle

4. “ ”Stop Loading Command

Figure 6: Fan Interface

1. This interface allows you to set

the nozzle cooling fan E1,

nozzle cooling fan E2 and the

fan rate of the motherboard

fan

Print More Materials, All For Application

- 16 -

2.3.3 Print Interface

Figure 1: Main Interface

Click "Print" to go to Figure 2

Figure 2: File Interface

Check Specify G-code file to print or

delete the file

Figure 3: Print Interface

1. This interface is the main

interface in print You can view

thumbnails

2. Hot bed, Nozzle Temperature

and chamber temperature

3. Elapsed time, Time remaining、

Current speed

4. File name, Print Progress Bar

5. You can control pause (resume)

and stop printing

6. Press " " to Figure 4

Figure 4:Print Setting Interface

1. This interface can be adjusted

during the printing process

2. Print Speed Ratio, Temperature

of Hot Bed, Nozzle

3. Fan Rate of E1/E2 and Chamber

4. Extrusion flow

5. Setting power off after printing

Print More Materials, All For Application

- 17 -

3. Device Usage

3.1 Unpacking

Step 1

1. Check if the packaging is complete

2. If there is a damage, please feedback by taking

photos in time

3. If serious damage, please refuse to receive

Step 2

1. The equipment is tightly packed and protected

2. Please be patient in removing the package

3. If you need to use tools, such as knives, scissors

4. Please be cautioned to avoid scratching the device

Step 3

Check whether the door glass and control panel are in

good condition

Step 4

Note: The starter kit and material pack are placed in

the material box on the right

Print More Materials, All For Application

- 18 -

3.2 Check Equipment Motion

Step 1

Use 6mm² cable to connect

AC220V single-phase power socket

Step 2

Plug in the power connector at the

rear of the machine to the main

power supply

Step 3

It is shown in Figure 3

Step 4

1. The XYZ axis movement is

controlled manually by touch

screen

2. Observe whether the figure

moves normally

Step 5

1. Control E1 and E2 extrusion

through the touch screen

2. Check whether the gears of the

left and right sprinklers rotate

clockwise

Step 6

1. Preheat through touch screen

2. It can set the temperature of hot

bed, left nozzle and right nozzle

3. The temperature on the right

represents the set temperature,

and the temperature on the left

represents the actual temperature

4. Recommended hot bed

temperature for first preheating:

50 ° C ±2 ° C

5. Left and right nozzle

temperature: 210℃±2℃

Please be careful with high

temperature and operate with

caution

Print More Materials, All For Application

- 19 -

4. Print Operation

4.1 Install Print Platform And Leveling

Step 1

Install sealing strips

Step 2

Install carbon fiber plate

Step 3

Turn on the vacuum suction switch

Print More Materials, All For Application

- 20 -

4.1.1 Use Auto Leveling To Print

Step 1

When starting the machine,

observe whether the automatic

leveling self-test passes. If it does

not pass, it must not be reset to

zero, otherwise there is a risk that

the platform will hit the nozzle,

resulting in machine failure.

(During the self-test, the self-test

will be performed twice. If there is

no action, manually pull out the

probe and start the self-test again)

Step 2

After passing the self-test, click

return to zero

Step 3

The X-axis (transverse) Y-axis

(vertical) is zeroed in turn, , and

finally the Z-axis is raised and

zeroed

This manual suits for next models

1

Table of contents

Other IEMAI 3D Printer manuals

Popular 3D Printer manuals by other brands

Ortur

Ortur Laser Master 2 PRO S2 user manual

3DMakerWorld

3DMakerWorld Artifex 2 user manual

Geeetech

Geeetech Delta Rostock mini G2 pro Building Instruction

3DUniverse

3DUniverse FlashForge Creator X manual

Prusa Research

Prusa Research Original Prusa SL1 manual

Flashforge

Flashforge Creator 3 Pro user guide