• Move the saw at least 3 metres away from the filling

point before starting the engine.

• Check that there is no-one in the range of action of

the saw. The chain saw must only be handled by one

person.

• Never start up the chain saw indoors.

• Never direct the silencer, and hence the exhaust

gases, in the direction of flammable materials.

• Check the minimum speed of the saw, which must

not allow the chain to rotate.

Moreover, after acceleration the engine must return

quickly to the minimum speed when the throttle is

released.

If this is not the case do not start to work, adjust the

minimum speed and solve these problems. (see

paragraph “Setting carburation”).

Warning: checking and adjusting the carburettor

and the minimum speed is the only operation

performed with the engine running.

• Check that chain lubrication is regular. Oil supply to

the chain indicates that the oil pump is functioning

correctly.

WARNING UNDER NO CIRCUMSTANCES

should the chain saw be used if the chain is

not lubricated, as this would cause irreparable

damage to all cutting parts in a very short time!

When working

When working comply with the following:

• work in daylight. Visibility is essential to guarantee

safety conditions;

• stand in a firm and steady position. Where possible,

avoid working on wet or slippery ground or ground

that is excessively rough or steep and does not allow

the operator to work in a steady position.

The user is responsible for assessing potential risks of

the working ground and taking all precautions required

to guarantee personal safety.

• Never work without a pawl. This is especially

important when felling.

• When working at a height:

a) only work on an elevating work platform

b) do not use ladders

c) do not climb on the tree

d) do not work in unstable positions

e) do not work above shoulder level

f) do not use only one hand.

• Always walk and never run to avoid losing balance.

Always take care over obstacles.

Always put the chain saw into the safety position

when moving around.

• Pay attention to materials projected by the action

of the chain. This occurs above all when the chain

comes into contact with foreign bodies (nails, stones,

etc.). Never operate the chain saw with bystanders in

the work area.

• Take care not to knock hard against foreign bodies;

this could damage the cutting parts: if this occurs,

switch off the saw and check for damage.

• Pay attention to any abnormal noise or vibrations.

If this occurs, switch off the saw and look for the

cause.

Felling and removing branches

Operations to fell and remove branches must be

performed by skilled personnel, trained to use the

chain saw in these difficult operations.

• Before starting felling operations for the first time,

practice cutting trunks placed on trestles, in a stable

and safe position. This will allow you to become

familiar with use of the saw.

Before commencing felling operations also check:

• that there are no bystanders in the work area (with the

exception of any others involved in the felling opera-

tion);

• that the work area is free from obstacles that could

endanger the operator and any collaborators;

• escape routes free from obstacles have been

established;

• the natural direction in which the tree is leaning and

consequently the area covered by the “falling” tree.

• that there are no strong winds; in this case postpone

felling operations.

In any case, do not work alone or in a remote spot as, in

the event of an accident, your calls for help might not be

heard by collaborators.

• Free the base of the trunk to be felled from any scrub,

branches or stones, as these could create dangerous

situations and damage the cutting parts of the chain

saw.

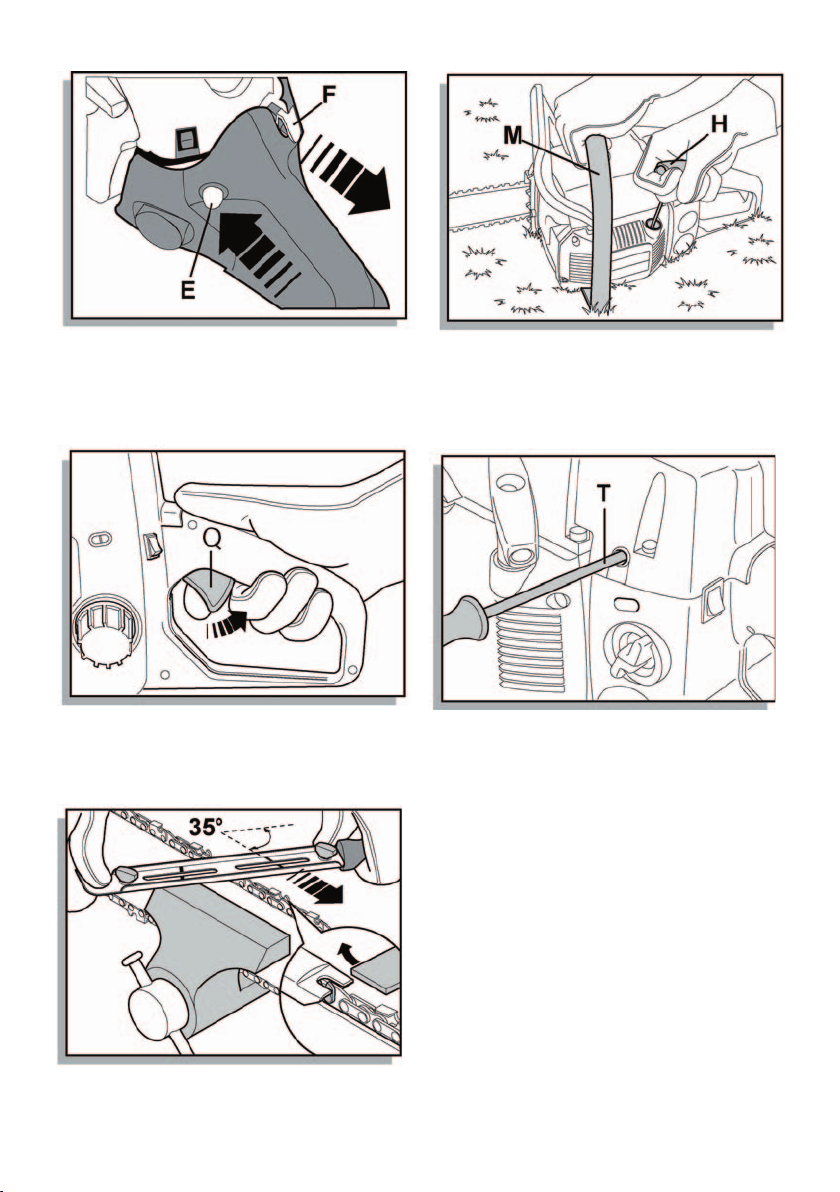

• Make a first undercut on the trunk on the side on which

the tree has been planned to fall. This facilitates and

partly guides the tree during felling. Then cut right

through the trunk, starting from the opposite side of

the tree.

When the tree is falling take care over springback of the

trunk or any splinters caused by the trunk breaking.

• When operating on felled trunks, if working on sloping

ground always stand above the tree to avoid danger

caused by movement of trunks.

Pay particular attention to the position of felled trees,

especially on uneven ground. Assess possible inner ten-

sions of the timber. Avoid getting the blade wedged in the

wood. Be alert for springback.

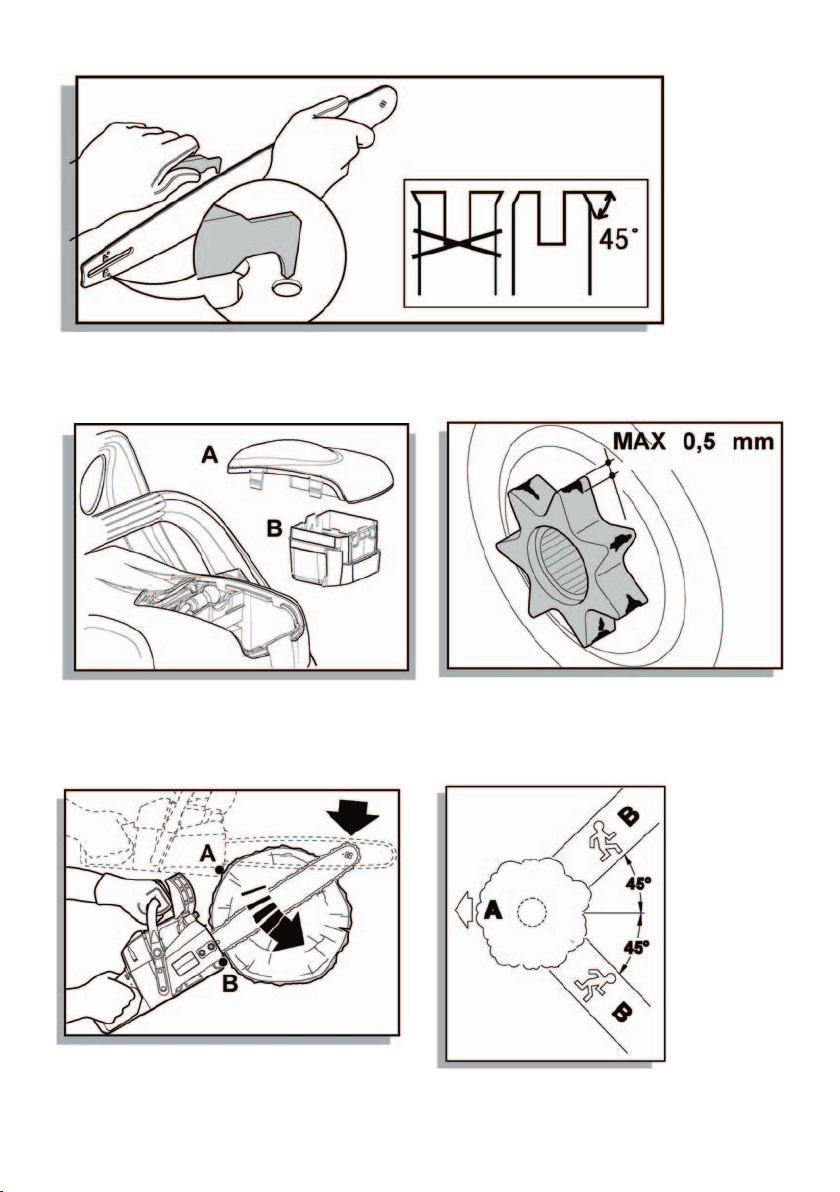

Removing branches

Beware of kickback. The chain saw can suddenly

kick back towards the operator. Avoid this dangerous

situation:

• do not cut using the tip.

• do not lodge the tip of the bar in the wood – only cut

one branch at a time – only cut with the chain saw

running at maximum speed

• remove any branches or foreign bodies from the

cutting area

• hold the saw firmly with both hands.

• stand in a stable position

• use chains with reduced tendency to kick back.

GB-4