2

Contents

1 Preliminary note���������������������������������������������������������������������������������������������������4

1�1 Explanation of symbols ���������������������������������������������������������������������������������4

2 Safety instructions �����������������������������������������������������������������������������������������������4

3 Items supplied������������������������������������������������������������������������������������������������������5

4 Functions and features ����������������������������������������������������������������������������������������5

5 Structure and operating principle�������������������������������������������������������������������������6

5�1 Actuator version���������������������������������������������������������������������������������������������7

5�2 Version AC903S (guard locking by spring force) �������������������������������������������7

5�3 Version AC904S (guard locking by solenoid force) ���������������������������������������7

5�4 Mechanical release����������������������������������������������������������������������������������������9

6 Installation������������������������������������������������������������������������������������������������������������9

6�1 Installation instructions ����������������������������������������������������������������������������������9

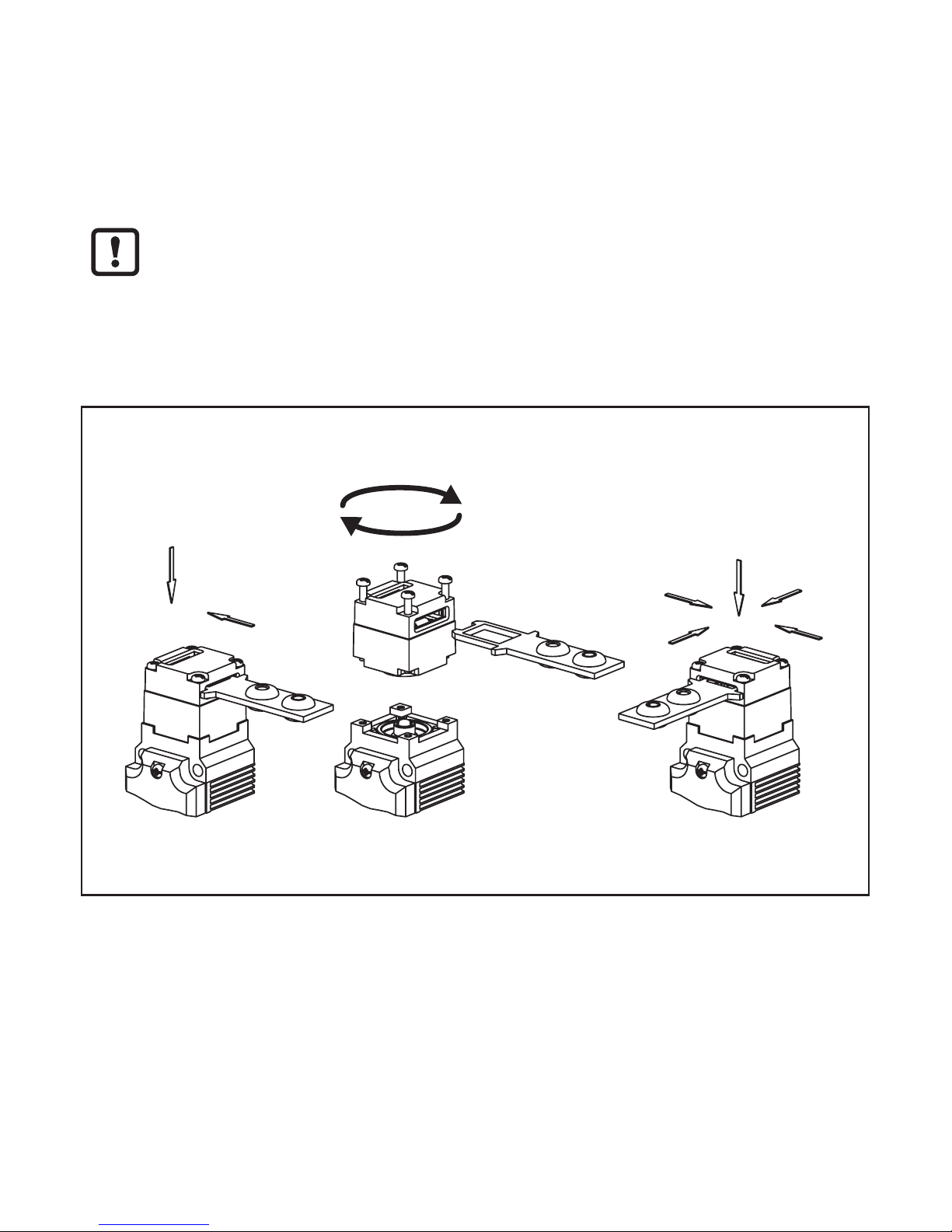

6�1�1 Changing the actuating direction��������������������������������������������������������10

6�2 Protection against environmental influences �����������������������������������������������10

7 Electrical connection������������������������������������������������������������������������������������������ 11

7�1 Wiring����������������������������������������������������������������������������������������������������������� 11

8 Set-up ���������������������������������������������������������������������������������������������������������������� 11

8�1 Setting of the AS-Interface address������������������������������������������������������������� 11

8�2 Configuration in the AS-Interface safety monitor ����������������������������������������� 11

8�2�1 Monitor with extended functions���������������������������������������������������������12

9 Operation�����������������������������������������������������������������������������������������������������������13

9�1 LED indicators / AS-Interface status messages ������������������������������������������13

10 Function check and troubleshooting����������������������������������������������������������������14

10�1 Mechanical function check ������������������������������������������������������������������������14

10�2 Electrical function check ����������������������������������������������������������������������������14

10�3 Troubleshooting �����������������������������������������������������������������������������������������14

11 Scale drawing ��������������������������������������������������������������������������������������������������16

12 Technical data��������������������������������������������������������������������������������������������������17

13 Terms and abbreviations����������������������������������������������������������������������������������18

14 Data bit table����������������������������������������������������������������������������������������������������19