IGM Fachmann 125-508819 User manual

man_125-508819_A5br_kolikovaci pripravek_EN+CZ+SK+HU+PL_v.3.2

Operationg instructions

Návod k obsluze

Návod na obshluhu

Használatiútmutató

Instrukcja obsługi

IGM DOWELLING JIG 30MM FOR DOWELS 6, 8 & 10MM

IGM KOLÍKOVACÍ PŘÍPRAVEK 30MM PRO D6, 8 A 10MM

IGM KOLÍKOVACÍ PRÍPRAVOK 30MM PRE D6, 8 A 10MM

IGM MESTERCSAPOZÓ 30MM 6, 8 ÉS 10MMES TIPLIKHEZ

IGM PRZYRZĄD DO DYBLOWANIA 30MM DO D6, 8 I 10MM

125-508819

www.igm.cz

2

Operating instructions / Návod k obsluze /

Návod na obsluhu / Használatiútmutató / Instrukcja obsługi

OPERATING INSTRUCTIONS

Figure 1 & 2: Mark the positions of the board in relation to

each other (X) and identify the boards with letters A& B.

Figure 3 & 4: Work On Board Afor all dowel joints. Clamp

board Ato the workbench.

Figure 5: Adjusting the drilling depth on board A: Dowel

Lengths (Board thickness of B5mm). For end-grain joints

half the dowel length. Use a drill bit with a depth stop.

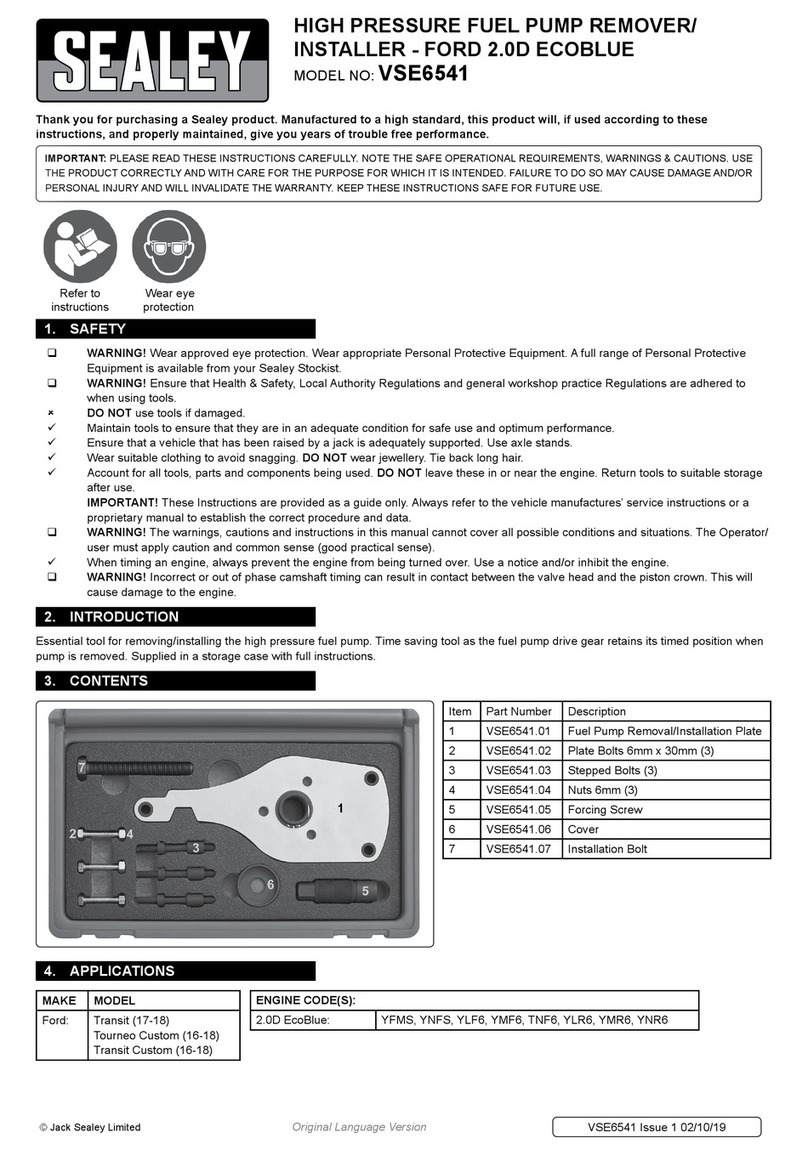

Figure 6, 7 & 8: Drill the holes in board A. Ensure that the

centre pin is pushed firmly against the board by pressing the

handle (see direction of arrow in Figure 8). Also ensure that

the manual dowel locator is placed level on the edge.

Important: First insert the drill bit in the drill bush and then

switch on the power drill.

Figure 12: Place the dowel locator on a dowel in board A.

Push the angle fence from the handle side into the guideway

until it rests firmly against the board. Finally tighten the

clamping screw.

6mm

Basic Dowelling Jig Operation

2

A

B

1

4

5

3

6

9

A

10

11

12

7

8

A

B

8mm

10mm

A

10mm

8mm

Max. 30mm

Max. 25mm

Max. 25mm 6mm

A

A

B

508819 Instructions.qxd 5/10/06 2:15 pm Page 2

OPERATING INSTRUCTIONS

Figure 1 & 2: Mark the positions of the board in relation to

each other (X) and identify the boards with letters A& B.

Figure 3 & 4: Work On Board Afor all dowel joints. Clamp

board Ato the workbench.

Figure 5: Adjusting the drilling depth on board A: Dowel

Lengths (Board thickness of B5mm). For end-grain joints

half the dowel length. Use a drill bit with a depth stop.

Figure 6, 7 & 8: Drill the holes in board A. Ensure that the

centre pin is pushed firmly against the board by pressing the

handle (see direction of arrow in Figure 8). Also ensure that

the manual dowel locator is placed level on the edge.

Important: First insert the drill bit in the drill bush and then

switch on the power drill.

Figure 12: Place the dowel locator on a dowel in board A.

Push the angle fence from the handle side into the guideway

until it rests firmly against the board. Finally tighten the

clamping screw.

6mm

Basic Dowelling Jig Operation

2

A

B

1

4

5

36

9

A

10

11

12

7

8

A

B

8mm

10mm

A

10mm

8mm

Max. 30mm

Max. 25mm

Max. 25mm 6mm

A

A

B

508819 Instructions.qxd 5/10/06 2:15 pm Page 2

OPERATING INSTRUCTIONS

Figure 1 & 2: Mark the positions of the board in relation to

each other (X) and identify the boards with letters A& B.

Figure 3 & 4: Work On Board Afor all dowel joints. Clamp

board Ato the workbench.

Figure 5: Adjusting the drilling depth on board A: Dowel

Lengths (Board thickness of B5mm). For end-grain joints

half the dowel length. Use a drill bit with a depth stop.

Figure 6, 7 & 8: Drill the holes in board A. Ensure that the

centre pin is pushed firmly against the board by pressing the

handle (see direction of arrow in Figure 8). Also ensure that

the manual dowel locator is placed level on the edge.

Important: First insert the drill bit in the drill bush and then

switch on the power drill.

Figure 12: Place the dowel locator on a dowel in board A.

Push the angle fence from the handle side into the guideway

until it rests firmly against the board. Finally tighten the

clamping screw.

6mm

Basic Dowelling Jig Operation

2

A

B

1

4

5

36

9

A

10

11

12

7

8

A

B

8mm

10mm

A

10mm

8mm

Max. 30mm

Max. 25mm

Max. 25mm 6mm

A

A

B

508819 Instructions.qxd 5/10/06 2:15 pm Page 2

OPERATING INSTRUCTIONS

Figure 1 & 2: Mark the positions of the board in relation to

each other (X) and identify the boards with letters A& B.

Figure 3 & 4: Work On Board Afor all dowel joints. Clamp

board Ato the workbench.

Figure 5: Adjusting the drilling depth on board A: Dowel

Lengths (Board thickness of B5mm). For end-grain joints

half the dowel length. Use a drill bit with a depth stop.

Figure 6, 7 & 8: Drill the holes in board A. Ensure that the

centre pin is pushed firmly against the board by pressing the

handle (see direction of arrow in Figure 8). Also ensure that

the manual dowel locator is placed level on the edge.

Important: First insert the drill bit in the drill bush and then

switch on the power drill.

Figure 12: Place the dowel locator on a dowel in board A.

Push the angle fence from the handle side into the guideway

until it rests firmly against the board. Finally tighten the

clamping screw.

6mm

Basic Dowelling Jig Operation

2

A

B

1

4

5

36

9

A

10

11

12

7

8

A

B

8mm

10mm

A

10mm

8mm

Max. 30mm

Max. 25mm

Max. 25mm 6mm

A

A

B

508819 Instructions.qxd 5/10/06 2:15 pm Page 2

EN

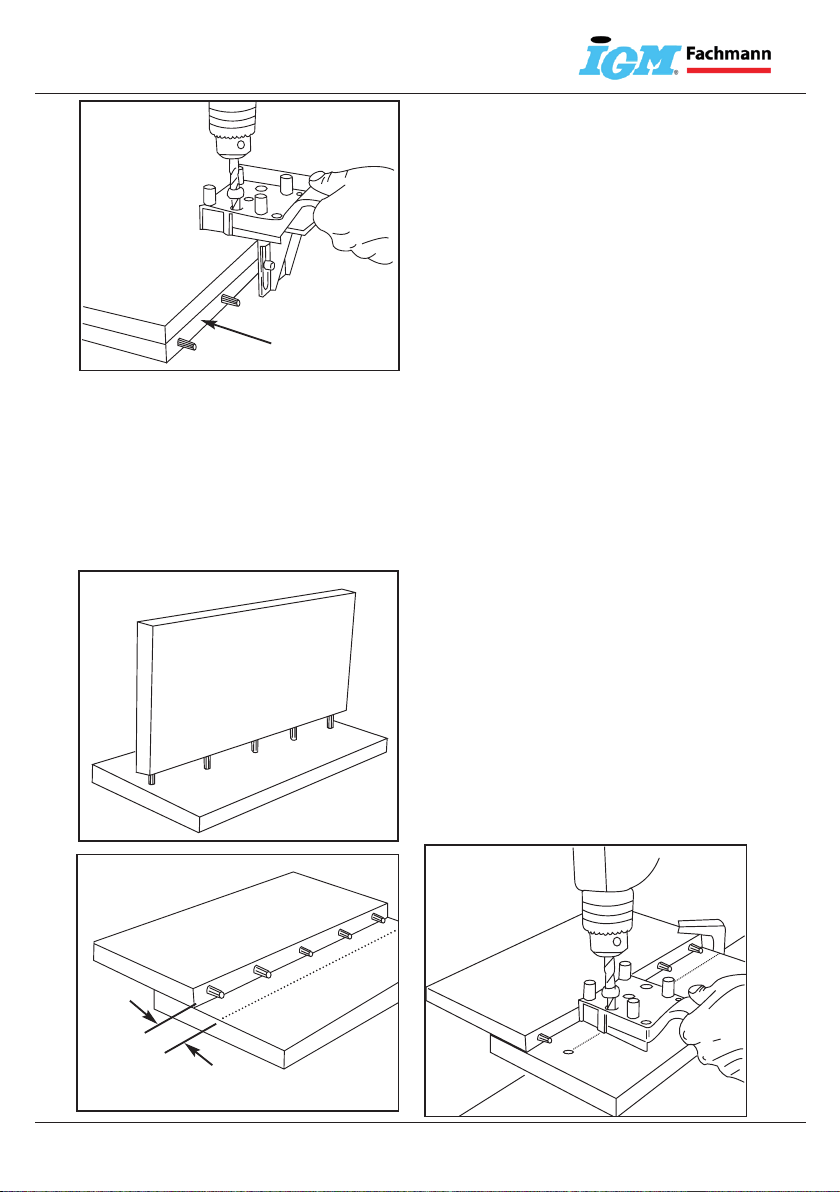

Figure 1 & 2: Mark the positions of the board in relation to

each other (X) and identify the boards with letters A& B.

CZ

Obrázek 1 a 2: Označuje pozice na desce a označuje desky

písmeny Aa B(obr.1 naznačuje rohový spoj a obr.2 spoj na

tupo.)

SK

Obrázok 1 a 2: Označuje pozície na doske a označuje dosky

písmenami Aa B(obr.1 naznačuje rohový spoj a obr.2 spoj na

tupo.)

HU

1. és 2. ábra: a lapokillesztésének a helyétvalamintaz A ésB

betűvelvalójelölésétábrázolja. (1.ábra – sarokkötés; 2.ábra -

toldás)

PL

Rysunek 1 i 2: Oznacza położenie na płycie oraz znakuje

płyty literami A i B (rys.1 naznacza połączenie kątowe, a rys. 2

połączenie czołowe).

EN

Figure 3 & 4: Work On Board Afor all dowel joints. Clamp

board Ato the workbench.

CZ

Obrázek 3 a 4: Pro vrtání do hrany, upneme desku do svěráku.

(obr.1 ukazuje rohový spoj, obr.2 ukazuje spoj na tupo.)

SK

Obrázok 3 a 4: Na vŕtanie do hrany, upneme dosku do zveráku.

(obr.1 ukazuje rohový spoj, obr.2 ukazuje spoj na tupo.)

HU

3. és 4. ábra:Szegélyfúráshoz a munkalapotfogassukszorítóba.

(1.ábra – sarokkötés, 2. ábra – toldás)

PL

Rysunek 3 i 4: W celu wiercenia do krawędzi należy zamocować

płytę do imadła. (rys.1 pokazuje połączenie kątowe, rys.2

prezentuje połączenie czołowe).

www.igm.cz 3

Operating instructions / Návod k obsluze /

Návod na obsluhu / Használatiútmutató / Instrukcja obsługi

OPERATING INSTRUCTIONS

Figure 1 & 2: Mark the positions of the board in relation to

each other (X) and identify the boards with letters A& B.

Figure 3 & 4: Work On Board Afor all dowel joints. Clamp

board Ato the workbench.

Figure 5: Adjusting the drilling depth on board A: Dowel

Lengths (Board thickness of B5mm). For end-grain joints

half the dowel length. Use a drill bit with a depth stop.

Figure 6, 7 & 8: Drill the holes in board A. Ensure that the

centre pin is pushed firmly against the board by pressing the

handle (see direction of arrow in Figure 8). Also ensure that

the manual dowel locator is placed level on the edge.

Important: First insert the drill bit in the drill bush and then

switch on the power drill.

Figure 12: Place the dowel locator on a dowel in board A.

Push the angle fence from the handle side into the guideway

until it rests firmly against the board. Finally tighten the

clamping screw.

6mm

Basic Dowelling Jig Operation

2

A

B

1

4

5

36

9

A

10

11

12

7

8

A

B

8mm

10mm

A

10mm

8mm

Max. 30mm

Max. 25mm

Max. 25mm 6mm

A

A

B

508819 Instructions.qxd 5/10/06 2:15 pm Page 2

OPERATING INSTRUCTIONS

Figure 1 & 2: Mark the positions of the board in relation to

each other (X) and identify the boards with letters A& B.

Figure 3 & 4: Work On Board Afor all dowel joints. Clamp

board Ato the workbench.

Figure 5: Adjusting the drilling depth on board A: Dowel

Lengths (Board thickness of B5mm). For end-grain joints

half the dowel length. Use a drill bit with a depth stop.

Figure 6, 7 & 8: Drill the holes in board A. Ensure that the

centre pin is pushed firmly against the board by pressing the

handle (see direction of arrow in Figure 8). Also ensure that

the manual dowel locator is placed level on the edge.

Important: First insert the drill bit in the drill bush and then

switch on the power drill.

Figure 12: Place the dowel locator on a dowel in board A.

Push the angle fence from the handle side into the guideway

until it rests firmly against the board. Finally tighten the

clamping screw.

6mm

Basic Dowelling Jig Operation

2

A

B

1

4

5

36

9

A

10

11

12

7

8

A

B

8mm

10mm

A

10mm

8mm

Max. 30mm

Max. 25mm

Max. 25mm 6mm

A

A

B

508819 Instructions.qxd 5/10/06 2:15 pm Page 2

OPERATING INSTRUCTIONS

Figure 1 & 2: Mark the positions of the board in relation to

each other (X) and identify the boards with letters A& B.

Figure 3 & 4: Work On Board Afor all dowel joints. Clamp

board Ato the workbench.

Figure 5: Adjusting the drilling depth on board A: Dowel

Lengths (Board thickness of B5mm). For end-grain joints

half the dowel length. Use a drill bit with a depth stop.

Figure 6, 7 & 8: Drill the holes in board A. Ensure that the

centre pin is pushed firmly against the board by pressing the

handle (see direction of arrow in Figure 8). Also ensure that

the manual dowel locator is placed level on the edge.

Important: First insert the drill bit in the drill bush and then

switch on the power drill.

Figure 12: Place the dowel locator on a dowel in board A.

Push the angle fence from the handle side into the guideway

until it rests firmly against the board. Finally tighten the

clamping screw.

6mm

Basic Dowelling Jig Operation

2

A

B

1

4

5

3

6

9

A

10

11

12

7

8

A

B

8mm

10mm

A

10mm

8mm

Max. 30mm

Max. 25mm

Max. 25mm 6mm

A

A

B

508819 Instructions.qxd 5/10/06 2:15 pm Page 2

EN

Figure 5: Adjusting the drilling depth on board A: Dowel

Lengths (Board thickness of B5mm). For end-grain joints

half the dowel length. Use a drill bit with a depth stop.

CZ

Obrázek 5: Nastavení hloubky vrtání do hrany: Prostrčte vrták

vrtacím pouzdrem nastavte délku poloviny délky kolíku +5mm.

Použijte vrták s hloubkovým dorazem.

SK

Obrázok 5: Nastavenie hĺbky vŕtania do hrany: Prestrčte vrták

vŕtacím puzdrom nastavte dĺžku polovice dĺžky kolíka +5 mm.

Použite vrták s hĺbkovým dorazom.

HU

5. ábra: A mélységbeállításaszegélyfúráshoz:Helyezze a fúrót

a fúróhüvelyenkeresztülúgy, hogy a fúrócsapozóalattihossza

megfeleljen a tiplihosszafelénekéshagyjonrá +5mm-t.

Használjonmélyütközöt a fúrófejen.

PL

Rysunek 5: Nastawienie głębokości wiercenia do krawędzi:

Przeciągnij wiertło uchwytem wiertarskim. Następnie ustaw

długość połowy długości kołka + 5 mm. Zastosuj wiertło z

ogranicznikiem głębokości.

EN

Figure 6, 7 & 8: Drill the holes in board A. Ensure that the

centre pin is pushed rmly against the board by pressing the

handle (see direction of arrow in Figure 8). Also ensure that

the manual dowel locator is placed level on the edge.

Important: First insert the drill bit in the drill bush and then

switch on the power drill.

OPERATING INSTRUCTIONS

Figure 1 & 2: Mark the positions of the board in relation to

each other (X) and identify the boards with letters A& B.

Figure 3 & 4: Work On Board Afor all dowel joints. Clamp

board Ato the workbench.

Figure 5: Adjusting the drilling depth on board A: Dowel

Lengths (Board thickness of B5mm). For end-grain joints

half the dowel length. Use a drill bit with a depth stop.

Figure 6, 7 & 8: Drill the holes in board A. Ensure that the

centre pin is pushed firmly against the board by pressing the

handle (see direction of arrow in Figure 8). Also ensure that

the manual dowel locator is placed level on the edge.

Important: First insert the drill bit in the drill bush and then

switch on the power drill.

Figure 12: Place the dowel locator on a dowel in board A.

Push the angle fence from the handle side into the guideway

until it rests firmly against the board. Finally tighten the

clamping screw.

6mm

Basic Dowelling Jig Operation

2

A

B

1

4

5

36

9

A

10

11

12

7

8

A

B

8mm

10mm

A

10mm

8mm

Max. 30mm

Max. 25mm

Max. 25mm 6mm

A

A

B

508819 Instructions.qxd 5/10/06 2:15 pm Page 2

CZ

Obrázek 6, 7 a 8: Vyvrtejte otvory do hrany desky A. Ujistěte se,

že středový čep je pevně přitlačen k desce. Tiskněte rukojeť viz

směr šipky na obr. 8.

Důležité:Nejprve vložte vrták do vrtacího pouzdra a pak

zapněte vrtačku.

SK

Obrázok 6, 7 a 8: Vyvŕtajte otvory do hrany dosky A. Uistite sa,

že stredový čap je pevne pritlačený k doske. Tlačte rukoväť pozri

smer šípky na obr 8.

Dôležité: Najprv vložte vrták do vŕtacieho puzdra a potom

zapnite vŕtačku.

HU

6. 7. és 8. ábra: FúrjakiazA munkalapnyílásait. Ügyeljenarra,

hogy a központicsapkellőennyomódjon a munkalaphoz.

A fogantyútnyomja a 8. ábra alapjánszemléltetettnyilak

irányába.

Figyelem: Előbbhelyezze a fúrót a fúróhüvelybe, csakazután

kapcsoljabe a fúrógépet.

PL

Rysunek 6, 7 i 8: Wywierć otwory w krawędzi płyty A. Upewnij

się, że centralny czop jest mocno dociśnięty do płyty. Naciśnij

rękojeść zgodnie z kierunkiem strzałki na rys. 8. Ważne: Najpierw

wsuń wiertło do uchwytu wiertarskiego, a następnie włącz

wiertarkę.

www.igm.cz

4

Operating instructions / Návod k obsluze /

Návod na obsluhu / Használatiútmutató / Instrukcja obsługi

EN

Figure 13 & 14: Place board Bin a desired position on

board Aand clamp to the workbench.

Important: The depth stop must be re-adjusted (board

thickness 5mm). Place the dowel locator over the

corresponding dowel of board Ain such a manner that the

angle fence rests rmly against the board and drill.

CZ

Obrázek 13 & 14: Položte desku Bna desku Aviz obr.13

(zarovnejte hrany). Upněte desky k pracovnímu stolu

Důležité: Hloubka dorazu se musí znovu upravit. Prostrčte vrták

vrtacím pouzdrem a nastavte délku jako je tloušťka desky B

-5mm.

Umístěte postraní doraz na kolík (příslušným otvorem

postraního dorazu podle použitého vrtacího pouzdra) Přitlačte k

desce a vrtejte do plochy.

SK

Obrázok 13 & 14: Položte dosku Bna dosku Apozri obr.13

(zarovnajte hrany). Upnite dosky k pracovnému stolu

Dôležité: Hĺbka dorazu sa musí znovu upraviť. Prestrčte vrták

vŕtacím pouzdrom a nastavte dĺžku ako je hrúbka dosky B-5mm.

Umiestnite postrannej doraz na kolík (príslušným otvorom

postraního dorazu podľa použitého vŕtacieho puzdra) Pritlačte k

doske a vŕtajte do plochy.

OPERATING INSTRUCTIONS

Figure 1 & 2: Mark the positions of the board in relation to

each other (X) and identify the boards with letters A& B.

Figure 3 & 4: Work On Board Afor all dowel joints. Clamp

board Ato the workbench.

Figure 5: Adjusting the drilling depth on board A: Dowel

Lengths (Board thickness of B5mm). For end-grain joints

half the dowel length. Use a drill bit with a depth stop.

Figure 6, 7 & 8: Drill the holes in board A. Ensure that the

centre pin is pushed firmly against the board by pressing the

handle (see direction of arrow in Figure 8). Also ensure that

the manual dowel locator is placed level on the edge.

Important: First insert the drill bit in the drill bush and then

switch on the power drill.

Figure 12: Place the dowel locator on a dowel in board A.

Push the angle fence from the handle side into the guideway

until it rests firmly against the board. Finally tighten the

clamping screw.

6mm

Basic Dowelling Jig Operation

2

A

B

1

4

5

36

9

A

10

11

12

7

8

A

B

8mm

10mm

A

10mm

8mm

Max. 30mm

Max. 25mm

Max. 25mm 6mm

A

A

B

508819 Instructions.qxd 5/10/06 2:15 pm Page 2

OPERATING INSTRUCTIONS

Figure 1 & 2: Mark the positions of the board in relation to

each other (X) and identify the boards with letters A& B.

Figure 3 & 4: Work On Board Afor all dowel joints. Clamp

board Ato the workbench.

Figure 5: Adjusting the drilling depth on board A: Dowel

Lengths (Board thickness of B5mm). For end-grain joints

half the dowel length. Use a drill bit with a depth stop.

Figure 6, 7 & 8: Drill the holes in board A. Ensure that the

centre pin is pushed firmly against the board by pressing the

handle (see direction of arrow in Figure 8). Also ensure that

the manual dowel locator is placed level on the edge.

Important: First insert the drill bit in the drill bush and then

switch on the power drill.

Figure 12: Place the dowel locator on a dowel in board A.

Push the angle fence from the handle side into the guideway

until it rests firmly against the board. Finally tighten the

clamping screw.

6mm

Basic Dowelling Jig Operation

2

A

B

1

4

5

36

9

A

10

11

12

7

8

A

B

8mm

10mm

A

10mm

8mm

Max. 30mm

Max. 25mm

Max. 25mm 6mm

A

A

B

508819 Instructions.qxd 5/10/06 2:15 pm Page 2

EN

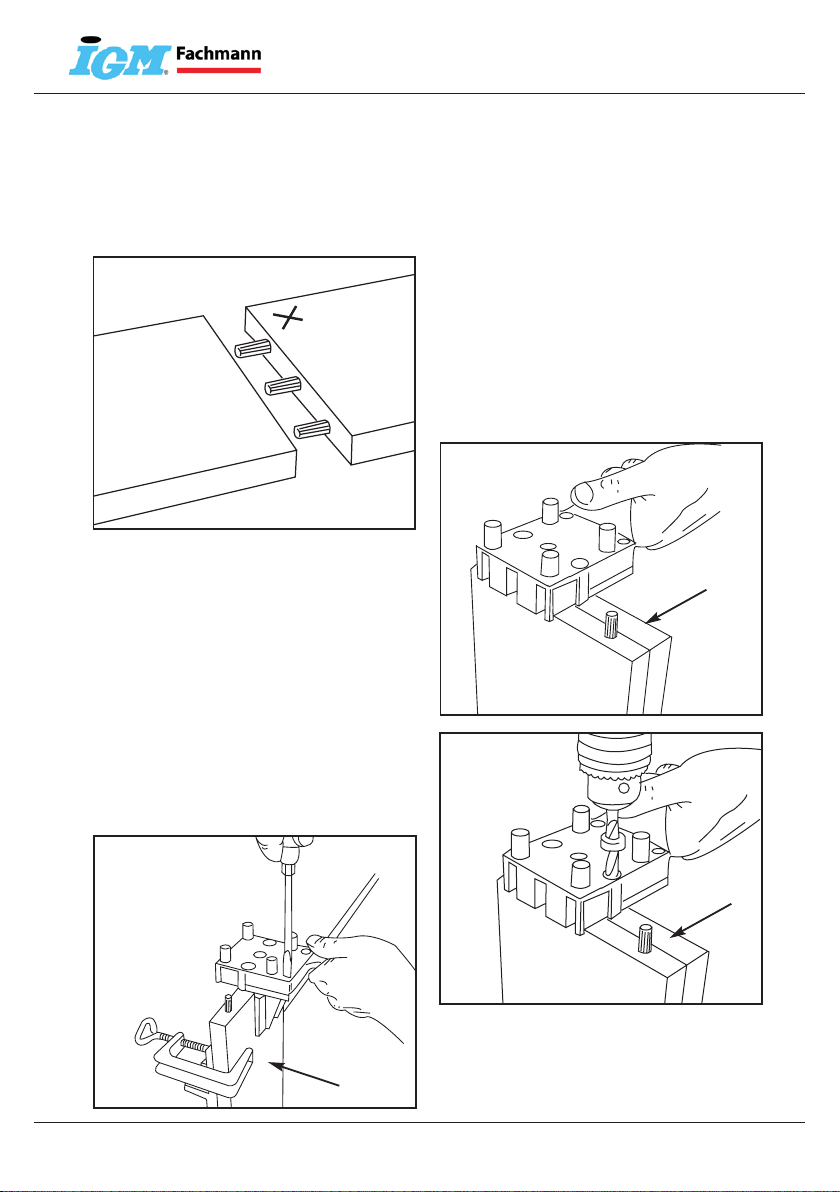

Figure 12: Place the dowel locator on a dowel in board A.

Push the angle fence from the handle side into the guideway

until it rests rmly against the board. Finally tighten the

clamping screw.

CZ

Obrázek 12: Umístěte hmoždinku do desky Aa položte na ní

vrtací čep, přitlačte postraní doraz a dotáhněte šrouby.

SK

Obrázok 12: Umiestnite hmoždinku do dosky Aa položte na nej

vŕtacie čap, pritlačte postranný doraz a dotiahnite skrutky.

HU

12. ábra: Helyezze a rögzítőtiplitazA munkalapraés

tegyerá a mestercsapozót.Szereljefelazoldalütköztetőt,

majdhúzzabe a szorítócsavart.

PL

Rysunek 12: Umieść kołek w płycie A potem nałóż na niego

czop wiertarski, dociśnij boczny ogranicznik, a następnie dokręć

śruby.

OPERATING INSTRUCTIONS

Figure 1 & 2: Mark the positions of the board in relation to

each other (X) and identify the boards with letters A& B.

Figure 3 & 4: Work On Board Afor all dowel joints. Clamp

board Ato the workbench.

Figure 5: Adjusting the drilling depth on board A: Dowel

Lengths (Board thickness of B5mm). For end-grain joints

half the dowel length. Use a drill bit with a depth stop.

Figure 6, 7 & 8: Drill the holes in board A. Ensure that the

centre pin is pushed firmly against the board by pressing the

handle (see direction of arrow in Figure 8). Also ensure that

the manual dowel locator is placed level on the edge.

Important: First insert the drill bit in the drill bush and then

switch on the power drill.

Figure 12: Place the dowel locator on a dowel in board A.

Push the angle fence from the handle side into the guideway

until it rests firmly against the board. Finally tighten the

clamping screw.

6mm

Basic Dowelling Jig Operation

2

A

B

1

4

5

36

9

A

10

11

12

7

8

A

B

8mm

10mm

A

10mm

8mm

Max. 30mm

Max. 25mm

Max. 25mm 6mm

A

A

B

508819 Instructions.qxd 5/10/06 2:15 pm Page 2

OPERATING INSTRUCTIONS

Figure 1 & 2: Mark the positions of the board in relation to

each other (X) and identify the boards with letters A& B.

Figure 3 & 4: Work On Board Afor all dowel joints. Clamp

board Ato the workbench.

Figure 5: Adjusting the drilling depth on board A: Dowel

Lengths (Board thickness of B5mm). For end-grain joints

half the dowel length. Use a drill bit with a depth stop.

Figure 6, 7 & 8: Drill the holes in board A. Ensure that the

centre pin is pushed firmly against the board by pressing the

handle (see direction of arrow in Figure 8). Also ensure that

the manual dowel locator is placed level on the edge.

Important: First insert the drill bit in the drill bush and then

switch on the power drill.

Figure 12: Place the dowel locator on a dowel in board A.

Push the angle fence from the handle side into the guideway

until it rests firmly against the board. Finally tighten the

clamping screw.

6mm

Basic Dowelling Jig Operation

2

A

B

1

4

5

36

9

A

10

11

12

7

8

A

B

8mm

10mm

A

10mm

8mm

Max. 30mm

Max. 25mm

Max. 25mm 6mm

A

A

B

508819 Instructions.qxd 5/10/06 2:15 pm Page 2

OPERATING INSTRUCTIONS

Figure 1 & 2: Mark the positions of the board in relation to

each other (X) and identify the boards with letters A& B.

Figure 3 & 4: Work On Board Afor all dowel joints. Clamp

board Ato the workbench.

Figure 5: Adjusting the drilling depth on board A: Dowel

Lengths (Board thickness of B5mm). For end-grain joints

half the dowel length. Use a drill bit with a depth stop.

Figure 6, 7 & 8: Drill the holes in board A. Ensure that the

centre pin is pushed firmly against the board by pressing the

handle (see direction of arrow in Figure 8). Also ensure that

the manual dowel locator is placed level on the edge.

Important: First insert the drill bit in the drill bush and then

switch on the power drill.

Figure 12: Place the dowel locator on a dowel in board A.

Push the angle fence from the handle side into the guideway

until it rests firmly against the board. Finally tighten the

clamping screw.

6mm

Basic Dowelling Jig Operation

2

A

B

1

4

5

36

9

A

10

11

12

7

8

A

B

8mm

10mm

A

10mm

8mm

Max. 30mm

Max. 25mm

Max. 25mm 6mm

A

A

B

508819 Instructions.qxd 5/10/06 2:15 pm Page 2

www.igm.cz 5

Operating instructions / Návod k obsluze /

Návod na obsluhu / Használatiútmutató / Instrukcja obsługi

Figure 16 & 17: Place the board B in the desired position on

board Aand clamp firmly. Draw a centre line for the dowel

holes on board B. Place the dowel locator with the side

centre marks on the centre line, push the angle fence

against board B and clamp. Then drill as shown in Figure

14.

Figure 18: T-Joint.

Figure 19 & 20: Draw a centre line for the dowel holes on

board B. Clamp board Aat a distance of 35mm from the

drawn line.

Important: The depth stop must be re-adjusted (board

thickness 5mm). Now place the dowel locator with the

corresponding guiding groove over the dowel. When drilling

ensure that the centre marks are aligned with the centre line.

Figure 21: End-grain joints.

Figure 22: Place the dowel locator on a dowel in board A.

Then push the angle fence from the handle side into the

guideway until it rests firmly against the board. Finally tighten

the clamping screw.

Figure 23 & 24: Clamp board A& Bin such a manner that

the marks are visible. Push the dowel locator with the

corresponding guiding groove over the dowel until the angle

fence rests firmly against the board and then drill.

Figure 13 & 14: Place board B in a desired position on

board Aand clamp to the workbench.

Important: The depth stop must be re-adjusted (board

thickness 5mm). Place the dowel locator over the

corresponding dowel of board Ain such a manner that the

angle fence rests firmly against the board and drill.

Figure 15: The distance of the dowel from the edge is

maximum 25mm.

13

A

B

A

A

B

B

14

25mm

35mm

16

17

18

15

B

19

22

23

24

20

21

A

B

A

B

A

B

A

B

A

A

A

B

A

508819 Instructions.qxd 5/10/06 2:15 pm Page 3

EN

Figure 15:The distance of the dowel from the edge is

maximum 25mm.

CZ

Obrázek 15: Vzdálenost hmoždinek od okraje je maximální

25mm.

EN

Figure 16 & 17: Place the board Bin the desired position on

board Aand clamp rmly. Draw a centre line for the dowel

holes on board B. Place the dowel locator with the side

centre marks on the centre line, push the angle fence

against board Band clamp.Then drill as shown in Figure 14

.

CZ

Obrázek 16 a 17: Pro rohový spoj, který má být odsazený od

hrany nakreslete středovou osu kolíků na desku B. Povolte

postraní doraz. Položte kolíkovací přípravek na desku Ba opřete

doraz o hranu viz obr.17 srovnejte osy děr podle naznačené osy

obr.16 a dotáhněte šrouby dorazu.

SK

Obrázok 16 a 17: Pre rohový spoj, ktorý má byť odsadený

od hrany nakreslite stredovú osu kolíkov na dosku B. Povoľte

postrannej doraz. Položte kolíkovací prípravok na dosku Ba

oprite doraz o hranu pozri obr.17 porovnajte osi dier podľa

naznačenej osi obr.16 a dotiahnite skrutky dorazu.

HU

16. és 17. ábra: Sarokkötéshezrajzoljafel a tiplikelcsúsztatott

tengelyét a Bmunkalapra. Lazítsafelazoldalütköztetőt.

Helyezze a gyorstiplizőt a B munkalapraéstámasszahozzáaz

oldalütköztetőtlásd17.ábra, a hüvelyektengelyéthelyezze

a felrajzolttengelyrelásd16.ábra, majdhúzzabe a csavarokat.

PL

Rysunki 16 i 17: Aby połączenie kątowe było umieszczone dalej

od krawędzi narysuj na płycie B oś centralną. Poluzuj boczny

ogranicznik. Na płytę Bumieść przyrząd do dyblowania oraz

oprzyj ogranicznik o krawędź, patrz rys.17.Następnie wyrównaj

osie otworów zgodnie z oznaczoną osią rys.16.Teraz dokręć

śruby oporowe

Figure 16 & 17: Place the board B in the desired position on

board Aand clamp firmly. Draw a centre line for the dowel

holes on board B. Place the dowel locator with the side

centre marks on the centre line, push the angle fence

against board B and clamp. Then drill as shown in Figure

14.

Figure 18: T-Joint.

Figure 19 & 20: Draw a centre line for the dowel holes on

board B. Clamp board Aat a distance of 35mm from the

drawn line.

Important: The depth stop must be re-adjusted (board

thickness 5mm). Now place the dowel locator with the

corresponding guiding groove over the dowel. When drilling

ensure that the centre marks are aligned with the centre line.

Figure 21: End-grain joints.

Figure 22: Place the dowel locator on a dowel in board A.

Then push the angle fence from the handle side into the

guideway until it rests firmly against the board. Finally tighten

the clamping screw.

Figure 23 & 24: Clamp board A& Bin such a manner that

the marks are visible. Push the dowel locator with the

corresponding guiding groove over the dowel until the angle

fence rests firmly against the board and then drill.

Figure 13 & 14: Place board B in a desired position on

board Aand clamp to the workbench.

Important: The depth stop must be re-adjusted (board

thickness 5mm). Place the dowel locator over the

corresponding dowel of board Ain such a manner that the

angle fence rests firmly against the board and drill.

Figure 15: The distance of the dowel from the edge is

maximum 25mm.

13

A

B

A

A

B

B

14

25mm

35mm

16

17

18

15

B

19

22

23

24

20

21

A

B

A

B

A

B

A

B

A

A

A

B

A

508819 Instructions.qxd 5/10/06 2:15 pm Page 3

Figure 16 & 17: Place the board B in the desired position on

board Aand clamp firmly. Draw a centre line for the dowel

holes on board B. Place the dowel locator with the side

centre marks on the centre line, push the angle fence

against board B and clamp. Then drill as shown in Figure

14.

Figure 18: T-Joint.

Figure 19 & 20: Draw a centre line for the dowel holes on

board B. Clamp board Aat a distance of 35mm from the

drawn line.

Important: The depth stop must be re-adjusted (board

thickness 5mm). Now place the dowel locator with the

corresponding guiding groove over the dowel. When drilling

ensure that the centre marks are aligned with the centre line.

Figure 21: End-grain joints.

Figure 22: Place the dowel locator on a dowel in board A.

Then push the angle fence from the handle side into the

guideway until it rests firmly against the board. Finally tighten

the clamping screw.

Figure 23 & 24: Clamp board A& Bin such a manner that

the marks are visible. Push the dowel locator with the

corresponding guiding groove over the dowel until the angle

fence rests firmly against the board and then drill.

Figure 13 & 14: Place board B in a desired position on

board Aand clamp to the workbench.

Important: The depth stop must be re-adjusted (board

thickness 5mm). Place the dowel locator over the

corresponding dowel of board Ain such a manner that the

angle fence rests firmly against the board and drill.

Figure 15: The distance of the dowel from the edge is

maximum 25mm.

13

A

B

A

A

B

B

14

25mm

35mm

16

17

18

15

B

19

22

23

24

20

21

A

B

A

B

A

B

A

B

A

A

A

B

A

508819 Instructions.qxd 5/10/06 2:15 pm Page 3

HU

13. és 14. ábra: Helyezze a Blapotaz A lapra, lásd13.ábra

(rendezzeegymásfölé a munkalapokszélét). Rögzítse

a munkalapokat a munkaasztalhoz.

Figyelem: A mélyütközőtújrabekellállítani. Nyomjaát

a fúrót a fúróhüvelyenkeresztülés a fúróhosszátállítsa a B

munkalapvastagságától 5mm-rel kevesebbre.

Helyezzeráazoldalütköztetőt a tiplire (azoldalütköztető

megfelelőnyílását a fúróhüvelyhasználataszerint).

A csapozótnyomja a munkalaphoz, majdfúrjon a felületbe.

PL

Rysunek 13 i 14: Umieść płytę B na płycie A tak jak jest

pokazane na rys.13 (wyrównaj krawędzie). Przymocuj płyty do

blatu stołu roboczego.

Ważne: Głębokość ogranicznika musi zostać ponownie

ustawiona.Przeciągnij wiertło przez uchwyt wiertarski i ustaw

długość,która ma być taka sama jak grubość płyty B -5mm.

Umieść boczny ogranicznik na kołek (odpowiednim otworem

bocznego ogranicznika według zastosowanego uchwytu

wiertarskiego).Dociśnij mocno do płyty i wierć do powierzchni.

SK

Obrázok 15: Vzdialenosť hmoždiniek od okraja je

maximálna 25mm.

HU

15. ábra:A fatipliktávolsága a munkalapszélétől

maximum 25mm-relehetnek.

PL

Rysunek 15: Odległość kołków od krawędzi powinna

wynosić maks. 25 mm.

www.igm.cz

6

Operating instructions / Návod k obsluze /

Návod na obsluhu / Használatiútmutató / Instrukcja obsługi

Figure 16 & 17: Place the board B in the desired position on

board Aand clamp firmly. Draw a centre line for the dowel

holes on board B. Place the dowel locator with the side

centre marks on the centre line, push the angle fence

against board B and clamp. Then drill as shown in Figure

14.

Figure 18: T-Joint.

Figure 19 & 20: Draw a centre line for the dowel holes on

board B. Clamp board Aat a distance of 35mm from the

drawn line.

Important: The depth stop must be re-adjusted (board

thickness 5mm). Now place the dowel locator with the

corresponding guiding groove over the dowel. When drilling

ensure that the centre marks are aligned with the centre line.

Figure 21: End-grain joints.

Figure 22: Place the dowel locator on a dowel in board A.

Then push the angle fence from the handle side into the

guideway until it rests firmly against the board. Finally tighten

the clamping screw.

Figure 23 & 24: Clamp board A& Bin such a manner that

the marks are visible. Push the dowel locator with the

corresponding guiding groove over the dowel until the angle

fence rests firmly against the board and then drill.

Figure 13 & 14: Place board B in a desired position on

board Aand clamp to the workbench.

Important: The depth stop must be re-adjusted (board

thickness 5mm). Place the dowel locator over the

corresponding dowel of board Ain such a manner that the

angle fence rests firmly against the board and drill.

Figure 15: The distance of the dowel from the edge is

maximum 25mm.

13

A

B

A

A

B

B

14

25mm

35mm

16

17

18

15

B

19

22

23

24

20

21

A

B

A

B

A

B

A

B

A

A

A

B

A

508819 Instructions.qxd 5/10/06 2:15 pm Page 3

EN

Figure 19 & 20: Draw a centre line for the dowel holes on

board B. Clamp board Aat a distance of 35mm from the

drawn line.

Important: The depth stop must be re-adjusted (board

thickness 5mm). Now place the dowel locator with the

corresponding guiding groove over the dowel. When drilling

ensure that the centre marks are aligned with the centre line.

CZ

Obrázek 19 a 20: Nakreslete středovou čáru pro otvory pro

kolíky na desce B. Položte desku Ave vzdálenosti 35mm od

nakreslené čáry.

Důležité: Hloubka dorazu se musí znovu upravit. Prostrčte vrták

vrtacím pouzdrem a nastavte délku jako je tloušťka desky B

-5mm.

Odmontujte postraní doraz. Položte kolíkovací přípravek na

desku B viz obr.20 před vrtáním se ujistěte, že středová čára

prochází přes středy vrtacích pouzder.

SK

Obrázok 19 a 20: Nakreslite stredovú čiaru pre otvory pre

kolíky na doske B. Položte dosku Avo vzdialenosti 35 mm od

nakreslené čiary.

Dôležité: Hĺbka dorazu sa musí znovu upraviť. Prestrčte vrták

vŕtacím puzdrom a nastavte dĺžku ako je hrúbka dosky B-5mm.

Odmontujte postrannej doraz. Položte kolíkovací prípravok na

dosku Bpozri obr.20 pred vŕtaním sa uistite, že stredová čiara

prechádza cez stredy vŕtacích puzdier.

HU

19. és 20. ábra: A Bmunkalaprarajzoljafel a fatiplik

nyílásainakközépvonalát.TegyeazA táblát 35mm távolságra

a felrajzoltvonaltól.

Figyelem:A mélyütközőtújrabekellállítani. Nyomjaát a fúrót

a fúróhüvelyenkeresztülés a fúróhosszátállítsa a Btábla

vastagságától 5mm-rel kevesebbre.

Távolítsaelazoldalütköztetőt. A gyorstiplizőthelyezze a B

munkalapralásd20.ábra, majd a fúráselőttgyőződjönmeg

arról, hogy a középvonalkeresztülhaladjon a fúróhüvelyek

közepén.

PL

Rysunek 19 i 20:Na płycie B narysuj linię centralną dla otworów

pod kołki. Płytę A umieść w odległości 35 mm od narysowanej

linii.

Ważne:Głębokość ogranicznika musi zostać ponownie

ustawiona.Przeciągnij wiertło przez uchwyt wiertarski i ustaw

długość,która ma być taka sama jak grubość płyty B -5mm.

Usuń boczny ogranicznik. Na płytę B umieść przyrząd do

dyblowania, patrz rys. 20. Przed rozpoczęciem wiercenia,

upewnij się, że linia centralna przechodzi przez środek

uchwytów wiertarskich.

Figure 16 & 17: Place the board B in the desired position on

board Aand clamp firmly. Draw a centre line for the dowel

holes on board B. Place the dowel locator with the side

centre marks on the centre line, push the angle fence

against board B and clamp. Then drill as shown in Figure

14.

Figure 18: T-Joint.

Figure 19 & 20: Draw a centre line for the dowel holes on

board B. Clamp board Aat a distance of 35mm from the

drawn line.

Important: The depth stop must be re-adjusted (board

thickness 5mm). Now place the dowel locator with the

corresponding guiding groove over the dowel. When drilling

ensure that the centre marks are aligned with the centre line.

Figure 21: End-grain joints.

Figure 22: Place the dowel locator on a dowel in board A.

Then push the angle fence from the handle side into the

guideway until it rests firmly against the board. Finally tighten

the clamping screw.

Figure 23 & 24: Clamp board A& Bin such a manner that

the marks are visible. Push the dowel locator with the

corresponding guiding groove over the dowel until the angle

fence rests firmly against the board and then drill.

Figure 13 & 14: Place board B in a desired position on

board Aand clamp to the workbench.

Important: The depth stop must be re-adjusted (board

thickness 5mm). Place the dowel locator over the

corresponding dowel of board Ain such a manner that the

angle fence rests firmly against the board and drill.

Figure 15: The distance of the dowel from the edge is

maximum 25mm.

13

A

B

A

A

B

B

14

25mm

35mm

16

17

18

15

B

19

22

23

24

20

21

A

B

A

B

A

B

A

B

A

A

A

B

A

508819 Instructions.qxd 5/10/06 2:15 pm Page 3

Figure 16 & 17: Place the board B in the desired position on

board Aand clamp firmly. Draw a centre line for the dowel

holes on board B. Place the dowel locator with the side

centre marks on the centre line, push the angle fence

against board B and clamp. Then drill as shown in Figure

14.

Figure 18: T-Joint.

Figure 19 & 20: Draw a centre line for the dowel holes on

board B. Clamp board Aat a distance of 35mm from the

drawn line.

Important: The depth stop must be re-adjusted (board

thickness 5mm). Now place the dowel locator with the

corresponding guiding groove over the dowel. When drilling

ensure that the centre marks are aligned with the centre line.

Figure 21: End-grain joints.

Figure 22: Place the dowel locator on a dowel in board A.

Then push the angle fence from the handle side into the

guideway until it rests firmly against the board. Finally tighten

the clamping screw.

Figure 23 & 24: Clamp board A& Bin such a manner that

the marks are visible. Push the dowel locator with the

corresponding guiding groove over the dowel until the angle

fence rests firmly against the board and then drill.

Figure 13 & 14: Place board B in a desired position on

board Aand clamp to the workbench.

Important: The depth stop must be re-adjusted (board

thickness 5mm). Place the dowel locator over the

corresponding dowel of board Ain such a manner that the

angle fence rests firmly against the board and drill.

Figure 15: The distance of the dowel from the edge is

maximum 25mm.

13

A

B

A

A

B

B

14

25mm

35mm

16

17

18

15

B

19

22

23

24

20

21

A

B

A

B

A

B

A

B

A

A

A

B

A

508819 Instructions.qxd 5/10/06 2:15 pm Page 3

EN

Figure 18: T-Joint.

CZ

Obrázek 18: T-spoj.

SK

Obrázok 18: T-spoj.

HU

18. ábra: T-kötés.

PL

Rysunek 18: T-połączenie.

Figure 16 & 17: Place the board B in the desired position on

board Aand clamp firmly. Draw a centre line for the dowel

holes on board B. Place the dowel locator with the side

centre marks on the centre line, push the angle fence

against board B and clamp. Then drill as shown in Figure

14.

Figure 18: T-Joint.

Figure 19 & 20: Draw a centre line for the dowel holes on

board B. Clamp board Aat a distance of 35mm from the

drawn line.

Important: The depth stop must be re-adjusted (board

thickness 5mm). Now place the dowel locator with the

corresponding guiding groove over the dowel. When drilling

ensure that the centre marks are aligned with the centre line.

Figure 21: End-grain joints.

Figure 22: Place the dowel locator on a dowel in board A.

Then push the angle fence from the handle side into the

guideway until it rests firmly against the board. Finally tighten

the clamping screw.

Figure 23 & 24: Clamp board A& Bin such a manner that

the marks are visible. Push the dowel locator with the

corresponding guiding groove over the dowel until the angle

fence rests firmly against the board and then drill.

Figure 13 & 14: Place board B in a desired position on

board Aand clamp to the workbench.

Important: The depth stop must be re-adjusted (board

thickness 5mm). Place the dowel locator over the

corresponding dowel of board Ain such a manner that the

angle fence rests firmly against the board and drill.

Figure 15: The distance of the dowel from the edge is

maximum 25mm.

13

A

B

A

A

B

B

14

25mm

35mm

16

17

18

15

B

19

22

23

24

20

21

A

B

A

B

A

B

A

B

A

A

A

B

A

508819 Instructions.qxd 5/10/06 2:15 pm Page 3

www.igm.cz 7

Operating instructions / Návod k obsluze /

Návod na obsluhu / Használatiútmutató / Instrukcja obsługi

Figure 16 & 17: Place the board B in the desired position on

board Aand clamp firmly. Draw a centre line for the dowel

holes on board B. Place the dowel locator with the side

centre marks on the centre line, push the angle fence

against board B and clamp. Then drill as shown in Figure

14.

Figure 18: T-Joint.

Figure 19 & 20: Draw a centre line for the dowel holes on

board B. Clamp board Aat a distance of 35mm from the

drawn line.

Important: The depth stop must be re-adjusted (board

thickness 5mm). Now place the dowel locator with the

corresponding guiding groove over the dowel. When drilling

ensure that the centre marks are aligned with the centre line.

Figure 21: End-grain joints.

Figure 22: Place the dowel locator on a dowel in board A.

Then push the angle fence from the handle side into the

guideway until it rests firmly against the board. Finally tighten

the clamping screw.

Figure 23 & 24: Clamp board A& Bin such a manner that

the marks are visible. Push the dowel locator with the

corresponding guiding groove over the dowel until the angle

fence rests firmly against the board and then drill.

Figure 13 & 14: Place board B in a desired position on

board Aand clamp to the workbench.

Important: The depth stop must be re-adjusted (board

thickness 5mm). Place the dowel locator over the

corresponding dowel of board Ain such a manner that the

angle fence rests firmly against the board and drill.

Figure 15: The distance of the dowel from the edge is

maximum 25mm.

13

A

B

A

A

B

B

14

25mm

35mm

16

17

18

15

B

19

22

23

24

20

21

A

B

A

B

A

B

A

B

A

A

A

B

A

508819 Instructions.qxd 5/10/06 2:15 pm Page 3

EN

Figure 22: Place the dowel locator on a dowel in board A.

Then push the angle fence from the handle side into the

guideway until it rests rmly against the board. Finally tighten

the clamping screw.

CZ

Obrázek 22: Umístěte hmoždinku do desky Aa položte na

ní vrtací čep, přitlačte postraní doraz a dotáhněte šrouby. viz

obr.22

SK

Obrázok 22: Umiestnite hmoždinku do dosky Aa položte na

ňu vŕtacii čap, pritlačte postranný doraz a dotiahnite skrutky.

pozri Obr.22

HU

22. ábra: Helyezze a fatipliketazA munkalapnyílasaiba, majd

tegyerá a mestercsapozót, helyezzefelazoldalütköztetőtés

húzzabe a szorítócsavarokat. Lásd 22.ábra

PL

Rysunek 22: W płycie Aumieść kołek, następnie nałóż na niego czop

wiertarski, dociśnij boczny ogranicznik i dokręć śruby, patrz rys. 22.

Figure 16 & 17: Place the board B in the desired position on

board Aand clamp firmly. Draw a centre line for the dowel

holes on board B. Place the dowel locator with the side

centre marks on the centre line, push the angle fence

against board B and clamp. Then drill as shown in Figure

14.

Figure 18: T-Joint.

Figure 19 & 20: Draw a centre line for the dowel holes on

board B. Clamp board Aat a distance of 35mm from the

drawn line.

Important: The depth stop must be re-adjusted (board

thickness 5mm). Now place the dowel locator with the

corresponding guiding groove over the dowel. When drilling

ensure that the centre marks are aligned with the centre line.

Figure 21: End-grain joints.

Figure 22: Place the dowel locator on a dowel in board A.

Then push the angle fence from the handle side into the

guideway until it rests firmly against the board. Finally tighten

the clamping screw.

Figure 23 & 24: Clamp board A& Bin such a manner that

the marks are visible. Push the dowel locator with the

corresponding guiding groove over the dowel until the angle

fence rests firmly against the board and then drill.

Figure 13 & 14: Place board B in a desired position on

board Aand clamp to the workbench.

Important: The depth stop must be re-adjusted (board

thickness 5mm). Place the dowel locator over the

corresponding dowel of board Ain such a manner that the

angle fence rests firmly against the board and drill.

Figure 15: The distance of the dowel from the edge is

maximum 25mm.

13

A

B

A

A

B

B

14

25mm

35mm

16

17

18

15

B

19

22

23

24

20

21

A

B

A

B

A

B

A

B

A

A

A

B

A

508819 Instructions.qxd 5/10/06 2:15 pm Page 3

EN

Figure 21: End-grain joints.

CZ

Obrázek 21: Spoj na tupo

SK

Obrázok 21: Spoj na tupo

HU

21. ábra: Toldás.

PL

Rysunek 21: Połączenie czołowe

EN

Figure 23 & 24: Clamp board A& Bin such a manner that

the marks are visible. Push the dowel locator with the

corresponding guiding groove over the dowel until the angle

fence rests rmly against the board and then drill.

CZ

Obrázek 23 & 24: Přiložte desku Bk desce Aa navlečte otvor

před vrtacím pouzdrem na kolík (vizobr.23). Doražte postraní

doraz. Vyvrtejte otvor do desky B.

SK

Obrázok 23 & 24: Priložte dosku Bk doske Apozri a navlečte

otvor pred vŕtacím puzdrom na kolík (pozri obr.23). Dorazte

postrannej doraz. Vyvŕtajte otvor do dosky B.

HU

23. és 24. ábra: A BmunkalapothelyezzeazA táblamellé,

ésültesse a csapozót a fúrnikívántlyukfelettifatiplire (lásd

23. kép). Ültessefelazoldalütköztetőt. Fúrjaki a B tábla

nyílását.

PL

Rysunek 23 i 24: Przyłóż płytę B do płyty A i nawlecz otwór

przed uchwytem wiertarskim na kołek (patrz rys. 23). Wbij

boczny ogranicznik. Wywierć otwór w płycie B.

Figure 16 & 17: Place the board B in the desired position on

board Aand clamp firmly. Draw a centre line for the dowel

holes on board B. Place the dowel locator with the side

centre marks on the centre line, push the angle fence

against board B and clamp. Then drill as shown in Figure

14.

Figure 18: T-Joint.

Figure 19 & 20: Draw a centre line for the dowel holes on

board B. Clamp board Aat a distance of 35mm from the

drawn line.

Important: The depth stop must be re-adjusted (board

thickness 5mm). Now place the dowel locator with the

corresponding guiding groove over the dowel. When drilling

ensure that the centre marks are aligned with the centre line.

Figure 21: End-grain joints.

Figure 22: Place the dowel locator on a dowel in board A.

Then push the angle fence from the handle side into the

guideway until it rests firmly against the board. Finally tighten

the clamping screw.

Figure 23 & 24: Clamp board A& Bin such a manner that

the marks are visible. Push the dowel locator with the

corresponding guiding groove over the dowel until the angle

fence rests firmly against the board and then drill.

Figure 13 & 14: Place board B in a desired position on

board Aand clamp to the workbench.

Important: The depth stop must be re-adjusted (board

thickness 5mm). Place the dowel locator over the

corresponding dowel of board Ain such a manner that the

angle fence rests firmly against the board and drill.

Figure 15: The distance of the dowel from the edge is

maximum 25mm.

13

A

B

A

A

B

B

14

25mm

35mm

16

17

18

15

B

19

22

23

24

20

21

A

B

A

B

A

B

A

B

A

A

A

B

A

508819 Instructions.qxd 5/10/06 2:15 pm Page 3

Figure 16 & 17: Place the board B in the desired position on

board Aand clamp firmly. Draw a centre line for the dowel

holes on board B. Place the dowel locator with the side

centre marks on the centre line, push the angle fence

against board B and clamp. Then drill as shown in Figure

14.

Figure 18: T-Joint.

Figure 19 & 20: Draw a centre line for the dowel holes on

board B. Clamp board Aat a distance of 35mm from the

drawn line.

Important: The depth stop must be re-adjusted (board

thickness 5mm). Now place the dowel locator with the

corresponding guiding groove over the dowel. When drilling

ensure that the centre marks are aligned with the centre line.

Figure 21: End-grain joints.

Figure 22: Place the dowel locator on a dowel in board A.

Then push the angle fence from the handle side into the

guideway until it rests firmly against the board. Finally tighten

the clamping screw.

Figure 23 & 24: Clamp board A& Bin such a manner that

the marks are visible. Push the dowel locator with the

corresponding guiding groove over the dowel until the angle

fence rests firmly against the board and then drill.

Figure 13 & 14: Place board B in a desired position on

board Aand clamp to the workbench.

Important: The depth stop must be re-adjusted (board

thickness 5mm). Place the dowel locator over the

corresponding dowel of board Ain such a manner that the

angle fence rests firmly against the board and drill.

Figure 15: The distance of the dowel from the edge is

maximum 25mm.

13

A

B

A

A

B

B

14

25mm

35mm

16

17

18

15

B

19

22

23

24

20

21

A

B

A

B

A

B

A

B

A

A

A

B

A

508819 Instructions.qxd 5/10/06 2:15 pm Page 3

IGM nástroje a stroje s.r.o., V Kněžívce 201,

Tuchoměřice, 252 67, Czech Republic, E.U.

www.igm.cz

© 2018 IGM nástroje a stroje s.r.o.

Other IGM Fachmann Tools manuals