iET 1316 Troubleshooting guide

♦PRECISION INSTRUMENTS FOR TEST AND MEASUREMENT ♦

Copyright © 2005 IET Labs, Inc.

1316 im/August, 2005

1316

Oscillator

User and Service Manual

TEL: (516) 334-5959 • (800) 899-8438 • FAX: (516) 334-5988

534 Main Street, Westbury, NY 11590

IET LABS, INC.

Formerly manufactured by

GenRad www.ietlabs.com

Standards •Decades •Strobes •Sound Level Meters •Bridges

♦PRECISION INSTRUMENTS FOR TEST AND MEASUREMENT ♦

TEL: (516) 334-5959 • (800) 899-8438 • FAX: (516) 334-5988

www.ietlabs.com

534 Main Street, Westbury, NY 11590

IET LABS, INC.

iii

WARRANTY

We warrant that this product is free from defects in material and workmanship and, when properly used, will

perform in accordance with applicable IET specifications. If within one year after original shipment, it is found

not to meet this standard, it will be repaired or, at the option of IET, replaced at no charge when returned to IET.

Changes in this product not approved by IET or application of voltages or currents greater than those allowed by

the specifications shall void this warranty. IET shall not be liable for any indirect, special, or consequential

damages, even if notice has been given to the possibility of such damages.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUD-

ING BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF MERCHANTIBILITY OR FITNESS FOR

ANY PARTICULAR PURPOSE.

vii

WARNING

OBSERVE ALL SAFETY RULES

WHEN WORKING WITH HIGH VOLTAGES OR LINE VOLTAGES.

Dangerous voltages may be present inside this instrument. Do not open the case

Refer servicing to qulified personnel

HIGH VOLTAGES MAY BE PRESENT AT THE TERMINALS OF THIS INSTRUMENT

WHENEVER HAZARDOUS VOLTAGES (> 45 V) ARE USED, TAKE ALL MEASURES TO

AVOID ACCIDENTAL CONTACT WITH ANY LIVE COMPONENTS.

USE MAXIMUM INSULATION AND MINIMIZE THE USE OF BARE

CONDUCTORS WHEN USING THIS INSTRUMENT.

Use extreme caution when working with bare conductors or bus bars.

WHEN WORKING WITH HIGH VOLTAGES, POST WARNING SIGNS AND

KEEP UNREQUIRED PERSONNEL SAFELY AWAY.

CAUTION

DO NOT APPLY ANY VOLTAGES OR CURRENTS TO THE TERMINALS OF THIS

INSTRUMENT IN EXCESS OF THE MAXIMUM LIMITS INDICATED ON

THE FRONT PANEL OR THE OPERATING GUIDE LABEL.

Specifications

Frequency:

10

Hz

to

100

kHz

in

4 decade ranges.

Controlled

by

one

11-position

and

one

10

-position

switch

for

the

most-significant

digits

and

a

continuously

adjustable

dial

with

detented

zero-

position

for

the

third

digit;

in-line

readout

with

decimal

point

and

frequency

units

.

Accuracy:

::!::

1%

of

setting~

Drift

(t

ypical

at

1 kHz),

warmup

0

.1

%,

shor

t-term

(10

min)

0.001%,

lon

g-term

(12

h)

0.0

05%.

Resettability,

within

0.005%.

Power

Output:

Controlled

by

5-posi

tion

switch

a

nd

uncalibrated

ve

rni

er.

Monitored

by

meter

with

::!::3%

.accuracy.

Available

at

rear

BNC

connector.

+with

continuously

adjustable

dial

set

at

zero

detent

position.

Output

Range

Open

circuit,

rms

1.s v i s v .I

1s

v 1

so

v 1 1so v

===

1.25 v-

===

4 v 1

===

12.s v 1

===

4o

v 1

===

125 v

Distortion

< 0.2%

from

100Hz

to

10kHz

Hum

0.003%

of

max

out

put

Resoonse

IO

Hr

IOO

Hr

lt~;Ht

IOOIII:Hz

f'fiEOUfNCY-

Hr

IJ16-1

Short

Circuit

Distortion

output

constant

within

±2%

from

10

Hz

to

50

kHz,

±5%

for

frequencies

>50

kHz

5A

I 1.6 A J

0.5

A j

0.16

A I 0.05 A

< 0.2%

from

100Hz

to

10kHz

Synchronization:

Input,

frequency

can

be

locked

to

external

signal;

lock

range,

::!:

1%

/V

rms

i

nput

up

to

10

V:

frequency

controls

func-

tion

as phase

adjustment.

Output,

==:o.3

V

rms

beh

ind

27

kO; use-

ful

to

sync

oscilloscope

or

to

drive

a

counter

or

another

osci

ll

ator

.

Single

rear

BNC

con

ne

ctor

serves as

both

input

and

output

Impedance

0.25

{l

l 2.5 0 l 25 0 j

250

0 l 2.5

kO

terminal.

·

Power

1.6

W

nominal

in

to

ma

tche

d load

Reference

Outputs:

Quadrature

output

lags

go•.

Each

availab

le

at

rear

BNC

connec

tors

. 1n-phase

output

by

Power: 100

to

125

and

200

to

250

v,

50

to

60

Hz,

36 W.

Mechanical:

Bench

or

rack

mount.

Dime.1sions (w X h x

d):

Bench,

19.75 X 5 X

13.06

in.

(502 X 127 X 332

mm);

rack,

19

X 3.47 X

11.44

in.

(483 X 88 X 291

mm)

. Weight:

Bench,

26

lb

(12 kg)

net,

32

lb

(14 kg)

shipping;

rack,

21

lb

(10 kg) net,

27

lb

(12

kg)

shipping.

-::--:---;---

-----:-

-

-:-:-

--

--

-

~

-l_n·

_

Ph

_

a~s-::e:::-

_

1

Quadrature

Output,

open-circuit

1.25 ::!:0.25 V

rms

Distortion,

100

Hz

to

10

kHz

- <- 0- .

-:-

2

-:-%.,--

-'1

<

0.4%

Response,

10

Hz

to

10

kHz

_

__

__

:t_2:-

0

:".Vo:_

_ _

__

_

10

kHz

to

100

kHz

:t4%

-----

Minimum

Load 47 kO

---GenRad

WARRANTY

Catalog

Number

1316-9700

1316-9701

Description

1316

Oscillator

Bench

Model

Rack

Model

We

warrant

that

this

product

is

free

from

defects

in

material

and

workmanship

and,

when

properly

used,

will

perform

in

accordance

with

GenRad's

applicable

published

specifications

.

If

within

one

(1)

year

after

original

shipment

it

is

found

not

to

meet

this

standard,

it

will

be

repaired

or

at

the

option

of

GenRad,

replaced

at

no

charge

when

re

turned

to

a

GenRad

service

facility.

CHANGES

IN

THE

PRODUCT

NOT

APPROVED BY

GENRAO

SHALL

VOID

THIS

WARRANTY.

GENRAD

SHALL

NOT

BE

LIABLE

FOR

ANY

INDIRECT,SPECIAL,

OR

CONSE-

QUENTIAL

DAMAGES, E

VEN

IF NOTICE

HAS

BEEN

GIVEN

OF

THE

POSSI-

BILITY

OF

SUCH

DAMAGES.

THIS

WARRANTY IS

IN

LI.EU

OF

ALL

OTHER

WARRANTIES, EXPRESS

OR

IMPLIED,

INCLUDING,

BUT

NOT

LIMITED

TO

,

ANY

IMPLIED

WARRANTY

OF

MERCHANTABILITY

OR

FITNESS

FOR

A PARTICULAR PURPOSE.

SERVICE

POLICY

Your

local

GenRad

office

or

representative

will

assist

you

in

all

matters

relating

to

product

maintenance

,

such

as

ca

librat

ion, repair,

replacement

parts

and

service

contracts.

GenRad

policy

is

to

maintain

product

repair

capability

for

a

period

of

five

(5)

years

after

origin

.

al

shipment

and

to

make

this

capabi

li

ty

available

at

the

then

prevailing

schedule

of

charges.

NOTE

The

material

in

this

manual

is

for

informational

purposes

only

and

is

subject

to

change

without

notice.

GenRad assumes

no

responsibility

for

any errors

or

for

consequential

damages

that

may result

from

the

use

or

misinterpretation

of

any

of

the

procedures

in

this

publication.

Introduction-Section

1

1.1

PURPOSE

1.2 DESCRIPTION . . . . . . . . . . . . .

1.3 CONTROLS, CONNECTORS,

AND

INDICATORS .

1.4 SYSTEMS . . . . . .

1·1

1-1

1-1

1-1

1

-1

1.5 ACCESSORIES SUPPLIED . .

1.1

PURPOSE.

The Type 1316

Osci

llator

is

a high-performance instru-

ment with

an

output

of

10 Hz

to

100 kHz.

It

was

specifically designed

for

use

wi

th

the

Ty

pe

1238 Detector

and

the Type 1616 Precision Capacitance Bridge,

and

is

also

an

excellent

general

purpose instrument.

1.2 DESCRIPTION.

The 1316 Oscillator

is

a decade-conductance-tuned,

Wien-bridge oscillator containing a low-distortion power

amplifier that

is

transformer coupled

to

provide isolation

from

th

e load. Output power and frequency are

se

lected

by

front

-pa

nel

controls;

al

l external connections

are

made

to

the

rear

pane

l

for

clutter-free operation.

A provision

to

introd

uce

or

extract a synchronizing

signal

is

included in the oscillator circuit. The extracted

signal

is

independent

of

the

output

setting and

can

be

used

to operate a counter

or

to

synchronize

an

oscilloscope.

Other features

are:

unambiguous in-line

re

adout,

dec-

ade-frequency selection

with

positioned decimal

po

int

and

units,

and

two

reference outputs (IN-PHASE

and

OUAD-

RATUR

E).

The

re

ference outputs

are

for

use

with

the Type

1238 phase-sensitive Detector.

1.3 CONTROLS, CONNECTORS, AND INDICATORS.

The front-

and

rear

-p

anel

c

ont

rols, connect

ors

and

indicator

are

shown

in

Figures 1

-1

and

1-2

respectively.

Refer

to

Tables 1

-1

and

1

-2

for

a functional

and

physical

description.

1.4 SYSTEMS.

The 1316

osci

llator

is

used

as

a component in the

1621

Pre

cision Capacitance

Measure

me

nt

System (Figure 1-3).

1.5 ACCESSORIES SUPPLIED.

A 3-wire, 7-ft power cord (P/N 4200-9625)

is

supplied

with the instrument.

INTRODUCTION

1-1

4 5 6 7 8

Figure 1·1. Front-panel controls, connectors·and indicators.

-------------------------------------Table1-1-------------------------------------

Figure 1·1

Ref.

No.

2

3

4

5

6

7

8

9

10

Name

POWER

swit

ch

FREQUENCY

se

lec

tor

FREQUENCY

se

l

ector

FREQUENCY

se

lec

tor

FREQUENCY

r

ange

swit

ch

OUTPUT

VOL

TAGE

RANGE

switch

Voltmet

er

OUTPUT

ADJUS

T

contro

l

1-2

INTRODUCTION

FRONT

PANEL

CONTROLS

AND

INDICATOR

Description

2-

position

toggle

switch,

down

position:

OFF.

10-

position

rotary

switch, dial-marked

1

to

10

.

11-position

rotary

switch,

dial

mark

ed

0

to

9 and X

(X

i

nd

icate$

10

or

0).

Stepless

potentiometer,

dial marked

0

to

9

with

detent

at 0.

4-position

switch,

dial marked Hz, H

z,

kH

z, and kHz.

5-position

rotary

switch,

panel-marked

1.5, 5.0,

15

.0, 50.0, a

nd

150

.

Ac

meter

wit

h

0-15

and 0-50-V

scales.

Steple

ss,

rotary

potentiom

eter

with

limits

labeled 0 and

MAX

.

Zero-adjust screw.

Front

-panel,

white

indi

cator

lights.

Function

Turns instrument

on

or

off

.

Se

lects and

indi

ca

tes 1st di

git

of

frequency.

Se

lects and indicates

2nd

digit

of

fr

e

qu

ency.

Se

lects and indicates

3rd

digit

of

frequency.

Se

lects frequency range, indicates

unit

s,

and c

ontrols

illuminated

decimal

point

.

Se

lects output-voltage range and

indicates

full-s

cale meter range

(item

7). Simultaneously switches

the

outp

ut

impedance

from

0.

25

n

to

2.5

kU in decade steps.

In

dicates

output

terminal

voltage,

in

ranges

sel

ected

by

it

em

6.

Co

ntrol

s

output

le

ve

l in the range

selected

by

it

em 6.

Mechanically adjusts

output-

voltage meter

for

mechanical zero.

Indi

cates posi

tion

of

decimal

point,

co

ntrolled

by

the

FRE

-

QUENCY

range switch

(item

5).

figure 1-2.

Rear

-

panel

control

and

connectors

.

-------

--

----------Table

1-2-----

- -

--

----

-

-----

Figure

1·2

R

ef.

No.

2

3

4

5

6

7

REAR-

PANEL

CONTROLS

AND

CONNECTORS

Na

me

D

esc

ription

QUADRATURE

REFEREN

CE

BNC jack

OUTPUT

IN-PHASE REFEREN

CE

OUTPUT

BNC jack

EXT

SYNC connector BNC jack

P

OW

ER OUTPUT connect

or

BNC j

ack

Fuse

Bussma

n MDL

8/

10

A,

slo-

blo

5Q-60 Hz Two-pos

iti

on s

li

dt.

10

0

V-

1

25

V

sw

it

ch

2

00

V-

25

0 V

Th

ree

-pin power plug

Fun

ction

Provi

des

a reference output that l

ags

the

"i

n

-p

hase" reference by 90° at 1.25 V o.c.

Provides a reference

output,

in

-p

has

e

wi

th

power

output,

at 1.25 V o.c.

For synchronizing

outp

ut f

req

uency

to

an

external source (lock r

ange

is ±1%/Vr

ms

, up

to

10

V)

or

constant-amplitude sig

na

l source

(0.3 V behind

27

knl.

Main output, 1.6 W nominal m

ay

be 125 V o.c.

or 5 A s.c.

Pr

ote

cti

on.

aga

inst

damage

from a sh

ort

c

ir

-

cu

it

for

110-

or

220-V operation.

Switches line power

co

nn

ec

ti

on

f

or

either

11

0-V

or

220-V operati

on

.

Accepts 3-wi

re

li

ne

cord to power

instrument.

INTRODUCTION 1-3

1-4 INTRODUCTION

~

...

_,.,.. ,IN

-

··

-·I

..

'

-..

...

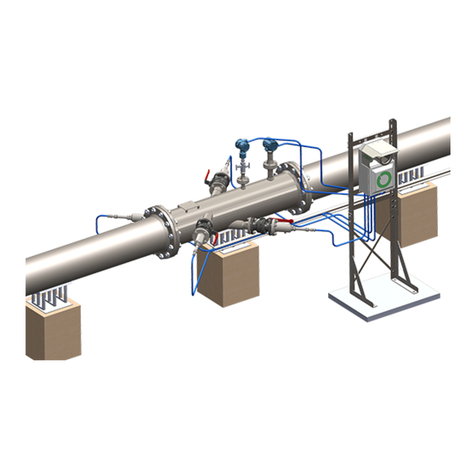

lVIII

Figure 1-

3.

Type

1621 Precision Capacitance-MeasurementSystem.

Installation-Section

2

2.1

GENERAL

2.1

GENERAL . . . . . .

2.2 DIMENSIONS . . . . .

2.3 POWER-LINE CONNECTION

2.4 BENCH MODELS . . . .

2.5 RACK MODELS . . . .

2.6 LINE-VOLTAGE REGULATION .

2.7

EXTERNAL

CONNECTIONS . .

The Type 1316

Osci

lla

tor

is available

for

either bench

use

or

installation in

an

E

IA

Standard

RS

-310,19-in. relay

r

ack

with

universal hole

spacing

. Appropriate cabin

et

and

hardware

se

ts

are

ava

il

ab

le

for

conversion of a bench model

for

rack installation

or

vice

ve

rsa

.

2.2 DIMENSIONS.

O

utl

ine

drawings showi

ng

overall dimensions

of

the

os

cillator in bench

and

rack models are shown

in

Figure

2-1.

2.3 POWER-LINE CONNECTION.

Power requirement is 36 W

at

100 to 125

or

200

to

250

V,

50

to

60Hz.

Make

co

nnections

as

fo

llows:

a.

Se

t the line-voltage

swi

tch on

th

e r

ear

panel

to

correspond with

th

e

avai

l

ab

le power-line voltage.

Use

a

sma

ll screwdriver to slide the switch.

b. Connect

th

e external power line

to

the power plug,

using the power

co

rd suppl

ied

or

an

equivalent, 3-conduc·

tor

co

rd.

A single

8/

1

0-

A

fuse

protects both the low· and

high-voltage circuits.

2.4 BENCH MODELS.

2.4.1 General.

2·1

2·1

2-1

2·1

2·2

2·4

2-4

E

ac

h bench model

comes

completely

as

semb

led

in

a

metal cabinet intended f

or

use

on a table

or

laboratory

ben

ch.

Th

e instrument

is

mounted on tracks that permit

easy

removal

for

inspection

or

repair.

2.4.2 Cabinet

Removal

.

a.

Set

th

e instrument in the horizontal posi

tion

, free of

unnecessary c

ables.

b.

Remove

the

four

dress-pane

l

screws

(A),

accessib

le

th

rough holes in the handles.

c.

Carefully pull the

ins

trument

out

of

the cabinet.

2.4.3

Conversion

for

Rack

Mounting.

To convert a

be

nch ins

tr

ume

nt

for

rack mounting,

exchange

th

e cabinet and i

nstal

l appropriate

ha

rdware,

as

follows:

a.

Ob

t

ain

a Rackable Cabinet Assembly PIN 4174-3240

(Table 2-1)

fr-om

General

Rad

io Company.

b.

Obtain, optionally, Bracket Set P/N 4174-2007 (Table

2·2). Th

is is

espec

ially recommended

for

a

heavy

instrument,

which

needs

support from the

rear

rail

of

the rack.

INSTALLATION

2·1

I.

19

.8 BE

NC

H MODEL

1 t

FRONT PANEL c

DIM.

A

B

c

D

END

VIEW

INCHES

11

.562

12

.837

4.

031

4.906

J D

1

J~'

ro'"~

1I

DI

M.

INCHES

p

13.640

Q

11.749

R

13.062

1r

-TOPVIEW

,

__1

, s 1.

625

W

L=f-J

T

3.469

19

RACK

MODEL

~

FRONT PANEL

~

l

~

END VIEW

T

l

Figure 2-1. Dimensions

of

the

1316

bench

and

rack·model

instruments

.

c.

Remove

the

cabinet,

as

in

paragraph 2.4.2.

d. Remove the rear cover

from

the bench cabinet,

wit

h

sc

r

ews

(B

Figure 2-2} ,

for

later installation on the rack

cab

inet.

e. Proceed

with

the

ra

ck installation; skip

to

paragraph

2.5.2, step b.

2.5 RACK MODELS.

2.5.1 General.

E

ac

h rack model

comes

completely assembled in a

suitable metal cabinet, which isdesigned

to

stay

sem

iperma-

nently

in

a rack. The instrument

can

be

drawn forward on

extending tracks

for

access

with

support,

or

(wi

th

a

lift}

withd

rawn completely. The cabinet and hardware li

sted

in

Tables

2-1

and 2-2 are all included

with

a

ra

ck-model

instrument.

2.5.2 Installation. Figure 2·3

Directions

fo

-

llow

fo

r mounting the cabinet in a rack and

installing

th

e instrument on

it

stracks:

a.

Remove 4 dress-panel screws (A)

and

slide the

in

strument

out

of

the

cab

in

et

until

the tracks

are

fully

extended.

Co

ntin

ue

pulling the instrument forward

unti

l

motion

along the tracks

is

stopped.

At

this juncture,

tilt

the

f

ront

of

the instrument up slig

htl

y

and

continue

with

-

drawal, past the stops,

unt

il it

is

free.

2-2

INSTALLATION

b.

Insert the

rack

cab

inet wherever

desi

red

in

the

rack

-

be

su

re

it's level - and fasten it

with

4

screws

(C)

to the

front

rai

ls

.

c. If the rack contains a rear support

rai

l,

use

brackets

(0)

to support the

cab

inet

with

th

e rear rail

s;

open-slotted

screw holes allow positioning.

d.

Use

the

se

t

of

slots

in

the si

des

of the

cab

inet that

allow alignment

of

the open-slotted holes in the brackets

with

threaded h

oles

in the

rai

l. The long fl

ange

should ex-

tend

to

the rear.

e.

Insert

screws

(E)

from inside the cabinet, through the

slotted holes and

dr

i

ve

them i

nto

the hol

es

in the long

flange of the bracket.

Each

si

de

takes 2.

--------Table

2·1--------

RACKABLE CABINET ASSEMBLY

(P

/N

4174-3240)

Quan-

tity

Description

Hardware set, including:

2 Screws, 0464-32, 1/4-in, thread

for

ming

("B"

for

rear cover).

4 Screws, 0.1

90

-32,

9/16

in,

dress

("A"

for

front

panel).

4

Sets

of

10-32 nutsand

was

hers

(for

screws

"A",

if

needed).

4174-2004

REAR

COVER

BENCH·

CA

BINET

ASSEMBLY

SLIDE

BLOCKS 417.0

Figure 2·2. Bench-cabinet installation.

NOTE

S

ta

rt

the screws in the ap

pr

o

pr

iate hol

es

off

the

rack, to make

th

e threading

easier

.

f.

Pass

sc

rews (B)

thr

ough brackets

and

screw 2 in

to

each

rear rail. (Details may

be

varied

to

suit particular

situa

tion

s.)

g.

To

install the

ins

trument, first

set

its rear

edge

in the

cabinet

front

opening. Slide the ins

tr

ument back, making

sure that

the

r

ea

r

and

the upper front slide blocks

enga

ge

the tracks. (Stops prevent further insertion.)

h.

Pul

l the instrument forward with the tracks, keeping a

hand

on

each

side (fingers underneath). Slide the instru-

ment back about

%in

. along

both

tracks, past the stops,

by

pressing down

on

the

tr

acks (w

ith

thumbs) while

tilt

ing

th

e

f

ront

of

the

i

nstr

um

e

nt

up

sl

igh

tl

y.

i.

Pus

h the instrume

nt

back i

nt

o the rack, checking

for

smooth o

pe

ra

t

ion

of

the trac

ks

and

sl

ide blocks.

NOTE

T

he

instrument

is

now

read

ily accessible

for

behind-the-panel

ad

justments.

It

slides in and

out

fr

ee

ly on extendi

ng

tracks.

B

FR

ONT

RAIL

RACK

·C

ABINET

ASSEMBLY

-------Table

2·2

--------

BRACKET

SET FOR RACK

MODEL

(P

/N

4174

-2

007)

R

ef

Quan

tity'

Descrip

lion

D 2 L brackets

with

open-slotted holes.

E 4 Screws, 8-32. 3

/1

6 in., thread forming.

C, B 8 Screws, 10-32, 1

/2

-in., t

hr

ead forming.

2.5.3

Conversion

for

Bench

Use.

To

convert a

ra

ck-mounting instrument

for

bench

use,

exchange the cabinet,

as

follows:

a. Obtain a Bench Cabin

et

assembly P/N 4172-4015

(Table 2

·3

)

fr

om

General Radio Company.

b. Remove

th

e instru

me

nt from the rack

ca

bin

et, using

the procedure in step

a,

para. 2.5.2.

c.

Sta

nd

the instrument fa

ce

down, to rest on its

handles,

and

slip the bench

ca

binet

over it. Carefully return

it

to a

hor

izo

nt

al positio

n.

A

Figure 2·3. Rack

-ca

binet installation.

INSTALLATION

2-3

d.

Fas

ten the instrument

to

the cabinet

usi

ng

dress-pa

nel

screws

(A, Figure 2-2).

e.

Transfer

th

e rear

cove

r,

with

screws (B), from rack

cab

in

et

to

bench

cab

in

et.

2.6 LINE-VOLTAGE REGULATION.

The accuracy

of

measureme

nt

s accomplished wi

th

pre-

cision electronic test

equ

ipment operated

from

ac

line

sources

ca

n

ofte

n

be

seriously degraded

by

flu

ctuat

io

ns

in

prim

ary

input

power. Line-voltage variations of ±15%

are

commonly encountere

d,

eve

n in laboratory environments.

Altho

ugh

most mod

ern

ele

c

tronic

i

ns

trum

e

nt

s in

co

rporate

some

de

gr

ee

of

regulation, possible power-sour

ce

problems

should

be

considered f

or

eve

ry ins

tru

mentation setup. The

use

of

lin

e-

voltage r

egu

la

tor

s between power l

ines

and

the

test

eq

uipment

is

recommended as the only s

ur

e way

to

rule

out

the effects on

measur

ement data

of

va

riations in

I

in

evol

tage.

2.7

EXTERNAL

CONNECTIONS.

2.

7.1

General.

All

ex

ternal

co

nne

ctions

to

the Type 1316

Osci

llator

are

made to rear-panel BNC connec

to

rs.

Th

is

feature facilitat

es

th

e

use

of

the 1316 in

th

e Type 1

621

Prec

is

ion-Capaci-

tance-Measurement

Sys

tem (Figure 1-3).

2.7.2 POWER OUTPUT Connector.

The

ma

in out

put

of

th

e

osci

llator is

ava

ilable at

th

e

r

ear

-p

anel P

OW

ER

OU

TPUT jack. Output-voltage

range

and

amplitude are con

tr

olled

by

th

e front-panel OUTP

UT

VOLTAGE

RAN

GE

and OU

TP

UT

ADJ

UST c

ontro

ls r

e-

spectively.

2.7.3

EXT

SYNC Connector.

A

si

ng

le r

ea

r-

pane

l BNC connector

serves

the dual

purpose

of

an

in

put

or

output

jack. As

an

input,

th

e

osci

ll

ator

fr

eq

ue

ncy c

an

be

locked

to

an

ex

ternal signa

l.

2·4

INSTALLA

TION

T

he

lock range

is

±1%/V

rms

in

pu

t.

up

to

10 V,

and

the

front

-

pane

l frequency controls func

ti

on

as

th

e

phase

adjustment. As

an

output

,

0.

3 V

rms

behind 27

kQ

is

avai

lable

to

lock

th

e frequency of another instrume

nt

to

th

at

of

the

asci

llator.

2.7.4 REFERENCE OUTPUT Connectors.

General. T

he

REFERENCE

OU

TPUT

co

nnectors were

designed

into

the

Osci

llator pri

ma

rily

to

provide low-l

eve

l

fixed-amplitude refer

ence

sig

nals

for

the Type 1238 Det

ec-

tor. However,

th

ey

ca

n

be

used

for

any appli

ca

tion

requiring a pair

of

1-V reference

signa

ls w

ith

a ph

ase

dif

ference of 90°.

IN

·PHASE. T

he

IN-PHASE o

utput

jack provides a

refer

ence

vol

tage

that

is

in ph

ase

w

ith

th

e main

POWER

OUTPUT

of

the 1316

Osci

llator. Thisvoltage (open c

ir

cu

it)

is 1.25

±0

.2

V

rms

. Distortion is

less

than 0.

2%

from 1

00

Hz to 10 kHz and the vo

lt

age

re

sponse

is

typi

ca

lly

±2%

from

10H

z to 10 kHz,and ±4%

fr

om

10kH

z

to

100kHz.

The

minimum load impedance should.be

47

k

0..

A smaller

impedan

ce

will redu

ce

the

output

voltage

and

poss

ibly

cause

distortion.

--------Table

2·3

--------

BENCH

CABINET

ASSEMBLY COMPLETE (4172-4015)

Quan·

tity

Description

Pa

rt

No.

1 Bench

Cabi

net

Assemb

ly, including:

4172

-2

042

1

Ca

binet

1

Gas

ket

1

Ba

se

with

hardware (includes

hinge

and

t

ogg

l

es

)

Fa

c

tory

assemb

l

ed

w

ith

:

2 Tracks

2 Bra

ck

ets,

rear

, (and

sc

rew

s)

Supplied w

it

h:

2 Scr

ews,

0.164

-3

2, 1/4 in., thread

forming

("B"

f

or

rea

r c

ove

r)

4

Sc

r

ews.

10-

32,

9/

16

in.

,

dress

("A"

f

or

fro

nt

panel)

OUADRATURE.

Th

e

OUADRA

TURE out

put

jack pro-

vides a referen

ce

vo

lt

age

that

leads

the IN-

PH

ASE and

POW

ER

OUTPUT vol

tages

by

90°. This voltage (open

circuit)

is

1.25 ±0.2 V rms. Distortion is l

ess

than 0

.4%

fr

om 100

Hz

to

10 kHz

and

the voltage

response

is

ty

pically ±4% from

10kHz

to

100kHz.

The

minimum

lo

ad

impedance shouldbe

47

kQ

.

INSTALLATION

2-5

2·6 INSTALLATION

NOTE

The instrument

is

fitted with a new-design power·

connector

that

is

in conformance with the Inter·

national Electrotechnical Commission publication

320. The 3 flat contacts are surrounded by a

cylindrical plastic

shroud

that

eliminates the pos·

sibility

of

electrical shock whenever

the

power

cord

is

being unplugged from

the

instrument. In

addition, the center ground pin

is

longer, which

means

that

it

mates first and disconnects last,

ensuring greater user protection from electric

shock.

The panel connector

is

a standard 3-pin ground·

ing·type,

the

design

of

which has been accepted

world wide

for

electronic instrumentation, and

is

rated

for

250 V

at

SA.

It

also meets require·

ments

of

Underwriter's

laboratories

in the U.S.

and

the

Canadian StandardsAssociation. The

receptacle accepts power cords fitted with the

Belden type SPH-

386

connector.

Operation-Section

J

3.1

GENERAL

3.1

GENERAL

. .

3.2

OPERATIONAL

CHECKS

3.3

NORMAL

OPERATION

3.4 APPLICATIONS

This section contains operational chec

ks,

operating

i

ns

tructions,

and

a basic description

of

some applications

fo

r which the 1316

Osci

llator

can

be

used.

3.1.1 Equipment Turn-on.

To

prepare the instrument

fo

r

use

, perform

th

e

fo

ll

ow

-

ing

steps:

a.

Set

th

e rear-

pane

l line-voltage

se

lec

tor

sw

it

ch to

th

e

lin

e-vo

lt

age

used

(100-1

25

V or 200-

250

V.

50-60Hz),

and

co

nnect the

in

strument to

th

e power line,

us

in

g the power

cab

le suppli

ed.

b. Set the power

sw

itch

to

POWER.

One

of

the

deci

ma

l-

point

lamps should glow. Its pos

it

ion

wi

ll depend

on the FREQUENCY range-switch setting (Refer to Table

3-

1

).

3

.1

.2 Meter Zeroing.

The

output

voltage meter

has

been

zeroed at

th

e factory.

If

it

becomes

ne

cessary

to

re-zero

th

e

me

ter, proceed

as

follows:

a.

Che

ck

to

see

that

th

e

POWER

swi

tch

is

se

t

to

OFF.

If

the instrument h

as

been

operating,

al

l

ow

suffi

cie

nt time

for

the meter indicator

to

stabili

ze

near

zero.

3-1

3-1

3-2

3-2

b.

Adjust the meter zero-adjust screw

for

a zero

indication. Gently tap the meter fa

ce

occasional

ly

during

adjustment.

c.

Se

t t

he

osci

ll

ator controls

for

any

output

with

in the

r

ange

of

the instrume

nt

.

d. Turn on

th

e

osc

ill

ator. Note that an

outp

ut

is

indicated

and

then

turn

of

f

th

e oscillator.

e.

Check

to

see

that

th

e meter indicator stabili

zes

on

ze

ro.

3.1.3Stray Capacitance.

S

tr

ay capacitance

of

most shielded l

eads

or coaxial

cab

l

es

is

about

30

pF per

foot.

which.

at

100kHz,

amounts

to

a shunt impedance

of

about 55 k

!l

Therefore, t

he

cable

l

eng

th

should

be

kept

to

a minimum when a high-im

ped-

ance

load

is

to

be

driven at high frequencies.

3.2

OPERATIONAL

CHECKS.

3.2.1 General.

Th

ese

procedures

can

be

used

for

incoming inspection,

operator familiari

za

ti

on,

or

as

a periodic quick-check on

instrument operation. T

ab

le

5-1

includes recommended t

est

equipme

nt

for

th

ese

c

he

cks. Refer to

para.

5.8 if unable

to

obtain the performance

ca

ll

ed

fo

r.

OPERATION

3-1

--------Table3-1

--------

DECIMAL

POINT POSITION

Position

of

A-55 (from

fully

counterclockwise)

1 (Hz)

2 (Hz)

3 (kHz)

4 (kHz)

• X = a

frequency

dial

3.2.2

Output

Frequency.

POSITION

OF

DECIMAL

POINT*

XX.X

XXX.

X.XX

XX.X

The frequency

of

the oscillator

output

signal should

correspond

with

the setting

of

the FREQUENCY selectors.

For

a quick-check

of

output

frequency proceed

as

follows:

a.

Set the 1192 counter controls

to

measure frequency

and connect

it

to

the oscillator

POWER

OUTPUT jack.

b.

Turn the oscillator on and

set

the frequency selectors

for

any frequency between

10Hz

and

100kHz.

c.

Observe the counter visual register.

It

should display

the

same

frequency set

by

the frequency selectors

±1

count.

3.2.3

Output

Voltage.

The Oscillator

is

equipped

with

an

ac

voltmeter

for

monitoring the

output

voltage. For

an

operational check

of

the

output

voltage, simply

turn

the instrument on,

set

the

frequency and voltage controls for

some

value

within

the

range

of

the instrument,

and

observe the front-panel meter.

This meter

will

indicate the voltage at the

output

jack

within

±3%.

3.3 NORMAL OPERATION.

To

use theinstrument

as

a source:

a.

Turn

on

the oscillator and allow approximately 1

minute

for

it

to

rea

ch normal operating temperature. For

optimum

frequency

and

amplitude stability allow 30-

minutes warmup.

b. Set

the

FREQUENCY

range

switch

to

the desired

frequency range. Notice that this control positions the

decimal point.

c.

Set the FREQUENCY selectors

to

the desired

frequency.

d. Set the OUTPUT VOLTAGE RANGE switch

to

the

range

that

will

provide the desired

output

voltage.

e.

Adjust the OUTPUT ADJUST control

to

obtain the

desired

output

voltage reading on the

output

voltage meter.

To

use the instrument synchronized to

an

external

source.

a.

Perform steps a·e above.

b. Connect the external signal

to

the

EXT

SYNC jack

(Figure 1-2). The lock

range

of

the oscillator

is

±1

%/V rms

sync

input

up

to

10 V. For example,

if

a 1-kHz, 1-V sync

signal

is

used,

the oscillator

output

frequency

will

lock

to

3·2

OPERATION

the external signal

within

the range 990-1010

Hz.

If

the

sync-signal voltage

is

doubled the lock

range

also

doubles

(980·1

020

Hz).

The oscillator

will

remain synchronized

so

long

as

it

is

operated w

ith

in the lock

range.

3.4 APPLICATIONS.

3.4

.1 General.

One

of

the most important fedtures

of

the Type 1316

Oscillator

is

that

it

provide-s

an

easy-to-read, unambiguous,

repeatable, in-line readout

of

its frequency. This

will

be

of

value in production testing and calibrating where many

accurate and repeatable frequencies must

be

selected

quickly.

Some

typical applications

are

presented in the following

paragraphs.

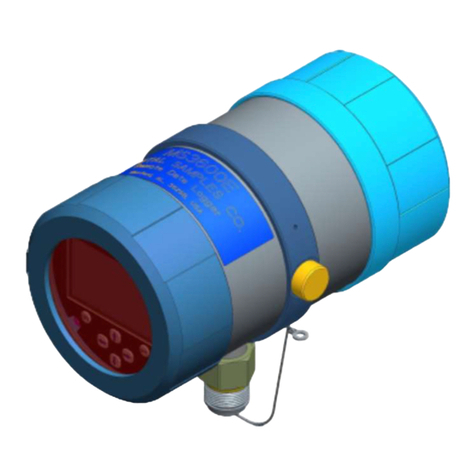

3.4.2 Slaved Oscillators.

Because

the

EXT

SYNC jack

is

simultaneously

an

input

and

an

output

connector,

two

or

more oscillators

can

be

synchronized

or

slaved

by connecting their

EXT

SYNC

jacks together (Figure 3·1). Oscillators connected in this

manner

will

operate at the

same

frequency, or multiple

th

ereof, and

can

be

made

to

differ

in

phase

(180° ±75°)

by

adjustment

of

the frequency selectors

within

the lock

range.

The lock

range

is

±1%/V rms input up

to

10

V.

Another obvious application

is

to

lock one

or

more

oscillators

to

a reference source

that

has

greater accuracy

and

long-term stability. This

is

done

by

connecting the

source

to

the

EXT

SYNC jack.

If

more than one oscillator

is

to

be

used,

connection between instruments

is

shown in

Figure 3·1. With the instrument(s) synchronized in this

fashion accuracy

and

long-term stability

will

be

identical

with

the reference; short-term stability

will

be

the

same

as

if

the oscillator

was

free-running.

3.4.3 Amplitude-Modu

Ia

ted Oscillator.

Amplitude modulation.

if

the oscillator

is

operated

out·

side

of

the lock

range,

the sync

signal

will

beat with the

oscillatorfrequency and produce

an

audio-frequency, ampli·

plitude-modulated

output.

The modulation

will

be

approxi·

mately sinusoidal

for

modulatian levels up

to

about

10%.

776-

C

~BNC

TEE

UG-274/U

PATCHCORO

~

~~1--'-.;.;.;.;.;~~...,D

L

{]

176

·C

) G 1

~

¢ PATCH

CORD

i

6

.------61----,

6

EX.T

SYNC

EXT

SYNC

EXT

S

Y ~C

GR

1316

OSCILLATOR

GR

1316

OSCILLATOR

GR

1316

OSCILLATOR

1316-3

Figure

3·1.

Method

of

connecting

slaved oscillators.

This arrangement

is

not

ideal,

but

it

does provide

amplitude-modulated signals in

th

e audio

range

where

normally they

are

not

conveniently obtainable. Modulated

outputs

of

this

type

can

be

used

to

measure

the effects

of

incidental

am

on other

meas

urements

and

to

provide a

modulated source

to

reduce meter-

friction

errors in

ac

measurements.

The figure shows

one

example

of

amplitude modulation:

Figure 3-2. 10.kHz output

of

an

oscillator modulated

at

500

Hz

by

a 9.5-kHz signal applied to the

EXT

SYNC jack.

3.4

.4 Output Sync.

Oscilloscope trigger. Since the sync

output

is

indepen-

dent

of

the

output

level,

it

ca

n

be

used

to

trigger

an

osci

l-

loscope in applications where the oscillator

output

is

often

varied, thereby eliminating frequent readjustment

of

the

oscilloscope trigger circuits.

Counter

trigger. A counter

can

be

driven

from

the

EXT

SYNC jack when more

pr

ecise

adjustment

of

frequency is

desired

or

when

the

front-panel out

put

is not sufficient

to

trigger the counter.

3.4.5 Systems

Use

.

All

external connections

to

the osc

illator

are

made at the

rear

panel-

a convenient feature

for

systems

use.

The 1316

is

one

of

3 integrated

units

in

our

Type 1621 Precision

Capacitance Measurement System (Figure 1-3).

It

functions

as

the drive oscillator

for

the system

and

supplies the

detector

with

2 referen

ce

inputs. The high level, stability,

and low-noise characteristics

of

this oscillator play a

large

role in producing the ultra-precise measurements

and

comparisons that the system iscapable

of

providing.

E

XT

SYNC

'--

OUTPUT•

GR

1316

0

EX~

TRIG

VERTICAL

--

f-.

IN our•

r-

~

IN

PUT

DEVICE UNDER

OSC

I

LL

OSCOPE

TEST

=

W,,j~

SYNC

GRI316

Figure 3-3. The oscillator used

to

trigger: a.

an

oscilloscope;

b.

a

counter.

OPERATION 3-3

Table of contents

Other iET Measuring Instrument manuals