4

ENGLISH

6HFXUHWKHSLVWRQZLWKRXWVSULQJLQWKHVDPHKROHVKRZQDERYH

With the barrier open, the spring must NOT be

compressed.

,QVWDOOWKHEHDPDQGLWVIL[LQJSRFNHWXVLQJWKHSURYLGHGVFUHZV

DVVKRZQLQ)LJUHIIURPto WKHUXEEHUSURILOHRIWKH

EHDPPXVWIDFHWKHFORVLQJGLUHFWLRQ

'RQRWJUHDVHWKH¿[LQJVFUHZRIWKHEDU

,I WKH DSSOLFDWLRQ UHTXLUHV D VHJPHQWHG EDU RQFH WKH ILUVW

VHJPHQW DQG IL[LQJ SRFNHW KDYH EHHQ DVVHPEOHG FORVH

WKH DXWRPDWLF V\VWHP ORFN LW DQG IROORZ WKH LQVWUXFWLRQV IRU

DGGLWLRQDO VHJPHQW DVVHPEO\ DV VKRZQ LQ )LJ UHI IURP

to

$GMXVWWKHRSHQLQJDQGFORVLQJPHFKDQLFDOVWRSVDVVKRZQLQ

)LJDQGWLJKWHQWKHORFNQXW

(QVXUH WKDW WKH EHDP LV EDODQFHG IROORZLQJ WKH LQVWUXFWLRQV

FRQWDLQHGLQSDUDJUDSKVDQG

The compartment should be fixed, as shown in the

sequence in Fig. 21, when all mechanical installations,

wiring and start-up have been completed.

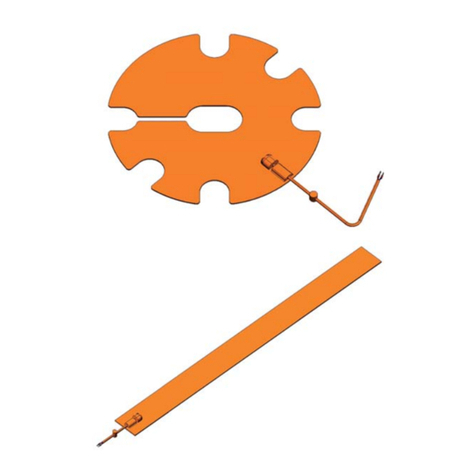

4.5 Fixing the plunging pistons

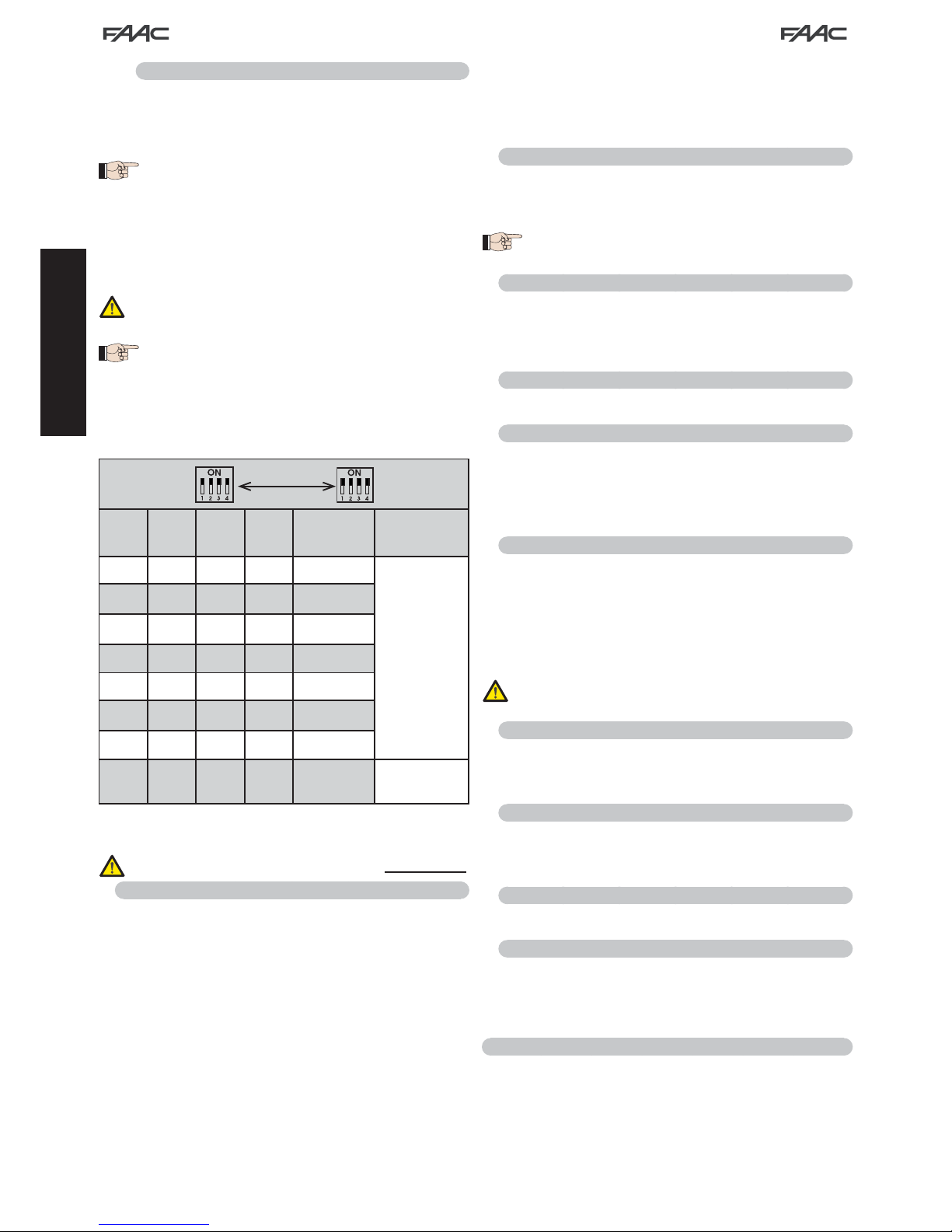

%DUULHUEDODQFLQJLVREWDLQHGE\FRUUHFWO\DGMXVWLQJWKHVSULQJSUHORDG

ULQJQXWVHHQH[WSDUDJUDSKEXWDOVRE\VHWWLQJWKHWZRSOXQJLQJ

SLVWRQVLQWKHPRVWVXLWDEOHSRVLWLRQ7KLVSRVLWLRQLVGHWHUPLQHGE\

WKHOHQJWKRIWKHEHDP DQG WKH SUHVHQFH RI DQ\ DFFHVVRULHV WKDW

PD\EHDSSOLHGWRLWVHHSDUDJUDSK

4.6 Balancing the barrier

WARNING: This procedure must be carried out as the barrier is

not internally balanced. The beam is balanced when, operating

manually (ref. paragraph 6) the beam remains stationary in the

45° position.

7REDODQFHWKHEDUULHUSURFHHGDVIROORZV

,QVWDOOWKHEDUDQGDOOUHODWHGDFFHVVRULHVRQWKHEDUULHUVWUXFWXUH

DVUHTXLUHGE\WKHILQDOFRQILJXUDWLRQRIWKHV\VWHP

(QVXUHWKDWWKHRSHUDWRULVUHOHDVHGVHHSDUDJUDSK

(QVXUHWKDWWKHSOXQJLQJSLVWRQVDUHVHFXUHGRQWKHURFNHUDUP

DFFRUGLQJWRWKHLQVWUXFWLRQVLQSDUDJUDSKLQ7DEOHRU7DEOH

GHSHQGLQJRQWKHLQVWDOOHGEHDPPRGHO6RU/UHVSHFWLYHO\

0DQXDOO\PRYHWKHEDUWRWKHSRVLWLRQDQGYHULI\LWUHPDLQV

VWDWLRQDU\,IWKHEDUWHQGVWRRSHQWXUQWKHVSULQJSUHORDGULQJ

QXWDQWLFORFNZLVH)LJUHILILWWHQGVWRFORVHWXUQWKHULQJ

QXWFORFNZLVH)LJUHI).

5. START-UP

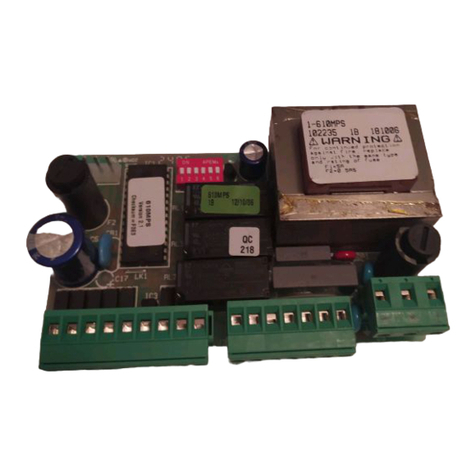

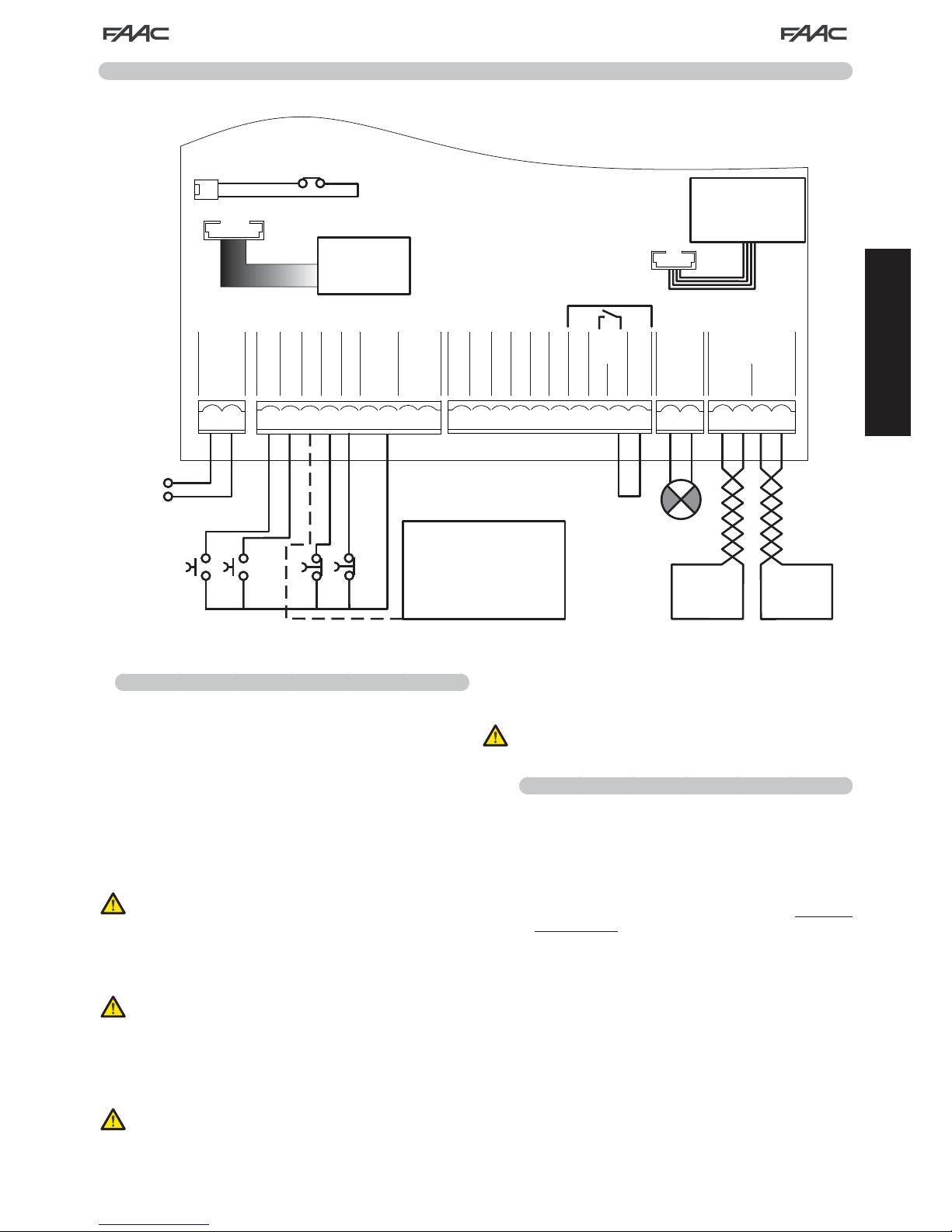

5.1 Connecting the control equipment

WARNING: Before carrying out any work on the control board

(connections, maintenance, etc.) always cut off the electrical

power.

Forallautomaticsystemconnectionsandtesting,refer

to the section dedicated to the electronic equipment,

paragraph 1 on page 6 and following.

5.2 Testing the automated system

2QFHLQVWDOODWLRQKDVEHHQFRPSOHWHGDSSO\WKHGDQJHUVLJQVWLFNHU

UHI)LJWRWKHWRSRIWKHXSULJKWSURILOH3URFHHGWRHQVXUHFRUUHFW

RSHUDWLRQRIWKHDXWRPDWHGV\VWHPDQGDOOWKHDFFHVVRULHV

connected to it.

Give the Customer the “User’s Manual”, the

documentation required by current law and show how

to correctly operate the barrier, pointing out the areas

of potential danger.

6. MANUAL OPERATION

6KRXOGPDQXDORSHUDWLRQRIWKHEDUULHUEHUHTXLUHGGXHWRHOHFWULFDO

SRZHU FXWRIIV RU DXWRPDWHG V\VWHP LQHIILFLHQF\ XVH WKH UHOHDVH

GHYLFHZLWKWKHSURYLGHGNH\

7KHSURYLGHGXQORFNLQJNH\LVHLWKHUWULDQJXODU)LJUHI) or

FXVWRPLVHG)LJUHIoptional).

,QVHUW WKH XQORFNLQJ NH\ LQ WKH ORFN DQG WXUQ WKH NH\

anticlockwiseXQWLOLWFOLFNVLQWRSODFHDVVKRZQLQ)LJ

2SHQRUFORVHWKHEHDPPDQXDOO\

With the bar released, the motor may start for

approximately3seconds.Thisisnormal and determined

by the parameter Hold Close / Hold Open

7. RESTORING NORMAL OPERATION

7RDYRLGDQDFFLGHQWDOSXOVHRSHQLQJWKHEDUULHUGXULQJWKLVRSHUDWLRQ

EHIRUHDFWLYDWLQJWKHORFNLQJV\VWHPFXWRIIDOOSRZHUWRWKHV\VWHP

triangular unlocking key (standard):

WXUQWKHNH\clockwiseXQWLOLWVWRSVDQGWKHQUHPRYHLW)LJ

ref. ).

customised unlocking key (optional):

WXUQWKHNH\clockwiseXQWLOLWVWRSVDQGWKHQUHPRYHLW)LJUHI

).

8. MAINTENANCE

:KHQSHUIRUPLQJVL[PRQWKPDLQWHQDQFHDOZD\VFKHFNWKHFRUUHFW

EDODQFLQJ RI WKH V\VWHP DQG WKH FRUUHFW RSHUDWLRQ RI WKH VDIHW\

devices.

8.1 Topping up the oil

&KHFNWKHDPRXQWRIRLOLQWKHWDQNHYHU\PRQWKV

7KHOHYHOPXVWEHLQFOXGHGEHWZHHQWKHWZRQRWFKHVRQWKHLQVSHFWLRQ

rod.

7RWRSXSXQVFUHZWKHILOOHUFDS)LJUHIDQGSRXURLOXSWR

the indicated level.

8VHRQO\)$$&+32,/

8.2 Air bleeding

)$$&SURGXFWVDUHGHOLYHUHGDOUHDG\EOHGRIDQ\DLULQWKHK\GUDXOLF

FLUFXLW 0DLQWHQDQFH RSHUDWLRQV UHSODFLQJ VSDUH SDUWV HJ

FRQQHFWLRQSLSHVRUFDUHOHVVWUDQVSRUWFDQFDXVHHQWU\RIDLULQWKH

K\GUDXOLFFLUFXLWZKLFKLQWXUQFDQFDXVHRSHUDWRULUUHJXODUPRYHPHQW

RUUHGXFHLWVWRUTXH6KRXOGEHDPPRYHPHQWEHLUUHJXODUUHOHDVH

WKHDLUIURPWKHK\GUDXOLFV\VWHPIROORZLQJWKHLQVWUXFWLRQVEHORZ

(OHFWULFDOO\RSHUDWHWKHEHDP

:KHQ RSHQLQJ LV FRPSOHWHG VOLJKWO\ ORRVHQ DQG WLJKWHQ WKH

EOHHGHU VFUHZ RI WKH SLVWRQ ZLWK WKH EDODQFH VSULQJ )LJ

ref. ).

:KHQ FORVLQJ LV FRPSOHWHG VOLJKWO\ ORRVHQ DQG WLJKWHQ WKH

EOHHGHUVFUHZRIWKHSLVWRQZLWKRXWWKHEDODQFHVSULQJ)LJ

ref. ).

,I QHFHVVDU\ UHSHDW WKH RSHUDWLRQ XQWLO UHJXODU PRYHPHQW RI WKH

beam is obtained.

Care needs to be taken at this stage as the pistons

contain oil under pressure which could leak out if the

screws are loosened too much.

If the parameters FO and FC in Advanced

Configuration have been changed and set to a value

lower than default, during bleeding we recommend

setting them to an equal or greater value, to facilitate

air bleeding