4

4 Function

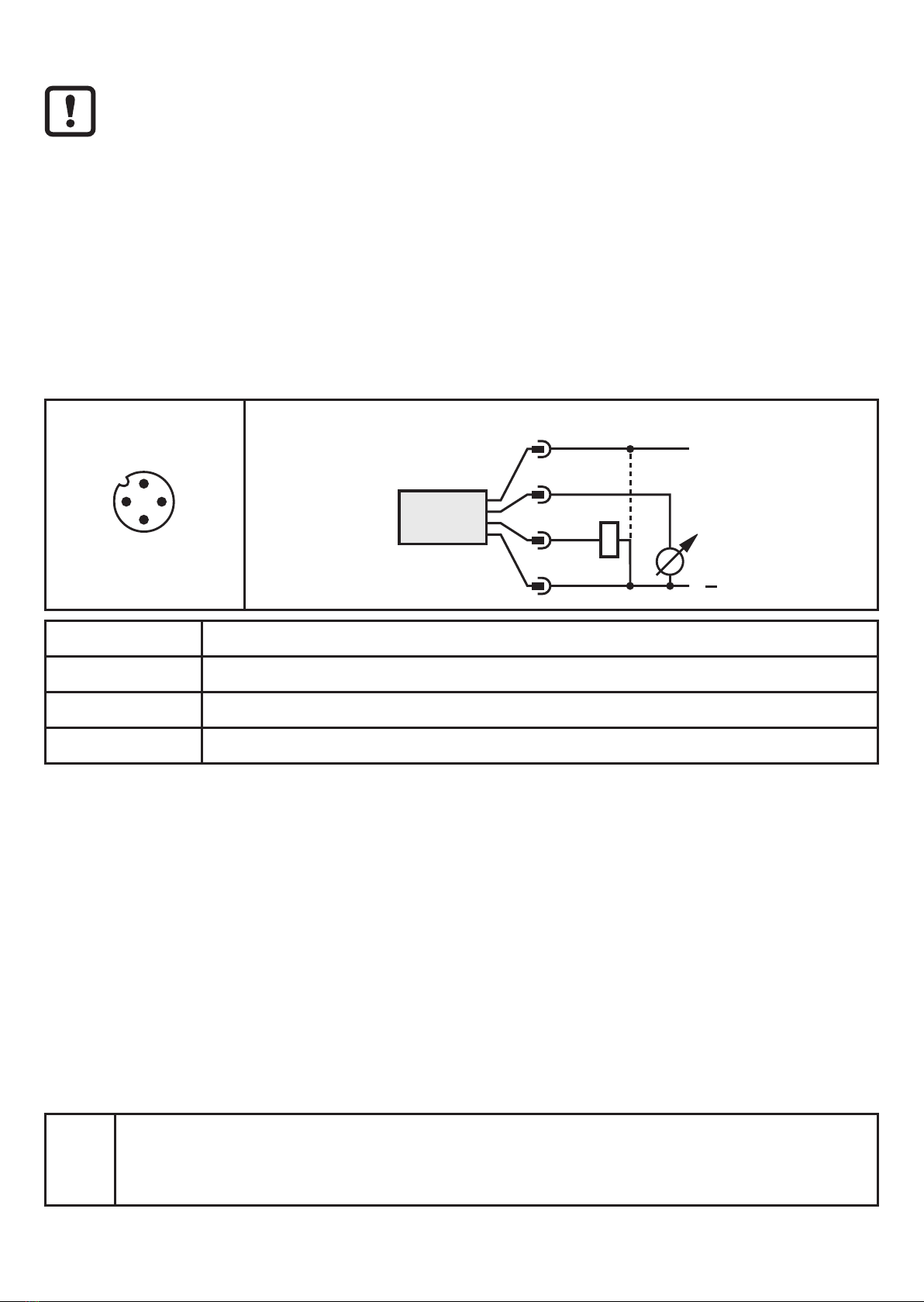

• The unit provides a temperature-proportional output signal (4���20 mA or

20...4mA).

• The measuring range is scalable�

• In addition to the analogue signal the unit provides a diagnostic signal� Sensi-

tivity and reaction to different error modes can be programmed� Pin 4 = output

fordiagnosticsignal(pnpornpn).

4.1 Monitoring and diagnostic functions

• By measuring with two different, thermically coupled sensor elements (NTC,

Pt1000)theunitautomaticallydetectsdriftsanderrorsduringtemperature

measurement with great reliability�

• If one of the two sensor elements fails, the temperature measurement can be

continuedwiththesecondelement(backupfunction).

• Very long-term stable measurement is achieved by using high-quality sensor

elements�

4.1.1 Drift / fault monitoring

To monitor the drift the unit compares the temperatures of two different sensor ele-

ments that are thermically coupled in the sensor tip� Normally these temperatures

are identical�

Due to the usual manufacturing tolerances a temperature difference of max� 0�1 K

can also occur with new sensor elements� This does not affect the drift monitoring

function�

If there is a drift in one or both sensor elements, the unit detects them due to the

difference between the two measured temperatures� It compares the difference

withthesetwarning/alarmthresholds(drW,drA→7Parametersetting).Ifthe

thresholds are exceeded, it generates corresponding diagnostic messages and

sets the corresponding status for the process value�

In case of high temperature changes in the measured medium (e�g� filling of a

hotmediumintoacoldvessel)theremaybeashort-termdifferencebetweenthe

temperatures of both measuring elements� This is based on the corresponding

specific response dynamics of the measuring elements� To prevent a drift warning

or alarm in these cases, a delay time can be set by means of the parameter ddr�