ILGI HTSV 30 User manual

2

DEAR CLIENT

We thank you for choosing İLGİ TARIM MAKİNA, which is in service for more than 45

years without sacrificing its quality.

You have bought one of our products by choosing it from our wide product range. First of

all, enjoy your new product; we are sure it will contribute to your agricultural activities.

Control the machine you received basing on the dispatch note and receive it in full.

Before the first use, please pay attention to the warnings and instructions specified in this

manual. Demand your spare parts from the spare parts list by its part number. Make your

machine’s maintenances regularly as it is specified in the manual.

Dear client; our manuals are being updated regularly. Please make contributions by your

proposals. You can convey us all kind of suggestions and complaints by mail, fax etc.

May you have wide crop.

İLGİ TARIM

3

INDEX

1. SECURITY MEASURES........................................................................ 4

1.1 BEFORE STARTING TO USE ........................................................................4

1.2 WARNING SIGNS ....................................................................................4

1.3 WARNING SIGNS SETTLEMENT PLAN...........................................................7

1.4 WORK SAFETY .......................................................................................7

2. DESCRIPTION OF MACHINE ..............................................................12

2.1 DESCRIPTIVE AND BASIC INFORMATION ON THE FEATURES OF MACHINE .......... 12

2.2 GENERAL STRUCTURE AND PARTS OF MACHINE..........................................13

3. USAGE INFORMATION AND SETTLEMENTS.......................................15

3.1 ATTACHMENT OF MACHINE TO TRACTOR..................................................15

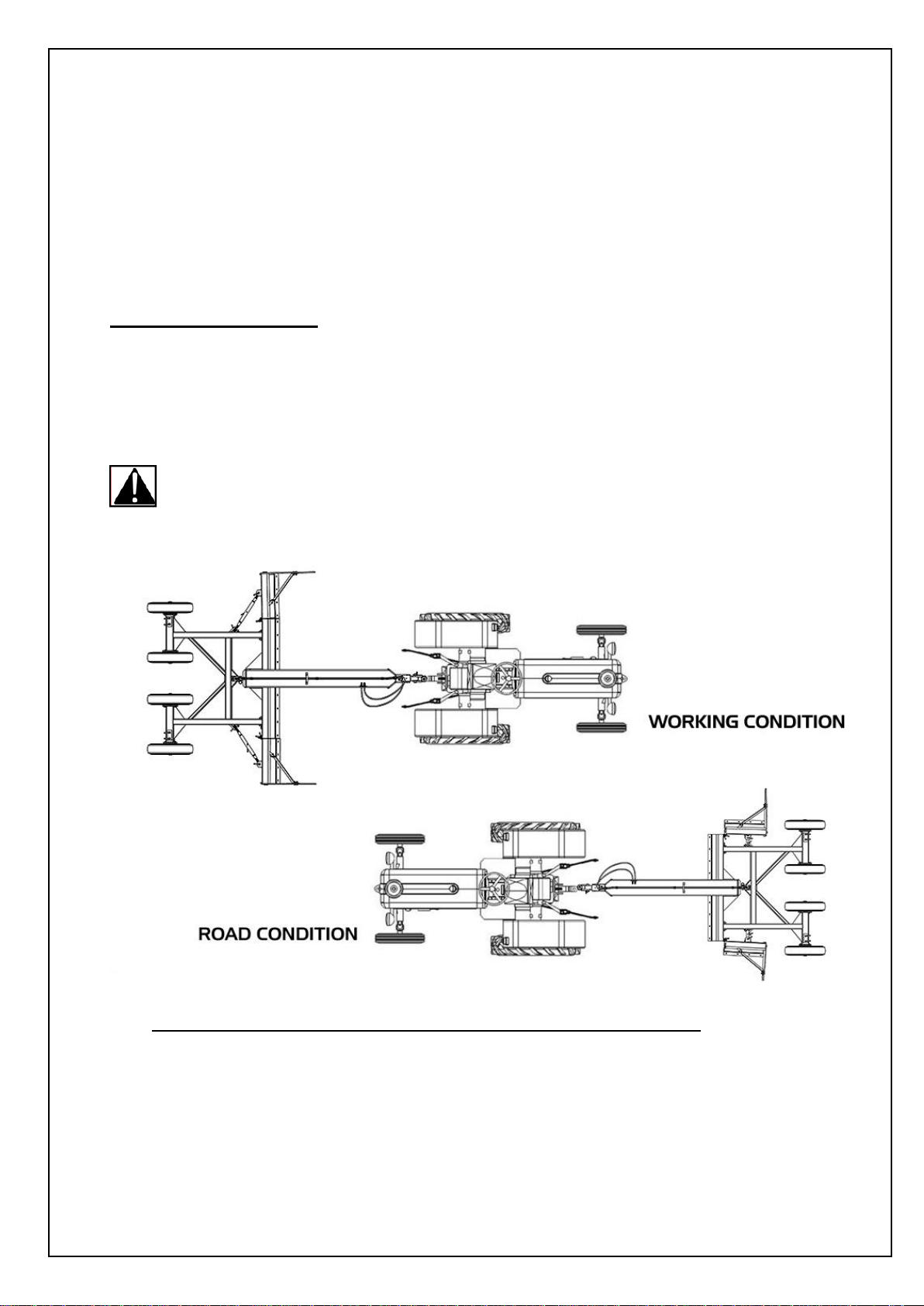

3.2 TAKING THE MACHINE TO WORK AND ROAD POSITIONS ................................15

3.3 PRELIMINARY PREPARATIONS FOR USAGE AND RULES TO BE .........................16

3.4 PARALLEL BLADE ADJUSTMENT ................................................................16

4. LEVELING OPERATION .....................................................................16

5. MAINTENANCE AND REPAIR ............................................................17

5.1 MAINTENANCE-REPAIR WHICH MAY BE DONE BY USER AND RULES TO BE

OBSERVED................................................................................................17

5.2 SEASON-END MAINTENANCE .................................................................19

5.3 REPAIR...............................................................................................19

5.4 CLEARANCE CONTROL AND ADJUSTMENT FOR WHEELS ................................ 20

5.5 BOLT TORCH VALUES .............................................................................21

6. TECHNICAL FEATURES ......................................................................22

4

1.SECURITY MEASURES

1.1 Before starting to use

Learn what all the warning and information signs mean on the machine. Read and

learn carefully the maintenance instructions manual. Dangerous consequences may occur in case of

false and inattentive use of the equipment..

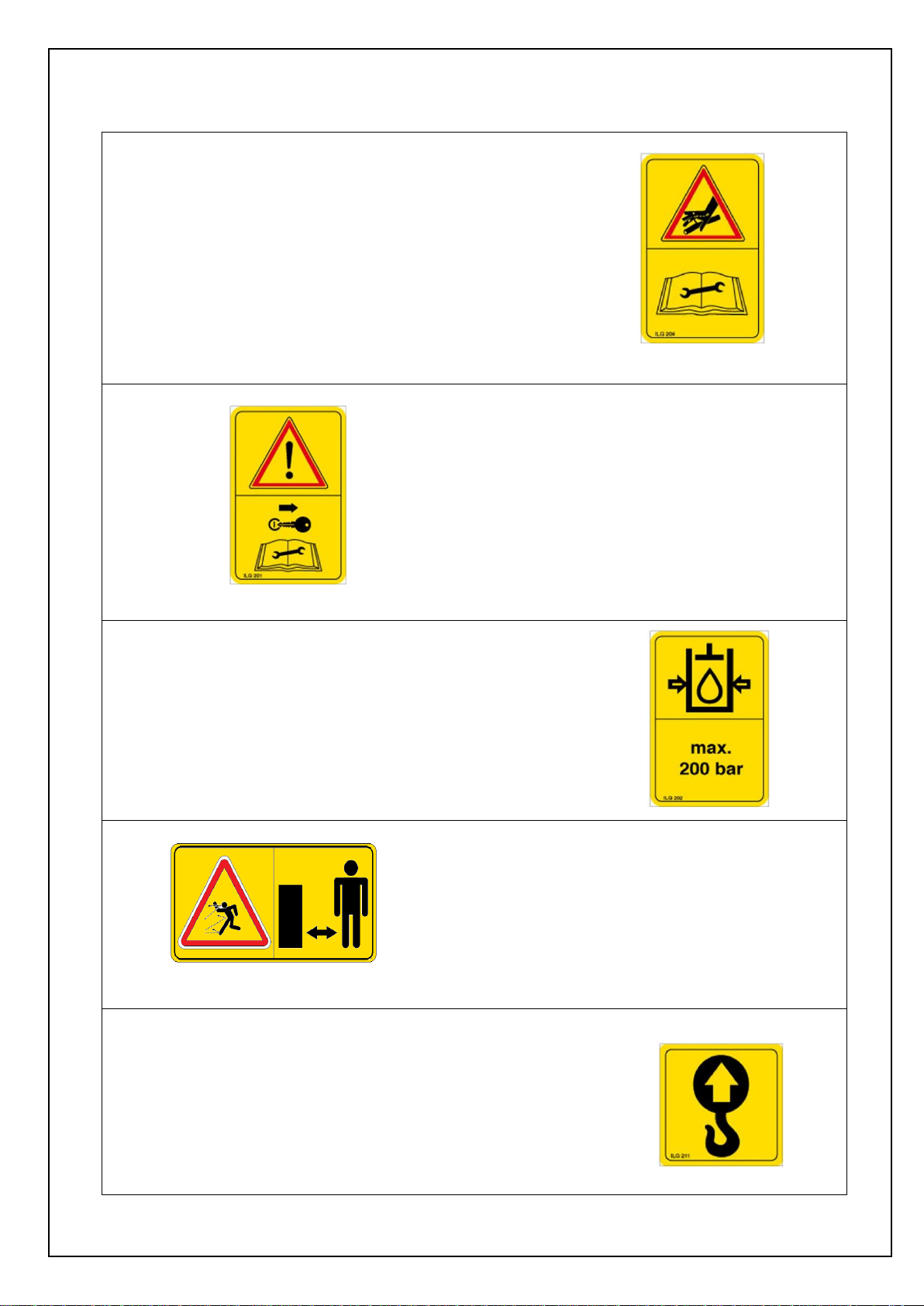

READ AND CARRY OUT CAREFULLY THE SECTIONS WHERE THIS SIGN IS

AVAILABLE

Read the manual carefully and make sure you understand it! Do not stand between the

equipment and the tractor. Wear suitable working clothes.

1.2 Warning signs

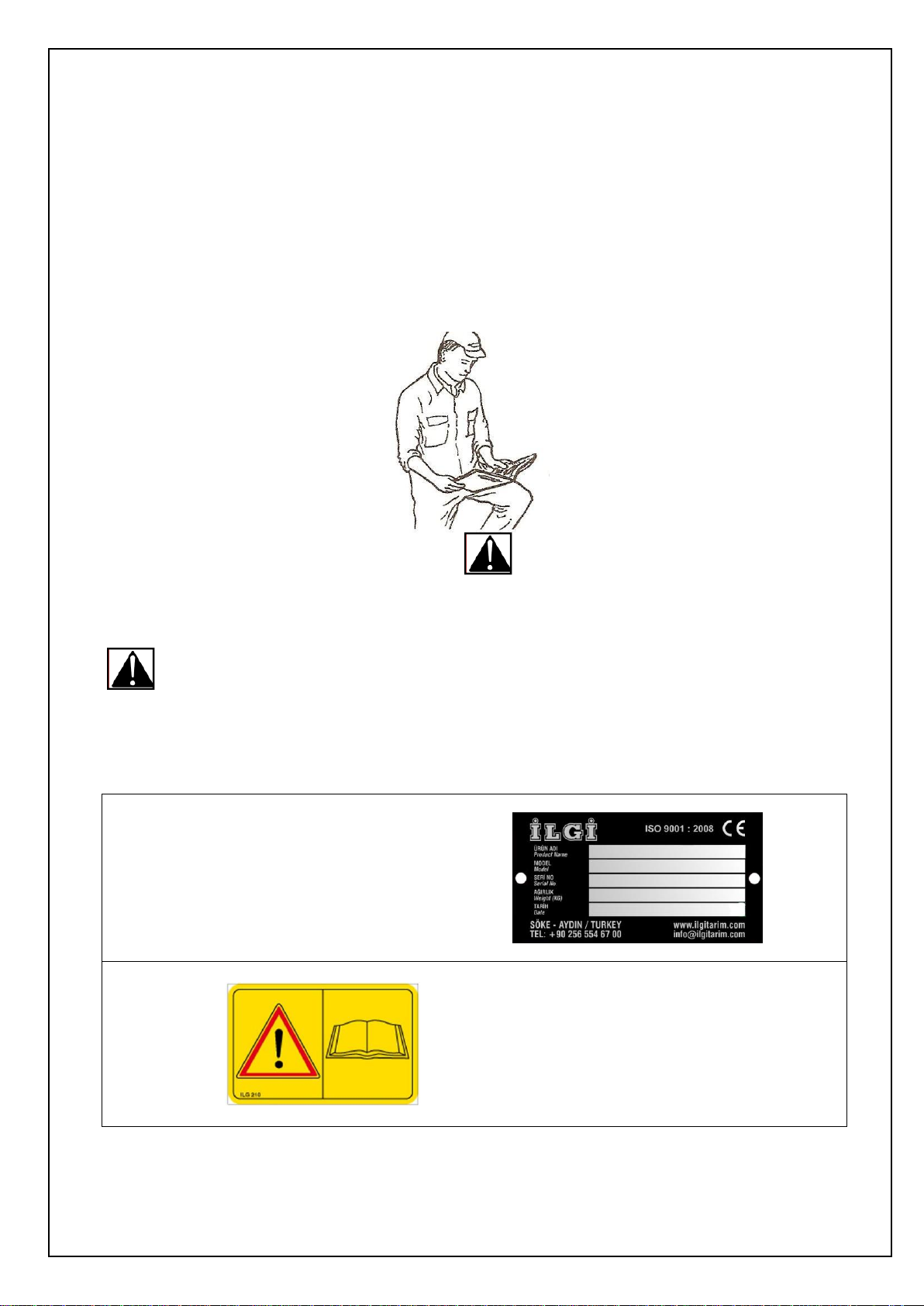

Machine’s Serial Number Label

ILG 210

Before starting to use the machine,

read the maintenance instructions

manual carefully

5

ILG 203

The CE Mark, indicates that the

machine is in accordance with the EU

legislations.

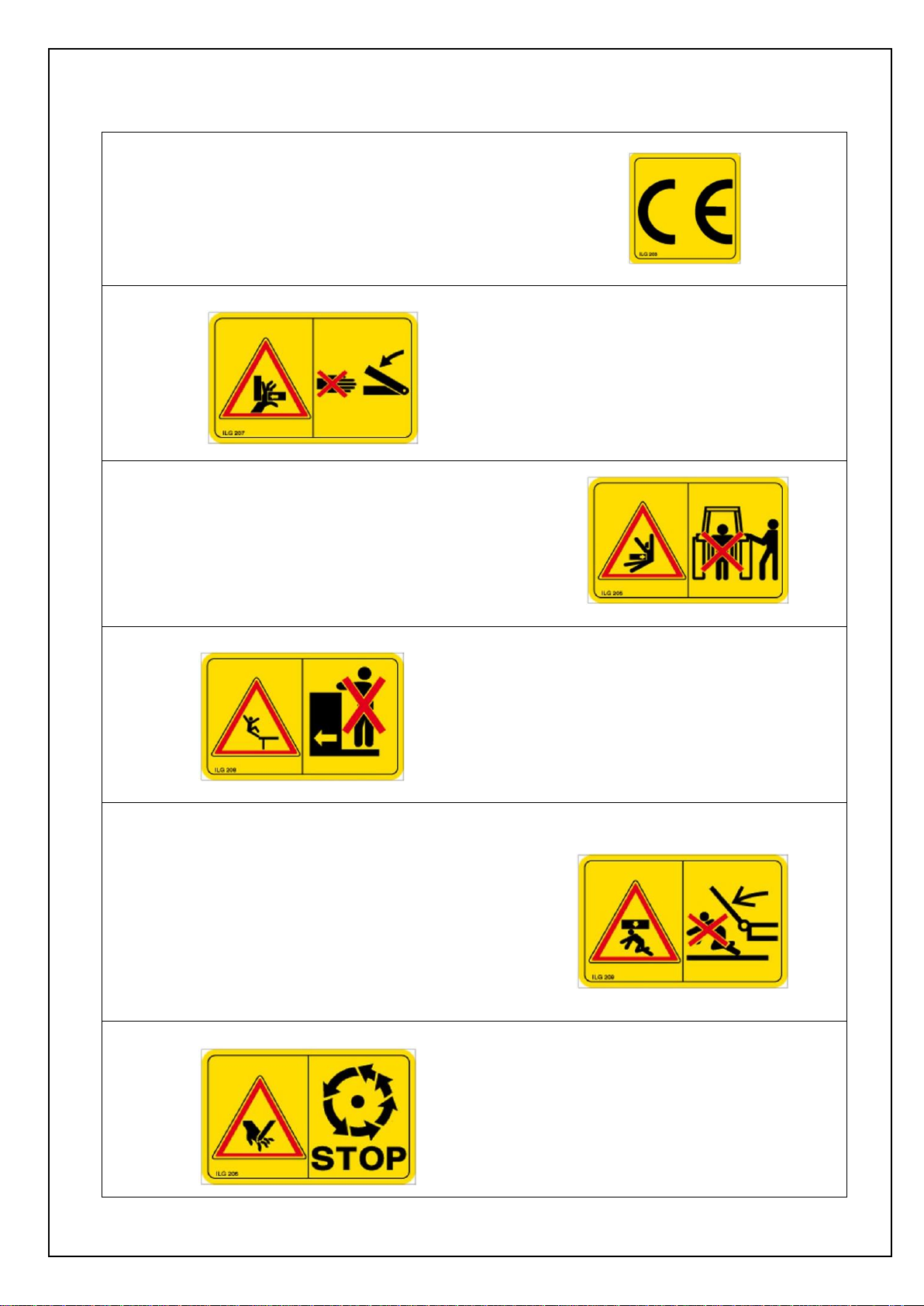

ILG 207

The risk to squeeze your hand or foot

between the parts.

Don’t put any of your organs between

shearing moving parts in the signed

area.

ILG 205

The risk to get squeezed between the

tractor and the equipment

Don’t enter between the tractor and

the equipment.

ILG 208

The risk of slipping and falling from the

chassis of the machine.

Please don’t step up onto the machine

or to use as a platform.

ILG 209

The risk of hit of the turning, folding

that is to say moving parts. This

danger may result in injuring or death

risk.

Don’t enter the movement area

of the parts during the running of the

machine

ILG 206

In case of spotting oil leakage on the

hydraulic components the power

source must be stopped

Control and prevent all the leakages in

the hydraulic circuit.

6

ILG 204

The oil leakages on the hydraulic

circuit must be controlled carefully as

there is high pressure in that circuit.

The pressurized oil may harm your

body or skin.

Don’t try to control and to close the oil

leakages manually. Prevent the

leakage by carefully reading the

instruction manual. Appeal to a health

organization in case of any injure.

ILG 201

Obey all the work safety rules and take

precautions during all your installations

and repair works. Otherwise there is

the risk of injure and death.

Take precautions against the slipping

and starting to work by itself. Read the

relevant sections on the instructions

manual and pay attention to the

warnings.

ILG 202

The maximum working pressure of the

hydraulic system is 200 bars.

ILG212

The pieces (stone, clay, machine piece

etc.) which can pop out from the

machine can cause to injuries.

Don’t get to the machine much closer

than the safety distance.

ILG 211

During the machine’s embarkation or

transportation, it must be elevated

from the points where there are this

sign.

7

1.3 Warning signs settlement plan

1.4 Work Safety

Before Operation:

If you use the machine for the first time, read all instructions carefully. If you doubt any

subject, seek to technical assistance of our firm.

Rules for the prevention of accidents and safety which are effective in trade associations

should be observed as well as the statements in the instruction books on the machine.

Warning and descriptive labels suited on the machine introduce significant descriptions for

risk-free working. To comply with these labels serve to your safety. Renew the damaged

warning and descriptive labels immediately.

Before working it is necessary to be sure about all orders and working parts as well as their

functions. Otherwise it may be so late in case of operation.

Obey the necessary traffic rules when you attach your machine to tractor and take the road.

Take safety precautions. Comply exactly with the instructions for safety use and rules for

the prevention of accidents.

In case of the transportation of your machine to another place, pay attention to lift the

machine from the lifting points stated on machine. When the machine is lifted by a crane,

stay never under the machine or near it.

Figure 1

8

Since laser leveling machine manufactured by our firm is a heavy and bulky machine, it

should be placed into carrier (Truck etc.) and fixed safely to it. Loading and unloading

operations should be made by a crane etc. if possible. While loading and unloading,

necessary safety precautions should be taken.

Please make sure that the operator using the tractor to which your machine is attached is

licensed, experienced and well-trained driver.

Exhaust gas is toxic, thus tractor shouldn’t be operated in inappropriate and closed areas.

Before removing the hydraulic hoses and pipes, it is necessary to make sure completely that

circuit is not under pressure. An oil leakage under pressure is dangerous. While searching

leakages in order to prevent serious injuries, it is necessary to use protective glasses and

gloves. Before working with hydraulic system oil pressure should be decreased. Make sure

that hydraulic hoses are attached to the right outlets.

Don’t attempt to run and maneuver the tractor without sitting on driver’s seat.

Make sure that control panel in the tractor should be set off in comings and goings

Stop lamps of machine and beacon lamps should be turned on permanently in comings from

and goings to the field as well as vehicle moving especially in dark weather and at the

evening hours.

Remind that the machine fixed to tractor will change the some functions of tractor (breaking

distance, steer ability, center of gravity etc.).

Please check the tire pressures before departing

Power take-off of tractor shouldn’t be operated while vehicle moving (Coming-Going).

Don’t let anyone to sit on the machine not only the comings from or goings to the field but

also during operation on the field.

Set the parking brake of tractor and shift the gear to neutral before fixing your machine to

tractor.

Make sure that no one stay between machine and tractor while machine is attached to or

removed from tractor.

Start to work after taking all safety precautions in your machine and tractor.

Figure 2

9

Attach your machine to a tractor with appropriate tractive force and hydraulic lifting order.

Pay attention to the area where hydraulic lifting arms are operated. This area is dangerous.

Tractor-machine connection should be done via the safety chains integrated onto the

machine later. (Figure 3)

Make sure that there is no one especially children and domestic animals is around the

machine before running it. Take necessary precautions in order to see around comfortably

Obstacles like tree roots and wastes like cloth, nylon etc. should be considered and obstacles

on field should be removed.

Very stony and grassy fields shouldn’t be processed.

Fields under heavy rain and very muddy fields shouldn’t be processed in order not to

damage the surface of field, because the earth leveled is adhered to shovel and prevents

leveling by preventing it from staying at intended place.

Machine should be kept clear against fire danger.

Check and connect handling equipment, lighting, warning orders as well as protection

orders.

Make sure that machine is taken to road position while coming from and going to the field.

It is necessary to drive slowly on uneven and stony roads, bends and in the event that

machine is shaken too much.

Figure 3

10

During Operation

Clutch is controlled softly and then tractor should

be run. Rapid and stern departures may cause

springs and under draughts especially while going

up or pulling.

When an abnormal voice is heard while machine is

working, machine should be stopped.

Don’t touch any moving and rotating part in any

way.

Wait that they completely stop before touching the

parts of machine.

Don’t force the limits of machine like the capacity, running speed etc.

Don’t add weight onto and don’t let anybody to sit on the machine while running.

Blades of shovel shouldn’t be kept close too much to the border of field and leveling

operation shouldn’t be done therein.

Don’t be close to the machine while working and don’t let anybody to be close to the

machine.

Don’t let anybody to stay on tractor or machine except operator.

Don’t work with the machine excessive rainy and windy days.

If your tractor is running, never leave the driver’s cab.

Never drive back when shovel contacts with the earth while working.

Don’t stay in the rotational and oscillation area of machine

Crushed and cut spaces occur in the sections operated with hydraulic or spring forces. Pay

attention to these points.

Don’t put your arm and leg between tractor and machine or don’t hold it during operation

After Operation

Before leaving tractor, take down the machine connected to hydraulic system. After

switching off the engine, set the parking brake and turn off the ignition key.

If possible tractor should be parked on a level surface and put into any gear and set the

parking brake. If it will be parked on an inclined surface, first gear should be put at uphill

and reverse gear should be put at downhill and parking brake should be set in both positions.

Perform the settings and repairs of your machine only when tractor engine is switched off

and shovel equipment is taken down. Before starting maintenance, adjustment and repair,

bring the ignition key of tractor.

Broken parts should be replaced with the original parts. Part taken from anywhere can’t be

in compliance with the machine. It may cause failures and great material damages. Use

original spare parts as much as possible.

While taken the machine from working position to road position or from road position to

working position, these operations should be done slowly. If it will be done stationary,

make sure that no one is around the machine.

11

Risks of jamming and cutting

While working under the machine lifted, prevent machine from slipping thanks to the

strong bases.

Don’t stay under the part lifted via hydraulic cylinder use the support leg for it.

Parts operated by hydraulic control system may fall down as a result of the rupture of

hydraulic lines.

Don’t make any settlement while tractor is running or machine is moving.

Don’t stay close to moving or rotating parts.

Risks in hydraulic hoses and pipes

Don’t bend the hose or pipe under high pressure.

Don’t use jammed, crushed or deformed hydraulic

transmission lines and replace them immediately.

When you see an oil leakage, stop immediately hydraulic

pump and tractor and replace the leaking line.

When contact with the skin high pressure oil may cause

serious injuries, penetrate into skin. Don’t check leakage

by your hands, seek to doctor in case of accident.

Check all hydraulic lines periodically tighten the loosened connection points at

recommended torque, use appropriate toolkit.

Don’t bend the hose or pipe under high pressure.

Don’t use jammed, crushed or deformed hydraulic transmission lines and replace them

immediately.

When you see an oil leakage, stop immediately hydraulic pump and tractor and replace the

leaking line.

When contact with the skin high pressure oil may cause serious injuries, penetrate into skin.

Don’t check leakage by your hands, seek to doctor in case of accident.

Check all hydraulic lines periodically tighten the loosened connection points at

recommended torque, use appropriate toolkit.

Driving safety on highway

Safety max. speed limit on highway is 25 km/h

Machine should be taken to road position in a manner blades are closed and blade safety

pins are locked.

Appropriate gear should be preferred at downhill

Speed should be decreased on turns

Another vehicle should be passed only when the road is empty, side projections of machine

should be considered.

Speed should be reduced in rainy days.

It should be stopped only in the appropriate areas permitted.

Tire pressures should be at recommended levels.

12

Service safety

Machine should be taken down completely in case of

repair and maintenance,

There should be no pressure in hydraulic circuit.

Safety should be ensured by placing a wedge under

the shovel in case of the replacement of the parts like

shovel blade.

Appropriate toolkit should be used.

2. DESCRIPTION OF MACHINE

2.1 Descriptive and basic information on the features of machine

Precise leveling machine is used for manual excavation without laser system

Success is higher because it is faster and easier to use than other leveling tools. Low cost of

leveling

Installation and operation is simple and easy

With the precision leveling machine, the land can be leveled at the required slope

The irrigation of the treated land is more efficient and the product is uniformly grown at

every point of the land.

The most important benefit of the machine is that efficiency is improving on the field.

Costs of production decrease and your profitability increases, because

Production labor force decreases

Less fertilizers are applied,

Less seeds are used,

Irrigation water is distributed orderly on the field, plants develop uniformly

Less irrigation water is used,

Soil loss caused by erosion is prevented,

Higher productivity is obtained.

13

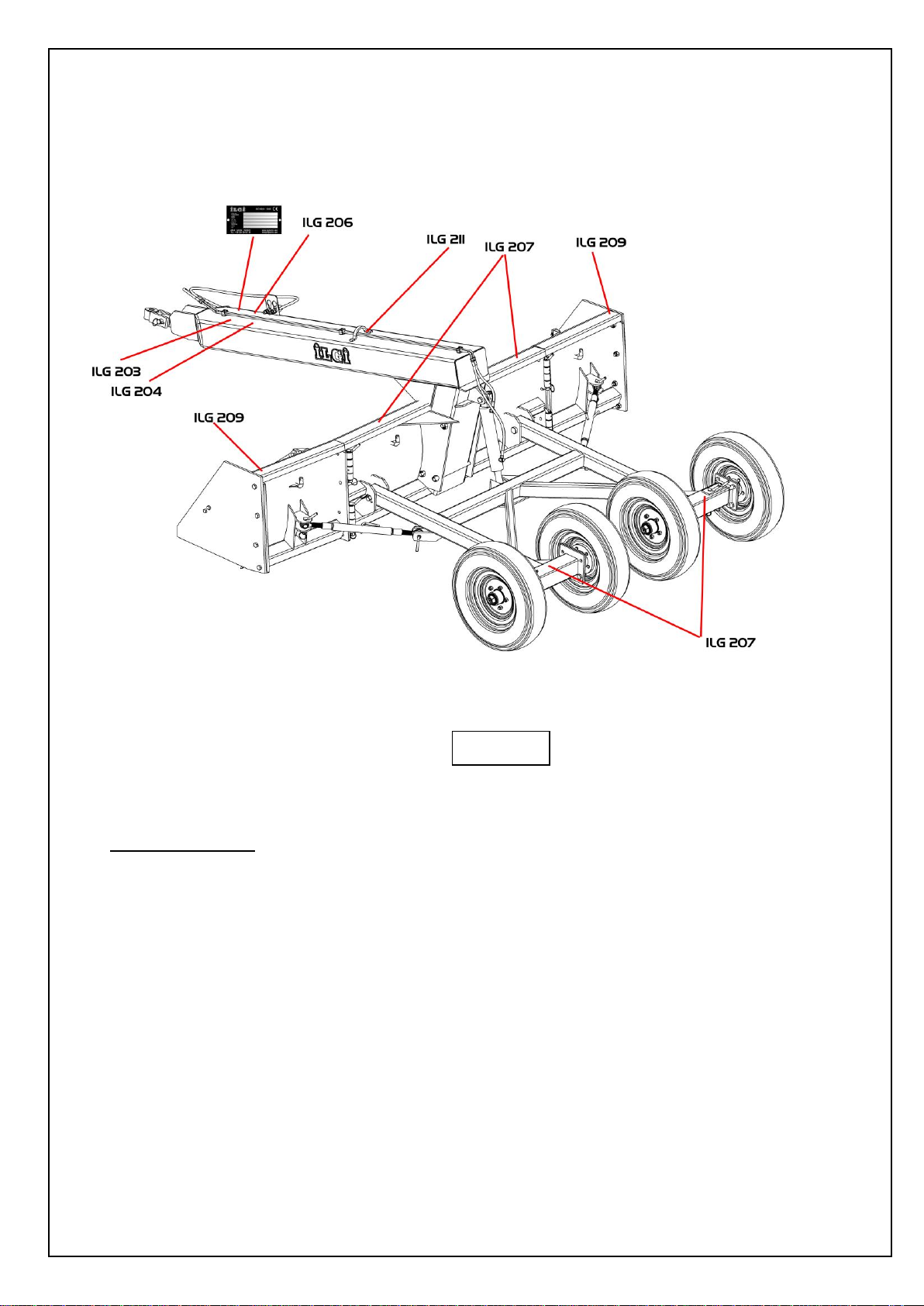

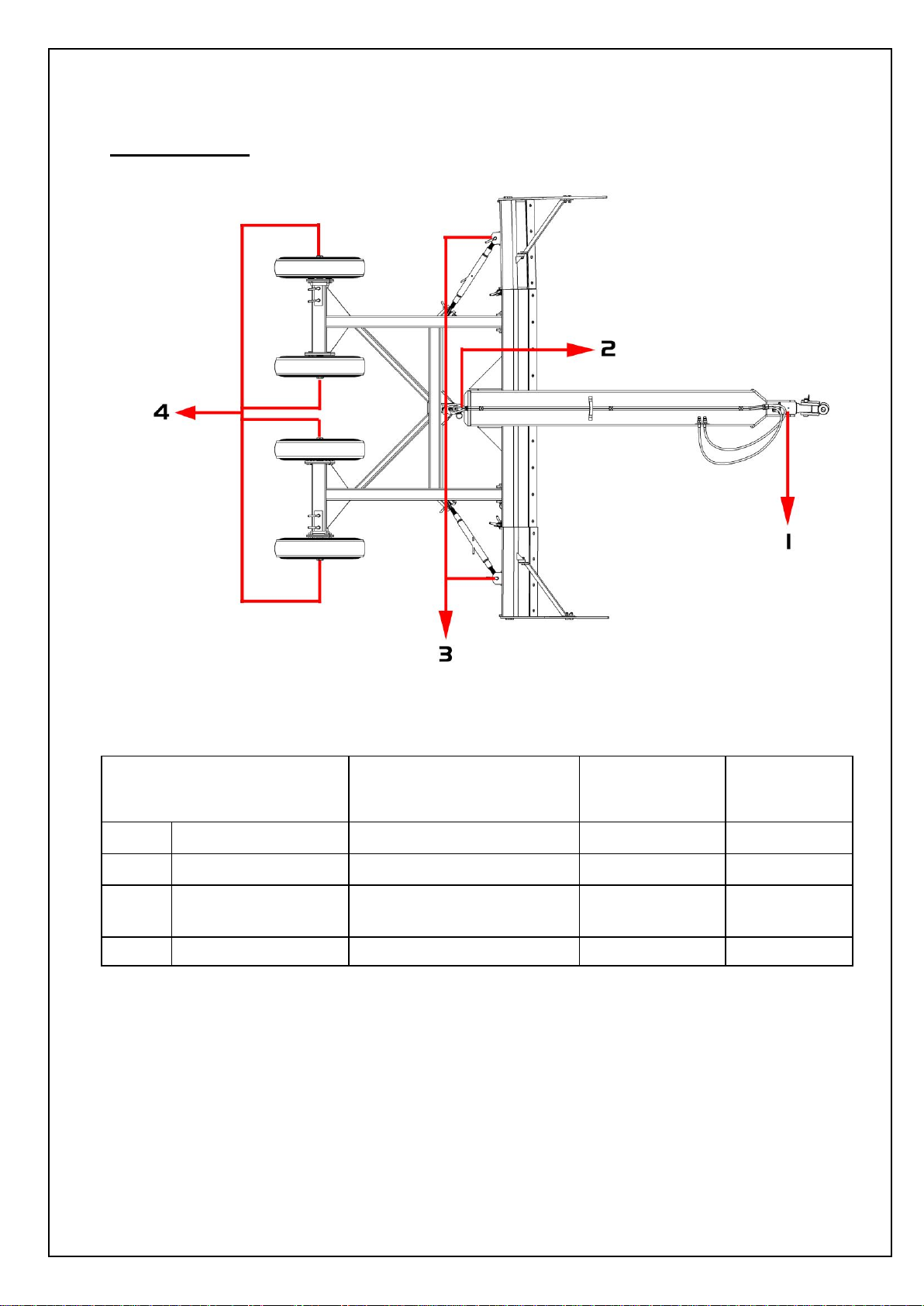

2.2 General Structure and parts of Machine

1. Draw bolt

2. Draw arrow

3. Middle shovel

4. Left-Right shovel

5. Axis

6. Whell

7. Axle cylinder

8. Middle arm

Figure 4

14

Chassis:

Appropriate material for heavy duty vehicle is used for chassis. It is designed to resist to

heavy excavation works.

Draw bolt:

Draw bolt has been manufactured as rotary in two axes, thus adjusted excavation height

doesn’t change in the lies of the field and machine works in compliance with the surface of the

field.

Sectional foldable shovel:

Total width which is in compliance with road condition is ensured by side shovels. Side

shovels may be folded hydraulically, thus total road width is lower than 3m.

Parallel blade adjusting mechanism:

Alignment of the blade to ground may be adjusted by hydraulic control mechanism in working

position. Tower hydraulic cylinder and tilt adjusting hydraulic cylinder are connected to the

hydraulic circuit of tractor with quick couplings, circuit will be changed on the three-way valve in

accordance with the one to be used.

Blade:

Blades for heavy construction equipment’s which are manufactured from special alloy steel

hardened 45-50 HRC are used in our machine.

Parts of Hydraulic System:

1. Oil transmission pipes and hoses

2. Hydrolic cylinder

15

3. USAGE INFORMATION AND SETTLEMENTS

3.1 Attachment of Machine to Tractor

Machine is fixed to the tow hook of tractor and used so.

Order of Transactions

1. Bring machine and tractor on a flat surface

2. Ground clearance of tractor should be minimum 50cm

3. Make tractor approach to machine with back maneuver

4. Your machine is ready for leveling

Grease nipples should be greased in the periods stated in the instruction books of laser

leveling machine and hydraulic oil level should be checked accordingly.

3.2 Taking the machine to work and road positions

Order of Transactions in passing from work position to road position

1. Remove the joint and pin from the side paddle and the axle case

2. Close the side shovels towards the rear

3. Attach the joint and pin to the side paddle and the middle paddle.

Reverse the abovementioned order to take it from road position to work position

Şekil 5

16

3.3 Preliminary Preparations for Usage and Rules to be

Before leveling via machine

Check tire pressures

Check parallel blade adjustment

Turn around the machine and check whether there is any hydraulic oil leakage or loosened

bolt etc.

Pay attention to the respects stated in safety rules before working

If the soil to be leveled is hard and compacted it should be loosened with chisel or plow

process

3.4 Parallel blade adjustment

For Adjustment;

1. Take the machine to a flat surface by tractor

2. Parallel adjustment for complete blade in accordance with ground plane is controlled and

adjusted.

3. We may perform this control so: Approximately 1-2 cm excavation is made through 20 m on

a plane surface. When we enter the excavation depth again without changing it, it means that

parallel blade adjustment is failed, adjustment is controlled again.

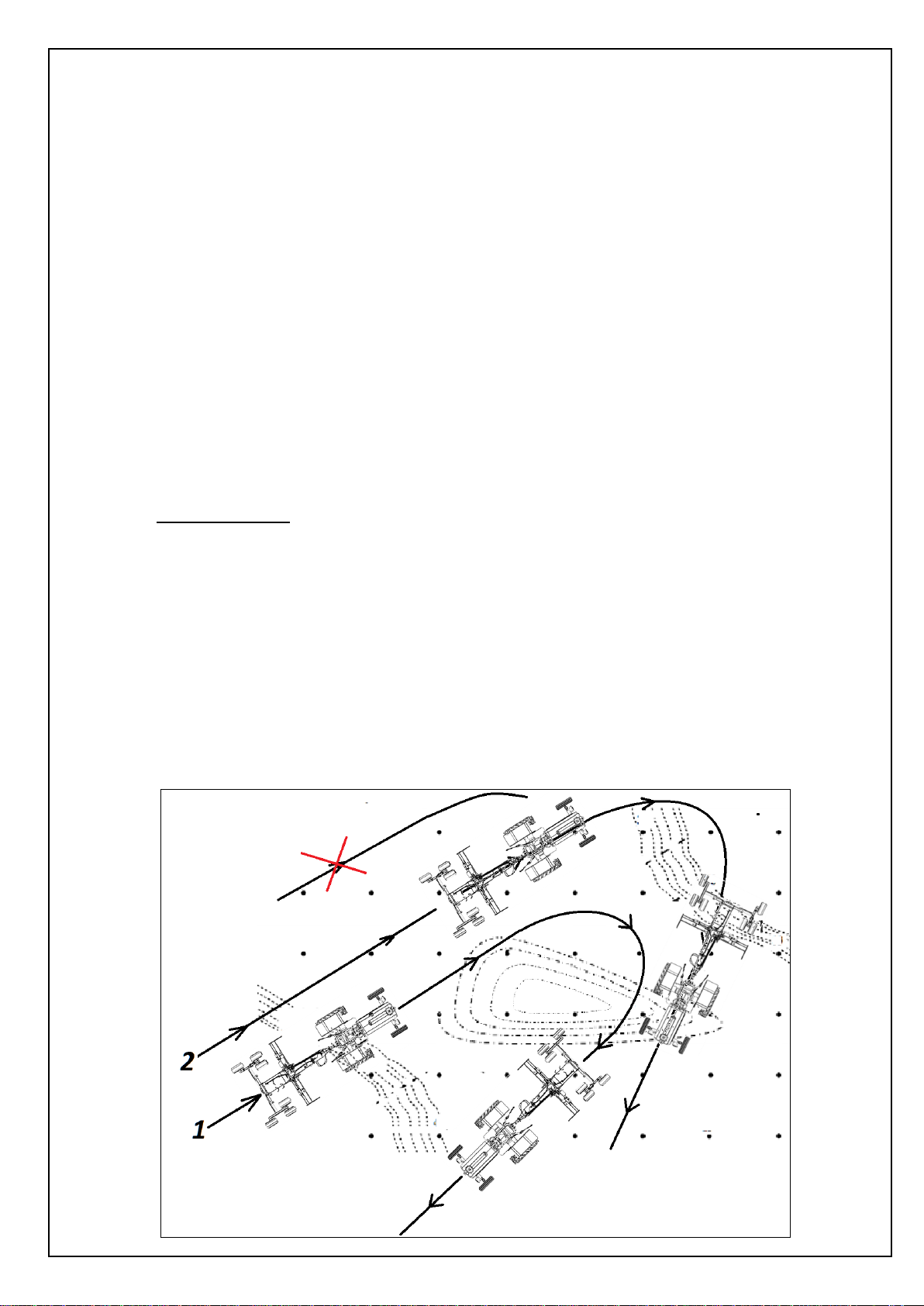

4. LEVELING OPERATION

17

1. When reached from the excavated area to the area to be filled, soil in the shovel is laid on

the area to be filled.

2. Precise leveling works by digging rough soil and filling and preparing the field before laser

leveling and providing economical and time-saving process.

3. In order that leveling operation is affordable and its cost is decreased, following respects

should be considered:

Operation should be done always from excavation to filling

Field traffic should be adjusted from excavation area to filling area

When shovel bearing capacity is full at the end of excavation, road should be taken

to filling area.

Excavation operation should be next to previous excavation in a manner that working

width of machine will cover the previous one at ¼ rate in second passes and no

entry should be done from a different point.

4. When adjusted levels are reached with latest passes, blade stops making excavation and this

shows that leveling is over.

Make sure that wheels don’t fallow into the pits greater than tire radius in

order for the chassis not to be damaged during work.

5. MAINTENANCE AND REPAIR

5.1 Maintenance-repair which may be done by User and Rules to be

Observed

Grease the points of machine to be greased periodically and after each pressure washing

in accordance with lubrication chart. This is important in terms of trouble-free and

permanent operation and decreasing repair costs.

Periodic maintenance intervals may vary in accordance with working conditions,

features of earth and operating speed and grease the required points regardless of its

term (Table 1)

Greasing should be done in turn in accordance with lubrication chart

Tightness of all screws and bolts should be checked after first operation hour and at

certain intervals through all season and should be tightened at recommended torque.

Wheel nuts of carrying wheels should be checked after first departure. Tightening

torque of wheel nut is 320 Nm

Hydraulic cylinders and roller bearings should be cleaned with high pressure water.

Otherwise seals may be damaged,

Machine not to be used for a long time should be kept in a closed area.

18

Greasing chart

Greasing point

Greasing Period

Oil Type

Number of

Greasing

Points

1

Tow place

After each leveling

Grease

1

2

Axis Cylinder

After each leveling

Grease

1

3

Impeller hinge

After each leveling

Grease

2

4

Wheel grease cap

After each leveling

Grease

4

19

5.2 Season-End Maintenance

Connection elements; Check the tightness of them. Check whether pins are complete or not

and whether safety pins are mounted.

Tires; Tire pressures should be controlled and if inadequate, they should be completed

Grease Nipples; Apply grease to grease nipples of machine

Running Parts; Grease the running parts of machine with protective grease.

Disconnect wheels from ground by putting a wedge under chassis

Surfaces of cylinder piston rods should be covered by protective grease against the

corrosion in winter season

5.3 Repair

Modifications stated in periodic maintenance section can be performed by user. Please refer to

your firm or authorized services for other repairs.

Tractor should be stopped while working with the hydraulic installment of machine

and repair should be started after decreasing the pressure of circuit.

Use original spare parts :

Use original spare parts as much as possible,

wearing condition of blades should be taken into consideration in terms of work quality and

work success of machine, blades should be controlled before every work and worn, bent

and broken parts should be replaced quickly.

Modifications stated in periodical maintenance can be done by consumer. It is necessary to

seek to authorized service for other repairs,

Replace removable intrinsically safe (fiber) bolts with new ones.

In case of any problem encountered by you about maintenance, repair

and usage, you may receive support after stating following information.

Customer’s name and address

Machine model

Date of purchase and area processed

Details about the problem encountered

20

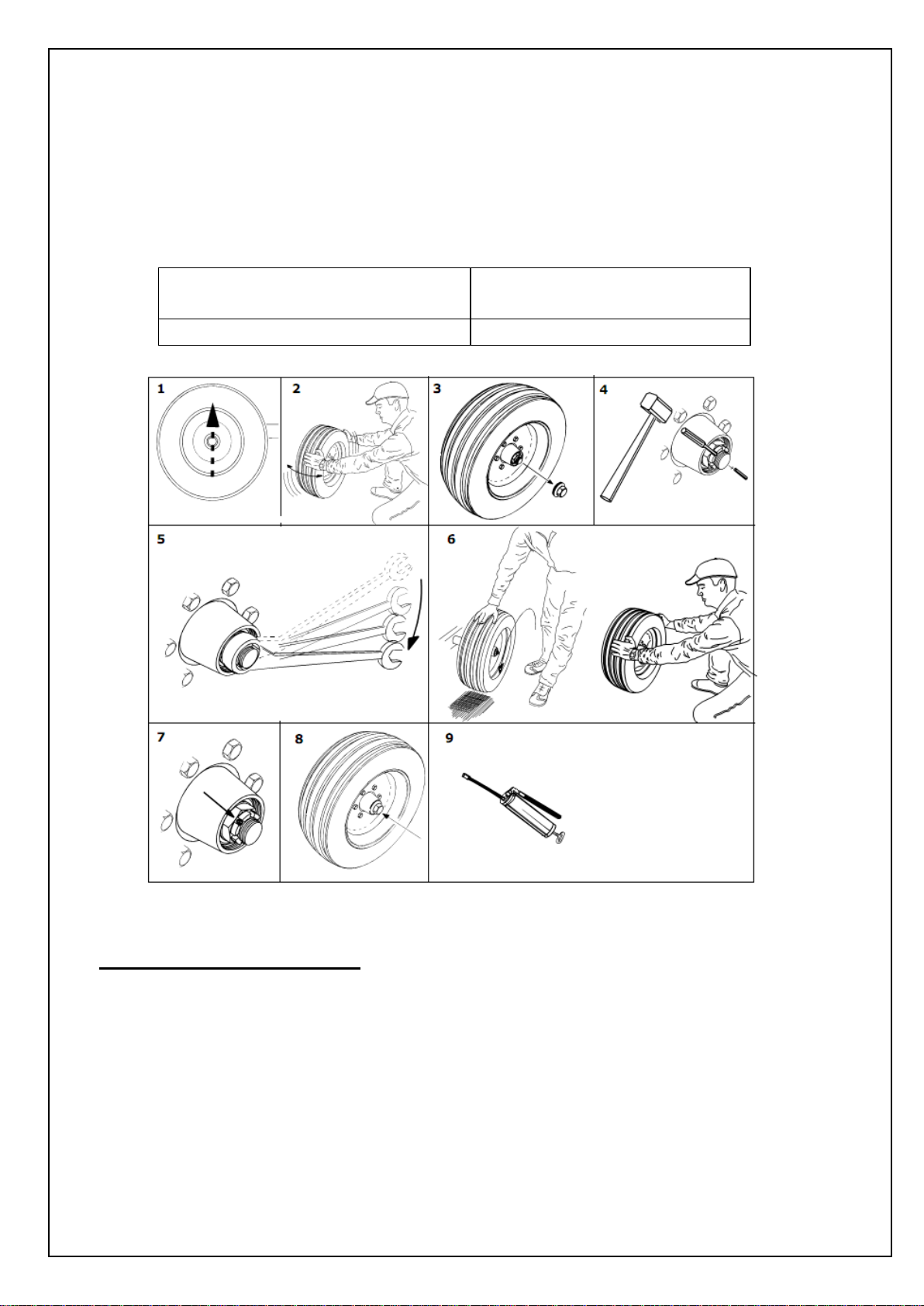

5.4 Clearance control and adjustment for Wheels

Wheels are lifted and held from below and above. If clearance is too much, clearance

adjustment is performed in following transaction order.

Tire Size

Tire Pressure

psi (bar)

10 / 75 - 15,3

52 (3.6)

Adjustment operation order

1- Wheels are taken up and disconnected from ground

2- Clearance is checked manually

3- If clearance is too much, hub cap is removed.

4- Crown nut’s cotter pin is removed

5- Nut is tightened until clearance is removed

6- Turning freeness is checked by turning the wheel, if breaking is available, bolt is untightened

little bit.

7- Cotter pin is locked.

8- Hub cap is covered

9- Grease is applied and then continued to be applied until fresh grease goes out from drain

plug.

This manual suits for next models

4

Table of contents

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions