12

Shearing tips

-Do not cut wire or cable with the shear.

-Keep the blade gap to the smallest distance possible.

-When shearing, the work should be squared against a guide.

-The pressure plate should be adjusted approximately 3 mm above the table when the shear blade

is in the up position. As you move the blade downward, the pressure plate should immediately

rest against the workpiece and hold it in place.

-To prevent distortion when shearing, snap the handle quickly to pierce the workpiece and then

continue with steady even pressure to complete the cut.

-After shearing, metal parts will have a sharp edge on them which may cause cuts when handled.

Deburr the workpiece to remove the edge before handling.

-Have the shear blades sharpened by a professional. This will lead to accurate, high-quality re-

sults.

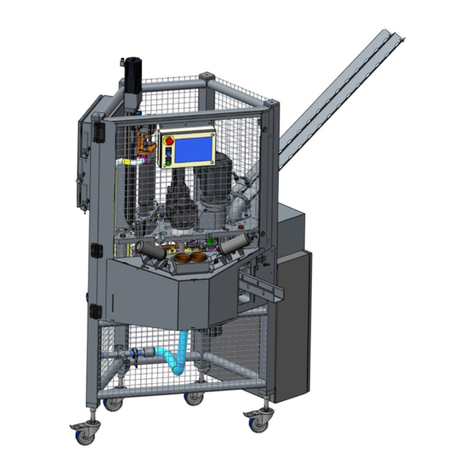

ROLLING OPERATION

Rolling

1. Open the roll cover (37) to expose the roll cylinders.

2. Lower the rear roll cylinder (45) by simultaneously loosening the slip roll adjustment knobs

(44). When complete, you should have an equal gap between the cylinders.

3. Insert the leading edge of the workpiece between the upper and lower roll cylinders.

4. Install the adjustment screws (43) in the holes.

5. Using both adjustment screws, adjust the gap so it is equal between the upper and lower cylin-

der. Both cylinders should make light contact with the workpiece.

6. Adjust the rear roller gap as needed for the radius required.

7. Crank the handle to advance the workpiece through the rollers.

8. Turn the notched shaft (36) and slip the upper roll cylinder out to remove the workpiece.

BENDING OPERATION

Bending

1. Install the stop assembly (48) in the holes in the brake die (62) and adjust the stop to required

depth. NOTE: The stop can be mounted on either the back or the front of the brake die.

2. Using the handle, raise the fingers until there is enough gap to fit the workpiece.

3. Bend the metal by lowering the fingers until you have the desired angle. NOTE: The brake die

is designed to bend material up to 90°.

4. Raise the fingers and remove the workpiece.

Finger adjustment

The sectional fingers are adjustable and removable to offer a wide variety of bending options.

1. Place a thin and flat piece of material (a spacer) over the notch of the brake die. This flat surface

will help you obtain equal finger length.

2. With the handle, lower the fingers so they are just touching the top of the spacer on the brake

die.

3. Loosen the screws (20) but do not remove them.

4. Slide the fingers horizontally to the desired position or rearrange them to get the desired width

combination for your project.

5. Using the handle, lower the fingers to apply light pressure. Check to make sure each finger has

continuous contact with the spacer.

6. Tighten the screws.