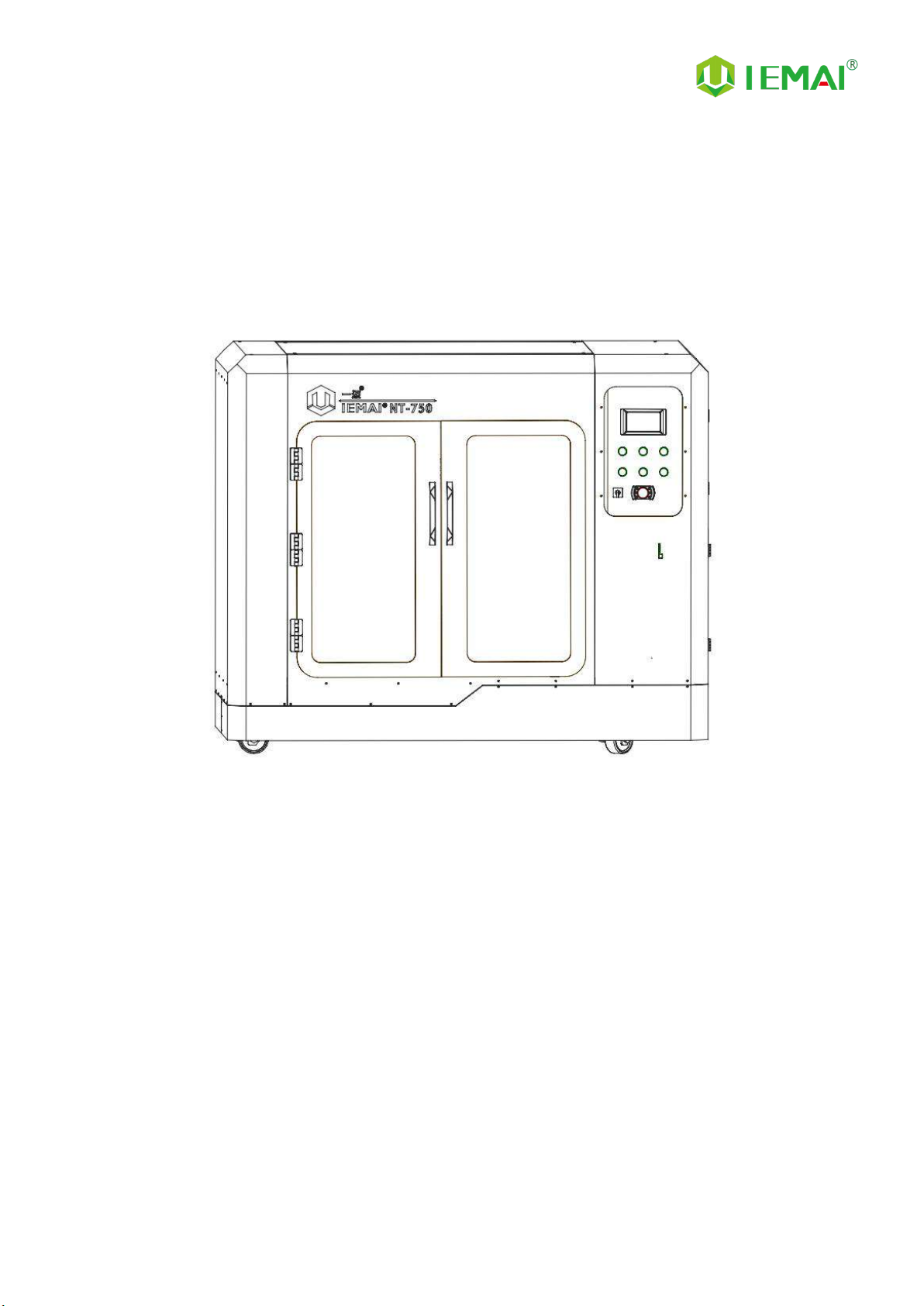

IEMAI Large Scale User manual

Print More Materials, All For Application

Large Scale 3D Printer

YM-NT-750

Operating Instructions

www.iemai3d.com

* Please read this manual carefully before starting to operate.

This device is a Class A product. Use in a general indoor environment may

cause radio interference and therefore requires the user to take appropriate

protective measures.

Print More Materials, All For Application

The contents of this operating instructions may be updated periodically. Scan the QR

code or visit the link below to get the latest version.

www.iemai3d.com/index.php/download/

Print More Materials, All For Application

Content

1.Overview..................................................................................................................................................................... 1

1.1 Machine Overview.............................................................................................................................................1

1.2 Precautions........................................................................................................................................................ 2

1.3 Safety.................................................................................................................................................................. 3

2. Detailed Parameter...................................................................................................................................................... 4

2.1. Specification......................................................................................................................................................4

2.2 Device Layout.................................................................................................................................................... 6

2.3 Interactive Interface...........................................................................................................................................9

3.Device Usage............................................................................................................................................................... 14

3.1 Unboxing for The First Time...........................................................................................................................14

3.2 Power Installation............................................................................................................................................ 16

3.3 Hardware Checking.........................................................................................................................................17

4. Print Operation...........................................................................................................................................................19

4.1 Installation of The Printing Platform and Auto-Calibration........................................................................ 19

4.3 Start Printing.................................................................................................................................................... 24

4.4 Model Removal............................................................................................................................................... 25

4.5 PC-based WIFI LAN Control.......................................................................................................................... 26

5. Function Introduction................................................................................................................................................ 27

5.1 Power Failure Recovery...................................................................................................................................27

5.2 Filament Absent Warning............................................................................................................................... 27

6. Maintenance and Care.............................................................................................................................................. 28

6.1 Maintenance of Linear Guide and Ball Screw............................................................................................... 28

6.2 Dust Removal from Fans.................................................................................................................................29

6.3 Nozzle Maintenance....................................................................................................................................... 30

6.4 Dual Print Head Nozzle Spacing Adjustment Method................................................................................ 32

6.5 Print Head Disassembly and Maintenance................................................................................................... 33

7. Common Problems and Their Solutions..................................................................................................................39

7.1 Movement........................................................................................................................................................39

7.2 Temperature.................................................................................................................................................... 40

7.3 Print.................................................................................................................................................................. 40

8. Appendix A................................................................................................................................................................. 43

Print More Materials, All For Application

— 1 —

1.Overview

1.1 Machine Overview

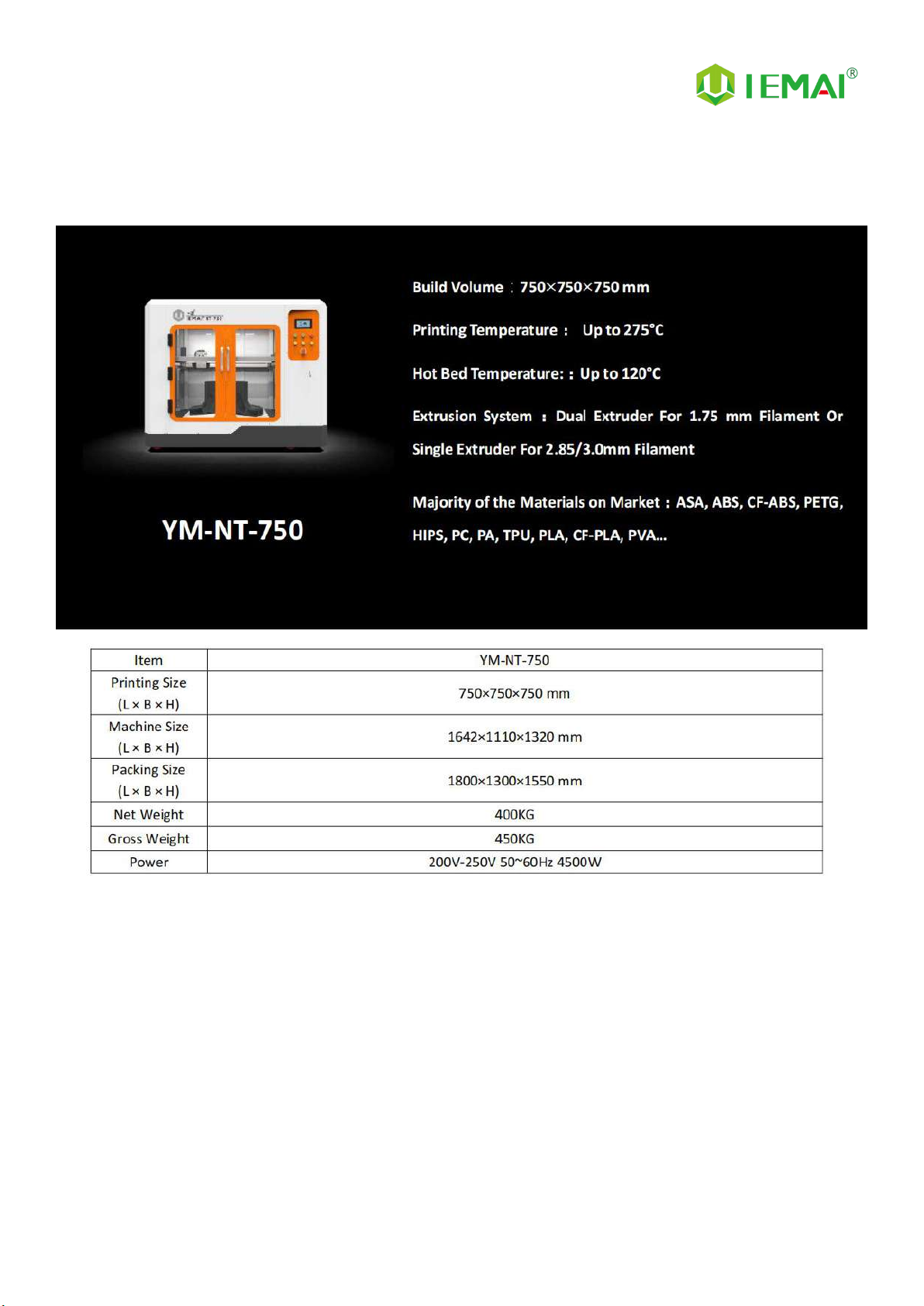

IEMAI’s Large Scale 3D printer YM-NT-750 based on the principle of fused filament deposition

(FFF) technology, with a printing temperature of up to 275 ℃ printing temperature , a hot bed

temperature of 120℃,It supports most polymer 3D printing materials on the market, including ASA,

ABS, PC, PA, CF-ABS, PETG, HIPS, TPU, PLA, CF-PLA, PVA.

YM-NT-750 Print Head can adopt Dual Print Heads(1.75mm Filament)or Single Print Head

(2.85/3.0mm filament),these print heads are modular and can be quickly replaced by the user.

When you use dual print heads, it can support using support materials, including water-soluble

material PVA, limonene soluble material HIPS, and when you use separate high flow print heads, you

can use large layer thickness fast printing mode.

Print More Materials, All For Application

— 2 —

1.2 Precautions

First of all, thank you for choosing IEMAI 3D Printer!

This Printer is a Professional equipment, please read this manual carefully before starting to use,

this manual contains important information about the installation, operation, maintenance, and

common problems of the 3D printer, the company is not responsible for all losses caused by violation

of the cautions and operating procedures given in this manual。

Materials: Please use the filament provided by our company or the third-party filament of official

authorized brand or choose the high-quality filament provided by other regular filament

manufacturers, and users should be responsible for the loss caused by using low-quality filament.

Please keep the consumables sealed and moisture-proof if not in use for a long time; please bake and

dry them in advance before using them again.

Software: Please use a 64-bit system with Windows 7 or above to run the software, more than

4G of RAM and more than 1G of GPU, please use a computer with a higher configuration if possible.

Installation Site Requirements: Installation Site≥2300*1900*1400mm (L*W*H).

Installation Power Requirements:200~250 V, 50~60 Hz,4500w,Electric cable 4 m2or more.

Operating Environment: 15-30°C, 10-90% Relative Humidity, non-condensation.

Storage Environment: 25-55°C, 10-90% Relative Humidity, non-condensation.

Print More Materials, All For Application

— 3 —

1.3 Safety

The printer has a specialized motion structure, control system and electrical control parts, users

need to pay careful attention to the safety label when using it to prevent burns, pinching, electric

shock, or other safety problems.

The maximum temperature of the print head of this equipment can reach 275°

C, its heating is strictly prohibited to touch.

The maximum temperature of the printing platform of this equipment can

reach 120 °C, its heating is strictly prohibited to touch.

Ensure that the power supply grounding terminal is well grounded to prevent

the printer from not working properly or posing a risk of electric shock.

Do not disassemble the case without permission, be careful of electric shock.

When the printer is working, it is forbidden to move in the printing area to

prevent collision, belt turning in, etc.

Print More Materials, All For Application

— 4 —

2. Detailed Parameter

2.1. Specification

Print More Materials, All For Application

— 5 —

Print More Materials, All For Application

— 6 —

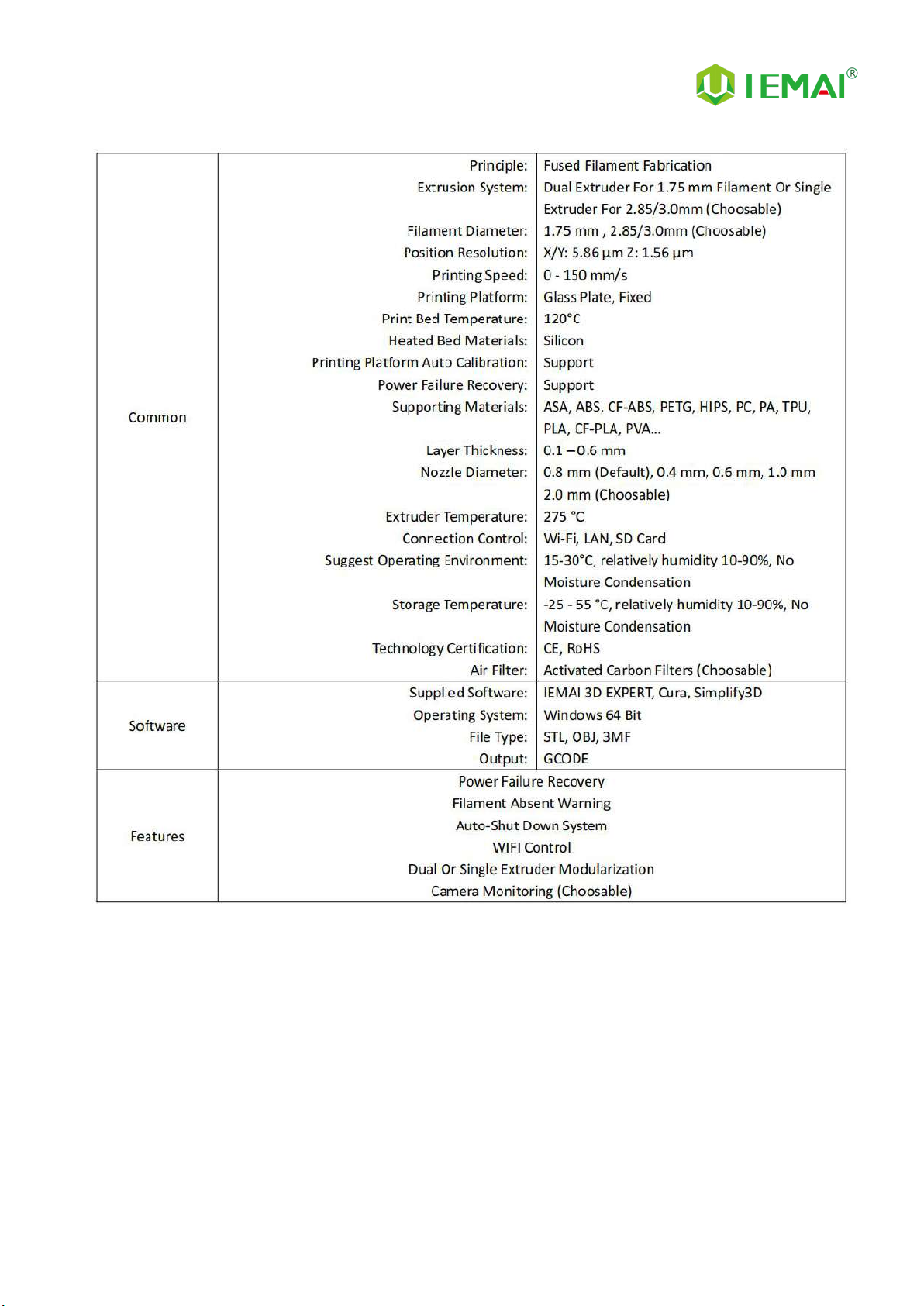

2.2 Device Layout

Front

Control Panel SD Card Slot and USB Connection

Single Door

Touch screen

Control Panel

Main Switch

SD Card Slot

USB Port

Print More Materials, All For Application

— 7 —

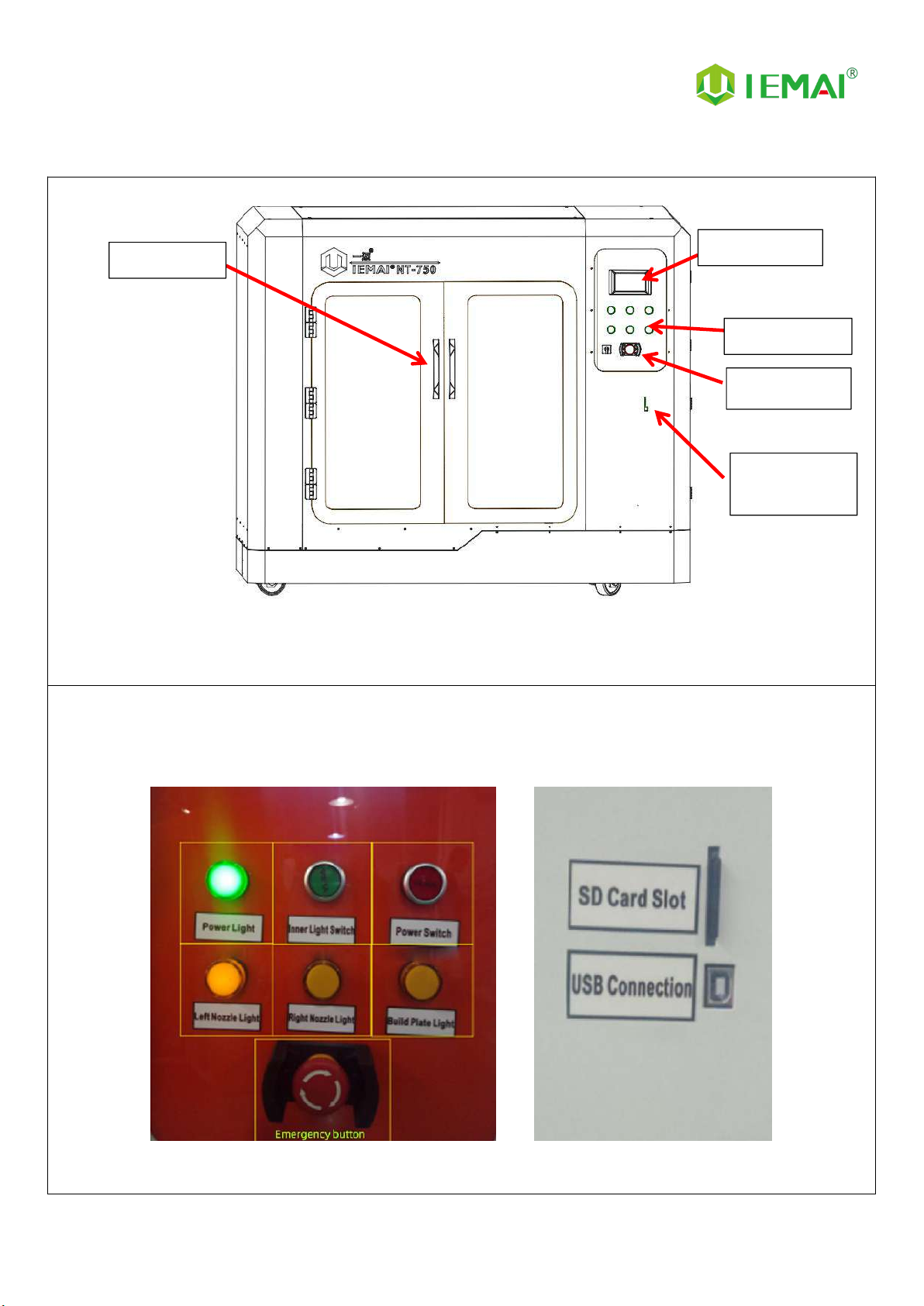

Back

Printer (Internal)

Cooling Fan

Power Port

Y-Axis

Positive X-Axis Limit

Negative X-Axis Limit

Negative Y-Axis Limit

Print More Materials, All For Application

— 8 —

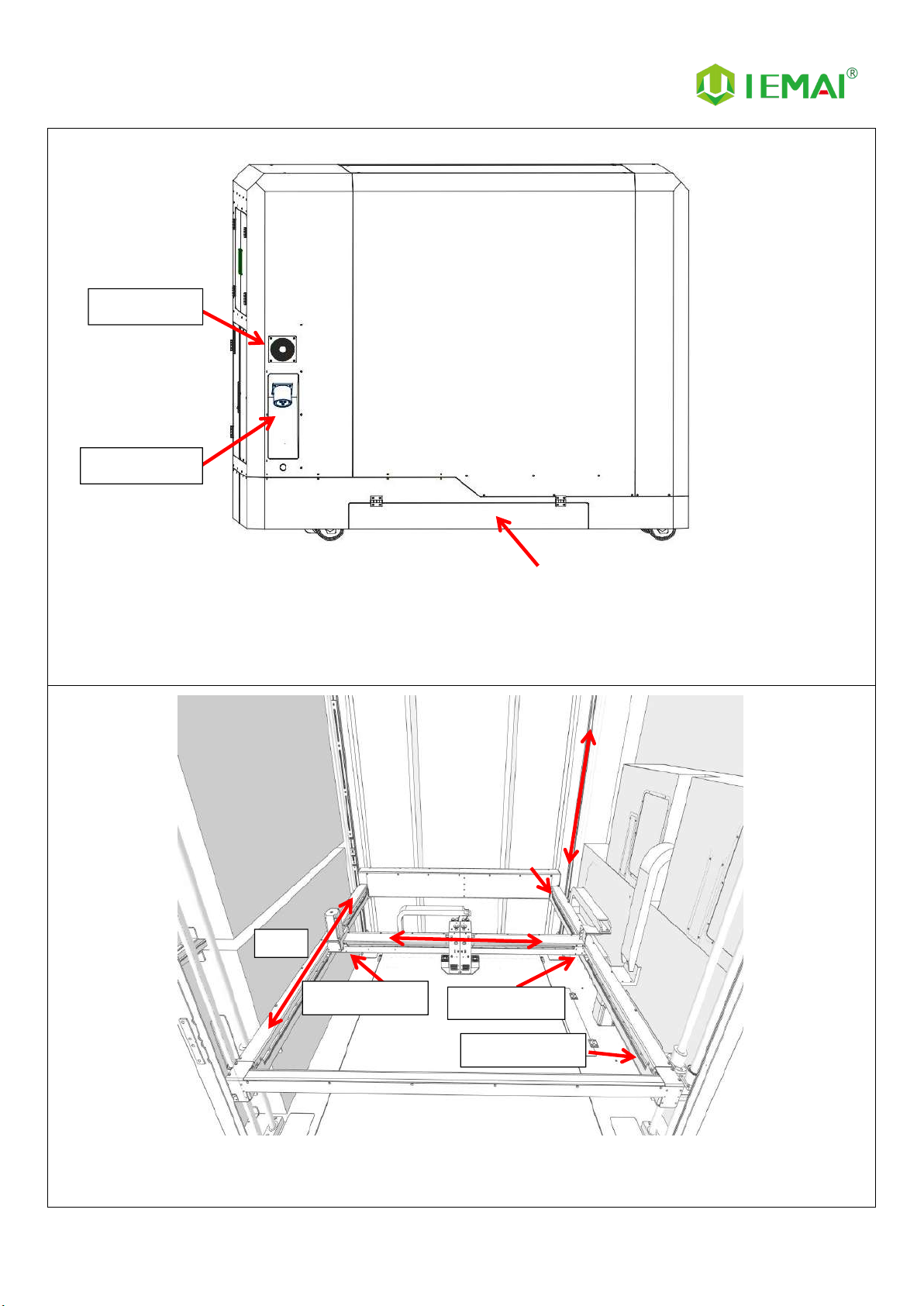

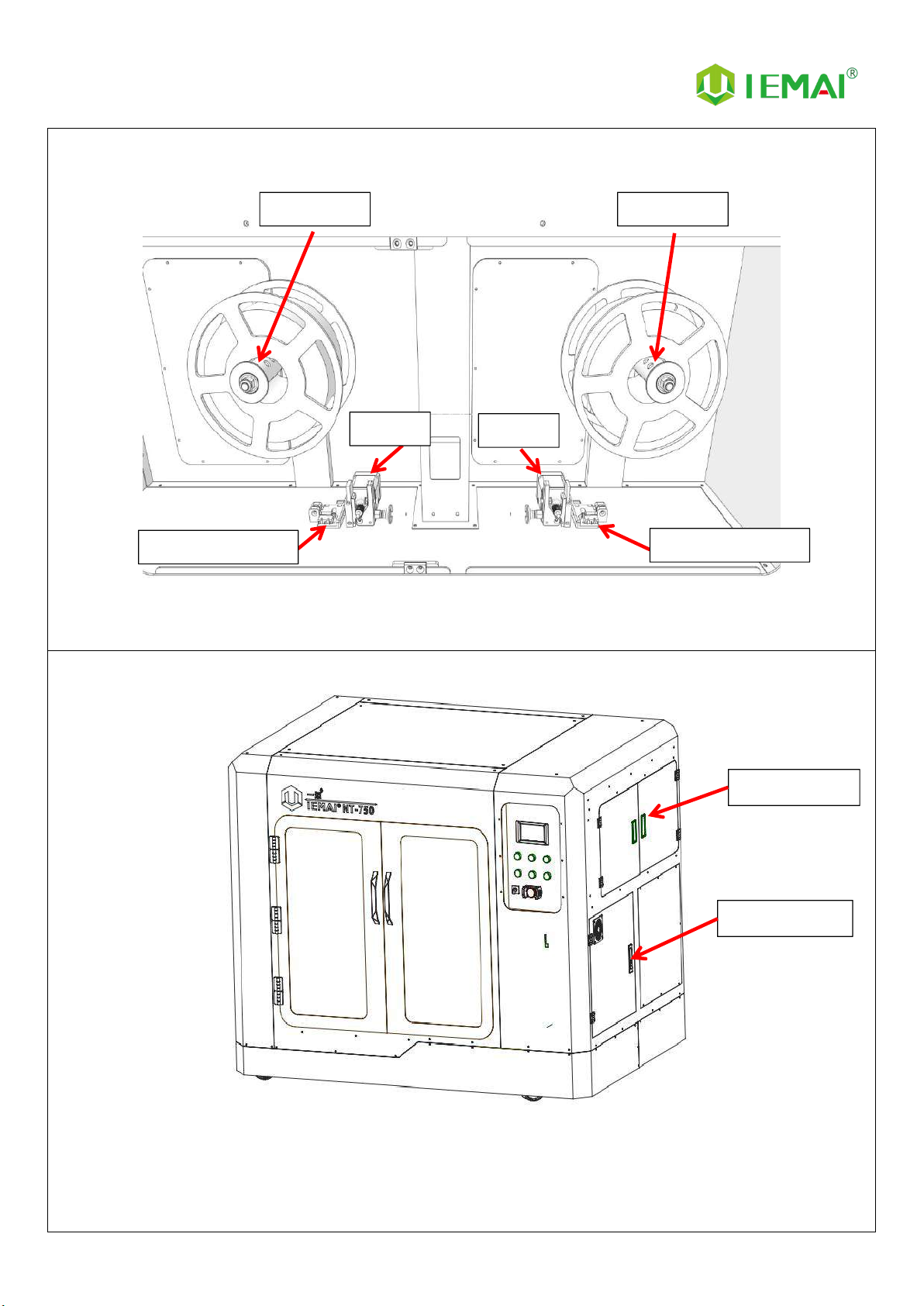

Filament Box (Internal)

Side

Filament Box

Electric Box

E1 Fixed Roller

E2 Fixed Roller

E1 Extruder

E2 Extruder

E1 Filament Absent Warning

E2 Filament Absent Warning

Print More Materials, All For Application

— 9 —

2.3 Interactive Interface

The interactive Interface of this device adopts a 5-inch Color Touch Screen (Resistive), please

read the following instructions carefully before first use

Logic diagram of interactive interface

Print More Materials, All For Application

— 10 —

2.3.1 System Interface

Figure 1: Main interface

Click "System" to go to Figure 2

Figure 2: System interface

1. Click "Info" to go to Figure 3

2. Click "About" to go to

Figure 4

3. Click "English" to switch to other

Language

4. Click "Default" to restore the

original factory settings

5. Tap TPAAdjustment to correct

the touch offset

6. Click "WIFI" to go to Figure 5

Figure 3: Info interface

1. This interface allows you to view

the current coordinates of the

XYZ axis

2. The current temperature of the

left nozzle, and right nozzle, and

hot bed

Figure 4: About interface

This interface allows you to view the

name, ID, system version, UI version,

and Power On/Off sounds

Figure 5: WiFi Setup Interface

This interface allows you to view

information about Wi-Fi

Print More Materials, All For Application

— 11 —

2.3.2 Tool interface

Figure 1: Main interface

Click "Tool" to go to Figure 2

Figure 2: Tool Interface

1. Click "Manual" to go to Figure 3

2. Click "Preheat" to go to Figure 4

3. Click "Filament” to go to Figure

5

4. Click "Level" to perform

automatic leveling

5. Click "Fan" to go to Figure 6

6. Click "Stop" to stop all execution

commands

7. Click "Support" to view the

after-sales contact information

Figure 3:Manual

Here can do the following

1. Select the moving unit of

0.1-10mm

2. Controls the XYZ axis for unit

movement

3. Click “ ” to go back to the

original point"

4. Select E1 or E2 for unit extrusion

Figure 4: Pre-Heat interface

1. This interface allows you to set

the preheat temperature of the

hot bed, left nozzle and Right

nozzle

Figure 5: Filament interface

1. Loading material “ ”

2. Unload material “ ”

3. E1- Left Nozzle,E2-Right Nozzle

4. “ ”Stop Loading Command

Figure 6: Fan Interface

1. This interface allows you to set

the nozzle cooling fan E1,

nozzle cooling fan E2 and the

fan rate of the motherboard fan

Print More Materials, All For Application

— 12 —

2.3.3 Print Interface

Figure 1: Main Interface

Click "Print" to go to Figure 2

Figure 2: File Interface

Check Specify G-code file to print or

delete the file

Figure 3: Print Interface

1. This interface is the main

interface in print You can view

thumbnails

2. Hot bed, Nozzle Temperature of

1 and 2

3. Elapsed time, Time remaining、

Current speed

4. File name, Print Progress Bar,

and more

5. You can control pause (resume)

and stop printing

6. Press " " to reset during the

printing process

Print More Materials, All For Application

— 13 —

Figure 4:Print Setting Interface

1. This interface can be adjusted

during the printing process

2. Print Speed Ratio, Printing

Temperature of Hot Bed, Nozzle

3. Fan Rate of Nozzle Fan E1 and

Nozzle Fan E2

4. Extrusion flow

5. As well as setting power off after

printing

Figure 5: Emergency Stop

1. For emergencies, the air switch

tripped X, Y, Z, E axis motor and

hot bed high-power equipment

power supply shut down the

machine to stop the movement,

you need to turn on and then

turn the air switch on the

electrical box to restore the

power supply of high-power

equipment.

Print More Materials, All For Application

— 14 —

3.Device Usage

3.1 Unboxing for The First Time

Step 1

1. Check if the packaging is

complete

2. If there is a damage, please

feedback by taking photos in

time

3. If serious damage, please refuse

to receive

Step 2

1. The equipment is tightly packed

and protected

2. Please be patient in removing

the package

3. If you need to use tools, such as

knives, scissors

4. Please be cautioned to avoid

scratching the device

Step 3

1. Check The Door Glass, Whether

the Control Panel is

Segmentation

2. Remove the starter kit from the

printer

Print More Materials, All For Application

— 15 —

Step 4

1. Cut the tie on the XY axis to

release

2. There are four paper boxes

pressed under the Z axis

3. The equipment can be removed

by rising the Z-axis after power

is applied

Step 5

1. After removing all packaging

2. The equipment is shown in the

picture

Step 6

Toolbox Items

Subject to delivery

Print More Materials, All For Application

— 16 —

3.2 Power Installation

Step 1

(Steps 1 to 3 connect the machine)

1. Open the A end of the power

cord to the position in the

middle as shown

Step 2

1. Align the A positioning point

with the B positioning point on

the machine and insert it to

complete the power connection.

Step 3

1. Insert A to the bottom, make

sure it is in tight contact

Step 4

1. (Step four to step six to connect

the main switch) to get the

power cord B, find the

positioning point

Step 5

1. Open the cover of the installed

matching power A connector

(do not insert your hand or

other metal objects into the

connector)

Step 6

1. The positioning point is facing

the A positioning hole, insert the

common connector of the

power cord

Step 7

1. Click the main power switch.

Power indicator lights up

Step 8

1. The screen lights up normally.

Then the device is successfully

powered on

Step 9

1. Press the internal light switch

Internal lights will on

Note: 1. Please operate carefully in the process of connecting electricity, to prevent electric shock.

2. Please use self-contained power cord, so as not to cause electric shock and fire and other adverse

consequences.

Print More Materials, All For Application

— 17 —

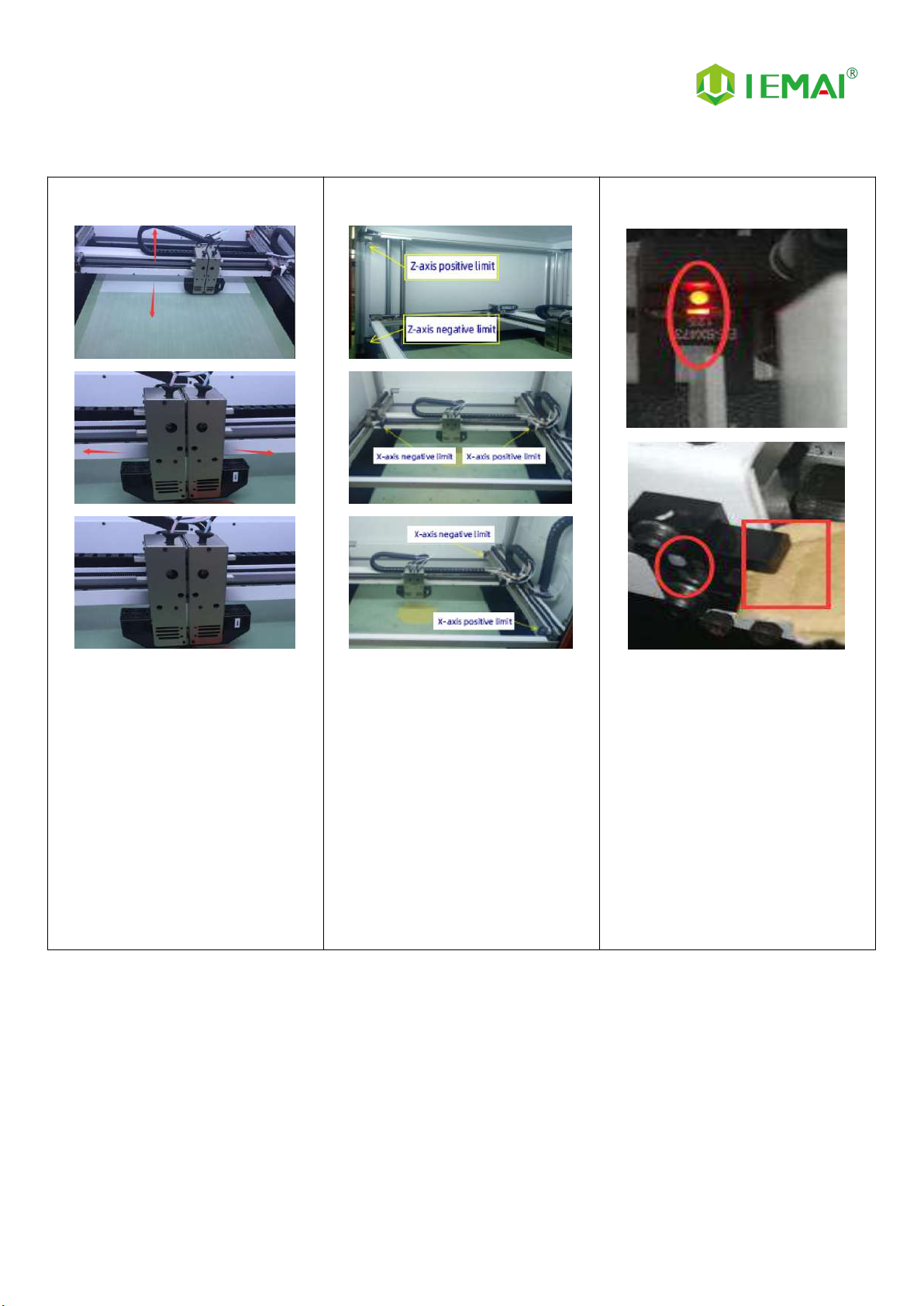

3.3 Hardware Checking

Step 1

1. Manually control the XYZ axis

movement through the touch

screen

2. Observe whether the normal

movement as shown

Step 2

1. Find the positive and negative

limits of XYZ axis respectively

Step 3

1. Place a sheet in the Z-axis

negative limit slot to make the

limit red light go out.

2. Moving the Z-axis upward and

hearing a beep and no

movement of the Z-axis

indicates that the Z-positive

limit switch is normal.

3. Remove the sheet

Other manuals for Large Scale

1

This manual suits for next models

1

Table of contents

Other IEMAI 3D Printer manuals