Toro MB TX 2500 User manual

FormNo.3421-177RevC

MBTX2500TrackedMudBuggy

ModelNo.68138—SerialNo.402100000andUp

ModelNo.68138G—SerialNo.402100000andUp

ModelNo.68138HD—SerialNo.400000000andUp

Original Instructions (EN)*3421-177*C

www.discount-equipment.com

Go to Discount-Equipment.com to order your parts

Discount-Equipment.com is your online resource for quality parts & equipment.

Florida: 561-964-4949 Outside Florida TOLL FREE: 877-690-3101

Need parts?

Click on this link: http://www.discount-equipment.com/category/5443-parts/ and

choose one of the options to help get the right parts and equipment you are looking

for. Please have the machine model and serial number available in order to help us

get you the correct parts. If you don’t find the part on the website or on one of the

online manuals, please fill out the request form and one of our experienced staff

members will get back to you with a quote for the right part that your machine needs.

We sell worldwide for the brands: Genie, Terex, JLG, MultiQuip, Mikasa, Essick, Whiteman,

Mayco, Toro Stone, Diamond Products, Generac Magnum, Airman, Haulotte, Barreto,

Power Blanket, Nifty Lift, Atlas Copco, Chicago Pneumatic, Allmand, Miller Curber, Skyjack,

Lull, Skytrak, Tsurumi, Husquvarna Target, Stow, Wacker, Sakai, Mi-T-M, Sullair, Basic,

Dynapac, MBW, Weber, Bartell, Bennar Newman, Haulotte, Ditch Runner, Menegotti,

Morrison, Contec, Buddy, Crown, Edco, Wyco, Bomag, Laymor, EZ Trench, Bil-Jax, F.S.

Curtis, Gehl Pavers, Heli, Honda, ICS/PowerGrit, IHI, Partner, Imer, Clipper, MMD, Koshin,

Rice, CH&E, General Equipment ,Amida, Coleman, NAC, Gradall, Square Shooter, Kent,

Stanley, Tamco, Toku, Hatz, Kohler, Robin, Wisconsin, Northrock, Oztec, Toker TK, Rol-Air,

APT, Wylie, Ingersoll Rand / Doosan, Innovatech, Con X, Ammann, Mecalac, Makinex, Smith

Surface Prep,Small Line, Wanco, Yanmar

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

Becauseinsomeareastherearelocal,state,or

federalregulationsrequiringthatasparkarresterbe

usedontheengineofthismachine,asparkarresteris

availableasanoption.Ifyourequireasparkarrester,

contactyourAuthorizedServiceDealer.GenuineToro

sparkarrestersareapprovedbytheUSDAForestry

Service.

Theenclosedengineowner'smanualissupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCaliforniaEmission

ControlRegulationofemissionsystems,maintenance,

andwarranty.Replacementsmaybeorderedthrough

theenginemanufacturer.

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknownto

theStateofCaliforniatocause

cancerandreproductiveharm.Wash

handsafterhandling.

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Introduction

Thismachineisintendedtobeusedbyprofessional,

hiredoperatorsincommercialapplications.This

machineisastable,reliable,andproductivemachine

forcarryingandmovingmaterialsforanyjobsite.Itis

primarilydesignedtomoveconcrete,mortar,gravel,

dirt,ordebrisaroundjobsites.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely.

YoumaycontactT orodirectlyatwww.Toro.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorT oroCustomerServiceandhavethemodel

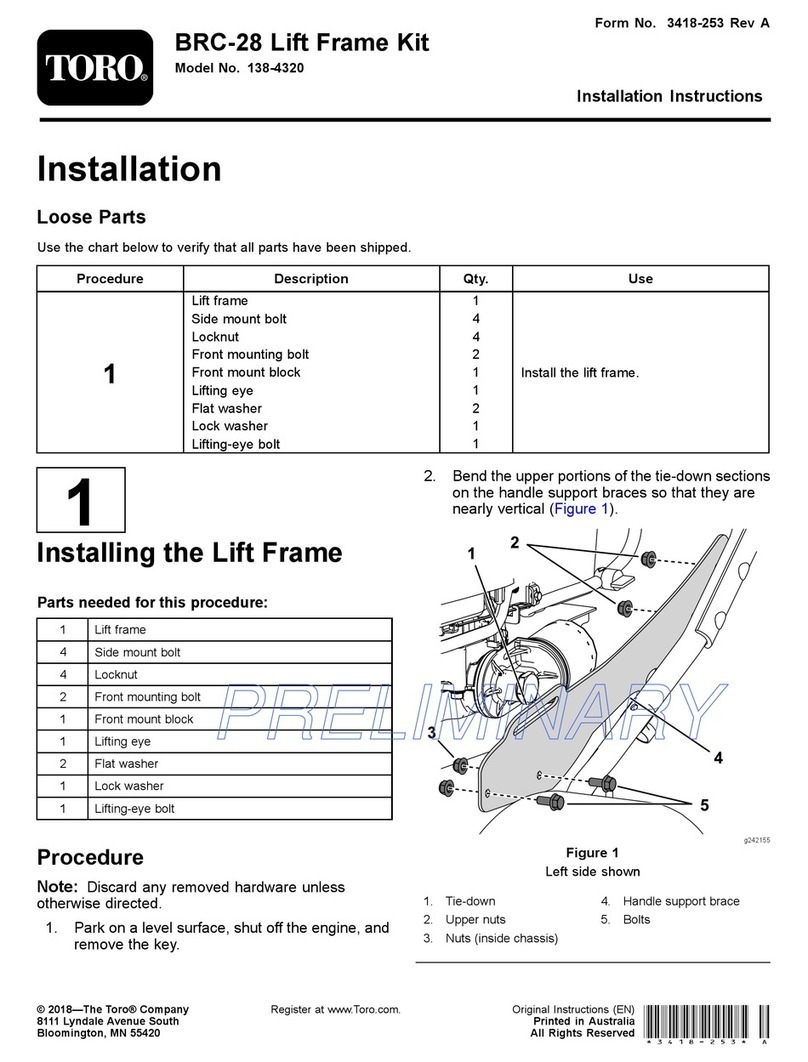

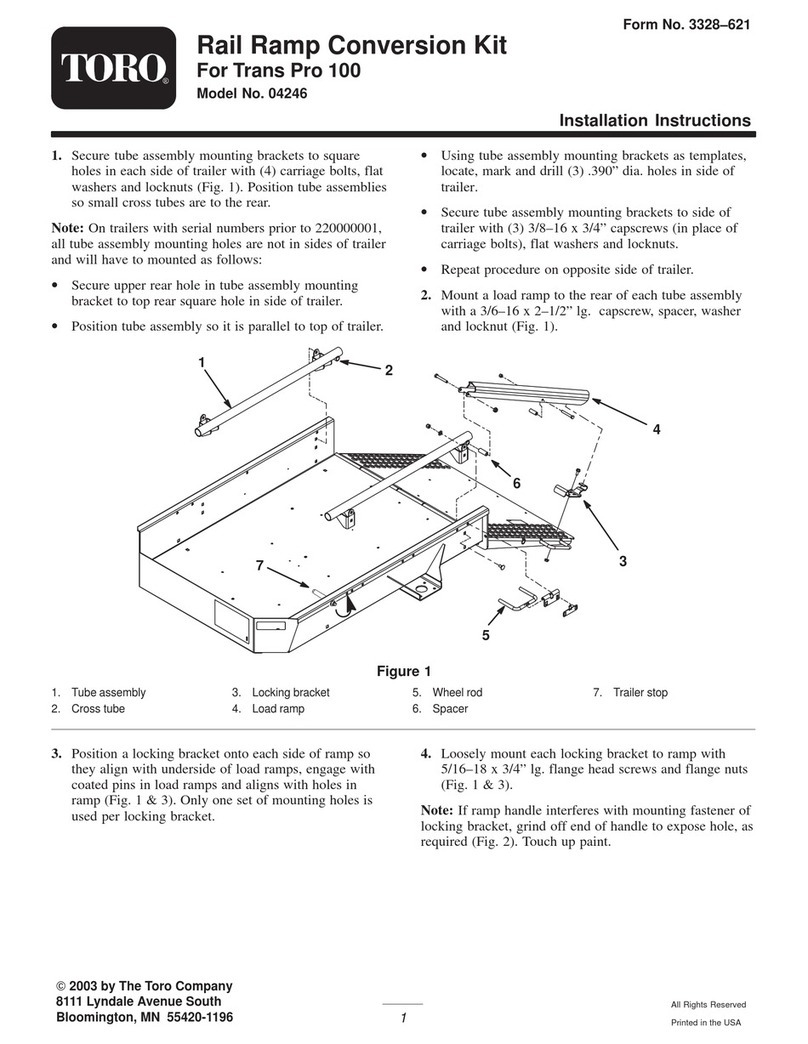

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

g241847

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

© 2018—The Toro® Company

2

Printed in the USA

All Rights Reserved

Go to Discount-Equipment.com to order your parts

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Safety.......................................................................4

SafeOperatingPractices....................................4

SafetyandInstructionalDecals..........................6

ProductOverview.....................................................9

Controls.............................................................9

Specications..................................................10

Attachments/Accessories.................................10

Operation................................................................10

AddingFuel......................................................10

PerformingDailyMaintenance..........................12

OperatingtheParkingBrake.............................12

OperatingtheThrottle.......................................13

OperatingtheChoke.........................................13

StartingtheEngine...........................................13

ShuttingOfftheEngine.....................................14

OperatingtheHopper.......................................14

RemovingDebrisfromtheMachine..................14

LoweringtheHopperwithoutPower..................15

TransportingtheMachine.................................15

LiftingtheMachine...........................................16

Maintenance...........................................................17

RecommendedMaintenanceSchedule(s)...........17

Pre-MaintenanceProcedures..............................18

ReleasingtheCushionforRearAccess............18

UsingtheCylinderLock....................................18

Lubrication..........................................................19

GreasingtheMachine.......................................19

EngineMaintenance...........................................19

ServicingtheAirCleaner..................................19

CheckingtheEngine-OilLevel..........................20

ChangingtheEngineOilandFilter....................21

ServicingtheSparkPlugs.................................22

CleaningtheBlowerHousing............................23

FuelSystemMaintenance...................................24

ReplacingtheFuelFilter...................................24

DrainingtheFuelT ank......................................24

RemovingtheFuelTank...................................25

ElectricalSystemMaintenance...........................25

ServicingtheBattery.........................................25

ServicingtheFuses..........................................27

DriveSystemMaintenance..................................27

ServicingtheTracks.........................................27

ServicingtheDriveBelt.....................................29

ControlsSystemMaintenance.............................30

AdjustingtheMotion-ControlLevers.................30

BrakeMaintenance...........................................31

HydraulicSystemMaintenance...........................32

ServicingtheHydraulicDriveSystem...............32

ServicingtheHydraulicLiftSystem...................34

CheckingtheHydraulicLines...........................36

Cleaning..............................................................37

RemovingDebrisfromtheMachine..................37

Storage...................................................................38

3

Go to Discount-Equipment.com to order your parts

Safety

Improperuseormaintenanceofthemachinecan

resultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafety-alertsymbol(Figure2),which

meansCaution,Warning,orDanger—personal

safetyinstruction.Failuretocomplywiththe

instructionmayresultinpersonalinjuryordeath.

SafeOperatingPractices

WARNING

Engineexhaustcontainscarbonmonoxide,

anodorlessgasthatislethalifinhaled.

Donotruntheengineindoorsorinan

enclosedarea.

Training

•ReadtheOperator'sManualandothertraining

material.Iftheoperator(s)ormechanic(s)cannot

readthismanual,itistheowner'sresponsibilityto

explainthismaterialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.

Theownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateor

servicetheequipment.Localregulationsmay

restricttheageoftheoperator.

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriesoccurringtohimselfor

herself,otherpeopleorproperty.

Preparation

•Wearappropriateclothingincludinghardhat,eye

protection,longpants,substantial,slip-resistant

footwear,andhearingprotection.Tiebacklong

hair.Donotwearloosejewelry.

•Inspecttheareawheretheequipmentistobe

usedandensurethatallobjectsareremovedfrom

themachinebeforeuse.

•Knowandmarkthelocationsofallutilitylines.

•Useextracarewhenhandlingfuels.Theyare

ammableandvaporsareexplosive.

–Extinguishallcigarettes,cigars,pipes,and

othersourcesofignition.

–Useonlyanapprovedcontainer

–Donotremovethefuelcaporllthefueltank

whiletheengineisrunningorhot.

–Donotaddordrainfuelinanenclosedspace.

–Donotstorethemachineorfuelcontainer

wherethereisanopename,spark,orpilot

light,suchasonawaterheaterorother

appliance.

–Ifyouspillfuel,donotattempttostartthe

engine;avoidcreatinganysourceofignition

untilthefuelvaporshavedissipated.

•Checkthattheoperator'spresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperatethemachineunlessthey

arefunctioningproperly.

Operation

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Neverrunanengineinanenclosedorpoorly

ventilatedarea.

•Operatethemachineonlyingoodlight,keeping

awayfromholesandhiddenhazards.

•Ensurethatalldrivesareinneutralbefore

startingtheengine.Starttheengineonlyfromthe

operator'sposition.

•Donotoperatethemachinewiththeguards

notsecurelyinplace.Besureallinterlocksare

attached,adjustedproperly,andfunctioning

properly.

•Donotchangetheenginegovernorsettingor

overspeedtheengine.

•Stopthemachineonlevelground,lowerthe

hopper,shutofftheengine,andremovethekey

beforeleavingtheoperator'spositionforany

reason.

•Nevercarrypassengersandkeeppetsand

bystandersaway.

•Slowdownandusecautionwhenmakingturns

andcrossingroadsandsidewalks.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Usecarewhenloadingorunloadingthemachine

intoatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

•Ensurethattheareaisclearofotherpeoplebefore

operatingthemachine.Shutoffthemachineif

anyoneentersthearea.

•Neverleavearunningmachineunattended.

•Donotexceedtheratedoperatingcapacity,asthe

machinemaybecomeunstablewhichmayresult

inlossofcontrol.

•Neverjerkthecontrols;useasteadymotion.

4

Go to Discount-Equipment.com to order your parts

•Watchfortrafcwhenoperatingnearorcrossing

roadways.

•Donottouchpartsthatmaybehotfromoperation.

Allowthemtocoolbeforeattemptingtomaintain,

adjust,orservice.

•Checkforoverheadclearances(i.e.,branches,

doorways,electricalwires)beforedrivingunder

anyobjectsanddonotcontactthem.

•Ensurethatyouoperatethemachineinareas

wheretherearenoobstaclesclosetoyou.Failure

tomaintainadequatedistancefromtrees,walls,

andotherbarriersmayresultininjuryasthe

machinebacksupduringoperationifyouare

notattentivetothesurroundings.Operatethe

machineonlyinareaswherethereissufcient

clearancefortheoperatortosafelymaneuverthe

product.

•Locatethepinchpointareasmarkedonthe

machineandkeephandsandfeetawayfrom

theseareas.

•Operatethemachineonlyingoodvisibilityand

appropriateweatherconditions.Donotoperate

themachinewhenthereistheriskoflighting.

•Donotoverloadthehopperandalwayskeepthe

loadlevelwhenoperatingthemachine.

SlopeOperation

•Slopesareamajorfactorrelatedtoloss-of-control

andtip-overaccidents,whichcanresultinsevere

injuryordeath.Theoperatorisresponsiblefor

safeslopeoperation.operatingthemachineon

anysloperequiresextracaution.Beforeusingthe

machineonaslope,youmust:

–Reviewandunderstandtheslopeinstructions

inthemanualandonthemachine.

–Evaluatethesiteconditionsofthedayto

determineiftheslopeissafeformachine

operation.Alwaysusecommonsense

andgoodjudgmentwhenperformingthis

evaluation.Changesintheterrain,suchas

moisture,canquicklyaffecttheoperationof

themachineonaslope.

•Raisingthehopperonaslopeaffectsthestability

ofthemachine.Keepthehopperinthelowered

positionwhenonslopes.

•Whenoperatingonaslope,foldtheplatformup

andwalkbehindthemachineuntilitisonat

ground.

•Operateupanddownslopeswiththeheavy

endofthemachineuphill.Weightdistribution

changeswithafullhopper.Afullhoppermakes

thefrontofthemachinetheheavyend,sowhen

travelingupordownslopeswithafullhopper,

walk-behindthemachinewiththefullhopperuphill.

•Identifyhazardsatthebaseoftheslope.Do

notoperatethemachineneardrop-offs,ditches,

embankments,waterorotherhazards.The

machinecouldsuddenlyrolloverifawheelortrack

goesovertheedgeortheedgecollapses.Keep

asafedistance(twicethewidthofthemachine)

betweenthemachineandanyhazard.

•Avoidstarting,stopping,orturningthemachineon

aslope.Avoidmakingsuddenchangesinspeed

ordirection;turnslowlyandgradually.

•Keepallmovementsonslopesslowandgradual.

Donotmakesuddenchangesinspeedor

direction.

•Donotoperatethemachineunderanyconditions

wheretraction,steering,orstabilityisinquestion.

Beawarethatoperatingthemachineonwetgrass,

acrossslopesordownhillmaycausethemachine

tolosetraction.Lossoftractiontothewheelsor

tracksmayresultinslidingandalossofbraking

andsteering.Themachinecanslideevenifthe

wheelsortracksarestopped.

•Removeormarkobstaclessuchasditches,holes,

ruts,bumps,rocksorotherhiddenhazards.T all

grasscanhideobstacles.Uneventerraincould

overturnthemachine.

•Ifyoulosecontrolofthemachine,stepoffand

awayfromthedirectionoftravelofthemachine.

MaintenanceandStorage

•Lettheenginecoolbeforestoringanddonotstore

themachinenearanopename.

•Engagetheparkingbrake,shutofftheengine,

removethekey,andwaitforallmovementto

stopbeforeadjusting,cleaning,orrepairingthe

machine.

•Cleandebrisfromdrives,mufers,andtheengine

tohelppreventres.Cleanupoilorfuelspills.

•Donotstorefuelnearamesordrainindoors.

•Parkthemachineonlevelground.Neverallow

untrainedpersonneltoservicethemachine.

•Usejackstandstosupportcomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectthebattery,negativeterminalrstand

positiveterminallast,beforemakinganyrepairs.

Connectthebatterypositiveterminalrstand

negativeterminallast.

•Keepyourhandsandfeetawayfrommoving

parts.Ifpossible,donotmakeadjustmentswith

theenginerunning.

5

Go to Discount-Equipment.com to order your parts

•Chargebatteriesinanopen,well-ventilatedarea,

awayfromsparkandames.Unplugthecharger

beforeconnectingordisconnectingitfromthe

battery.Wearprotectiveclothinganduseinsulated

tools.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

•Usethecylinderlocktosecurethehopperinthe

raisedposition.

•Keepnutsandboltstight.Keepequipmentin

goodcondition.

•Nevertamperwithsafetydevices.

•UseonlygenuineT ororeplacementpartsto

ensurethatoriginalstandardsaremaintained.

•Batteryacidispoisonousandcancauseburns.

Avoidcontactwithskin,eyes,andclothing.Protect

yourface,eyes,andclothingwhenworkingwitha

battery.

•Batterygasescanexplode.Keepcigarettes,

sparks,andamesawayfromthebattery.

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthigh-pressurehydraulic

uid.Usecardboardorpapertondhydraulic

leaks;neveruseyourhands.Hydraulicuid

escapingunderpressurecanpenetrateskinand

causeinjuryrequiringsurgerywithinafewhours

byaqualiedsurgeon;otherwise,gangrenemay

result.

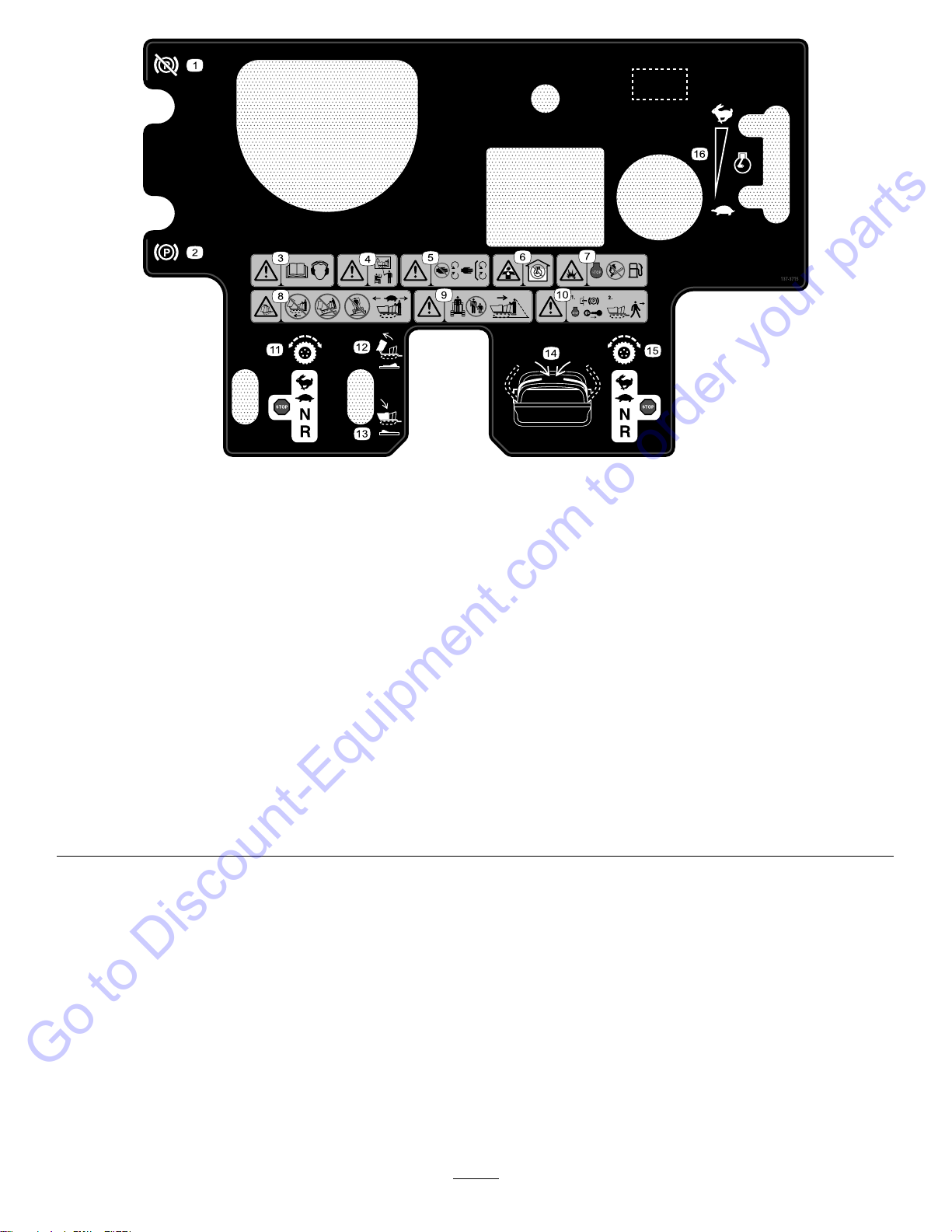

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

decal115-4212

115-4212

1.Hydraulic-uidlevel3.Warning—donottouchthe

hotsurface.

2.ReadtheOperator's

Manual.

decal115-4858

115-4858

1.Crushinghazardofhandsorfeet—installthecylinderlock.

decal116-8775

116-8775

1.ReadtheOperator’s

Manual.

2.Warning—lltothebottom

ofthellerneck;donot

overllthetank.

decal133-5619

133-5619

6

Go to Discount-Equipment.com to order your parts

decal132-8961

132-8961

1.Batterychargingcondition4.Hopperislowering.

2.Hourmeter5.Hopperisdown.

3.Hopperisraising.6.Hopperislowering

automatically.

decal132-9051

132-9051

1.Tie-downpoint

decal132-9052

132-9052

1.Main(15A)3.Logic(7.5A)

2.Auxiliary(15A)

decal137-0575

137-0575

1.ReadtheOperator’s

Manual.

3.Cold-llline

2.Transmissionuid

decal137-8899

137-8899

1.ReadtheOperator’sManual.

7

Go to Discount-Equipment.com to order your parts

decal137-3715

137-3715

1.Parking-brakerelease7.Explosionhazard—shutofftheengine

beforeaddingfuel;nore,open

ames,orsmokingwhenaddingfuel.

13.Lowerhopper

2.Parkingbrake8.Machinetippinghazard—donotdrive

forwardwiththehopperraised;do

notdrivedownslopeswiththehopper

raised;donotdriveacrossslopeswith

thehopperraised;driveslowlywiththe

hopperdown.

14.Movethehandlesintooperate.

3.Warning—readtheOperator’sManual;

hearingprotectionmustbeworn.

9.Warning—keepbystandersasafe

distanceawayfromthemachine;watch

behindyouwhenmovinginreverse.

15.Righttractioncontrols

4.Warning—alloperatorsshouldbe

trainedbeforeoperatingthemachine.

10.Warning—engagetheparkingbrake,

shutofftheengine,andremovethekey

beforeleavingtheoperator’sposition.

16.Engine-speedcontrol

5.Warning-keepawayfrommovingparts;

keepallguardsandcoversinplace.

11.Lefttractioncontrols

6.Poisonousfumesortoxicgases,

asphyxiationhazard—donotrunthe

engineinanenclosedspace.

12.Raisehopper

8

Go to Discount-Equipment.com to order your parts

ProductOverview

g038268

Figure3

1.Hopper4.Fuel-tankcap

2.Hood5.Operatorplatform

3.Controlpanel6.Track

Controls

Becomefamiliarwithallthecontrols(Figure4)before

youstarttheengineandoperatethemachine.

g038269

Figure4

1.Parking-brakelever6.Throttlelever

2.Hydraulic-tankcap7.Leftmotion-controllever

3.Hourmeter8.Dumpswitch

4.Chokecontrol9.Rightmotion-controllever

5.Keyswitch

ParkingBrakeLever

Toengagetheparkingbrake,pullbackthelever.

(Figure4).

Todisengagetheparkingbrake,pushthelever

forward.

HourMeter

Thehourmeterrecordsthenumberofhoursthe

enginehasoperated.Itoperateswhentheengine

isrunning.Usethesetimesforschedulingregular

maintenance(Figure4).

ChokeControl

Usethechoketostartacoldengine.Pullthechoke

knobuptoengageit.Pushthechokeknobdownto

disengageit(Figure4).

KeySwitch

Usethekeyswitchtostarttheengine(Figure4).The

switchhas3positions:OFF,RUN,andSTART.

ThrottleLever

ThethrottleleverisvariablebetweentheFASTand

SLOWpositions(Figure4).

Motion-ControlLevers

Usethemotion-controlleverstodrivethemachine

forwardandreverseandtoturneitherdirection

(Figure4).

DumpSwitch

Usethedumpswitchtodumpandlowerthehopper.

Ifyouholdtheswitchdown0.2to1.3seconds,the

hopperfullylowersautomatically.

9

Go to Discount-Equipment.com to order your parts

Specications

Note:Specicationsanddesignaresubjectto

changewithoutnotice.

Width90.2cm(35-1/2inches)

Length268.0cm(105-1/2inches)

Height121.2cm(47.7inches)

Weight734kg(1,619lb)

Hoppercapacity0.45m3(16ft3)

Maximumload1,134kg(2,500lb)

DischargeHeight38.1cm(15inches)

Attachments/Accessories

AselectionofT oroapprovedattachmentsand

accessoriesisavailableforusewiththemachine

toenhanceandexpanditscapabilities.Contact

yourAuthorizedServiceDealerorauthorizedToro

distributororgotowww.Toro.comforalistofall

approvedattachmentsandaccessories.

Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineT oro

replacementpartsandaccessories.Replacement

partsandaccessoriesmadebyothermanufacturers

couldbedangerous,andsuchusecouldvoidthe

productwarranty.

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Important:Beforeoperating,checkthefueland

oillevel,andremovedebrisfromthemachine.

Also,ensurethattheareaisclearofpeopleand

debris.

AddingFuel

•Forbestresults,useonlyclean,fresh(lessthan

30daysold),unleadedgasolinewithanoctane

ratingof87orhigher((R+M)/2ratingmethod).

•ETHANOL:Gasolinewithupto10%ethanol

(gasohol)or15%MTBE(methyltertiarybutyl

ether)byvolumeisacceptable.Ethanoland

MTBEarenotthesame.Gasolinewith15%

ethanol(E15)byvolumeisnotapprovedforuse.

Neverusegasolinethatcontainsmorethan10%

ethanolbyvolume,suchasE15(contains15%

ethanol),E20(contains20%ethanol),orE85

(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/or

enginedamagewhichmaynotbecoveredunder

warranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessyouuseafuel

stabilizer.

•Donotaddoiltogasoline.

10

Go to Discount-Equipment.com to order your parts

DANGER

Incertainconditions,fuelisextremely

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanyfuel

thatspills.

•Neverllthefueltankinsideanenclosed

trailer.

•Donotllthefueltankcompletelyfull.

Addfueltothefueltankuntilthelevelis6

to13mm(1/4to1/2inch)belowthebottom

ofthellerneck.Thisemptyspaceinthe

tankallowsfueltoexpand.

•Neversmokewhenhandlingfuelandstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

•Storefuelinanapprovedcontainerand

keepitoutofthereachofchildren.Never

buymorethana30-daysupplyoffuel.

•Donotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingaspark,

whichcanignitethefuelvapors.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

•Alwaysplacefuelcontainersontheground

awayfromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicle

oronatruckortrailerbedbecauseinterior

carpetsorplastictruckbedlinersmay

insulatethecontainerandslowthelossof

anystaticcharge.

•Whenpractical,removefuel-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelsonthe

ground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainerratherthanfroma

fuel-dispensernozzle.

•Ifyoumustuseafuel-dispensernozzle,

keepthenozzleincontactwiththerimof

thefueltankorcontaineropeningatall

timesuntilfuelingiscomplete.

WARNING

Fuelisharmfulorfatalifswallowed.

Long-termexposuretovaporscancause

seriousinjuryandillness.

•Avoidprolongedbreathingofvapors.

•Keepyourfaceawayfromnozzleandfuel

tankorconditioneropening.

•Keepfuelawayfromeyesandskin.

11

Go to Discount-Equipment.com to order your parts

UsingStabilizer/Conditioner

Usefuelstabilizer/conditionerinthemachinetokeep

thefuelfreshlongerwhenusedasdirectedbythe

fuel-stabilizermanufacturer.

Important:Donotusefueladditivescontaining

methanolorethanol.

Addtheamountoffuelstabilizer/conditionertofresh

fuelasdirectedbythefuel-stabilizermanufacturer.

FillingtheFuelTank

Fuel-tankcapacity:40.1L(10.6USgallons)

1.Cleantheareaaroundthefuel-tankcap.

2.Removethecap.

3.Addfueluntilitisatthebottomofthellerneck.

Note:Donotllthefueltankcompletelyfull.

Theemptyspaceinthetankallowsthefuelto

expand.

4.Installthecap.

g038312

Figure5

PerformingDaily

Maintenance

Beforestartingtheengineeachday,performthe

followingprocedures:

•Checktheengine-oillevel—refertoCheckingthe

Engine-OilLevel(page20).

•Checkthehydraulic-uidlevelforthedrive

system—refertoCheckingtheHydraulic-Fluid

LevelfortheDriveSystem(page32)

•Checkthehydraulic-uidlevelforthelift

system—refertoCheckingtheHydraulic-Fluid

LevelfortheLiftSystem(page34).

OperatingtheParking

Brake

Alwaysengagetheparkingbrakewhenyoustopthe

machineorleaveitunattended.Beforeeachuse,

checktheparkingbrakeforproperoperation.

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhile

itisunattended.

Removetheignitionkeyandengagethe

parkingbrakewheneveryouleavethe

machineunattended.

EngagingtheParkingBrake

Pulltheparking-brakeleverrearwardintothe

ENGAGEDposition(Figure6).

g009465

Figure6

1.Parkingbrake—ENGAGED

position

2.Parkingbrake—RELEASED

position

ReleasingtheParkingBrake

Pushtheparking-brakeleverforward(Figure6).

12

Go to Discount-Equipment.com to order your parts

OperatingtheThrottle

ThethrottlecontrolmovesbetweenFASTandSLOW

positions(Figure7).

AlwaysusetheFASTpositionwhenmovingthe

machine.

g008946

Figure7

OperatingtheChoke

Usethechoketostartacoldengine.

1.Pullupthechokeknobtoengagethechoke

beforeusingthekeyswitch(Figure8).

Note:Ensurethatyoufullyengagethechoke.

Youmayneedtoholdtheknobupwhenyou

usethekeyswitch.

2.Pushdownthechoketodisengagethechoke

aftertheenginehasstarted(Figure8).

g008959

Figure8

1.ONposition2.OFFposition

StartingtheEngine

1.Engagetheparkingbrake.

2.Engagethechoke.

Note:Awarmorhotenginemaynotrequire

choking.Youmayneedtorepeatthestarting

cyclewhenyoustarttheengineforthersttime

afteryouhavelledacompletelyemptyfuel

systemwithfuel.

3.MovethethrottlebetweentheFASTandSLOW

positions.

4.TurnthekeyswitchtotheSTARTposition.

5.Whentheenginestarts,disengagethechoke.

Important:Donotengagethestarterformore

than5secondsatatime.Iftheenginefailstostart,

allowa15-secondcool-downperiodbetween

attempts.Failuretofollowtheseinstructionscan

burnoutthestarter.

g038313

Figure9

13

Go to Discount-Equipment.com to order your parts

ShuttingOfftheEngine

1.MovethethrottlebetweentheFASTandSLOW

positions.

2.Engagetheparkingbrake.

3.TurnthekeyswitchtotheOFFpositionand

removethekey.

g038314

Figure10

OperatingtheHopper

Hoppercapacity:1134kg(2,500lb)

Knowtheloadcapacityofthemachineandnever

exceedit.Thismachinenormallyoperatesonuneven,

unpaved,bumpy,and/orinclinedsurfaces—adjustthe

loadaccordingly.

1.Positionthemachinewhereyouintendtodump

theload.

2.Dumpthehopperbypushingthetopofthe

dumpswitch(Figure11).

3.Lowerthehopperbypushingthebottomofthe

dumpswitch(Figure11).

Note:Ifyouholdthebottomoftheswitch

0.2to1.3seconds,thehopperfullylowers

automatically.

g038270

Figure11

1.Dumpthehopper.2.Lowerthehopper.

RemovingDebrisfromthe

Machine

1.Parkthemachineonalevelsurface,move

themotion-controlleverstotheNEUTRAL-LOCK

position,engagetheparkingbrake,andlower

thehopper.

2.Shutofftheengineandremovethekey.Allow

theenginetocool.

3.Cleantheinsideofthehopperusingahose.

Important:Donotuseahammertoremove

materialfromtheinsideofthehopper;this

maycausedamagetothemachine.

4.Cleananydebrisfromunderthehopper.

5.Wipeawaydebrisfromtheaircleaner.

6.Cleananydebrisbuildupontheengineandin

thetransmissionwithabrushorblower.

Important:Blowoutdirtratherthanwash

itout.Ifyouusewater,keepitawayfrom

electricalpartsandhydraulicvalves.Donot

useahigh-pressurewasher.High-pressure

washingcandamagetheelectricalsystem

andhydraulicvalvesordepletegrease.

14

Go to Discount-Equipment.com to order your parts

LoweringtheHopper

withoutPower

1.Installthecylinderlock;refertoInstallingthe

CylinderLock(page18).

2.Ensurethatthetubisempty.

3.Placealargedrainpanunderthe

hydraulic-manifoldblock(Figure12).

g186548

Figure12

1.Hydraulic-manifoldblock

4.Disconnectthehosettingsinthemanifold

blockandallowtheuidtodrainintothepain.

Note:Disposeoftheuseduidatacertied

recyclingcenter.

5.Connectthehosettings.

6.Useahoistorhave2peopleholdupthehopper

andremovethecylinderlock.

7.Carefullylowerthehoppertothemachineframe.

TransportingtheMachine

Useaheavy-dutytrailerortruckwithfull-widthramps

totransportthemachine.Ensurethatthetraileror

truckhasallthenecessarybrakes,lighting,and

markingasrequiredbylaw.Pleasecarefullyreadall

thesafetyinstructions.Knowingthisinformationcould

helpyou,yourfamily,petsorbystandersavoidinjury.

Refertoyourlocalordinancesfortrailerandtie-down

requirements.

Important:Donotoperateordrivethemachine

onroadways.

1.Lowerthehopper.

2.Ifusingatrailer,connectittothetowingvehicle

andconnectthesafetychains.

3.Ifapplicable,connectthetrailerbrakes.

4.Carefullyloadthemachineontothetraileror

truck.

5.Shutofftheengine,removethekey,andset

thebrake.

6.Usethemetaltie-downloopsonthemachineto

securelyfastenthemachinetothetrailerortruck

withstraps,chains,cable,orropes(Figure13).

g185890

Figure13

1.Fronttie-downloops2.Reartie-downloops

15

Go to Discount-Equipment.com to order your parts

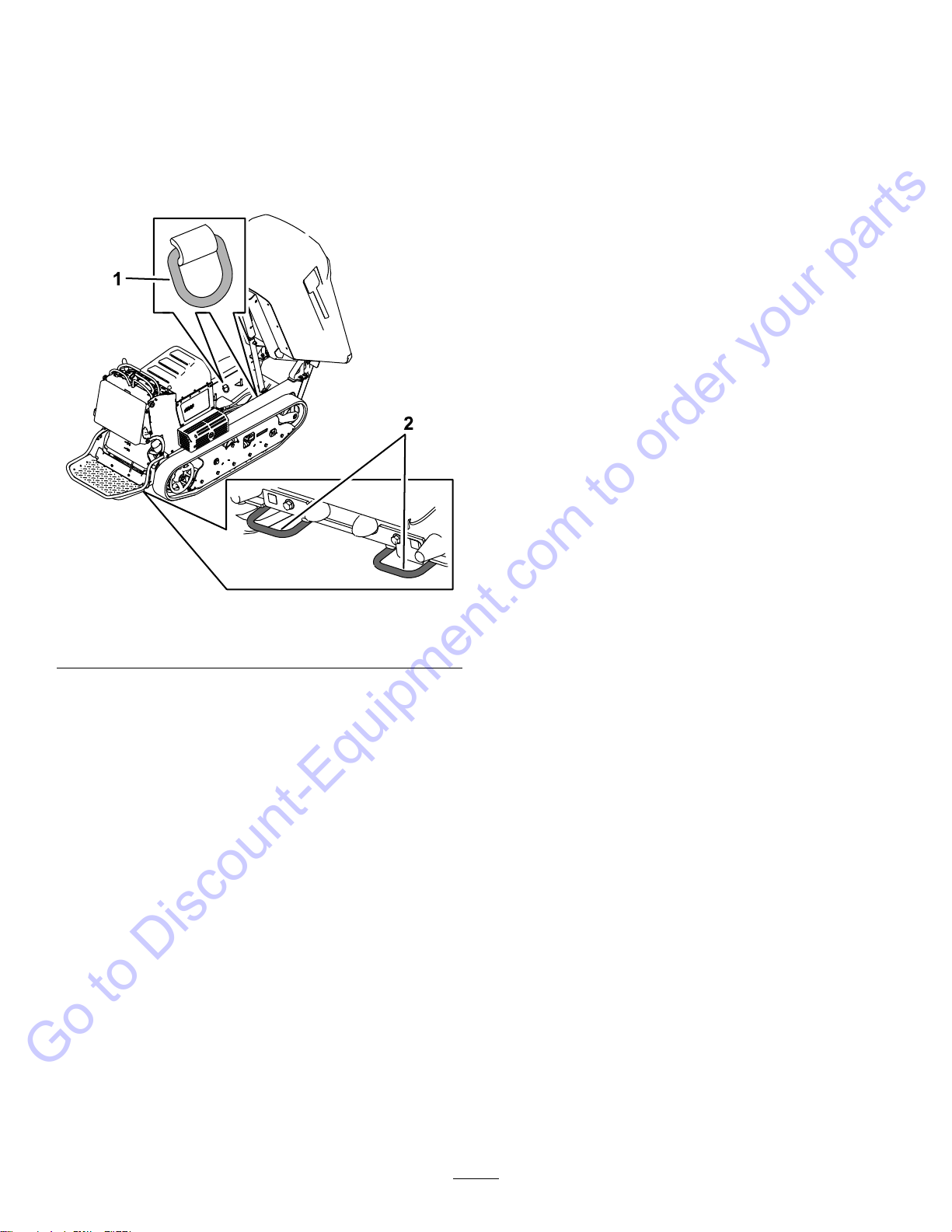

LiftingtheMachine

Hoistthemachineusing2liftpointsunderthehopper

and2reartie-downloops.Tiltthehopperforwardto

locatethe2liftloopsandattachachainorstrapsat

eachoftheloopsasshowninFigure14.

Note:T akeuptheslackinthechainorstrapsto

properlybalancetheunit.

g194436

Figure14

1.Liftpointsunderhopper2.Reartie-downloops

16

Go to Discount-Equipment.com to order your parts

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

IntervalMaintenanceProcedure

Aftertherst10hours•Checkandadjustthetracktension(every10hoursuntil50hours).

Beforeeachuseordaily

•Checktheengine-oillevel.

•Cleantheblowerhousing(moreoftenunderextremelydusty,dirtyconditions).

•Checktheconditionofthetrack.

•Checktheparkingbrakeoperation.

•Checkthehydraulic-uidlevelforthedrivesystem.

•Checkthehydraulic-uidlevelfortheliftsystem.

•Removedebrisfromthemachine.

•Checkforloosefasteners.

Every25hours•Serviceorreplacetheair-cleanerfoamelement(moreoftenunderextremelydusty,

dirtyconditions).

Every40hours•Checkthehydrauliclinesforleaks,loosettings,kinkedlines,loosemounting

supports,wear,anddeterioration.

Every50hours

•Greasethemachine(greaseimmediatelyaftereverywashing).

•Checkthebattery.

•Checkandadjustthetracktension.

Every100hours

•Replacetheair-cleanerpaperelement(moreoftenunderextremelydusty,dirty

conditions).

•Changetheengineoilandtheengine-oillter.

•Checkthesparkplug.

•Removethecoolingshroudsandcleanthecoolingareas(moreoftenunder

extremelydusty,dirtyconditions).

•Replacethefuellter(moreoftenunderdusty,dirtyconditions).

•Inspectthedrivebelt.

•Cleandirtbuildupinthechassis.

Every300hours

•Replacethesparkplug.

•Checktheroadwheels.

•Replacethedrivebelt.

•Changethehydraulicuidandlterforthedrivesystem.

•Changethehydraulicuidfortheliftsystem.

•Replacethehydrauliclterfortheliftsystem.

Important:Refertoyourengineowner'smanualforadditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyintheswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheswitchbeforeyouperformanymaintenance.

17

Go to Discount-Equipment.com to order your parts

Pre-Maintenance

Procedures

ReleasingtheCushionfor

RearAccess

Youcanreleasethecushionforrearaccesstothe

machineformaintenanceoradjustment.

1.Lowertheplatform.

2.Loosenthetwistknobsoneachsideofthe

machine(Figure15).

g032556

Figure15

1.Twistknob2.Cushion

3.Removethecushionandlowerittotheplatform.

4.Performanymaintenanceoradjustmentonthe

machine.

5.Raisethecushion,andslideitontothepinson

bothsidesofthemachine.

6.Tightenthetwistknobs.

UsingtheCylinderLock

InstallingtheCylinderLock

1.Parkthemachineonalevelsurface,move

themotion-controlleverstotheNEUTRAL-LOCK

position,engagetheparkingbrake,andfully

raisethehopper.

2.Removethe2cotterlesspinssecuringthe

cylinderlocktothemachine.

3.Slidethecylinderlockoverthelift-cylinderrod

andsecurewiththecotterlesspins(Figure16).

g185887

Figure16

1.Cylinderlock2.Lift-cylinderrod

4.Slowlylowerthehopperuntilthecylinderlock

contactsthecylinderbodyandrodend.

RemovingandStoringthe

CylinderLock

Important:Removethecylinderlockfromthe

lift-cylinderrodandfullysecureitinthestorage

positionbeforeoperatingthemachine.

1.Startthemachine.

2.Fullyraisethehopper.

3.Shutofftheengine.

4.Removethecotterlesspinssecuringthecylinder

lock.

5.Placethecylinderlockonthepostsinsidethe

machineframeandsecurewiththecotterless

pins.

6.Lowerthehopper.

18

Go to Discount-Equipment.com to order your parts

Lubrication

GreasingtheMachine

ServiceInterval:Every50hours

Whenoperatingthemachineundernormalconditions,

lubricateallgreasettingsforthebearingsand

bushingswithNo.2lithiumgrease.Lubricatethe

bearingsandbushingsimmediatelyafterevery

washing,regardlessoftheintervallisted.Applyalight

coatingofoilontothecontrolcables.

Cylinderpivots(2)—Figure17

g019608

Figure17

EngineMaintenance

ServicingtheAirCleaner

ServiceInterval:Every25hours—Serviceorreplace

theair-cleanerfoamelement(more

oftenunderextremelydusty,dirty

conditions).

Every100hours—Replacetheair-cleaner

paperelement(moreoftenunderextremely

dusty,dirtyconditions).

Note:Operatingtheenginewithlooseordamaged

air-cleanercomponentscouldallowunlteredairinto

theengine,causingprematurewearandfailure.

Note:Servicetheaircleanermoreoftenunder

extremelydusty,dirtyconditions.

RemovingtheElements

1.Rotatethelatchesoutward.

2.Removethecovertoaccesstheair-cleaner

elements(Figure18).

g243624

Figure18

1.Air-cleanercover2.Air-cleanerlatch

3.Removethefoamandpaperelements(Figure

19).

4.Removethefoamelementfromthepaper

element(Figure19).

19

Go to Discount-Equipment.com to order your parts

Other manuals for MB TX 2500

2

This manual suits for next models

5

Table of contents

Other Toro Industrial Equipment manuals

Toro

Toro Ultra Buggy e2500 User manual

Toro

Toro Groundsmaster 3320 User manual

Toro

Toro FM 330 User manual

Toro

Toro 22340 User manual

Toro

Toro LAC TM User manual

Toro

Toro 04246 User manual

Toro

Toro Greensmaster eFlex 1021 User manual

Toro

Toro Workman 07224-90001 Instruction Manual

Toro

Toro MH-400SH2 User manual

Toro

Toro 110-5076 User manual