iET PRS-300 Series User manual

♦PRECISION INSTRUMENTS FOR TEST AND MEASUREMENT ♦

TEL: (516) 334-5959 • (800) 899-8438 • FAX: (516) 334-5988

www.ietlabs.com

IET LABS, INC.

PRS-300 SERIES

Programmable

Decade Resistance Substituters

(IEEE-488.2, Ethernet and USB)

Operation Manual

TEL: (516) 334-5959 • (800) 899-8438 • FAX: (516) 334-5988

www.ietlabs.com

IET LABS, INC.

♦PRECISION INSTRUMENTS FOR TEST AND MEASUREMENT ♦

TEL: (516) 334-5959 • (800) 899-8438 • FAX: (516) 334-5988

www.ietlabs.com

IET LABS, INC.

Copyright © 2017 IET Labs, Inc.

PRS-300 IM / June 2018

PRS-300 SERIES

Programmable

Decade Resistance Substituters

(IEEE-488.2, Ethernet and USB)

Operation Manual

TEL: (516) 334-5959 • (800) 899-8438 • FAX: (516) 334-5988

www.ietlabs.com

IET LABS, INC.

♦PRECISION INSTRUMENTS FOR TEST AND MEASUREMENT ♦

WARRANTY

We warrant that this product is free from defects in material and workmanship and, when properly used,

will perform in accordance with applicable IET specifications. If within one year after original shipment,

it is found not to meet this standard, it will be repaired or, at the option of IET, replaced at no charge when

returned to IET. Changes in this product not approved by IET or application of voltages or currents greater

than those allowed by the specifications shall void this warranty. IET shall not be liable for any indirect,

special, or consequential damages, even if notice has been given to the possibility of such damages.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR

FITNESS FOR ANY PARTICULAR PURPOSE.

WARNING

OBSERVE ALL SAFETY RULES

WHEN WORKING WITH HIGH VOLTAGES OR LINE VOLTAGES.

Dangerous voltages may be present inside this instrument. Do not open the case

Refer servicing to qualified personnel

HIGH VOLTAGES MAY BE PRESENT AT THE TERMINALS OF THIS INSTRUMENT

WHENEVER HAZARDOUS VOLTAGES (> 45 V) ARE USED, TAKE ALL MEASURES TO

AVOID ACCIDENTAL CONTACT WITH ANY LIVE COMPONENTS.

USE MAXIMUM INSULATION AND MINIMIZE THE USE OF BARE

CONDUCTORS WHEN USING THIS INSTRUMENT.

Use extreme caution when working with bare conductors or bus bars.

WHEN WORKING WITH HIGH VOLTAGES, POST WARNING SIGNS AND

KEEP UNREQUIRED PERSONNEL SAFELY AWAY.

CAUTION

DO NOT APPLY ANY VOLTAGES OR CURRENTS TO THE TERMINALS OF THIS

INSTRUMENT IN EXCESS OF THE MAXIMUM LIMITS INDICATED ON

THE FRONT PANEL OR THE OPERATING GUIDE LABEL.

SAFETY SUMMARY

The following general safety precautions must be observed during all phases of operation, service,

and repair of this instrument. Failure to comply with these precautions or with specific WARNINGS

elsewhere in this manual may impair the protection provided by the equipment. Such noncompliance

would also violate safety standards of design, manufacture, and intended use of the instrument.

IET Labs assumes no liability for the customer’s failure to comply with these precautions.

The PRS-300 complies with INSTALLATION CATEGORY I as well as POLLUTION DEGREE 2

in IEC61010-1.

If an instrument is marked CAT I (IEC Measurement Category I), or it is not marked with a

measurement category, its measurement terminals must not be connected to line-voltage mains.

The PRS-300 is an indoor use product.

DANGEROUS PROCEDURE WARNINGS

Comply with all WARNINGS - Procedures throughout in this manual prevent you from potential

hazard. These instructions contained in the warnings must be followed.

BEFORE APPLYING POWER

Verify that all safety precautions are taken. Make all connections to the instrument before applying

power. Note the instrument’s external markings described under “Safety Symbols”.

GROUND THE INSTRUMENT

This is a Safety Class I instrument. To minimize shock hazard, the instrument chassis and cabinet

must be connected to an electrical ground. The power terminal and the power cable must meet

International Electrotechnical Commission (IEC) safety standards.

CAUTION

• DO NOT Operate in an Explosive Atmosphere

• Do not operate the instrument in the presence of inflammable gasses or fumes

• Operation of any electrical instrument in such an environment clearly constitutes a safety

hazard

• Use Caution around live circuits

• Operators must not remove instrument covers

• Component replacement and internal adjustments must be made by qualified maintenance

personnel only

• DO NOT substitute parts or modify the instrument

To avoid the danger of introducing additional hazards, do not install substitute parts or perform

unauthorized modifications to the instrument.

Return the instrument to an IET Labs for service and repair to ensure that safety features are maintained

in operational condition.

Safety Symbols

General definitions of safety symbols used on the instrument or in manuals are listed below.

Caution symbol: the product is marked with this symbol when it is necessary for the user to

refer to the instruction manual.

Hazardous voltage symbol: the product is marked with this symbol when high voltage maybe

present on the product and an electrical shock hazard can exist.

Indicates the grounding protect terminal, which is used to prevent electric shock from the

leakage on chassis. The ground terminal must connect to earth before using the product

Direct current.

Alternating current.

Frame or chassis terminal. A connection to the frame (chassis) of the equipment which

normally includes all exposed metal structures.

On supply.

Off supply.

Hot surface. Avoid contact. Surfaces are hot and may cause personal injury if touched.

Disposal

Waste Electrical and Electronic Equipment (WEEE) Directive 2002/96/EC

This product complies with the WEEE Directive (2002/96/EC) marking requirements.

The affixed label indicates that you must not discard this electrical/ electronic product in domestic

household waste.

Product Category: With reference to the equipment types in the WEEE directive Annex 1, this product

is classified as a “Monitoring and Control instrumentation” product.

Do not dispose of electrical appliances as unsorted municipal waste, use separate collection facilities.

Contact your local government for information regarding the collection systems available. If electrical

appliances are disposed of in landfills or dumps, hazardous substances can leak into the groundwater

and get into the food chain, damaging your health and well-being.

When replacing old appliances with new one, the retailer is legally obligated to take back your old ap-

pliances for disposal.

PRS-300 Series

iiTable of Contents

CONTENTS

WARRANTY........................................................................................................... i

WARNING ............................................................................................................. ii

CAUTION .............................................................................................................. ii

CONTENTS.......................................................................................................... iii

FIGURES.............................................................................................................. iv

TABLES ............................................................................................................... iv

Chapter 1: INTRODUCTION ................................................................................ 1

Chapter 2: SPECIFICATIONS .............................................................................. 3

2.1 Specifications .................................................................................................................3

2.2 General Specifications and Stability ..............................................................................4

2.2 Typical Label..................................................................................................................5

Chapter 3: OPERATION....................................................................................... 6

3.1 Initial inspection and setup ............................................................................................6

3.2 Connection .....................................................................................................................6

3.2.1 General Considerations ........................................................................................6

3.2.2 Electrical Considerations......................................................................................6

3.3 Condensed Operating Instructions.................................................................................6

3.4 Menu Structure...............................................................................................................7

3.4.1 Main Menu ...........................................................................................................8

3.4.2 Setting a Resistance Value....................................................................................8

3.4.3 Menu Button.........................................................................................................8

3.4.4 Standard Values Screen ........................................................................................8

3.4.5 TABLE Key..........................................................................................................9

3.4.6 Increment INCR Key............................................................................................9

3.4.7 OPEN Key............................................................................................................9

3.4.8 STO,RCL Keys...................................................................................................10

3.4.9 VOLT Key ..........................................................................................................10

3.4.10 2 and 4 Wire Connections ................................................................................10

3.4.11 Thermal emf Considerations ............................................................................10

3.4.12 Environmental Conditions................................................................................11

3.4.13 Remote Operation.............................................................................................11

Chapter 4: USB Interface .................................................................................. 12

4.1 Introduction..................................................................................................................12

4.2 Capabilities ..................................................................................................................12

4.3 USB Operation.............................................................................................................12

Chapter 5: ETHERNET INTERFACE OPTION................................................... 14

5.1 Ethernet Programming.................................................................................................14

5.2 Network Setup .............................................................................................................14

5.3 Ethernet Test Keyboard................................................................................................14

5.4 Network Configuration ................................................................................................15

PRS-300 Series

iii Table of Contents

5.5 Web Browser Configuration.........................................................................................15

5.6 VXI Configuration Utility............................................................................................17

5.7 Resetting Default Network Settings.............................................................................19

5.8 PRS Programming .......................................................................................................19

Chapter 6: IEEE INTERFACE OPTION.............................................................. 20

6.1 Introduction..................................................................................................................20

6.2 Capabilities ..................................................................................................................20

6.3 Address Switch and Communications Settings............................................................20

6.4 IEEE Option Operation................................................................................................20

Chapter 7: PROGRAMMING................................................................... 22

7.1 Introduction ......................................................................................... 22

Chapter 8: MAINTENANCE .................................................................... 23

8.1 Verification of Performance .................................................................... 23

8.1.1 Calibration Interval........................................................................ 23

8.1.2 General Considerations .................................................................. 23

8.1.3 Calibration Procedure .................................................................... 23

8.1.4 Adjustment of Internal Resistors ..................................................... 23

Chapter 9: PRS-DMM Self Adjusting Software .................................... 25

9.1 PRS-DMM Self Adjusting Softtware ....................................................... 25

9.1.1 PRS-DMM Self Adjusting Software Overview ................................. 25

9.1.2 General Requirements.................................................................... 25

9.1.3 Software Installation ...................................................................... 25

9.1.3 Connection Between DMM and PRS-300 ........................................ 25

9.1.3 PC Connection Between DMM and PRS-300................................... 25

9.2 PRS-DMM Main Screen ........................................................................ 26

9.2.1 PRS-DMM Main Screen Operation ................................................. 26

9.3 PRS-DMM Settings ............................................................................... 26

9.3.1 PRS-DMM Settings Screen ............................................................ 26

9.3.2 PRS-DMM Settings ....................................................................... 26

9.3.3 Meter Settings ............................................................................... 27

9.3.4 Adjust PRS ................................................................................... 27

9.3.4 PRS-DMM Speed.......................................................................... 28

APPENDIX A: SCPI COMMAND REFERENCE...................................... 29

APPENDIX B: IEEE.2 COMMON COMMANDS ...................................... 33

INTRODUCTION

PRS-300 Series

1

Chapter 1

INTRODUCTION

The PRS-300 (Figure 1.1) is a high

precision manual and programmable decade

substituter. The PRS-300 series provide direct

resistance substitution as well as RTD (Resis-

tance Temperature Detector) simulation.

The PRS-300 substituter is a precision

resistance source with excellent characteristics

of stability, temperature coefficient, and power

coefficient. These features combined with a

low virtually constant “zero resistance” make

for very versatile instruments.

Operation is both local using convenient

display and keypad and remote standard USB

or optional Ethernet, and IEEE-488.2 interfac-

es. An RS-232 interface is also available upon

request.

The PRS-300 employs very low resis-

tance, low thermal emf relays with gold-clad

silver-alloy contacts. A special design keeps

contact resistance to a minimum. The gold

plating keeps the silver contacts from becom-

ing tarnished when unused, or when only low

currents are passed through them. This is most

often the case when only minute test currents

are drawn by digital multimeters and other test

instruments. Contact resistance remains low

and repeatable.

High-quality gold-plated tellurium-copper

five-way binding posts serve to minimize the

thermal emf effects, which would produce er-

rors in dc resistance measurements.

With a resolution as low as 1 Ωand a

maximum available resistance of 20 MΩ, the

PRS-300 may be used for exacting precision

measurement applications requiring high accu-

racy, good stability, and low zero resistance.

The PRS-300 is suited for automatic and

manual calibration and testing, simulation of

RTD’s, programmable loads, and many other

laboratory and industrial applications.

The PRS Series may be rack mounted

to serve as components in measurement and

control systems.

The PRS-300 (Figure 1.1) is part of the

PRS family of high precision manual and

programmable decade substituters. This series

Figure 1.1: High Precision Programmable Decade

Resistance Substituter

INTRODUCTION

PRS-300 Series

2

offers a wide choice of ranges, power, voltage,

and accuracies for a wide variety of design and

production applications.

The PRS-300 uses a microcontroller design

to enhance the ease of use and calibration. It

provides direct resistance substitution as well

as RTD (Resistance Temperature Detector)

simulation. It allows for higher precision and

tighter tolerances.

The PRS-300 is a precision resistance source

with excellent characteristics of accuracy, sta-

bility, temperature coefficient, and power coef-

ficient. It is direct reading without the need to

subtract “zero resistance.”

The PRS-300 offers the option of true 4-wire

Kelvin measurement for calibration applica-

tions and 2-wire mode for use in series as a

substitute resistor and for RTD applications.

The front panel display indicates the mode

selected: 2-wire or 4-wire.

There are two pre-programmed RTD resistance

tables, and others may be added by the user.

The controller allows for other convenient pro-

grammed features.

The unique design makes adjustment of the

PRS-300 for calibration semiautomatic. An

internal calibration routine guides the user to

perform measurements using only a precision

ohmmeter and enter the measured values into

the PRS-300. No other standards are required.

IET Labs offers the PRS-DMM Self

Adjusting Software which works with the PRS-

300 and Fluke 8508A or Keysight 3458A to

automate this adjustment process and eliminate

the need for a technician to manual enter the

resistance values manually into the PRS-300

SPECIFICATIONS

PRS-300 Series

3

Chapter 2

SPECIFICATIONS

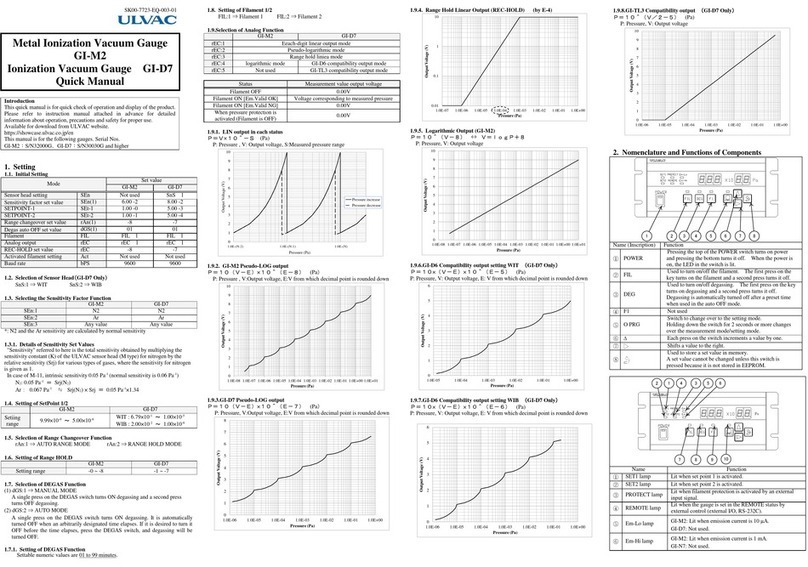

For convenience to the user, the pertinent

specifications are given in an OPERATING

GUIDE, shown typically in Figure 2.1, affixed

to the case of the instrument.

2.1 Specifications

User interface:

Numeric keypad to enter resistance value with digital

display.

Accuracy: ±(70 ppm + 1 m) 2 and 4 Terminal at

23°C ±5°C Also see section 2.2

Minimum setting: 0.1

Resolution: 1 or 6 digits

Range: 0.1 - 20 M

Stability: See section 2.2

Thermal emf: < 15 V

MaximumLoad: 2 A, 200 V (peak), 0.5 W whichever

applies first

Resistors: Precision wire-wound and metal foil

TC of Resistors: < 1 ppm/°C for R4 and above

RTD Tables:

9 RTD tables can be entered into memory to allow

user selection of temperature and the correct value

of resistance will automatically be programmed.

PT-100 and PT-1000 tables for both Fahrenheit and

Celsius are pre-programmed into memory locations

1 to 4.

Adjustment:

Automatic adjustment procedure utilizing a high pre-

cision DMM eliminates the requirement for manual

trimming of resistors.

AC Frequency Response:

Residual Capacitance Terminals to GND: < 850 pF

Resistance Typical ac/dc difference @ 1 kHz

0.1 -10 k<100 ppm

10 - 100 k<200 ppm

100 k- 1 M<1%

1 - 20 M<20%

Terminals:

Four low-emf, gold-plated, tellurium-copper 5-way

binding posts are used for HI and LO terminal pairs

for CURRENT and SENSE. GND binding post is

connected to the case, to the chassis ground and to

the earth ground.

Switching time: 15 ms Max for relay switch time

between values, typically < 1 ms.

< 20 ms to interpret command and switch via

ieee.488 interface

Power requirements:

90 - 264 Vac , 47 - 63 Hz. 30 Watts Max.

Environmental conditions:

Operating: 10°C to 40°C; <80% RH

Storage: -40°C to 70°C

Note: exposure to humidity >60% for extended

periods of time can cause the resistors to drift

some of which is reversible. See 2.2 for more

information

Dimensions:

Bench model: 43 cm W x 8.9 cm H x 33 cm D (17” x

3.5” x 13”) in front of panel: 3.8 cm (1.5”).

Weight:

Bench model: 5.5 kg (12 lb); weight specifications

are nominal.

Remote Control:

USB: USB Type B connector standard on rear panel

Remote Control Options:

IEEE:

GPIB standard 24 pin connector, conforms to IEEE-

488.2; SCPI 1994.0 command set; Hardware or

software configurable addressing range of 1 to 30.

Ethernet:

IEEE 802.3 compliant, Speeds 10 BaseT

(10 Mb/s) and 100 BaseT (100 Mb/s), IP Address

Static or DHCP, Factory setting 192.168.0.254 static

SPECIFICATIONS

PRS-300 Series

4

2.2 General Specifications and Stability

Warmup:

This unit utilizes custom designed low

thermal emf relays for high stability and low-

level signal applications. This thermal voltage

is nominally less than 15 μV under laboratory

conditions. Please note that a change in this

thermal emf will give a false drift in resistance

as measured by a dc ohmmeter, since the ohm-

meter will interpret this emf as an effective

resistance. The worst case such effective drift

after warm-up is less than ±25 ppm, primar-

ily due to stabilization of this emf at the relay

contacts as settings are changed.

Unit should be allowed to stabilize for

one hour. For maximum stability, allow unit to

warm-up over two hours.

Recommended Calibration Interval:

Typical calibration interval 12 months.

Adjustment can easily be accomplished us-

ing IET’s PRS-DMM software. Adjusting the

PRS-300 can improve accuracy.

Environmental:

This product complies with the WEEE

Directive (2002/96/EC) marking

requirements. The affixed label

indicates that you must not discard this

electrical/electronic product in domestic

household waste.

Product Category: With reference to the

equipment types in the WEEE Directive Annex

I, this product is classed as a “Monitoring and

Control instrumentation” product.

Effects of Humidity:

Exposure to humidity >60% for a periods

of weeks can cause the resistors to drift some

of which is reversible. It is recommended that

the PRS-300 be stored at humidities less than

50% to minimize this.

More information of the effects of humid-

ity on foil resistors can be found at:

http://www.vishaypg.com/docs/63516/VFR_

TN110.pdf

Short-term Stability:

The PRS-300 was tested for extended pe-

riods of time. Based upon this testing the fol-

lowing stability information was determined.

These specifications apply for the PRS-300 in

4 terminal mode with shorting links removed

and without switching to another value.

Typical short-term stability without switch-

ing:

< ±(4 ppm + 100 ) / 10 minutes

Typical 24 hr. Accuracy after Adjustment:

After performing an adjustment per 8.1.4

using a Fluke 8508A and then performing a

calibration verification per 8.1.3 within 24

hours the typical accuracy is:

±(30 ppm + 300 ) for values less than 1 M

±60 ppm for values of 1 Mand higher

See graph below for actual performance with 6

digit resolution across resistance range.

SPECIFICATIONS

PRS-300 Series

5

FIGURE 2.1 Typical OPERATING GUIDE Affixed to Unit

(Please see label affixed to your unit)

PRS-300 PROGRAMMABLE DECADE RESISTANCE SUBSTITUTER

CONSULT INSTRUCTION MANUAL FOR PROPER INSTRUMENT OPERATION

MODEL: PRS-300 SN: B1-17341127

PRS-300 Nov. 2016

WARNING

Observe all safety rules when working with high voltages or line voltages. Connect the (GND) terminal to earth ground in order to maintain the case at a safe voltage.

Whenever hazardous voltages (>45 V) are used, take all measures to avoid accidental contact with any live components: a) Use maximum insulation and minimize the use

of bare conductors. b) Remove power when adjusting switches. c) Post warning signs and keep personnel safely away.

IET LABS, INC. www.ietlabs.com

CAGE CODE: 62015

• Long Island, New York

Accuracy: ±(0.007% + 1 m) 2 and 4 Terminal at 23°C ±5°C

Minimum setting: 0.1

Resolution: 1 or 6 digits

Range: 0.1 - 20 M

Thermal emf: < 15 V

Maximum Load: 2 A, 200 V (peak), 0.5 W whichever applies first

Resistors: Precision wire-wound and metal foil

RTD Tables:

9 RTD tables can be entered into memory to allow user selection of temperature

and the correct value of resistance will automatically be programmed.

PT-100 and PT-1000 tables for both Fahrenheit and Celsius are programmed

into memory locations 1 to 4.

Adjustment:

Automatic adjustment procedure utilizing a high precision DMM eliminates the

requirement for manual trimming of resistors.

Terminals:

Four low-emf, gold-plated, tellurium-copper 5-way binding posts are used for HI

and LO terminal pairs for CURRENT and SENSE. GND binding post is connected

to the case, to the chassis ground and to the earth ground.

Switching time: <1 second per change

Power requirements:

90 - 264 Vac , 47 - 63 Hz. 30 Watts Max.

Remote Control:

USB: Standard USB Type B connector on rear panel, uses FTDI driver

Remote Control Options:

IEEE: GPIB standard 24 pin connector, conforms to IEEE-488.2; SCPI 1994.0

command set; Hardware or software configurable addressing range of 1 to 30.

Ethernet: IEEE 802.3 compliant, Speeds 10 BaseT

(10 Mb/s) and 100 BaseT (100 Mb/s), IP Address Static or DHCP, Factory setting

192.168.0.254 static

SPECIFICATIONS

PRS-300 Series

6

PRS-300 Series

OPERATION 7

Chapter 3

OPERATION

3.1 Initial inspection and setup

This instrument was tested and carefully

inspected before shipment. It should be in

proper electrical and mechanical order upon

receipt.

An OPERATING GUIDE is attached

to the case of the instrument to provide ready

reference to specifications.

Mount the unit in a standard 19” rack if

the rack mount option is specified.

3.2 Connection

3.2.1 General Considerations

The PRS-300 Decade Resistor utilizes a

5-terminal connection. The binding posts are

standard laboratory type and readily accept

banana plugs, spade lugs, alligator clips, and

bare wire. Binding posts are located on the

front panel of the instrument unless specifically

ordered with a Rear Output option.

The Kelvin terminals consisting of a

CURRENT and a SENSE pair, each labeled

HI and LO. These minimize contact resis-

tance.

4 Wire connection the gold shorting links

must be removed on the binding posts of the

PRS-300 and the PRS-300 set to 4 Wire.

2 Wire connection the gold shorting links

must be used on the binding posts of the PRS-

300 and the PRS-300 set to 2 Wire.

See section 3.4.10 for more information

The GND terminal on all models is con-

nected to the case and to earth and chassis

grounds. This may be used as a shield terminal.

3.2.2 Electrical Considerations

The performance of the PRS-300 is direct-

ly affected by the quality of the connection to

the system under test. This is particularly true

with the precision series models having higher-

accuracy and/or lower-impedance decades.

For optimum performance, contact resis-

tance should be kept to a minimum by using

the most substantial mating connection possi-

ble, and by assuring that the connection is well

secured to the binding posts.

3.3

Condensed Operating Instructions

1. Turn on the PRS-300 ON using POWER

SWITCH

2. Select a desired resistance value in one of

the following ways:

a) Enter a value using the number keys,

then press ENTER.

b) Press a Quick Value key (A– B) to

display a user-defined value or a factory

default value.

OPERATION

PRS-300 Series

8

Default values are: A: 10 kB: 100

k

c) Press RCL then a number key (0 – 9)

to display a user-defined value or a fac-

tory default value.

Default values are: 0- 100 1- 1

k2- 2 k

3. To prevent possible damage to

the PRS-300, set the maximum

applied voltage by pressing VOLT,

entering the voltage on the keypad, then

pressing ENTER. (Default: 0.5 V)

The firmware sets the minimum selectable

resistance value so that the power does not

exceed 1 W. To ensure that the whole range

of resistances is selectable, VOLT setting

must be ≤1 V.

Rmin is limited to >V2, where V is the

VOLT setting.

4. Select 2-wire or 4-wire mode by press-

ing the MENU button, selecting CON-

FIGURE, pressing the “2” will change

between 2-wire and 4-wire modes

In 2-wire mode shorting links must be in-

stalled across high and low terminal pairs.

In 4-wire remove the shorting links.

5. Connect to the circuit or device under test.

To isolate the PRS-300 from the application,

press OPEN to open the circuit. To close the

circuit, press OPEN again.

3.4 Menu Structure

The main table below show menu struc-

ture of the PRS-300 and basic function of each

button and menu selection.

Key Description Function

Basic operation

enter enter button Sets resistance value

0-9, 000/(-) Used to enter numerical values. To select desired numerical

value, press value as required.

(-) is used with tables for nega-

tive temperature

Deletes the last character from

the display.

To delete the last character,

press .

Options

MENU Displays the following submenu:

1. STANDARD VALUES

1: 1% STD VALUES

2: 5% STD VALUES

3: 10% STD VALUES

4: RATIOMETRIC

2. CONFIGURE

1: LCD CONTRAST

2: 2W / 4W MODE

3. CALIBRATE

4. VERSION

Press MENU to select one of the

following:

1. STANDARD VALUES - se-

lects increments for UP

and DOWN keys

2. CONFIGURE - allows user

to adjust display contrast

and change between 2-wire

and 4-wire modes

3. CALIBRATE - see Section 8

4. VERSION - Displays cur-

rent firmware version and

release date.

INCR Selects the increments for the

UP and DOWN keys

Default value: Ratiometric (0.8%

of displayed value)

To adjust increments:

1. Press INCR.

2. Enter desired increment

value on the keypad.

3. Press ENTER to save.

Storing and recalling resistance values

STO Stores a resistance value in

memory locations A-D and 0-9.

To store a value, press STO and

then press the desired location

button A-D or 0-9.

A, B Recalls a stored resistance

value.

Default values:

A: 10 kB: 100 k

To change stored values:

1. Enter a resistance value

2. Press STO and then A, B

RCL Recalls a stored resistance

value from memory location 0-9.

To recall a stored value, press

RCL, then press the desired

location button (0-9)

Limiting Current

VOLT Sets voltage to limit the current

in order to protect the PRS-300

from possible damage.

Default value: 0.5 V

To adjust voltage:

1. Press VOLT.

2. Enter desired voltage on the

keypad.

3. Press ENTER to save.

Electrical Isolation

OPEN Isolates the connection terminals

by establishing an open circuit.

To open the circuit, press OPEN.

To close, press OPEN again.

Option: Simulating RTD’s and transducers

TABLE Loads up to 9 stored data

tables for simulating RTD’s or

transducers.

To select the desired table,

press TABLE to cycle through

the three options.

PRS-300 Series

OPERATION 9

3.4.1 Main Display

The main display shows the resistance

value in ohms or temperature value if tables

are used. The main display also shows if the

unit is configured for 4W (4-wire mode) or 2W

(2-wire mode) in the upper left corner of the

display.

Figure 3-1 Main Display showing 4-Wire

See section 3.2.3 for more information on

2-wire and 4-wire connections.

3.4.2 Setting a Resistance Value

To set a resistance value use the numeric

keypad to enter the value followed by the

ENTER button. The 000 button can be used

to increase the resistance value by a factor of

1000.

The UP and DOWN keys can also

be used to increment or decrement the resis-

tance value. See 3.4.6 INCR Key for more

information.

3.4.3 Menu Button

Pressing the MENU button will show four

selections. See Figure 3-2

Figure 3-2 Menu Screen

Press the numerical value 1 to 4 on the

keypad for the desired selection.

Press the MENU button to cancel and

return to previous screen at anytime.

3.4.4 Standard Values Screen

There are 4 selections available in the

STANDARD VALUES menu. The operation

of the standard values allows the PRS-300 to

be used as an automated resistance carousel

with built-in EIA “preferred value” resistance

tables of 1% (E96), 5% (E24), 10% (E12)

increments or RATIOMETRIC user specified

increment.

Figure 3-3 Standard Values Menu

Press the numerical value 1 to 4 on the

keypad for the desired standard values.

Resistors are available in a number of

standard ranges, often called ‘preferred val-

ues’ These ranges, or series, are set out by the

Electronic Industries Association (EIA), and

common values are E12, E24, E48, and E96.

The number after the ‘E’ denotes the number of

values the series contains per decade.

The series are logarithmic and are derived

from the resistor tolerance; resistors with a

tighter tolerance can have more values in the

series that won’t overlap one another. The se-

ries are sometimes referred to by the tolerance,

the two being related as follows:

E12: 10% tolerance

E24: 5% tolerance

E48: 2% tolerance

E96: 1% tolerance

When a STANDARD VALUE is selected

on the PRS-300 pressing the UP or DOWN ar-

rows will increment the resistance value to the

OPERATION

PRS-300 Series

10

next “preferred” resistance value.

RATIOMETRIC allows a custom toler-

ance value to be entered by the user. The

default value is 0.8% but can be set to the

required value in %.

3.4.5 Tables Key

Pressing the TABLE key allows use of

tables. There are 9 tables that can be selected.

The first 4 tables, 1 to 4, are defined as PT-100

C, PT-100 F, PT-1000 C and PT-1000 F where

C is degrees Celcius and F is degrees Fahren-

heit.

Press TABLE key and then a number key

0 through 9 followed by the ENTER key will

select a table. Table 0 is defined as no table is

used and resistance is shown.

Figure 3-4 No translation Table

Press the numerical value 1 to 9 on the

keypad for the desired table to be used. For

example pressing TABLE key, then “1” and

ENTER key will select use of the PT-100 C

table as shown in Figure 3-5

Figure 3-5 Table 1 PT-100 C

Once the table is selected the display

will change showing temperature on top and

resistance on bottom. Any value entered via

front panel or remotely will be assumed to be a

table value rather than a resistance value. For

example if 0.25 is entered then the screen will

look like Figure 3-5 showing temperature on

top line and resistance on the bottom line.

Figure 3-5 PR-100 C set to 0.25 °C

For negative temperatures press the 000/

(-) key prior to entering the value.

If a value is not listed in the table and is

entered using the numeric keypad or selected

using the UP and DOWN keys interpolation is

used between the two closest table values.

Custom tables can be entered in locations

5 to 9 by using the USB interface and remote

CONIG:TABLE commands. See Appendix B

for more information.

3.4.6 Increment INCR Key

The INCR key allows entry of a numeric

value. The numeric value representing the

step or increment size the UP and DOWN

keys use.

For example pressing INCR key and then

10 would result in the displayed value being in-

cremented or decremented 10 for each time

the UP or DOWN key is pressed.

INCR can also be used for tables in the

same way so that the operator can press the UP

or DOWN key and increment or decrement the

displayed value in °C or °F.

3.4.7 OPEN Key

The OPEN key opens all relays in the

PRS-300 resulting in high resistance at the

resistance terminals. The display will shown

OPEN Ω. Pressing the OPEN key again will

cause the resistance to return to the previous

set value.

For short enter lowest value of 0.1 us-

ing keypad or remote.

Table of contents

Other iET Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Iskra

Iskra WM3x6 Series User and installation manual

ITS Telecom

ITS Telecom H560 Dewpoint Pro user manual

Campbell

Campbell SR11 instruction manual

Apera

Apera TDS20 instruction manual

Gossen MetraWatt

Gossen MetraWatt DIGISIX 2 operating instructions

TSI Instruments

TSI Instruments BlueSky 8145 quick start guide