IEMAI MAGIC-HT-M User manual

Print More Materials, All For Application

HIGH TEMPERATURE SERIES

3D PRINTER

MAGIC-HT-M

Operating Instructions

www.iemai3d.com

* Please read this manual carefully before starting to operate.

This device is a Class A product. Use in a general indoor environment

may cause radio interference and therefore requires the user to take

appropriate protective measures.

Warning

Print More Materials, All For Application

The contents of this operating instructions may be updated periodically. Scan the QR code or visit the

link below to get the latest version.

www.iemai3d.com/index.php/download/

Print More Materials, All For Application

Content

1.Overview............................................................................................................................................................................................. 1

1.1 Machine Overview.................................................................................................................................................................. 1

1.2 Precautions................................................................................................................................................................................2

1.3 Safety...........................................................................................................................................................................................3

2. Detailed Parameter............................................................................................................................................................................4

2.1. Specification.............................................................................................................................................................................4

2.2 Device Layout...........................................................................................................................................................................6

2.3 Interactive Interface................................................................................................................................................................8

3.Device Usage......................................................................................................................................................................................12

3.1 Unboxing for The First Time..............................................................................................................................................12

3.2 Device Movement Check...................................................................................................................................................13

4. Print Operation.................................................................................................................................................................................14

4.1 Operation of Auto-Calibration.........................................................................................................................................14

4.2.1 Unload Filament.................................................................................................................................................................16

4.3 Start Printing...........................................................................................................................................................................18

4.4 Model Removal..................................................................................................................................................................... 19

4.5 PEEK Material Printing Precautions.................................................................................................................................20

4.6 PC-based WIFI LAN Control............................................................................................................................................. 21

5. Function Introduction.....................................................................................................................................................................22

5.1 Power Failure Recovery.......................................................................................................................................................22

5.2 Filament Absent Warning.................................................................................................................................................. 22

5.3 Temperature Setting of The Constant Temperature Chamber............................................................................. 23

6. Maintenance and Care...............................................................................................................................................................24

6.1 Maintenance of Linear Guide and Ball Screw..............................................................................................................24

6.2 Adjustment of Belt Looseness.......................................................................................................................................... 25

6.3 Dust Removal from Electrical Box Fans......................................................................................................................... 26

6.4 Nozzle Maintenance............................................................................................................................................................27

6.5 Print Head Disassembly and Maintenance...................................................................................................................29

6.6 Steps to Disassemble The Nozzle................................................................................................................................... 30

7. Common Problems and Their Solutions.............................................................................................................................. 31

7.1 Movement...............................................................................................................................................................................31

7.2 Temperature...........................................................................................................................................................................32

7.3 Print........................................................................................................................................................................................... 32

7.4 Clean Up Carbon Blockage............................................................................................................................................... 33

8. Appendix:....................................................................................................................................................................................34

Appendix A.................................................................................................................................................................................... 34

Appendix B.....................................................................................................................................................................................35

Print More Materials, All For Application

第1页 共 32 页

1.Overview

1.1 Machine Overview

IEMAI's High-Performance 3D printer MAGIC-HT-M is a 3D printing device based on the

principle of fused filament deposition (FFF) technology, with a printing temperature of up to 450°C, a

hot bed temperature of 150 ° C, and a cavity temperature of 90 ° C. It supports most polymer 3D

printing materials on the market, including PEEK, PEKK, PPSU, ULTEM etc., creating excellent

temperature conditions to do great printing.. We have adopted a modular design, for example, both

the print head and the platform can be quickly disassembled, thus creating conditions for easy

maintenance.

Print More Materials, All For Application

2

1.2 Precautions

First of all, thank you for choosing IEMAI 3D Printer!

This device is a Professional equipment, please read this manual carefully before starting to use,

this manual contains important information about the installation, operation, maintenance, and

common problems of the 3D printer, the company is not responsible for all losses caused by violation

of the cautions and operating procedures given in this manual。

Consumables: Please use the filament provided by our company or the third-party filament of

official authorized brand or choose the high-quality filament provided by other regular filament

manufacturers, and users should be responsible for the loss caused by using low-quality filament.

Please keep the consumables sealed and moisture-proof if not in use for a long time; please bake and

dry them in advance before using them again.

Software: Please use a 64-bit system with Windows 7 or above to run the software, more than 4G

of RAM and more than 1G of GPU, please use a computer with a higher configuration if possible.

Installation Site Requirements: Installation Site≥600*1000*900mm (L*W*H).

Installation Power Requirements:200~250 V, 50~60 Hz, 950w,Electric cable 1.5 m2or more.

Operating Environment: 15-30°C, 10-90% Relative Humidity, non-condensation

Storage Environment: 25-55°C, 10-90% Relative Humidity, non-condensation

Print More Materials, All For Application

3

1.3 Safety

The device has a specialized motion structure, control system and electrical control parts, users

need to pay careful attention to the safety label when using it to prevent burns, pinching, electric

shock, or other safety problems.

The maximum temperature of the print head of this equipment can reach 450°

C, its heating is strictly prohibited to touch

The maximum temperature of the printing platform of this equipment can

reach 150 °C, its heating is strictly prohibited to touch

The maximum temperature of the chamber of this equipment can reach 90°C,

and it is strictly forbidden to touch it when it is heated.

Ensure that the power supply grounding terminal is well grounded to prevent

the printer from not working properly or posing a risk of electric shock

Do not disassemble the case without permission, be careful of electric shock

When the printer is working, it is forbidden to move in the printing area to

prevent collision, belt turning in, etc.

Print More Materials, All For Application

4

2. Detailed Parameter

2.1. Specification

Print More Materials, All For Application

5

Print More Materials, All For Application

6

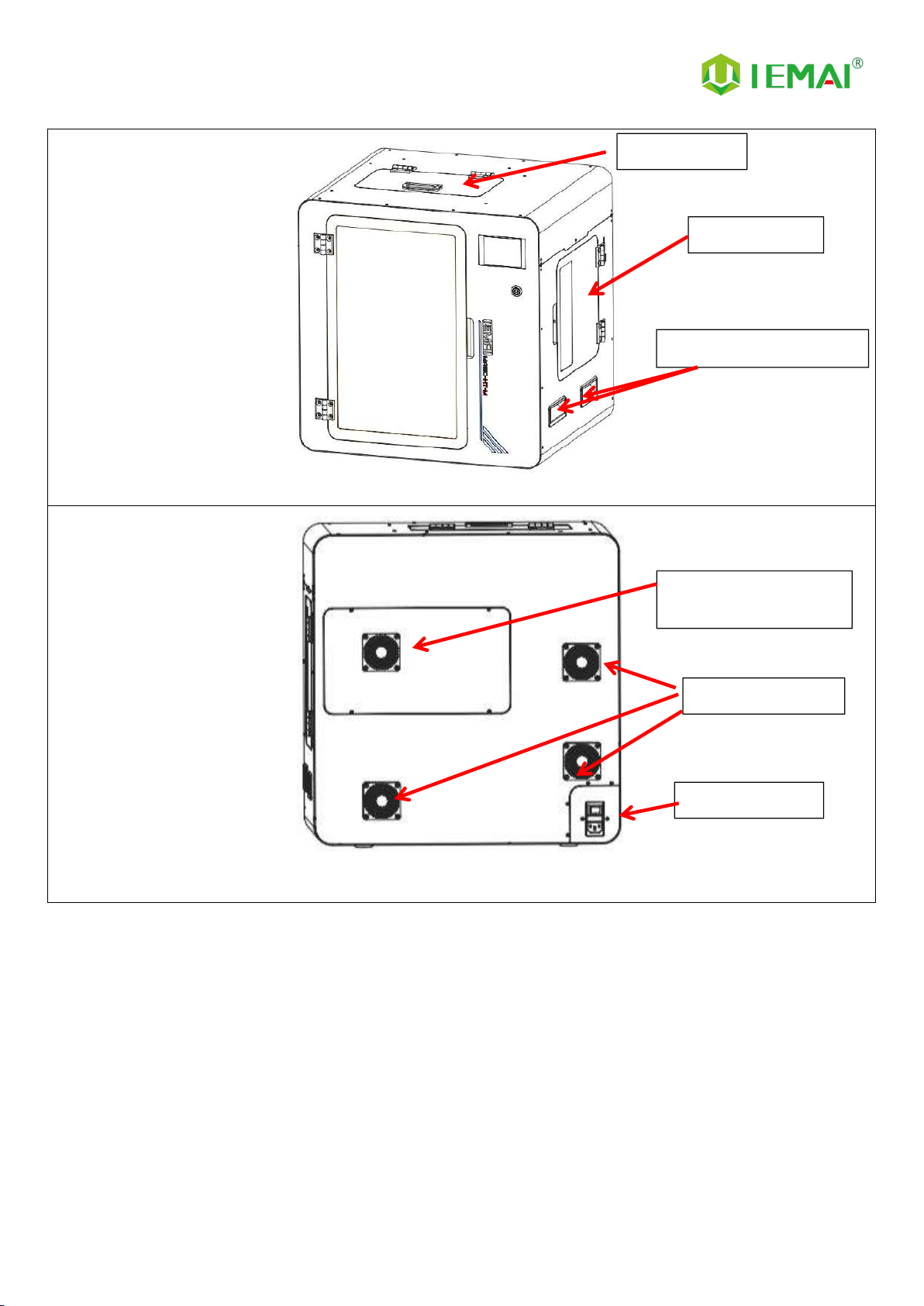

2.2 Device Layout

Control Panel

Switch

Handle(Carry Machine)

Print More Materials, All For Application

7

Top Window

Filament Box

Handle(Carry Machine)

Motherboard Cooling

Fan

Cooling Fan

Main Switch

Print More Materials, All For Application

8

2.3 Interactive Interface

The interactive Interface of this device adopts a 3.5-inch Color Touch Screen (Resistive), please

read the following instructions carefully before first use

Logic diagram of interactive interface

Print More Materials, All For Application

9

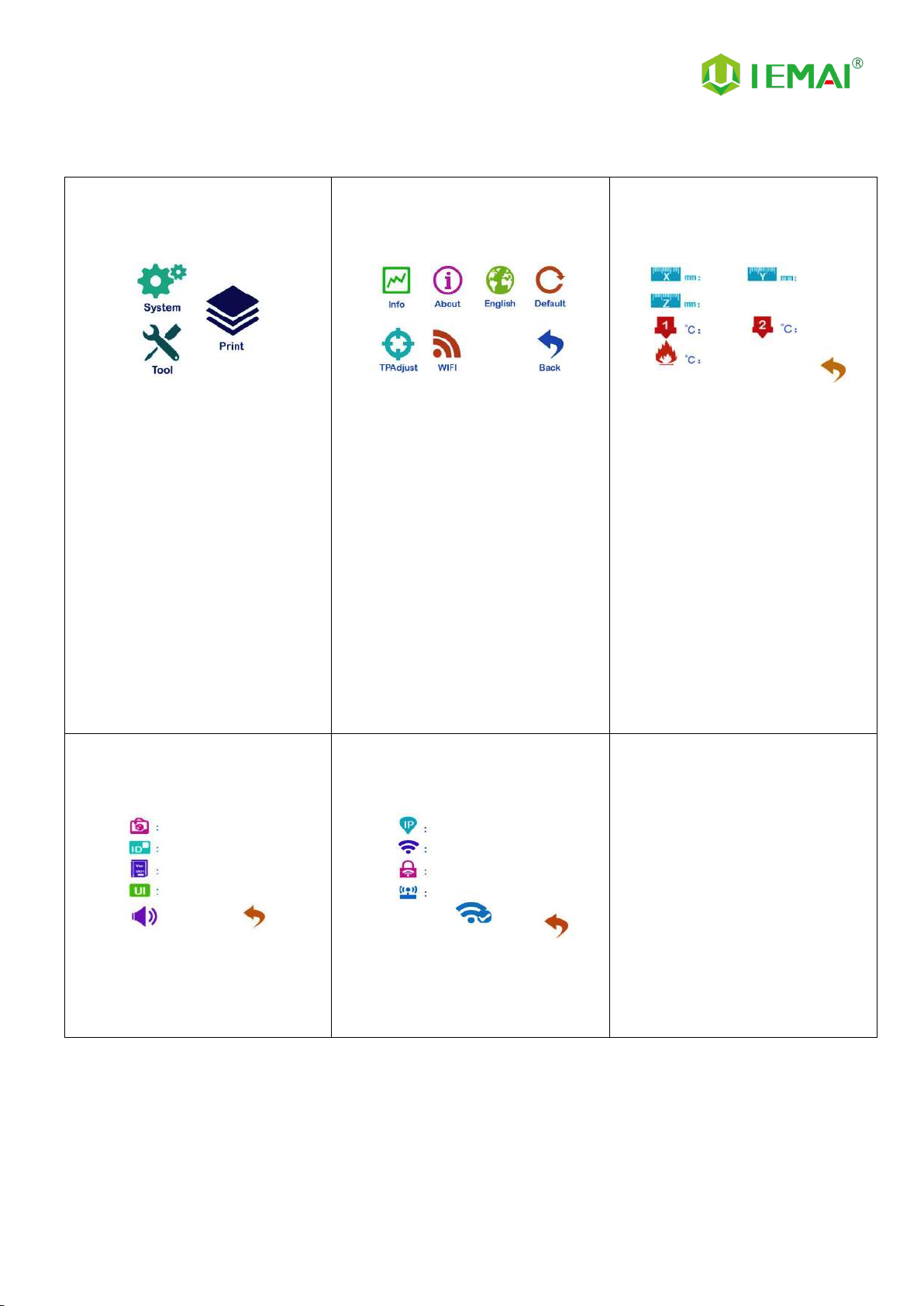

2.3.1 System Interface

Figure 1: Main interface

Click "System" to go to Figure 2

Figure 2: System interface

1. Click "Info" to go to Figure 3

2. Click "About" to go to Figure 4

3. Click "English" to switch to other

Language

4. Click "Default" to restore the

original factory settings

5. Tap TPAAdjustment to correct the

touch offset

6. Click "WIFI" to go to Figure 5

Figure 3: Info interface

1. This interface allows you to view

the current coordinates of the

XYZ axis

2. The current temperature of the

left nozzle, and right nozzle, and

hot bed

Figure 4: About interface

This interface allows you to view the

name, ID, system version, UI version,

and Power On/Off sounds

Figure 5: WiFi Setup Interface

This interface allows you to view

information about Wi-Fi

Print More Materials, All For Application

10

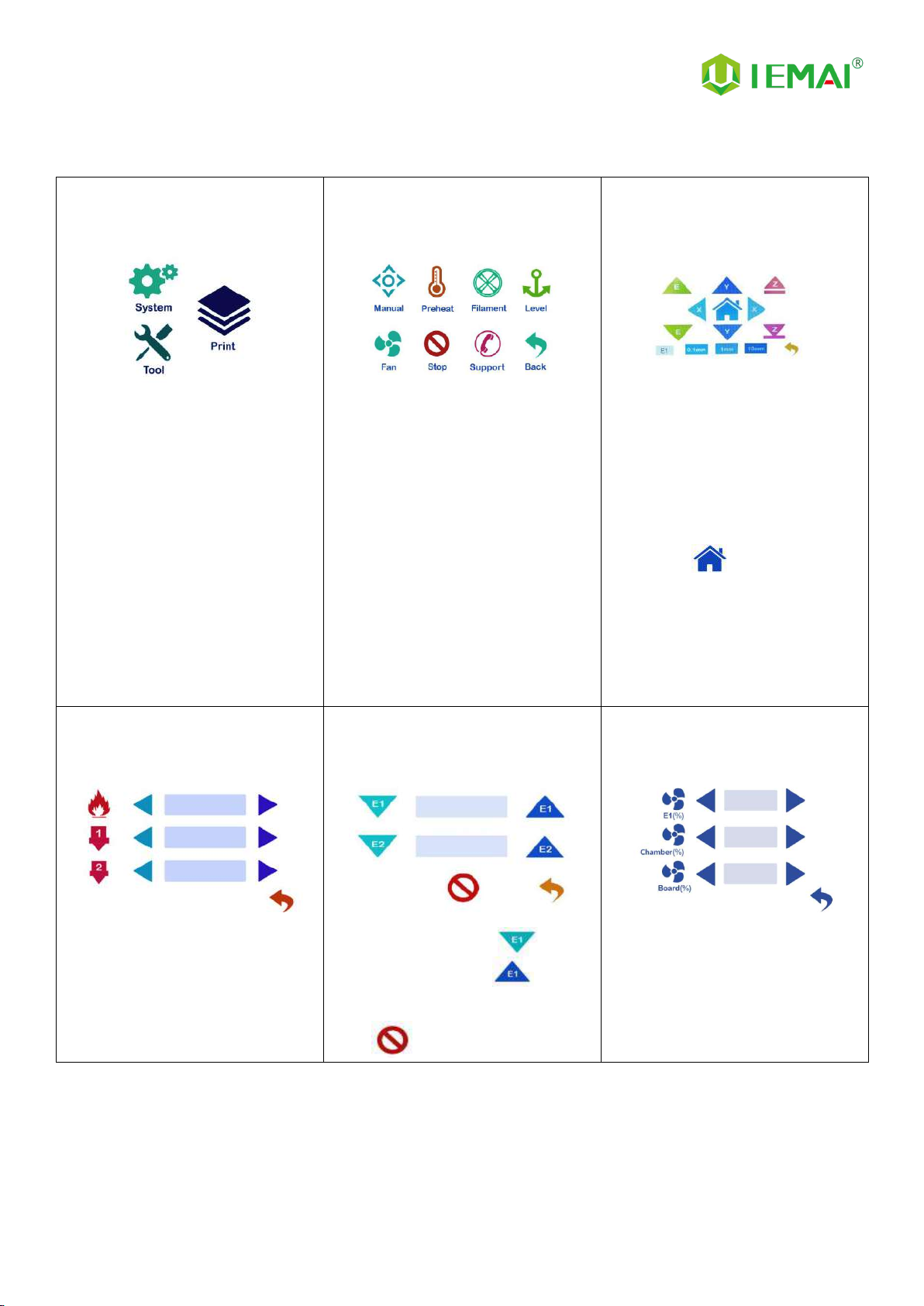

2.3.2 Tool interface

Figure 1: Main interface

Click "Tool" to go to Figure 2

Figure 2: Tool Interface

1. Click "Manual" to go to Figure 3

2. Click "Preheat" to go to Figure 4

3. Click "Filament” to go to Figure 5

4. Click "Level" to perform

automatic leveling

5. Click "Fan" to go to Figure 6

6. Click "Stop" to stop all execution

commands

7. Click "Support" to view the

after-sales contact information

Figure 3:Manual

Here can do the following

1. Select the moving unit of

0.1-10mm

2. Controls the XYZ axis for unit

movement

3. Click “ ” to go back to the

original point"

4. Select E1 or E2 for unit

extrusion

Figure 4: Pre-Heat interface

1. This interface allows you to

set the preheat temperature

of the hot bed, left nozzle

and Right nozzle

Figure 5: Filament interface

1. Loading material “ ”

2. Unload material “ ”

3. E1- Left Nozzle,E2-Right Nozzle

4. “ ”Stop Loading Command

Figure 6: Fan Interface

1. This interface allows you to set

the nozzle cooling fan E1 and

the fan rate of the Chamber

Print More Materials, All For Application

11

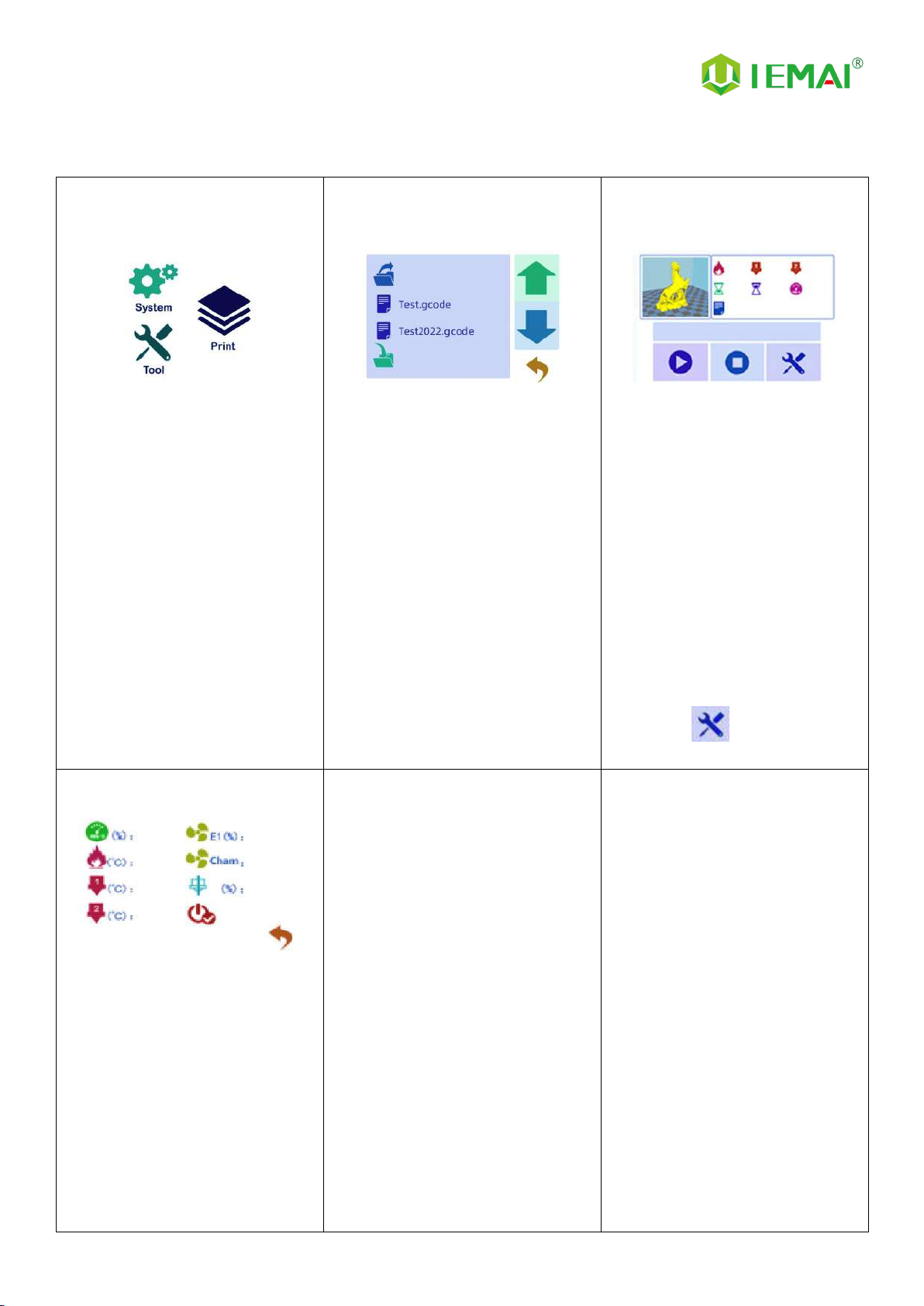

2.3.3 Print Interface

Figure 1: Main Interface

Click "Print" to go to Figure 2

Figure 2: File Interface

Check Specify G-code file to print or

delete the file

Figure 3: Print Interface

1. This interface is the main

interface in print You can view

thumbnails

2. Hot bed, Nozzle Temperature

and chamber temperature

3. Elapsed time, Time remaining、

Current speed

4. File name, Print Progress Bar,

and more

5. You can control pause

(resume) and stop printing

6. Press " " to reset during

the printing process

Figure 4:Print Setting Interface

1. This interface can be adjusted

during the printing process

2. Print Speed Ratio, Temperature

of Hot Bed, Nozzle

3. Fan Rate of Nozzle Fan E1 and

Chamber Fan

4. Extrusion flow

5. As well as setting power off

after printing

Print More Materials, All For Application

12

3.Device Usage

3.1 Unboxing for The First Time

Step 1

1. Check if the packaging is

complete

2. If there is a damage, please

feedback by taking photos in

time

3. If serious damage, please refuse

to receive

Step 2

1. The equipment is tightly packed

and protected

2. Please be patient in removing

the package

3. If you need to use tools, such as

knives, scissors

4. Please be cautioned to avoid

scratching the device

Step 3

1. Check The Door Glass, Whether

the Control Panel is

Segmentation

2. Notice the starter kit and

material package are placed

under the platform

3. Please connect the power to

start the equipment and then

move up the platform to take

out

Step 4

Remove the power cord from the left material box, use the cutter to cut the XY axis fixing tie,

wrong operation may damage the belt.

The kit under the Z-axis needs to be removed after turning on the machine to rise the Z-axis

Print More Materials, All For Application

13

3.2 Device Movement Check

Step 1

1. As shown in the diagram

2. Connect the device power to

the cradle power

Step 2

1. Under normal condition, all

lights of the device are lit as

shown in the figure

Step 3

1. Click the Z-axis up and down

respectively.

2. Observe if it moves normally as

shown

Step 4

1. Manually control the XY axis

movement through the touch

screen

2. Observe if it moves normally as

shown

Step 5

1.Through pre-heat via the

touchscreen.

2.The temperature can be set for the

hot bed, left nozzle, and chamber.

3.The temperature on the right

represents the set temperature.

4.The temperature on the left

represents the actual temperature.

5.The recommended bed temp for

the first warm-up:50℃±2℃.

6.Nozzle temperature:210℃±2℃.

7.Please be careful of high temps

and handle with caution.

Attention: The chamber fan needs to

be turned on before the inner

chamber warms up, it is

recommended to use 100% of the air

volume used, and the temperature

chamber only supports a maximum

of 90 ℃ stable printing.

Print More Materials, All For Application

14

4. Print Operation

4.1 Operation of Auto-Calibration

1. Carry out the basic leveling of the

platform to ensure that the basic

leveling of the platform will not be

excessively inclined

Step 1

1. Press the spring firmly

2. Ensure that the platform does

not shake

Step 2

1. Raise z-axis platform

Step 3

1. Use fixed height objects as

shown

2. Positioning platform with

nozzle height

Step 4

1. Adjust the nut

2. So that the platform and nozzle

just pass through the object

Step 5

1. Push the print head to the inner

corner by hand

2. Adjust again

Step 6

1. Hand push to the last corner

of the adjustment, after the

completion of the platform

four points from the nozzle

distance are the same height.

Print More Materials, All For Application

15

2. Click the leveling button to use automatic leveling to

get the platform data. Wait for the printer to

automatically measure the platform 49 each test point.

3. Start printing and Z-axis compensation

After testing the printing platform, you can start printing.

If you find that the nozzle and platform spacing is not

ideal during the printing process, you can open and

change the data in the file of "Automatic leveling

compensation parameters" through Notepad, put the

changed file into the SD card, and use the 3D printer to

print this TXT file once, the compensation parameters are

changed.

Print More Materials, All For Application

16

4.2.1 Unload Filament

Step 1

1. Pre-heataccording to the

material to be loaded

2. Refer to Step 10 for the

preheating temperature of

different materials

Step 2

1. Straighten the material

2. Cut the material to the tip

Step 3

1. Load the material through the

break test port

2. Manually feed it to the gears

Step 4

1. Click to load material “ ”

2. E1 for the nozzle

Step 5

1. Till the nozzle appears fine

filament

2. Click “ ” Stop loading

command

Step 6

3. When unloading materials

4. Pull material in advance by hand

5. and apply a certain amount of

tension

Step 7

1. Click to uninstall material

“ ”

2. E1 for the nozzle

Step 8

1. After the material exits the gear

2. Manually ripping it out

3. And fix the threads

4. Do good moisture preservation

Print More Materials, All For Application

17

Step 10: Recommended preheating nozzle temperature for commonly used materials

Super Performence

PEEK:430℃

PEKK:430℃

PEI 1010:360℃

PEI 9085:360℃

PPSU:360℃

PPS:300℃

Reinforced Composites

CF-PEEK/GF-PEEK:450℃

CF-PEKK/ESD-PEKK:430℃

GF-PA/CF-PA:300℃

CF-PC/PC-FR/PC-ABS:270℃

CF-ABS:260℃

ESD-PETG:260℃

CF-PLA:220℃

General engineering materials

PA:260℃

PC:260℃

ABS:240℃

PETG:230℃

PLA:200℃

TPU:230℃

Table of contents

Other IEMAI 3D Printer manuals