Installation

Inspection

The RWB-2000 and RWB-3000 are normally

shipped by common carrier and should be careful-

ly inspected for damages that may occur en route.

Any damage should be noted and the carrier noti-

fied immediately.

Ship Loose Items

Items shipped loose with the Remote Weld Bench

may include:

lRemote Weld Bench Installation and Operation

Manual, IOM 9421701.

Preinstallation

Note: See Specification Control Drawing for foot-

print dimensions, weights, and any other load

information.

The standard Remote Weld Bench is delivered

completely assembled. See the Specification

Control Drawing for footprint dimensions and

weights. The total weight of the unit should

include auxiliary equipment and other live loads.

Remove all crating, strapping, wrap and securing

hardware from both outside and/or inside the unit.

Check the parts received with the packing slips. If

parts are missing or damaged, notify the carrier

and your local Donaldson representative immedi-

ately.

The welding work surface is seven gauge hot rolled

steel. A waterborne, corrosion-resistant clear film

has been applied to the work surface. Remove this

film by washing the work surface with a detergent

cleaner and then drying with a cloth before weld-

ing.

Note: DO NOT weld without removing the corro-

sion-resistant film. Oily residue will be generated if

the film is not removed.

6

Donaldson Company, Inc.

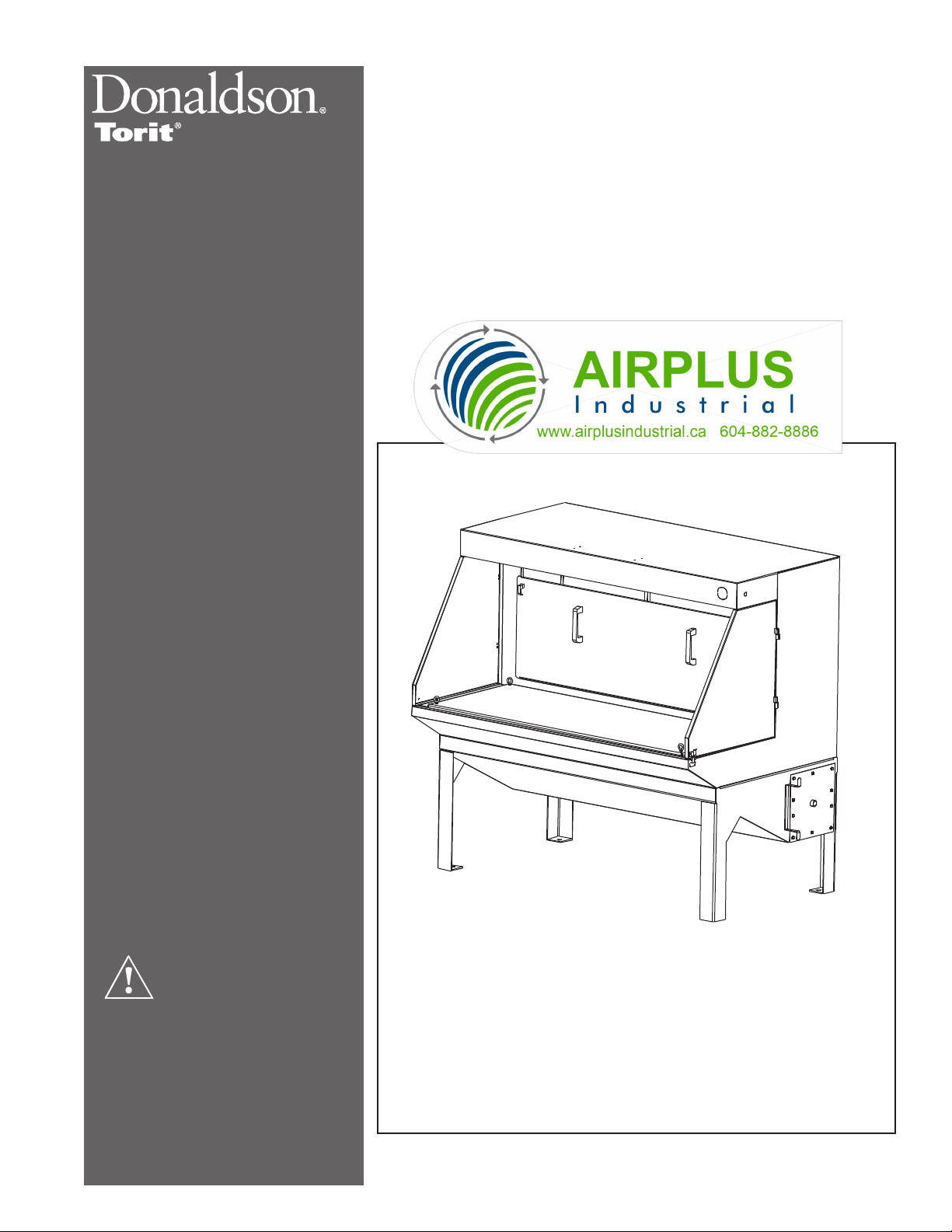

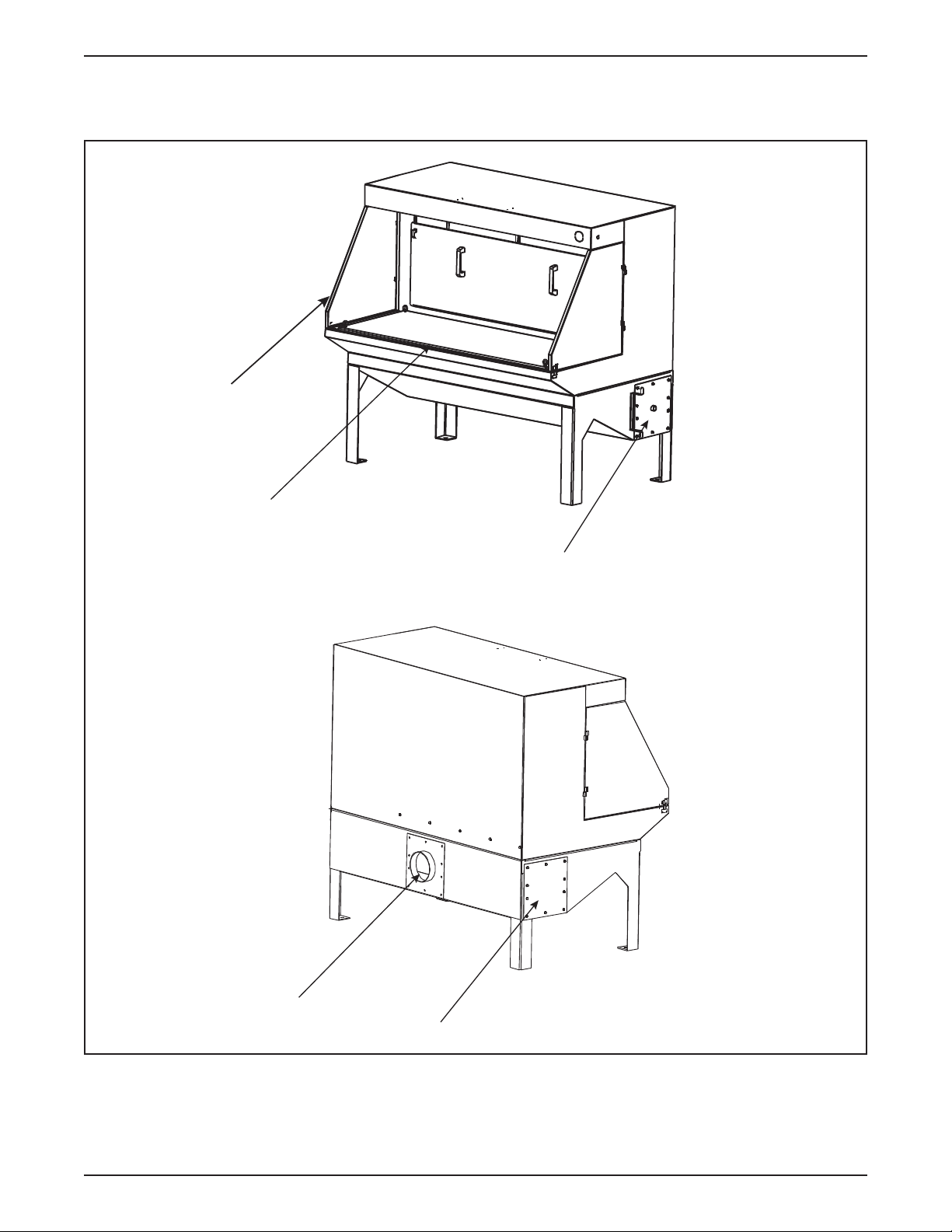

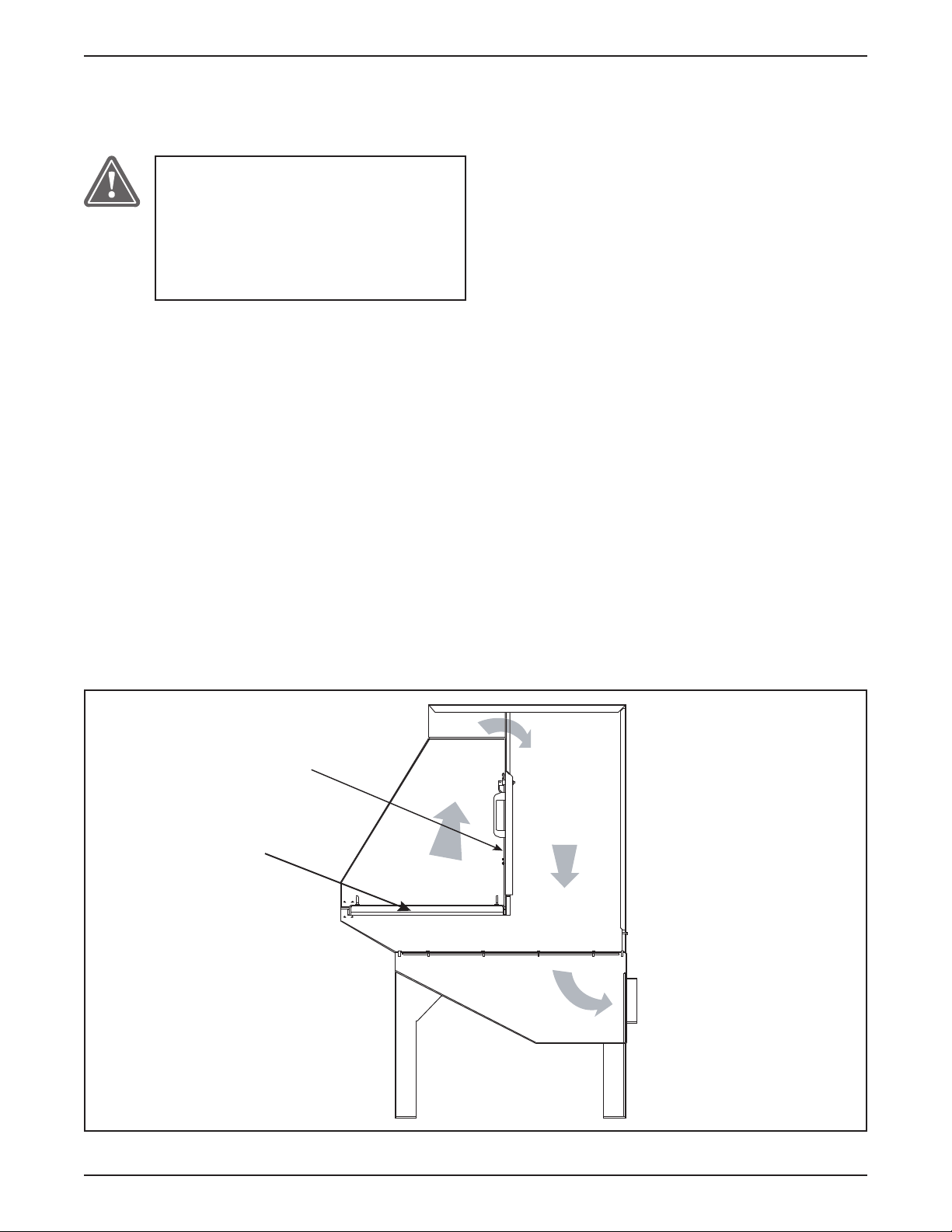

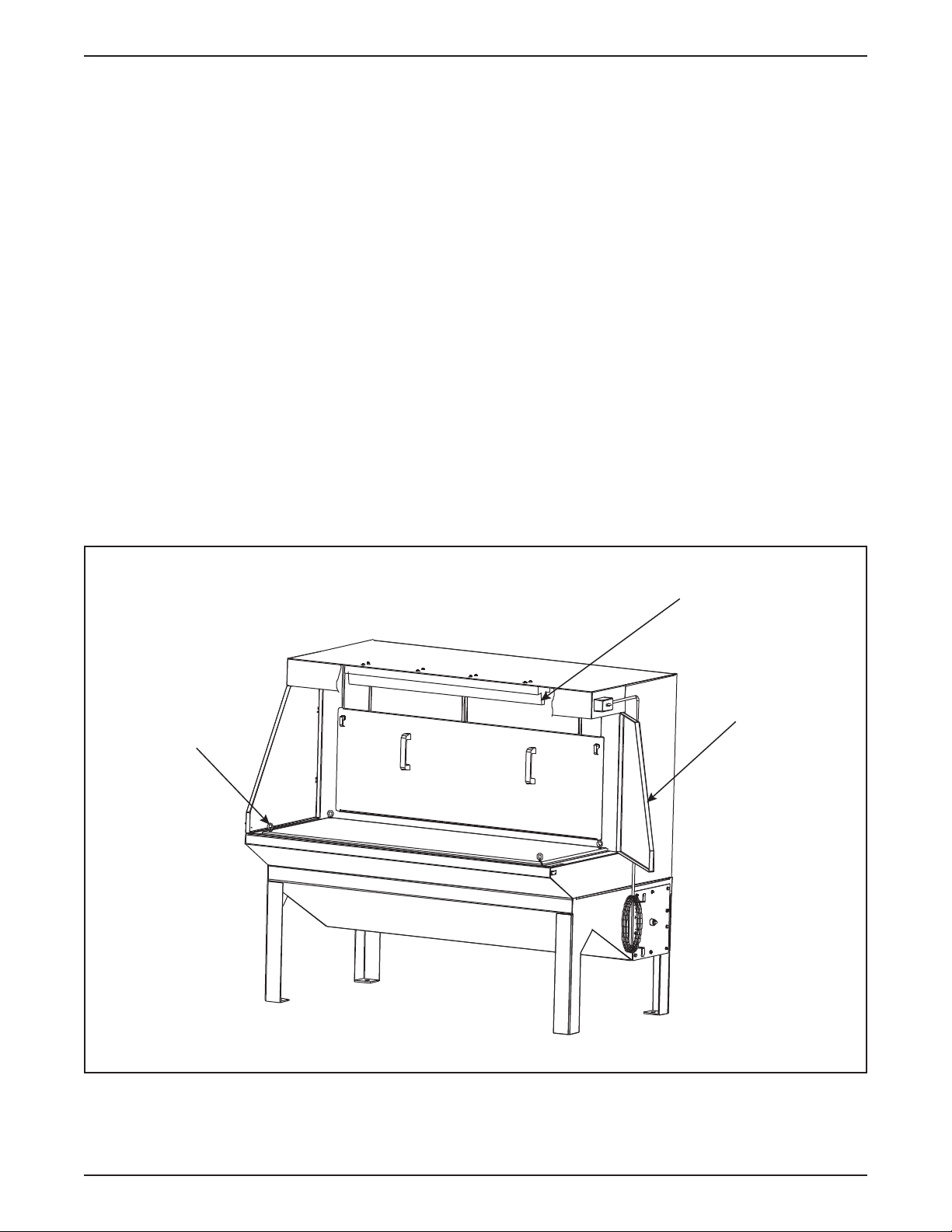

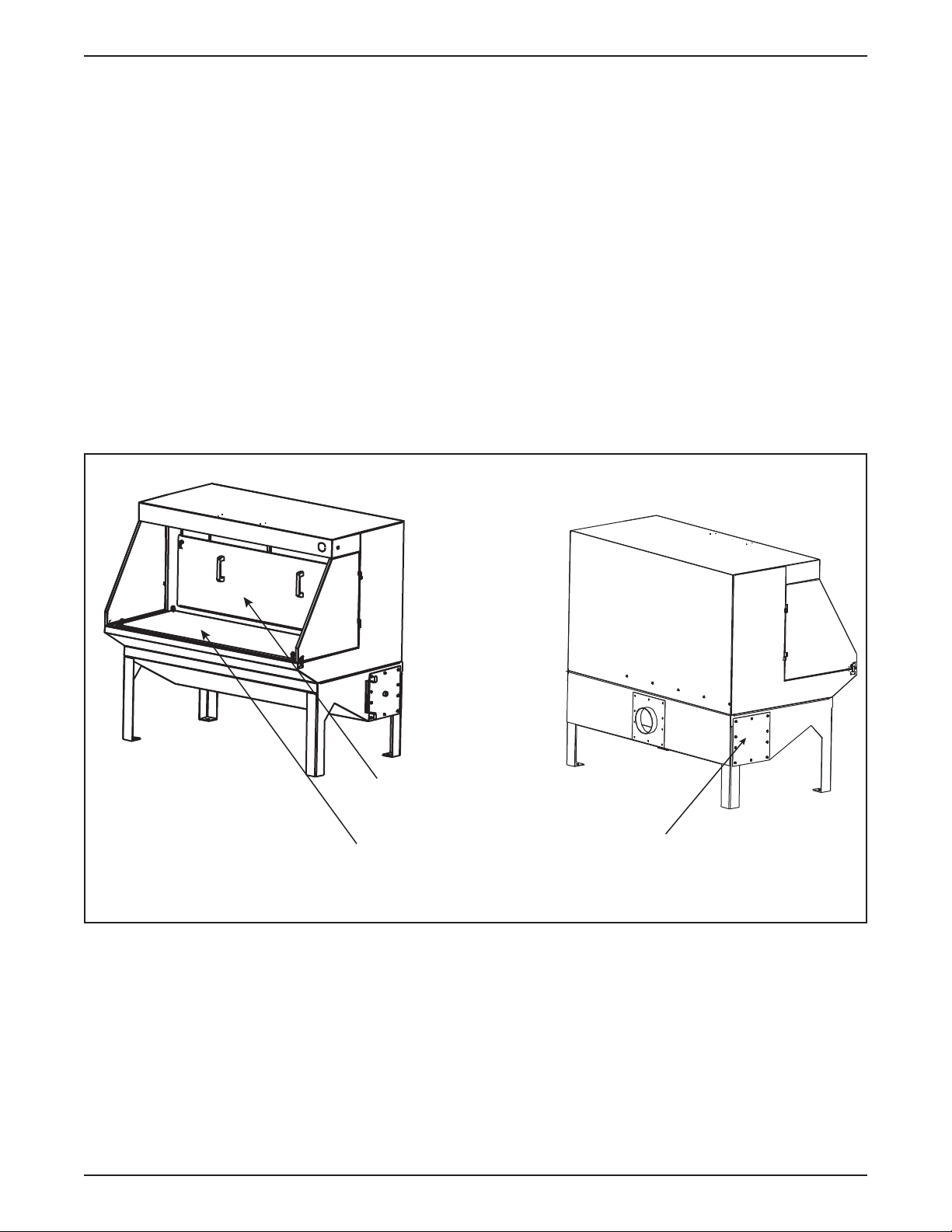

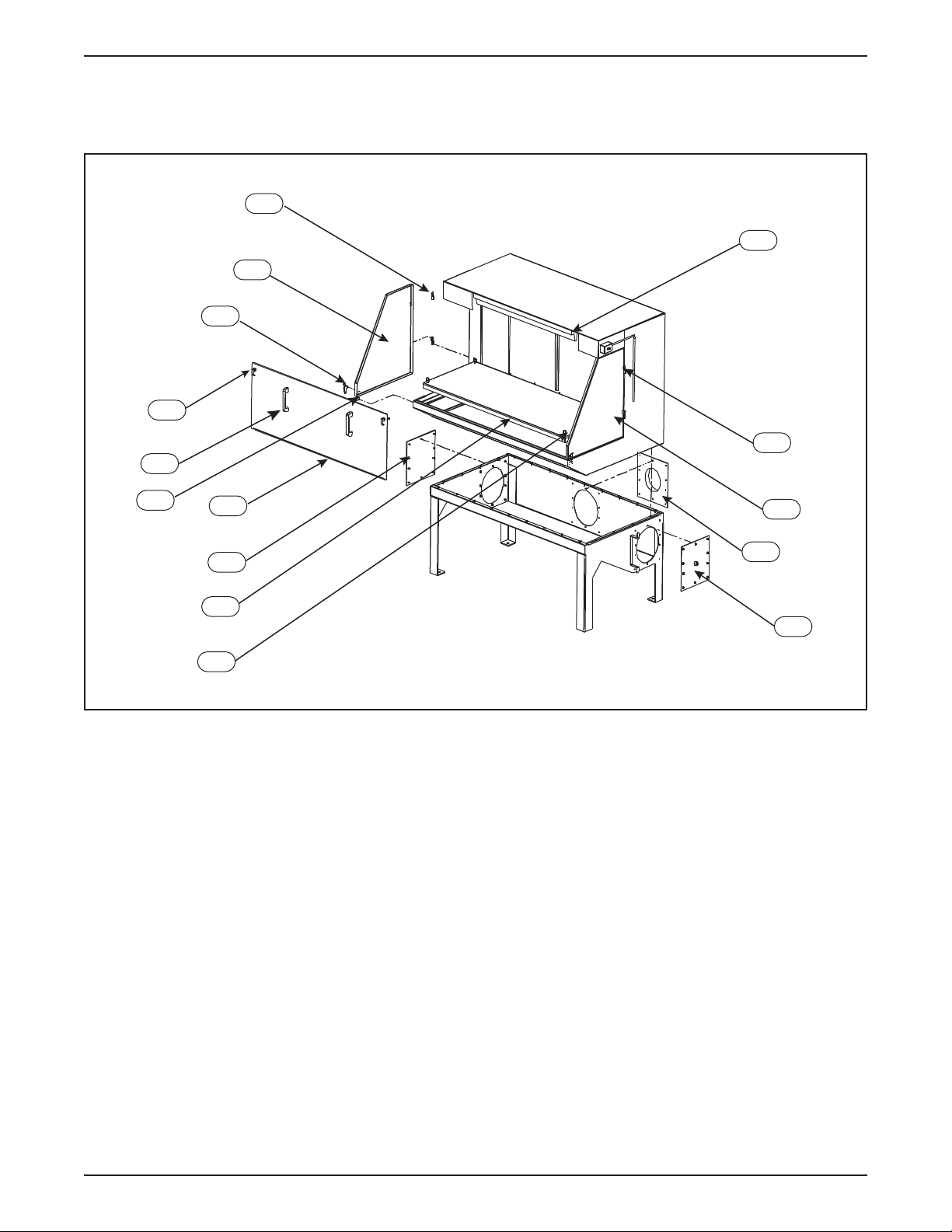

Assembly of Standard Equipment (See Figure 1)

Each Remote Weld Bench is shipped fully assem-

bled from the factory. The RWB-2000 weighs

approximately 600-lbs. The forklift must be able

to safely lift the unit. The Remote Weld Bench

standard collar pack is factory installed in the back

of the unit. The collar pack can be relocated to

either side of the hopper by switching it with either

the maintenance access panel or the 3/4” NPT

sprinkler coupling panel. See Figure 1, Typical

Remote Weld Bench Installation.

Sprinkler Coupling

A 3/4” NPT pipe coupling is located on the right-

hand side of the hopper. It is used to attach a

sprinkler head if necessary. Check your local codes

for sprinkler requirements. See Figure 1, Typical

Remote Weld Bench Installation.

Note: Donaldson equipment does not include fire

prevention equipment, all sprinkler heads must be

supplied by others.

CAUTION!

Use care in selecting the installation

location for dust collection equipment

and follow all appropriate national and

local fire codes.