Ignite Auger 75 DDH Manual

7519274 enUS (A)

June 2023

Printed in USA

Original Instructions

© 2023 Ignite Attachments.

All Rights Reserved.

Operation & Maintenance Manual

Auger

Auger 75 DDH S/N: B6EM00101 & Above

Auger 165 DDH S/N: B6EN00101 & Above

Auger 150 PH S/N: B6EP00101 & Above

Auger 210 PH S/N: B6ER00101 & Above

1

FOREWORD............................................................................................................................................................3

MANUFACTURER.............................................................................................................................................3

North America ...............................................................................................................................................3

SERIAL NUMBER LOCATION ...........................................................................................................................3

Attachment / Implement Serial Number...............................................................................................................3

ATTACHMENT IDENTIFICATION .......................................................................................................................4

FEATURES AND ACCESSORIES ......................................................................................................................4

Standard Items..............................................................................................................................................4

Options And Accessories.................................................................................................................................4

SAFETY AND TRAINING RESOURCES....................................................................................................................5

SAFETY INSTRUCTIONS..................................................................................................................................5

Safe Operation Is The Operator’s Responsibility ...................................................................................................5

Safe Operation Needs A Qualified Operator.........................................................................................................5

Use Safety Rules ...........................................................................................................................................5

Call Before You Dig ........................................................................................................................................5

Silica Dust Exposure.......................................................................................................................................6

FIRE PREVENTION...........................................................................................................................................6

Maintenance.................................................................................................................................................6

Operation.....................................................................................................................................................6

Electrical......................................................................................................................................................6

Hydraulic System...........................................................................................................................................6

Fueling ........................................................................................................................................................7

Starting........................................................................................................................................................7

Spark Arrester Exhaust System......................................................................................................................... 7

Welding And Grinding .....................................................................................................................................7

Fire Extinguishers ..........................................................................................................................................7

PUBLICATIONS AND TRAINING RESOURCES .................................................................................................8

ATTACHMENT SIGNS .......................................................................................................................................9

OPERATING INSTRUCTIONS ................................................................................................................................ 12

INITIAL SETUP ............................................................................................................................................... 12

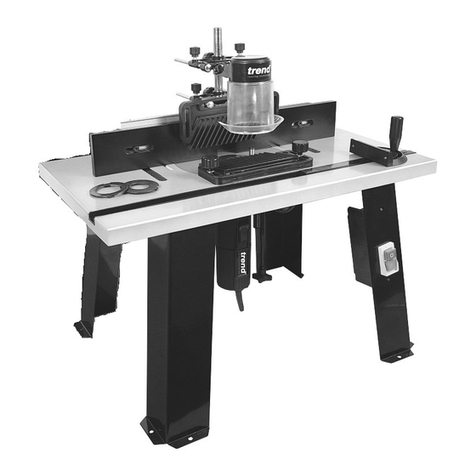

Installing The Auger On The Loader Attachment Mounting Frame .......................................................................... 12

Removing The Auger From The Loader Attachment Mounting Frame...................................................................... 12

Installing The Hydraulic Hoses On The Auger .................................................................................................... 12

Installing The Auger Bit ................................................................................................................................. 12

DAILY INSPECTION........................................................................................................................................ 14

Inspecting Attachment Mounting Frame ............................................................................................................ 14

Inspecting The Machine Quick Coupler............................................................................................................. 14

OPERATING PROCEDURE WITH LOADERS................................................................................................... 15

Approved Loader Models And Requirements ..................................................................................................... 15

Entering And Exiting The Machine ................................................................................................................... 16

Installing The Attachment .............................................................................................................................. 16

Hydraulic Quick Couplers .............................................................................................................................. 21

Operating The Controls ................................................................................................................................. 22

Operation With The Loader ............................................................................................................................ 22

Removing The Attachment............................................................................................................................. 23

LIFTING THE ATTACHMENT........................................................................................................................... 25

TRANSPORTING THE ATTACHMENT ON A TRAILER ..................................................................................... 25

Fastening The Attachment On A Trailer With The Loader Mounting Frame ............................................................... 25

Transporting The Attachment And Machine On A Trailer ....................................................................................... 26

TABLE OF CONTENTS

2

PREVENTIVE MAINTENANCE............................................................................................................................... 28

MAINTENANCE SAFETY WARNINGS ............................................................................................................. 28

TROUBLESHOOTING ..................................................................................................................................... 29

Troubleshooting The Attachment..................................................................................................................... 29

SERVICE SCHEDULE ..................................................................................................................................... 30

LUBRICATING THE ATTACHMENT ................................................................................................................. 31

Lubricating The Auger 150PH And 210PH Models .............................................................................................. 31

Lubricating The Auger 75DDH and 165DDH Models............................................................................................ 31

REMOVING AND INSTALLING STANDARD / HEAVY DUTY AUGER TEETH..................................................... 32

REMOVING AND INSTALLING HYDRAULIC MOTOR AND GEAR BOX............................................................ 33

ASSEMBLING AND DISASSEMBLING CHAIN REDUCTION DRIVES............................................................... 34

ATTACHMENT STORAGE AND RETURN TO SERVICE ................................................................................... 37

Attachment Storage...................................................................................................................................... 37

Return To Service ........................................................................................................................................ 37

SPECIFICATIONS.................................................................................................................................................. 38

ATTACHMENT SPECIFICATIONS.................................................................................................................... 38

Auger Dimensions........................................................................................................................................ 38

Performance Specifications............................................................................................................................ 39

Attachment Capacities .................................................................................................................................. 39

TORQUE SPECIFICATION FOR BOLTS .......................................................................................................... 40

Torque For General SAE Bolts ........................................................................................................................ 40

Torque For General Metric Bolts...................................................................................................................... 40

HYDRAULIC CONNECTION SPECIFICATIONS ............................................................................................... 42

O-ring Face Seal Connection.......................................................................................................................... 42

Straight Thread O-ring Fitting.......................................................................................................................... 42

Tubelines And Hoses.................................................................................................................................... 42

Tightening The Flare Fitting............................................................................................................................ 42

O-ring Flare Fitting ....................................................................................................................................... 43

Port Seal Fitting........................................................................................................................................... 45

Push To Connect Fittings ............................................................................................................................... 45

WARRANTY .......................................................................................................................................................... 48

ATTACHMENT / IMPLEMENT WARRANTY...................................................................................................... 48

TABLE OF CONTENTS

3

MANUFACTURER

North America

Ignite Attachments

2741 20th Avenue South

Moorhead, MN 56560

SERIAL NUMBER LOCATION

Attachment / Implement Serial Number

Figure 1

C221397a

Always use the serial number (Item 1) [Figure 1] of the

auger when requesting service information or when

ordering parts. Earlier or later models (identification made

by serial number) may use different parts, or it may be

necessary to use a different procedure in doing a specific

service operation.

FOREWORD

4

ATTACHMENT IDENTIFICATION

Figure 2

C221403a

REF. Description

1 Auger Bit

2 Auger Drive

3 Mounting Frame

4 Hydraulic Hose

FEATURES AND ACCESSORIES

Standard Items

The attachment is equipped with the following standard

items:

• Hex Drive Shaft

• Flush Face Connect Under Pressure Hydraulic Quick

Couplers

Options And Accessories

Below is a list of Options and Accessories available for

your attachment.

Auger Bits:

• Standard duty bits and teeth

• Heavy duty bits and teeth

Extensions:

• Hex extension, 610 mm (24 in)

• Hex extension, 914 mm (36 in)

Adapters:

• Hex to round adapter, 5.08 cm (2.0 in) to 6.51 cm

(2.563 in)

Augers With Standard Duty Bits:

• 15,24 cm (6 in, double flight)

• 22,86 cm (9 in, double flight)

• 30,48 cm (12 in, double flight)

• 38,1 cm (15 in, double flight)

• 45,72 cm (18 in, double flight)

• 60,96 cm (24 in, double flight)

Augers With Heavy Duty Bits:

• 15,24 cm (6 in, double flight)

• 22,86 cm (9 in, double flight)

• 30,48 cm (12 in, double flight)

• 38,1 cm (15in, double flight)

• 45,72 cm (18 in, double flight)

• 60,96 cm (24 in, double flight)

FOREWORD

5

SAFETY INSTRUCTIONS

Safe Operation Is The Operator’s

Responsibility

Safety Alert Symbol

This symbol with a warning statement means:

“Warning, be alert! Your safety is involved!” Carefully

read the message that follows.

DANGER

The signal word DANGER on machine signs and in

the manuals indicates a hazardous situation which, if

not avoided, will result in serious injury or death.◂

D-1002

WARNING

The signal word WARNING on the machine and in the

manuals indicates a potentially hazardous situation

which, if not avoided, could result in serious injury or

death.◂

W-2044

IMPORTANT

This notice identifies procedures which must be

followed to avoid damage to the machine.◂

I-2019

The machine and attachment must be in good operating

condition before use.

Safe Operation Needs A Qualified Operator

For an operator to be qualified, he or she must not use

drugs or alcoholic drinks which impair alertness or

coordination while working. An operator who is taking

prescription drugs must get medical advice to determine

if he or she can safely operate a machine.

Use Safety Rules

• Read and follow instructions in the machine and the

attachment’s Operation & Maintenance Manual

before operating.

• Check for underground lines before operating

attachment (if applicable).

• In addition to the design and configuration of

equipment, hazard control, and accident prevention

are dependent upon the awareness, concern,

prudence, and proper training of personnel involved

in the operation, transport, maintenance, and

storage of equipment.

• Check that the attachment is securely fastened to

the machine.

• Make sure all the machine controls are in the neutral

position before starting the machine.

• Operate the attachment only from the operator’s

position.

• Operate the attachment according to the Operation

& Maintenance Manual.

• When learning to operate the attachment, do it at a

slow rate in an area clear of bystanders.

• DO NOT permit personnel to be in the work area

when operating the machine and attachment.

• The attachment must be used ONLY on approved

machines. Visit igniteattachments.com for an

updated list of approved attachments for each

machine model.

• DO NOT modify equipment or add attachments that

are not approved by the manufacturer.

• DO NOT make any adjustments or repairs on the

machine or attachment while the engine is running.

• Keep shields and guards in place. Replace if

damaged.

Call Before You Dig

P200081

Dial 811 (USA Only)

Dial 1-888-258-0808 (USA & Canada)

When you call, you will be directed to a location in your

state / province / city for information about buried lines

(telephone, cable TV, water, sewer, gas, etc.).

SAFETY AND TRAINING RESOURCES

6

Silica Dust Exposure

NA3504

Silica dust can cause lung disease and is known to the

state of California to cause cancer.

Cutting or drilling concrete containing sand or rock

containing quartz may result in exposure to silica dust.

Do not exceed Permissible Exposure Limits (PEL) to

silica dust as determined by OSHA or other job site Rules

and Regulations. Use a respirator, water spray, or other

means to control dust.

FIRE PREVENTION

NA3505

Maintenance

The machine and some attachments have components

that are at high temperatures under normal operating

conditions. The primary source of high temperatures is

the engine and exhaust system. The electrical system, if

damaged or incorrectly maintained, can be a source of

arcs or sparks.

Flammable debris (leaves, straw, etc.) must be removed

regularly. If flammable debris is allowed to accumulate, it

can cause a fire hazard. Clean often to avoid this

accumulation. Flammable debris in the engine

compartment is a potential fire hazard.

The operator’s area, engine compartment, and engine

cooling system must be inspected every day and cleaned

if necessary to prevent fire hazards and overheating.

All fuels, most lubricants, and some coolant mixtures are

flammable. Flammable fluids that are leaking or spilled

onto hot surfaces or onto electrical components can

cause a fire.

Operation

Do not use the machine where exhaust, arcs, sparks, or

hot components can contact flammable material,

explosive dust, or gases.

Electrical

P200082

Check all electrical wiring and connections for damage.

Keep the battery terminals clean and tight. Repair or

replace any damaged part or wires that are loose or

frayed.

Battery gas can explode and cause serious injury. Use

the procedure in the Operation & Maintenance Manual for

connecting the battery and for jump starting. Do not jump

start or charge a frozen or damaged battery. Keep any

open flames or sparks away from batteries. Do not

smoke in battery charging area.

Hydraulic System

Check hydraulic tubes, hoses and fittings for damage and

leakage. Never use open flame or bare skin to check for

SAFETY AND TRAINING RESOURCES

7

leaks. Hydraulic tubes and hoses must be properly routed

and have adequate support and secure clamps. Tighten

or replace any parts that show leakage.

Always clean fluid spills. Do not use gasoline or diesel

fuel for cleaning parts. Use commercial nonflammable

solvents.

Fueling

P200084

Stop the engine and let it cool before adding fuel. No

smoking! Do not refuel a machine near open flames or

sparks. Fill the fuel tank outdoors.

Ultra Low Sulfur Diesel (ULSD) poses a greater static

ignition hazard than earlier diesel formulations with

higher sulfur content. Avoid death or serious injury from

fire or explosion. Consult with your fuel or fuel system

supplier to ensure the delivery system is in compliance

with fueling standards for proper grounding and bonding

practices.

Starting

Do not use ether or starting fluids on any engine that has

glow plugs or an air intake heater. These starting aids

can cause explosion and injure you or bystanders.

Use the procedure in the Operation & Maintenance

Manual for connecting the battery and for jump starting.

Spark Arrester Exhaust System

The spark arrester exhaust system is designed to control

the emission of hot particles from the engine and exhaust

system, but the muffler and the exhaust gases are still

hot.

Check the spark arrester exhaust system regularly to

make sure it is maintained and working properly. Use the

procedure in the Operation & Maintenance Manual for

cleaning the spark arrester muffler (if equipped).

Welding And Grinding

Always clean the machine and attachment, disconnect

the battery, and disconnect the wiring from the Ignite

Attachments controllers before welding. Cover rubber

hoses, battery, and all other flammable parts. Keep a fire

extinguisher near the machine when welding.

Have good ventilation when grinding or welding painted

parts. Wear a dust mask when grinding painted parts.

Toxic dust or gas can be produced.

Dust generated from repairing nonmetallic parts such as

hoods, fenders, or covers can be flammable or explosive.

Repair such components in a well-ventilated area away

from open flames or sparks.

Fire Extinguishers

P200083

Know where fire extinguishers and first aid kits are

located and how to use them. Inspect the fire

extinguisher and service the fire extinguisher regularly.

Obey the recommendations on the instructions plate.

SAFETY AND TRAINING RESOURCES

8

PUBLICATIONS AND TRAINING

RESOURCES

The following publications are also available for your

Ignite Attachments machine. Access them online at

Igniteattachments.com.

C221554

Operation & Maintenance

Manual

Complete instructions on

the correct operation and

the routine maintenance

of your attachment.

7519274

For the latest information on Ignite Attachments products

and the Ignite Attachments Company, visit our website at

Igniteattachments.com

SAFETY AND TRAINING RESOURCES

11

REF. DECAL

1 EMISSIONS WARNING

Located on the top side of the drive unit and on the auger bit

73536420IG

7353640IG

2 DRILLING ELECTRIC SHOCK WARNING

Located on both sides of the drive unit

7130147

7130147

3 DO NOT ENTER / EXIT ON THIS SIDE WARNING DECAL

Located on the mounting frame

7130141

7130141

SAFETY AND TRAINING RESOURCES

12

INITIAL SETUP

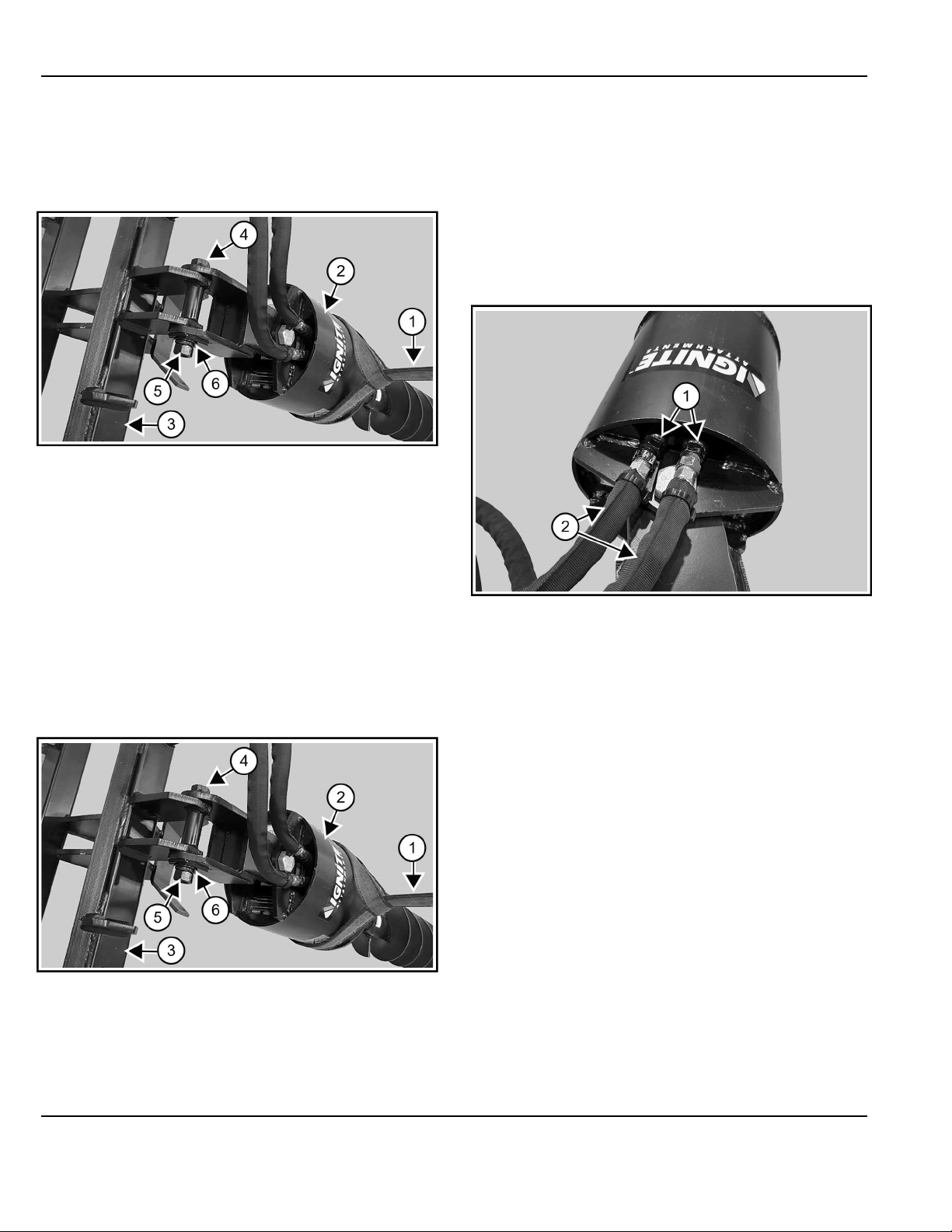

Installing The Auger On The Loader

Attachment Mounting Frame

Figure 5

C221404c

1. Install a lifting device (Item 1) around the auger drive

(Item 2) [Figure 5].

2. Align the loader attachment mounting frame (Item 3)

with the auger (Item 2) [Figure 5].

3. Install the bolt (Item 4) and lock washer (Item 6)

[Figure 5].

4. Install the nut (Item 5) [Figure 5] and tighten.

(See Torque Specification For Bolts on Page 40)

Removing The Auger From The Loader

Attachment Mounting Frame

Figure 6

C221404c

1. Install a lifting device (Item 1) [Figure 6] around the

auger drive (Item 2) and raise the auger and

mounting frame (Item 3) slightly.

2. Remove the nut (Item 5) [Figure 6].

3. Remove the bolt (Item 4) and lock washer (Item 6)

[Figure 6].

4. Remove the loader attachment mounting frame (Item

3) [Figure 6].

5. Lower the auger drive (Item 2) [Figure 6] fully.

Installing The Hydraulic Hoses On The

Auger

Figure 7

C221601b

1. Install the hydraulic hoses (Item 2) [Figure 7] onto

the hydraulic fittings (Item 1) on the auger drive and

tighten.

(See Hydraulic Connection Specifications on Page

42)

Installing The Auger Bit

NOTE: The auger bit installation is shown with the auger

drive connected to the machine.

OPERATING INSTRUCTIONS

13

Figure 8

C221406a

1. Remove the locking clip (Item 1) and pin (Item 2)

[Figure 8].

Figure 9

C221407a

2. Raise the auger drive and align the hole on the auger

drive shaft (Item 1) with the hole in the auger bit

(Item 2) [Figure 9]

3. Slide the auger bit onto the shaft.

Figure 10

C221408a

4. Install the pin and locking clip (Item 1) [Figure 10].

OPERATING INSTRUCTIONS

14

DAILY INSPECTION

Inspecting Attachment Mounting Frame

Figure 11

C221409a

• Inspect the attachment mounting system wedge

mounts (Item 1) [Figure 11] and mounting flanges

(Item 2) [Figure 11].

• Inspect all welds on the mounting frame for wear and

damage each time the auger is removed from the

machine

Inspecting The Machine Quick Coupler

WARNING

CRUSHING HAZARD

Failure to secure attachment coupler wedges can

allow attachment to come off and cause serious

injury or death.

Both wedges must extend through the holes in the

attachment mounting frame. Levers must be fully

down and locked.◂

W-2715-EF

Figure 12

NA3448a

• Lower down the quick coupler levers until they are

fully engaged in the locked position [Figure 12]

(wedges fully extended through the attachment

mounting frame holes).

The levers and wedges must move freely

[Figure 12].

Figure 13

NA3450A

The wedges must extend through the holes in the

attachment mounting frame, securely fastening the

attachment to the machine quick coupler [Figure 13].

If the wedge does not contact the lower edge of the

hole, the attachment will be loose and can come off

the quick coupler.

OPERATING INSTRUCTIONS

15

Figure 14

NA13065S

• Inspect the attachment mounting frame.

• Replace any parts that are damaged, bent, or

missing [Figure 14].

• Keep all fasteners tight.

• Look for cracked welds.

• Contact your Ignite Attachments representative for

replacement parts.

• Lubricate the wedges. (See the machine’s Operation

& Maintenance Manual for the correct procedure.)

OPERATING PROCEDURE WITH LOADERS

Approved Loader Models And Requirements

WARNING

MODIFICATION AND INSUFFICIENT INSTRUCTION

HAZARD

Use of unapproved attachments / implements or

improperly sized attachments / implements can

cause serious injury or death.

Attachments / implements and buckets for safe loads

of specified densities are approved for each model.

Never use attachments / implements or buckets

which are not approved by Ignite Attachments.◂

W-2662

WARNING

INSTABILITY HAZARD

Excessive load can cause loss of control or tipping

leading to serious injury or death.

DO NOT exceed Rated Operating Capacity (ROC).◂

W-2053

Warranty on this implement is void if used on a non-

approved carrier. Contact your Ignite Attachments

representative for a current list of compatible carriers.

AUGER

MODEL 75DDH 165DDH 150PH 210PH

Attach-

ment

inter-

face

Univer-

sal

Quick-

Attach

Univer-

sal

Quick-

Attach

Univer-

sal

Quick-

Attach

Univer-

sal

Quick-

Attach

Flow

Range

8-20

GPM

(36-76

Lpm)

14-25

GPM

(53-95

Lpm)

10-20

GPM

(38-76

Lpm)

15-30

GPM

(57-114

Lpm)

Pres-

sure

2,000 to

3,500

PSI

2,000 to

3,500

PSI

2,000 to

3,500

PSI

2,000 to

3,500

PSI

OPERATING INSTRUCTIONS

16

Figure 15

p85281

The loader must be equipped with front auxiliary

hydraulics [Figure 15].

Entering And Exiting The Machine

WARNING

GENERAL HAZARD

Failure to follow instructions can cause serious

injury or death.

• Fasten seat belt, start, and operate only from the

operator’s seat.

• Never wear loose clothing when working near

machine.◂

W-2135

Figure 16

C216077a

• Use the attachment / implement steps (if equipped),

grab handles, and safety treads (on the machine and

frame) to get in and out of the machine, maintaining

a three-point contact at all times [Figure 16]. Do not

jump.

• See the machine’s Operation & Maintenance Manual

for detailed instructions on entering and exiting the

machine.

Installing The Attachment

Installing With Non-powered Machine Quick Coupler

The attachment mounting frame for the attachment has a

top flange that is designed to receive the top edge of the

machine quick coupler and the lower part of the frame is

designed to receive the quick coupler wedges.

WARNING

GENERAL HAZARD

Failure to obey warnings can cause serious injury or

death.

Obey all warnings on the machine and in the

manuals.◂

W-2744

Always inspect the machine’s quick coupler and the

attachment mounting frame before installation. (See the

machine’s Operation & Maintenance Manual.)

(See Daily Inspection on Page 14)

Figure 17

NA3445A

1. Pull the quick coupler levers up until they are fully

raised (wedges fully raised) [Figure 17].

2. Enter the machine.

3. Turn the machine on.

4. Release the parking brake.

5. Lower the lift arms and tilt the machine quick coupler

forward.

OPERATING INSTRUCTIONS

17

Figure 18

NA3446a

6. Drive the machine slowly forward until the top edge

of the quick coupler is completely under the top

flange of the attachment [Figure 18].

NOTE: Be sure the quick coupler levers do not hit

the attachment.

Figure 19

C221410a

7. Tilt the quick coupler backward until the attachment

is slightly off the ground [Figure 19].

NOTE: When leaving the operator’s seat to install an

attachment, tilt the attachment until it is

slightly off the ground.

This will cause the attachment mounting frame to fit

up against the front of the quick coupler.

8. Turn the machine off and exit the machine.

(See Entering And Exiting The Machine on Page 16)

WARNING

GENERAL HAZARD

Failure to follow instructions can cause serious

injury or death.

Before you leave the operator’s seat:

• Lower the lift arms and put the attachment /

implement flat on the ground.

• Engage the parking brake.

• Move all controls to the NEUTRAL / LOCKED

position to make sure the lift, tilt, and drive

functions are deactivated.

• Stop the engine.◂

W-3156

Figure 20

NA3448A

9. Push down on the quick coupler levers until they are

fully engaged in the locked position [Figure 20]

(wedges are fully extended through the attachment

mounting frame holes).

If both levers do not engage in the locked position,

see your machine dealer or representative for

maintenance.

OPERATING INSTRUCTIONS

18

Figure 21

NA3450A

10. The wedges must extend through the holes in the

attachment mounting frame, securely fastening the

attachment to the quick coupler [Figure 21].

WARNING

CRUSHING HAZARD

Failure to secure attachment coupler wedges can

allow attachment to come off and cause serious

injury or death.

Both wedges must extend through the holes in

the attachment mounting frame. Levers must be

fully down and locked.◂

W-2715-EF

11. Connect auxiliary hydraulic hoses (if applicable).

(See Hydraulic Quick Couplers on Page 21)

Installing With Powered Machine Quick Coupler

Some machines may be equipped with a powered

machine quick coupler. For specific control location and

operation of the machine’s powered quick coupler, see

the machine’s Operation & Maintenance Manual.

WARNING

GENERAL HAZARD

Failure to obey warnings can cause serious injury or

death.

Obey all warnings on the machine and in the

manuals.◂

W-2744

1. Enter the machine.

2. Turn the machine on.

3. Release the parking brake.

Figure 22

NA3453A

4. Operate the powered quick coupler until the levers

are fully raised (wedges fully raised) [Figure 22].

5. Lower the lift arms and tilt the machine quick coupler

slightly forward.

Figure 23

NA3446a

6. Drive the machine slowly forward until the top edge

of the quick coupler is completely under the top

flange of the attachment mounting frame [Figure 23].

NOTE: Be sure the quick coupler levers do not hit

the attachment.

OPERATING INSTRUCTIONS

This manual suits for next models

3

Table of contents

Popular Tools manuals by other brands

BEA

BEA 145/32-178C Spare parts list/service instructions

RODCRAFT

RODCRAFT RC8006 Operation manual

Force

Force 5564C Instructions-parts list

SCHUNK

SCHUNK KSC 125 Series Installation and operating instructions

Sunex Tools

Sunex Tools SX243 operating instructions

EINHELL

EINHELL Druckluftset Profi 11011 Original operating instructions