- 4 - 40246462

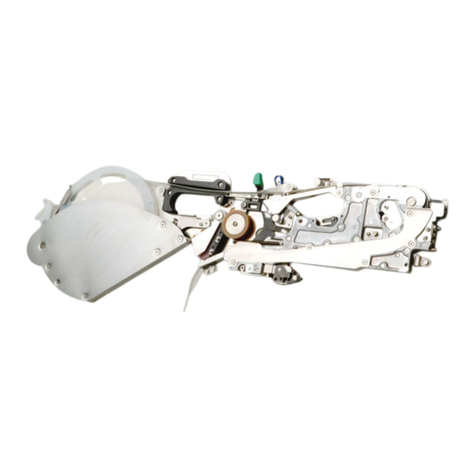

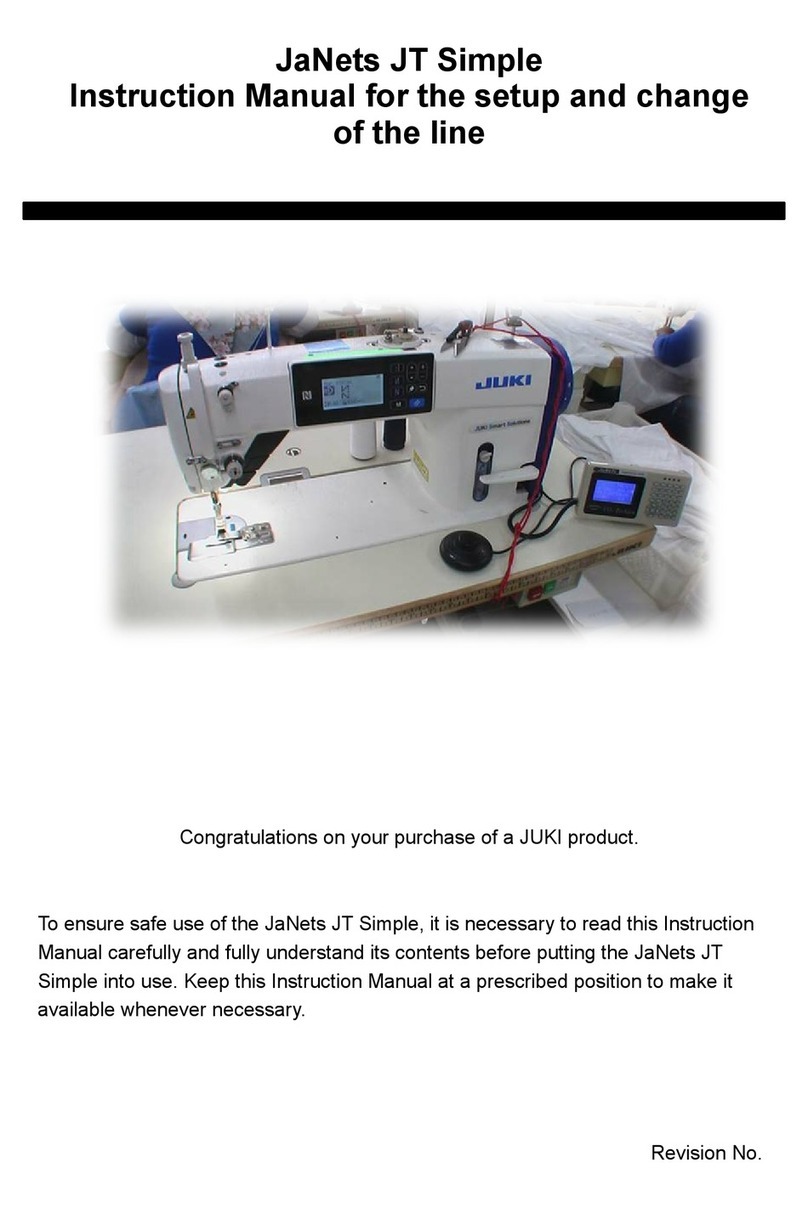

Even Feed Foot

Generally, this presser foot is used for hard-to-feed or for dicult-to-feed materials such as velvet, jersey, vinyl, cloth articial leather,

leather, etc. This smoothly feeds the material and prevents the material from slipping.

Install the even feed foot.

Fit forked portion of the actuating lever

to the needle clamp, insert the installing

portion into the presser bar, and securely

tighten the screw in the presser foot.

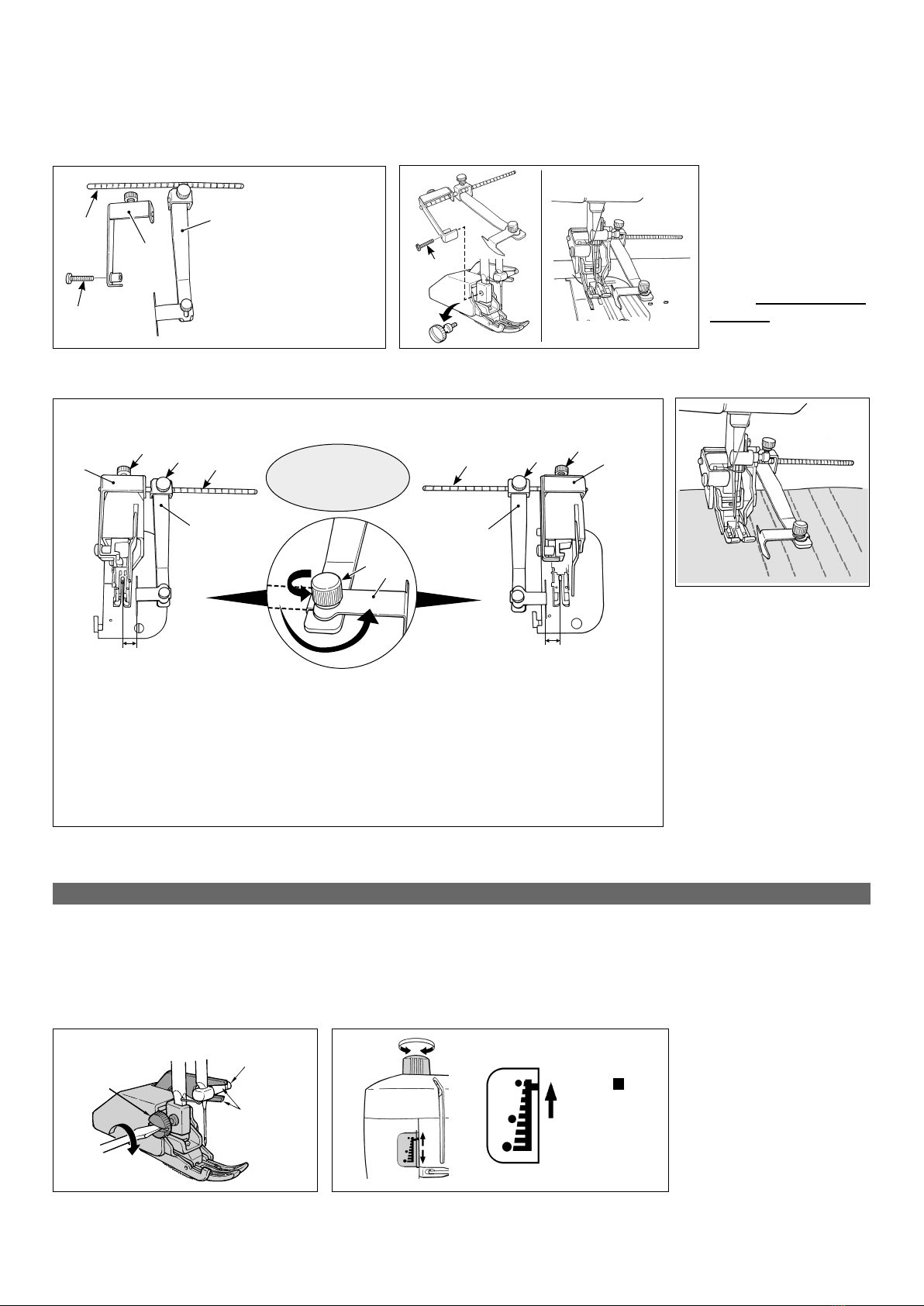

1Turn the presser foot pressure regulator to set

the presser foot pressure to “low”.

2

Set the pressure to “lowest” when sewing the velvet

material.

Use the sewing machine at medium speed.

Needle clamp

screw

Actuating

lever

Screw in the

presser foot Turn to to

decrease the

presser foot

pressure.

Increase Decrease

Accessory bag

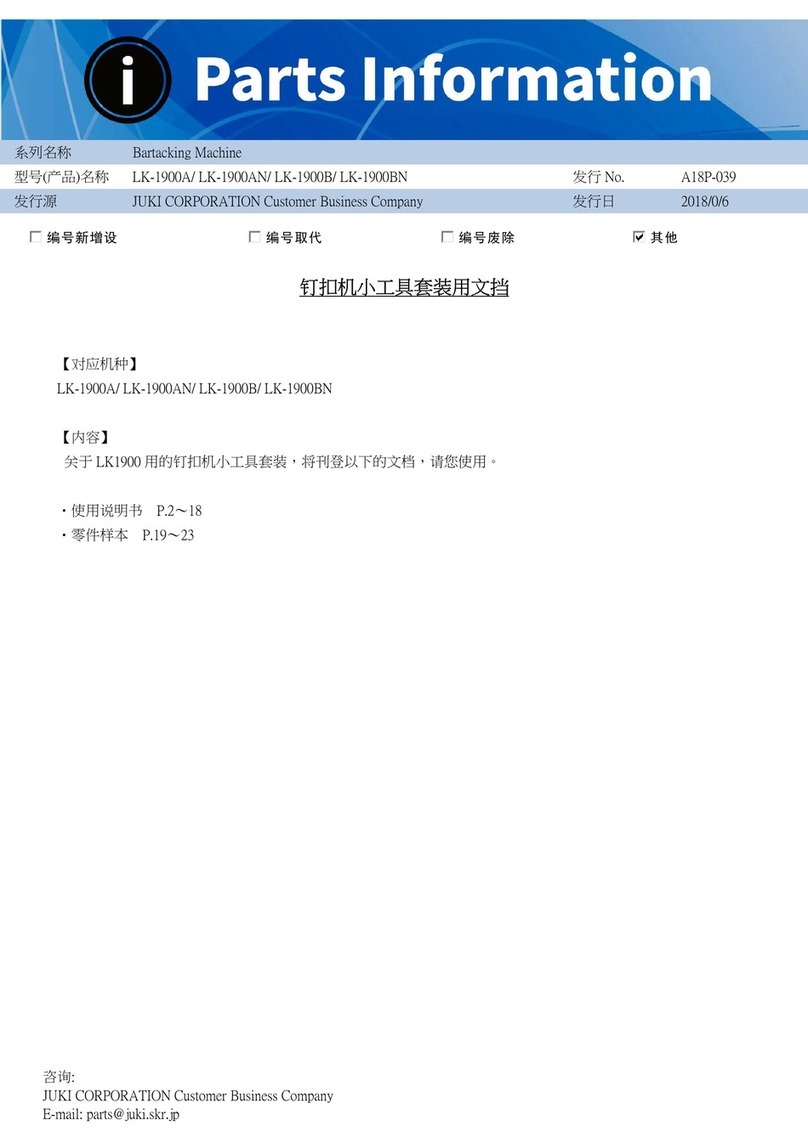

Quilt Guide for Even Feed Foot

Stitches can be sewn at regular intervals using the walking foot.

* Use the sewing machine at medium speed.

Remove walking foot

setscrew which xes the

walking foot.

Aligning the mounting

sections of the stitch

ruler and walking foot

with each other, securely

tighten the walking foot

setscrew D.

A

D

B

C

D

3

①Aligning the leftmost scale mark

on guide bar Awith the left edge

of guide base B, tighten setscrew

❸.

②Aligning guide C with the rst

scale mark from the right edge of

guide base B, tighten setscrew

❹. The distance from the needle

position to the guide is 1 cm.

Carry our sewing using

the guide as reference.

4

Stitches can be sewn while

keeping the regular stitch

intervals.

Adjusting the guide position.

In the case of setting the guide on

the right side of needle

In the case of setting the guide on

the left side of needle

①Aligning the rightmost scale mark

on guide bar Awith the right edge

of guide base B, tighten setscrew

❸.

②Aligning guide Cwith the second

scale mark from the left edge of

guide base B, tighten setscrew ❹.

The distance from the needle posi-

tion to the guide is 1 cm.

Adjust the guide position referring to the needle position and positional relation between the bar

scale and guide. Securely tighten the setscrew.

The interval of

scale marks on the

guide bar is 5 mm.

(Example: In the case of guiding the material so that it is kept

1 cm away from the needle position)

Remove setscrew ❶.

The stitch ruler can

be used on both the

right and left sides by

changing the mounting

position of guide sec-

tion ❷from right to left

or left to right.

B

C

A

1 cm

❸❹❸

❹

A

C

B

1 cm

❶❷

1Check the relevant parts. 2

Assembling and installing the stitch ruler.

AStitch guide bar ×1

BStitch guide base ×1

CStitch guide ×1

DScrew ×1