IMAGO VisionDevice User manual

Manual

VisionDevice – Industrial DashCam 1 000

Version 1.0 – August 2023

Contents Page 2 / 31

IMAGO Technologies GmbH

Strassheimer Str. 45; 61169 Friedberg; Germany; Tel. +49(0)6031-6842611

info@imago-technologies.com; www.imago-technologies.com

Contents

1 Handling and Safety Instructions ............................................................ 4

2 Introduction ................................................................................................. 5

Main features ...................................................................................................................... 6

3 Operating Conditions ................................................................................. 7

4 Interfaces ..................................................................................................... 8

Power and I/O ..................................................................................................................... 8

4.1.1 Digital I/Os ......................................................................................................................................... 9

1 Gbit/s Ethernet M12 ...................................................................................................... 10

Status LEDs ...................................................................................................................... 10

5 Mechanical Drawings ................................................................................ 11

6 Web Based Graphical User Interface (WebGUI) ................................... 12

Overview ........................................................................................................................... 12

Accessing the GUI ........................................................................................................... 12

Welcome Page .................................................................................................................. 12

6.3.1 Indicator bar .................................................................................................................................... 14

6.3.2 Navigation panel ............................................................................................................................. 14

Event Log .......................................................................................................................... 15

View Live Page ................................................................................................................. 16

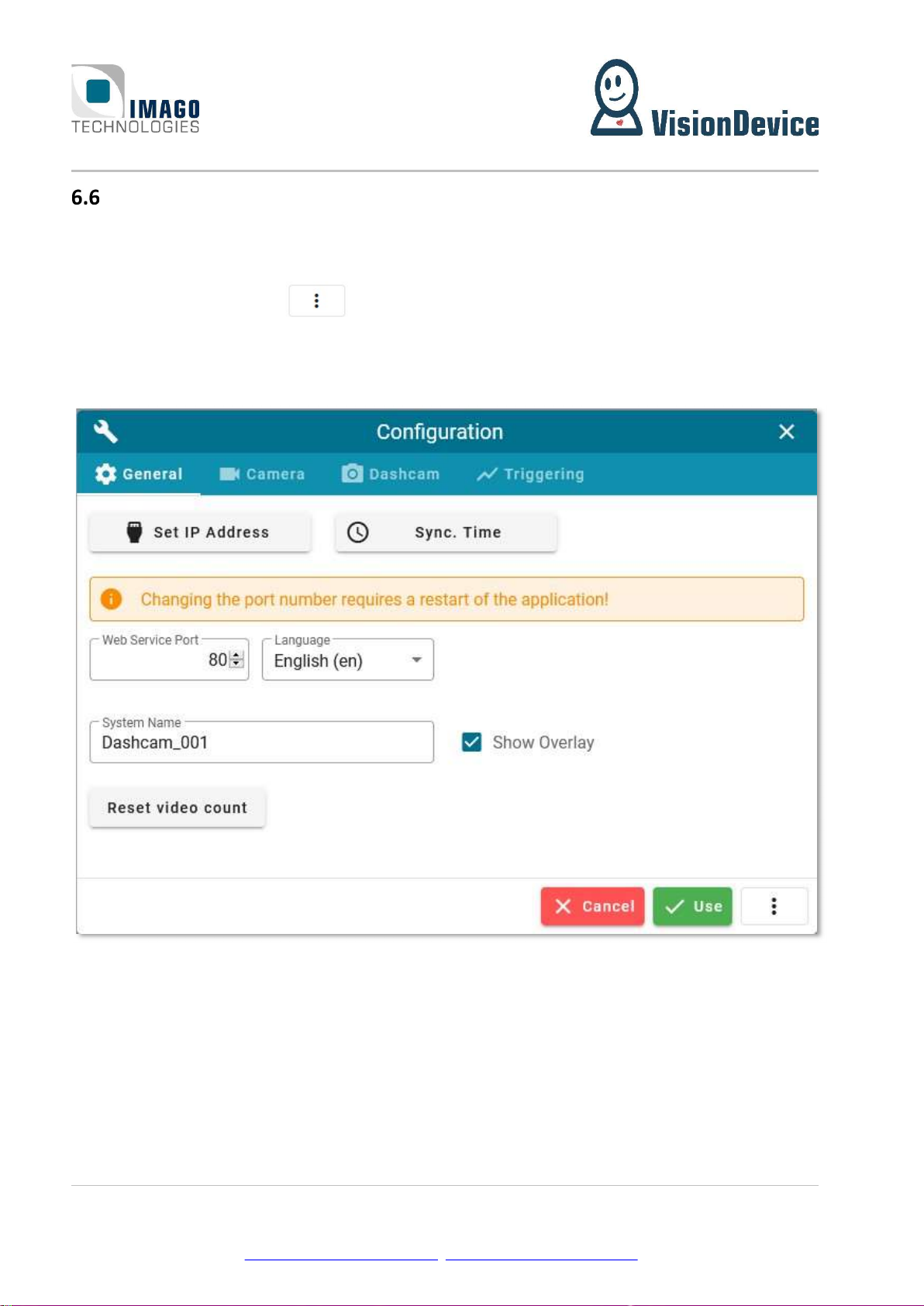

Configuration Page .......................................................................................................... 18

6.6.1 Setting IP-address and Web-Service Port .................................................................................. 19

6.6.2 Language and System Name ........................................................................................................ 19

6.6.3 Synchronize Time ........................................................................................................................... 19

6.6.4 Camera Settings ............................................................................................................................. 20

6.6.5 Setting Area of Interest.................................................................................................................. 21

6.6.6 Setting Encoder Bitrate and FPS ................................................................................................. 22

6.6.7 Setting Recording mode and video length ................................................................................ 22

6.6.8 Set triggering options .................................................................................................................... 23

View Video page............................................................................................................... 25

6.7.1 Viewing a Video – Simple player.................................................................................................. 26

6.7.2 Viewing a Video – Advanced ........................................................................................................ 27

Contents Page 3 / 31

IMAGO Technologies GmbH

Strassheimer Str. 45; 61169 Friedberg; Germany; Tel. +49(0)6031-6842611

info@imago-technologies.com; www.imago-technologies.com

About Page ........................................................................................................................ 28

Exit page ............................................................................................................................ 29

7 Support ....................................................................................................... 30

8 History ......................................................................................................... 31

1 Handling and Safety Instructions Page 4 / 31

IMAGO Technologies GmbH

Strassheimer Str. 45; 61169 Friedberg; Germany; Tel. +49(0)6031-6842611

info@imago-technologies.com; www.imago-technologies.com

1 Handling and Safety Instructions

Depending on the operating conditions, the housing temperature can exceed

60 °C. There is a risk of injury!

Caution! LED risk group 2. Do not look directly into the LED flash!

EMC conformity according to EN/IEC 61000-6-2:2005 is qualified for cable

lengths ≤ 30 m.

Electrical installation should be executed without power applied to the device

and all connected devices.

Please take special note of the voltage range which may be applied to the device.

Otherwise, permanent damage to the device may result!

Due to the characteristics and physical principles inside flash memory, memory

cards have a finite lifetime dictated by the number of write operations.

Therefore, take care of the regular write operations to prevent an early flash

damage.

2 Introduction Page 5 / 31

IMAGO Technologies GmbH

Strassheimer Str. 45; 61169 Friedberg; Germany; Tel. +49(0)6031-6842611

info@imago-technologies.com; www.imago-technologies.com

2 Introduction

Even in perfect machines, unwanted situations occur from time to time, which lead to machine downtime

and thus to loss of production. It is crucial to know what exactly have led to the downtime for avoiding the

sequence of events next time. Often, observing a working machine by a naked eye does not bring much due

to the speed of the machine. Moreover, sometimes it is impossible or even dangerous. For such cases

IMAGO has developed the VisionDevice – Industrial DashCam 1 000(VD-IDC).

The Industrial DashCam 1 000 is a surveillance and remote monitoring camera for industrial environments

in a match box form factor. The concept is similar to a dash-cam, adapted for industrial environments. In-

dustrial DashCam continuously monitors a scene without storing anything. Upon an event, which can be

defined by the user, the Industrial DashCam saves the video on to local storage media. The length of the

video as well as its span in time before and after the event can be defined by user. There are three types of

possible events: it can be a hardware trigger, absence of a heartbeat or changes in image. The Industrial

DashCam offers two digital inputs for the events. Furthermore, the Industrial DashCam is equipped with a

powerful internal LED lighting unit (S-Mount only), which is perfect for difficult lighting conditions.

This document is the manual of the Industrial DashCam. Hardware related aspects as well as the WebGUI

operation are described.

2 Introduction Page 6 / 31

IMAGO Technologies GmbH

Strassheimer Str. 45; 61169 Friedberg; Germany; Tel. +49(0)6031-6842611

info@imago-technologies.com; www.imago-technologies.com

Main features

18 - 30 V DC power supply

Passive cooling without heat sink

Image sensors:

o 2560 × 2048 pixels

o Global shutter

o Monochrome or

Lens:

o C-Mount

Internal LED lighting:

o Controllable via software

o Automatic current regulation

Recording:

o Web-GUI available via the IP-address of the device

o File Format: MPEG4 (H.264)

o Frame rate: 1048 × 600: = 1133 fps

1200 × 680: = 1000 fps

1400× 1400: = 436 fps

o Recording time: ≤ 10 s (past, future or a mix of both)

o Mass storage 32 GB

o Trigger Modes:

Regular: Video is recorded when the digital input signal raises

Heartbeat: Video is recorded when the Heartbeat signal is lost

Software: Recording is started after a threshold of change is reached within a ROI

o Recording modes:

History: Video prior to the trigger event is saved

Future: Video after the trigger event is saved

Mixed: Video prior and after the trigger event is saved

Digital inputs / outputs:

o 4x digital output

o 4x digital input

Ethernet interface 1000 Mbit/s

Housing:

o 18 - 30 VDC power supply

o Passive cooling without heat sink

3 Operating Conditions Page 7 / 31

IMAGO Technologies GmbH

Strassheimer Str. 45; 61169 Friedberg; Germany; Tel. +49(0)6031-6842611

info@imago-technologies.com; www.imago-technologies.com

3 Operating Conditions

Power Supply:

Parameter Min. Typ. Max. Unit

Supply voltage 18 24 30 V

Supply current (@24V) A

Digital Input:

Parameter Min. Typ. Max. Unit

Input voltage range 0 25 V

Rising edge threshold voltage 7.4 9.4 V

Falling edge threshold voltage 4.7 6.3 V

Input resistance 15.5 k

Digital Output:

Parameter Min. Typ. Max. Unit

Output current 50 mA

Output high voltage VSupply - 0.2 V

Environment:

Parameter Value Unit

Weight, including cable g

Operating temperature °C

Operating humidity, relative, non-condensing %

Storage temperature -10 … +70 °C

Storage humidity, relative, non-condensing 5 … 95 %

4 Interfaces Page 8 / 31

IMAGO Technologies GmbH

Strassheimer Str. 45; 61169 Friedberg; Germany; Tel. +49(0)6031-6842611

info@imago-technologies.com; www.imago-technologies.com

4 Interfaces

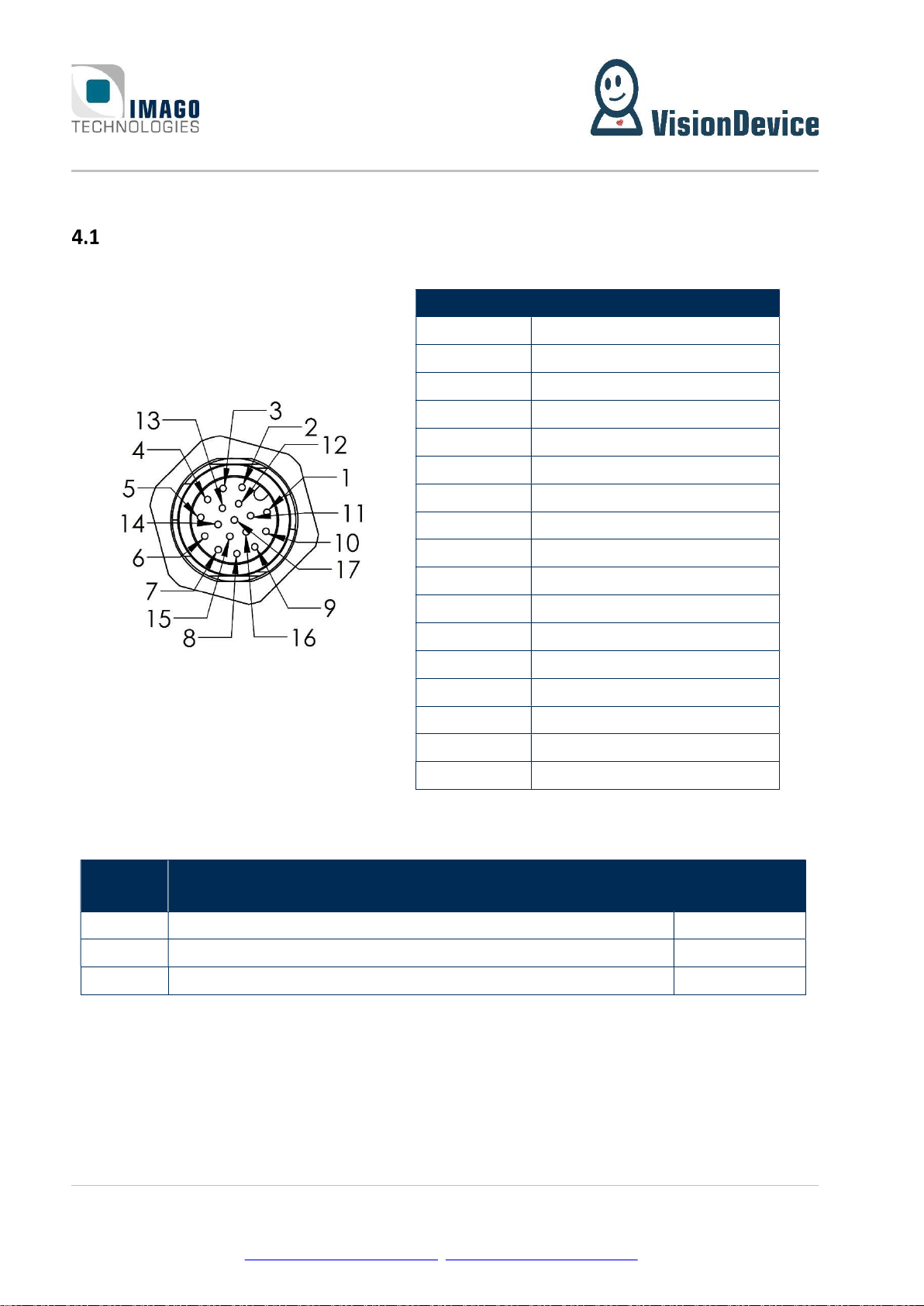

Power and I/O

A 17-pin M12 A-coded male connector is used for power supply and I/O signals.

Pin Number Function

1 GND (supply and I/O)

2 Power supply (+24 V)

3 RS-232 TX

4 RS-232 RX

5 Digital IN0

6 Digital IN1

7 Digital IN2

8 Digital OUT0

9 Digital OUT1

10 Digital OUT2

11 Digital OUT3

12 Digital IN3

13 USB D+

14 USB D-

15 Reserved

16 Reserved

17 VBUS (+5 V output)

We recommend using shielded cables, for example:

Length Product IMAGO

order code

1.5 m Phoenix contact 1430284 “SAC-17P- 1,5-35T/FS SH SCO” 10004440

3 m Phoenix contact 1430297 “SAC-17P- 3,0-35T/FS SH SCO” 10004441

5 m Phoenix contact 1430307 “SAC-17P- 5,0-35T/FS SH SCO” 10004442

There are also angled and solder versions available.

4 Interfaces Page 9 / 31

IMAGO Technologies GmbH

Strassheimer Str. 45; 61169 Friedberg; Germany; Tel. +49(0)6031-6842611

info@imago-technologies.com; www.imago-technologies.com

4.1.1 Digital I/Os

The following illustration shows the electrical equivalent circuit for the digital input and output signals:

Figure 1: Simplified digital I/O circuit

The input signals use a Schmitt trigger circuit with the power supply GND as voltage reference.

The digital output circuit uses open-emitter configuration. All outputs are internally supplied by the 24V

power input.

4 Interfaces Page 10 / 31

IMAGO Technologies GmbH

Strassheimer Str. 45; 61169 Friedberg; Germany; Tel. +49(0)6031-6842611

info@imago-technologies.com; www.imago-technologies.com

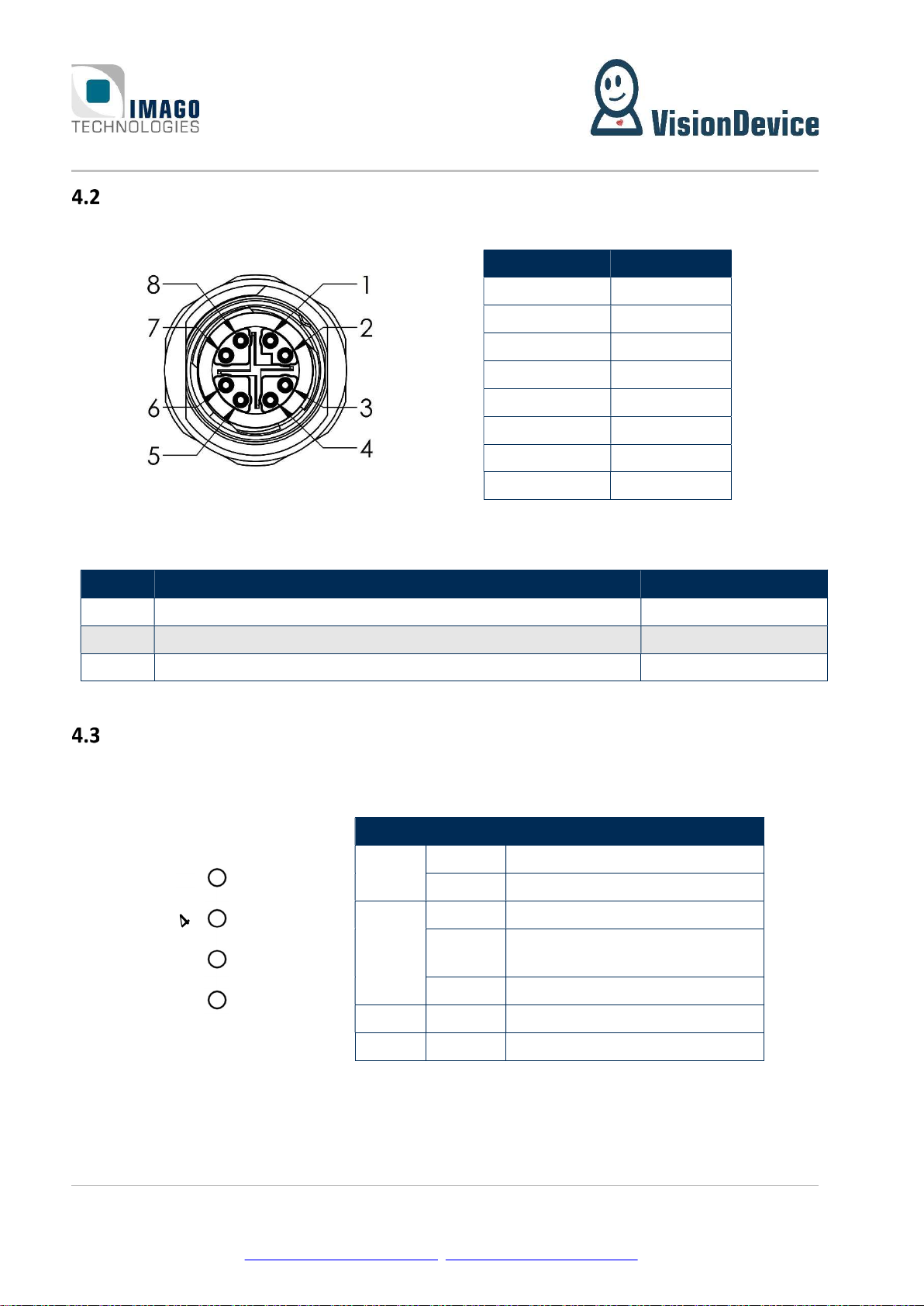

1 Gbit/s Ethernet M12

The Vision Cam uses an 8-pin M12 X-coded female connector for Ethernet.

Pin Number Function

1 D1+

2 D1-

3 D2+

4 D2-

5 D4+

6 D4-

7 D3-

8 D3+

We recommend using shielded cables, for example:

Length Product IMAGO order code

1 m Phoenix contact 1407471 “NBC-MSX/ 1,0-94F/R4AC SCO” 10007049

2 m Phoenix contact 1407472 “NBC-MSX/ 2,0-94F/R4AC SCO” 10007050

5 m Phoenix contact 1407473 “NBC-MSX/ 5,0-94F/R4AC SCO” 10008076

Status LEDs

The meaning of each status LED and its color is listed in the tables below.

LED Color Function

Green Ethernet link is up

Red Ethernet activity

Green Power On

Green

blinking USB recovery mode

Red Power off

U0 Green User LED 0

U1 Green User LED 1

U1

U0

5 Mechanical Drawings Page 11 / 31

IMAGO Technologies GmbH

Strassheimer Str. 45; 61169 Friedberg; Germany; Tel. +49(0)6031-6842611

info@imago-technologies.com; www.imago-technologies.com

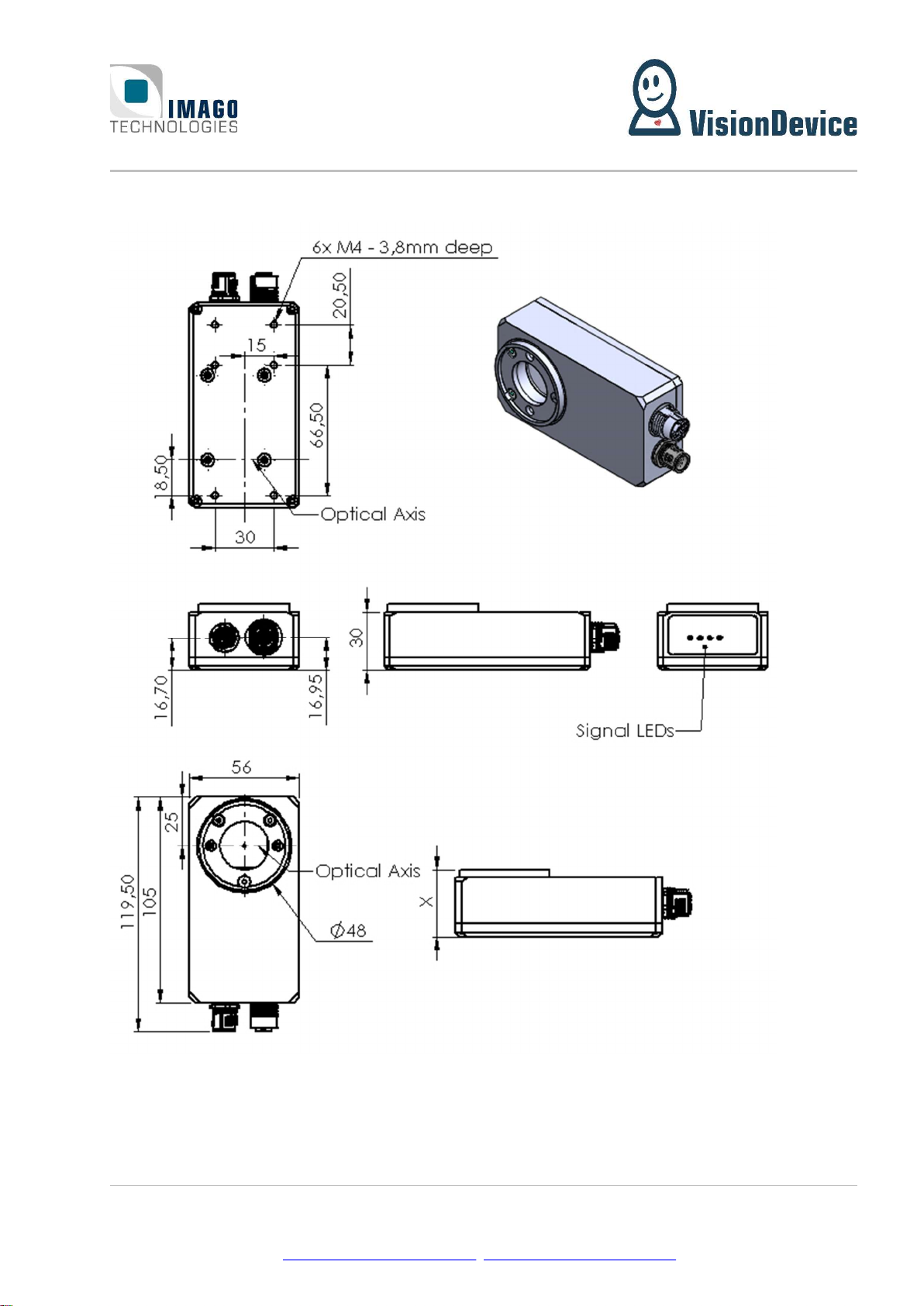

5 Mechanical Drawings

6 Web Based Graphical User Interface (WebGUI) Page 12 / 31

IMAGO Technologies GmbH

Strassheimer Str. 45; 61169 Friedberg; Germany; Tel. +49(0)6031-6842611

info@imago-technologies.com; www.imago-technologies.com

6 Web Based Graphical User Interface (WebGUI)

Overview

In this chapter the operation of the Industrial DashCam 1 000 by means of the WebGUI are described. The

GUI is a Web-based GUI, namely, it runs in an Internet-browser, for instance, Firefox, Microsoft Edge and so

on. Thus, it is platform and operation system independent. WebGUI is operational as long as modern

browser is supported.

The WebGUI has been designed with the universality as the basis idea combined with the minimalism con-

cepts. Under “universality” the authors mean the possibility to use the interface in a laboratory where low

level features and settings must be available and in a production line, where the functionality must be re-

duced to bare minimum. In addition to that, the “universality” refers to the possibility of using the interface

on devices, which do and do not support touch input.

The Industrial DashCam operation is independent from the WebGUI, namely the VD-IDC keeps operating

even if the WebGUI is closed.

Accessing the GUI

The GUI is accessible from a browser running on a PC or a laptop. The PC or laptop must be connected to

the same network (also logical, not only physical) as the Industrial DashCam. IP-address or the serial number

of the Industrial DashCam is used for accessing the WebGUI. IP-address is entered into the address-line of

the browser. Alternatively, the serial number can be used. The user should enter the serial number in the

address line of the browser omitting the dashes and append “.local” to it. For example, assuming the

serial number on the device is “VSPV-3003-100001”, the following should be entered into the browsers ad-

dress line “VSPV3003100001.local”.

Welcome Page

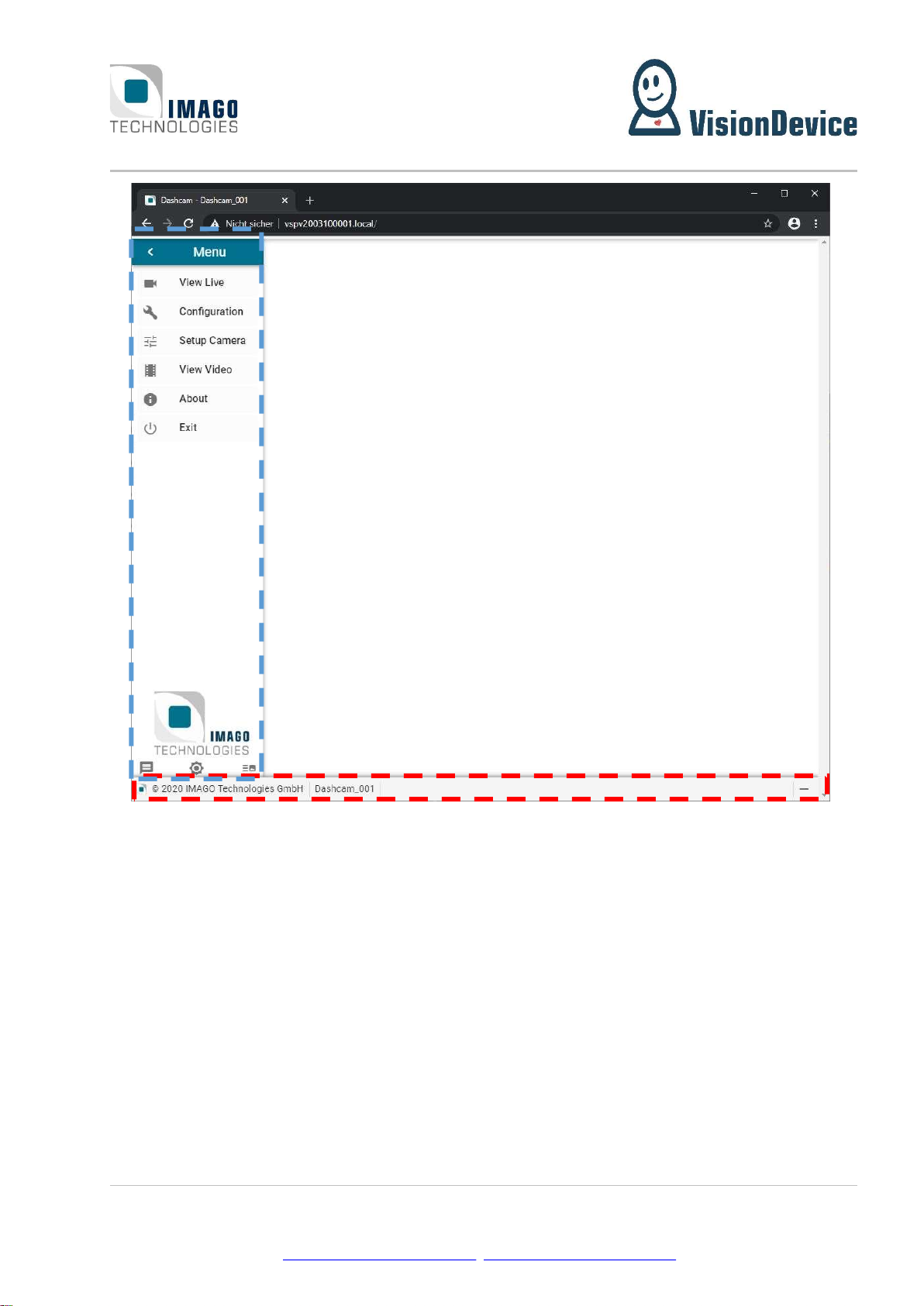

Welcome page is the first page shown to the user on the startup of the Industrial DashCam’s WebGUI. Wel-

come page contains the Indicator bar and the Navigation panel (Menu). The latter can be placed on the left,

as presented on Figure 2, or on the right side. Indicator bar is always located on the bottom of the page and

contains most used information about Industrial DashCam.

6 Web Based Graphical User Interface (WebGUI) Page 13 / 31

IMAGO Technologies GmbH

Strassheimer Str. 45; 61169 Friedberg; Germany; Tel. +49(0)6031-6842611

info@imago-technologies.com; www.imago-technologies.com

Figure 2: Welcome page. Navigation panel on the left (marked with dashed blue line); Indicator bar on the bottom

(marked with red dashed line).

6 Web Based Graphical User Interface (WebGUI) Page 14 / 31

IMAGO Technologies GmbH

Strassheimer Str. 45; 61169 Friedberg; Germany; Tel. +49(0)6031-6842611

info@imago-technologies.com; www.imago-technologies.com

6.3.1 Indicator bar

Indicator bar contains several indicators, see Figure 3.

There are indicators for the following information:

1. IMAGO Technologies Copyright note

2. Name of the system (can be changed on the Configuration page).

3. “Saving in progress” indicator.

The indicators are numbered in Figure 3, the numbers correspond to the list above. When placing a mouse

courser above an indicator a description of its function will appear in a pop-up blob.

1 2 3

Figure 3: Indicator bar. The name of the Industrial DashCam is “Dashcam_001”, as indicated by 2. The video saving is

currently not in progress otherwise an icon of a diskette would be shown at 3.

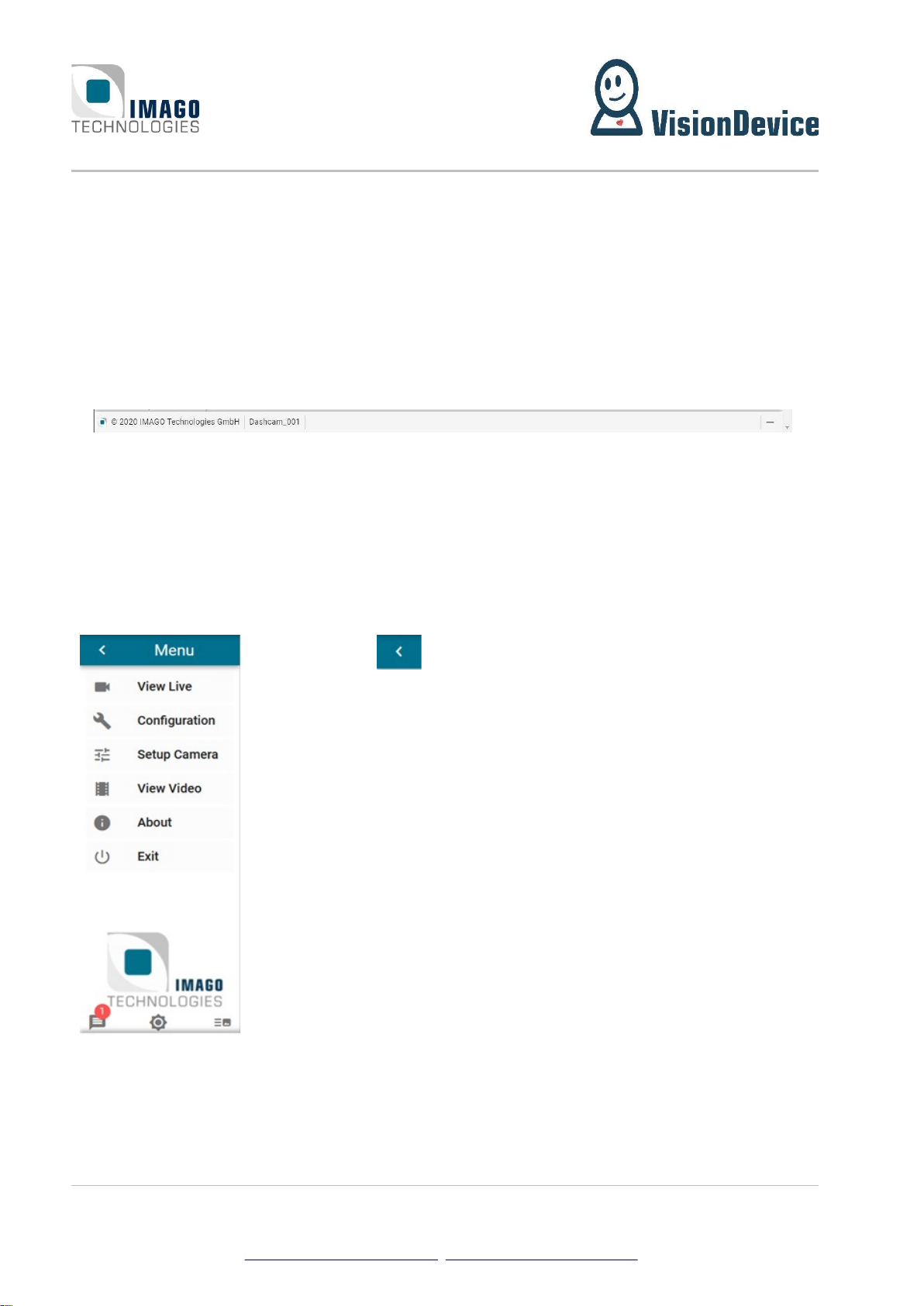

6.3.2 Navigation panel

Navigation panel consists of the buttons for accessing the functions of the Industrial DashCam, setting the

appearance of the GUI and displaying the Event Log.

Press the arrow in order to hide or show the menu.

Live View page

Configuration page

Camera setup page

Visualization page

About page

Exit page

Event Log Theme toggle (dark or bright) Toggle menu position (left

or right side of the screen)

Figure 4: Navigation panel in the full state with the function of the buttons.

6 Web Based Graphical User Interface (WebGUI) Page 15 / 31

IMAGO Technologies GmbH

Strassheimer Str. 45; 61169 Friedberg; Germany; Tel. +49(0)6031-6842611

info@imago-technologies.com; www.imago-technologies.com

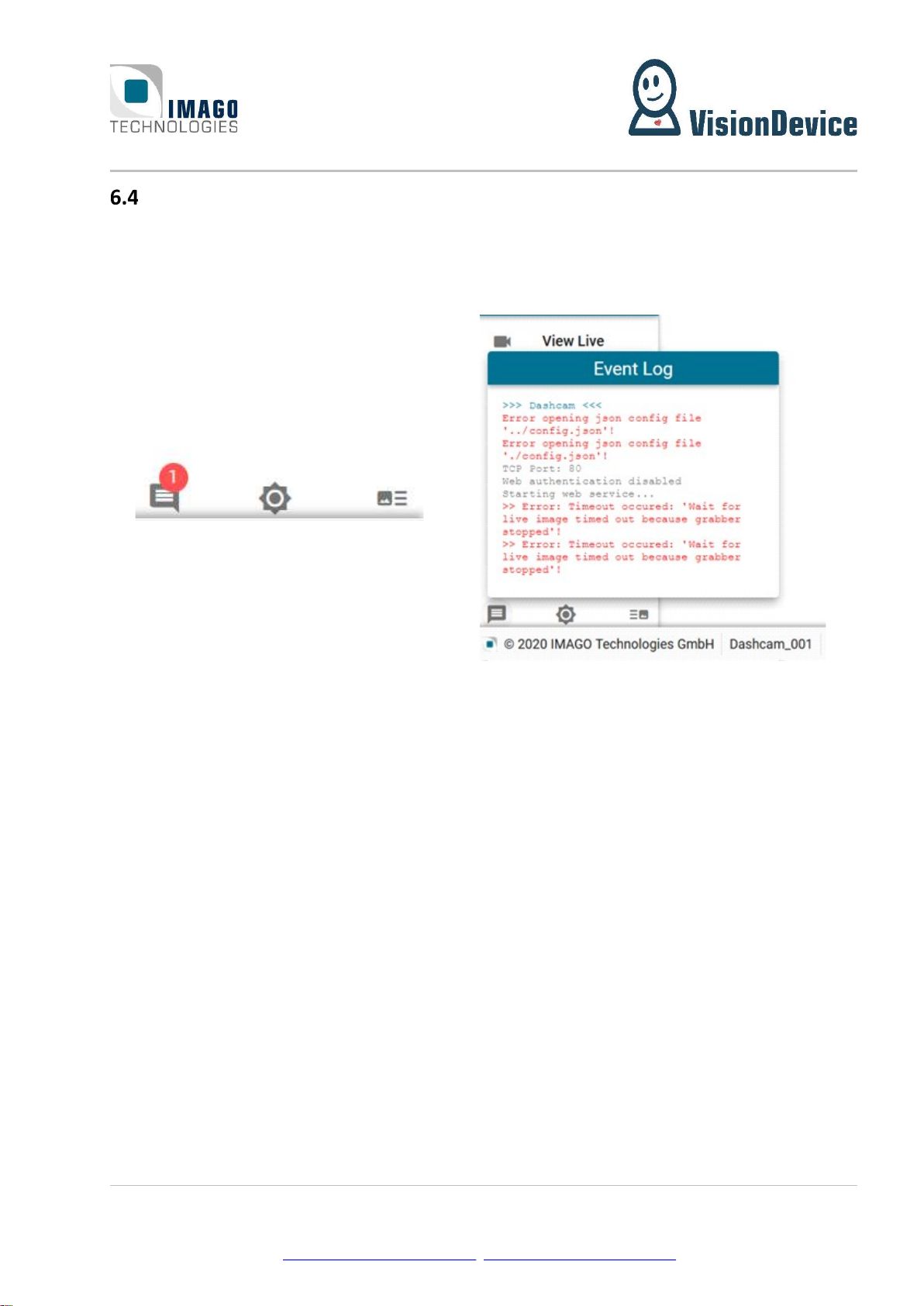

Event Log

Event log contains the messages of the Industria lDashCam, such as error messages etc. It is hidden by de-

fault, see Figure 4. In case of any error messages the button will show the number of unread messages in a

red circle. Once the button is clicked all the messages are marked as read and remain in the Event Log, see

Figure 5.

Figure 5: Left, Event Log button indicating one error. Right, Example of the Event log with an error

6 Web Based Graphical User Interface (WebGUI) Page 16 / 31

IMAGO Technologies GmbH

Strassheimer Str. 45; 61169 Friedberg; Germany; Tel. +49(0)6031-6842611

info@imago-technologies.com; www.imago-technologies.com

View Live Page

View live page is for visualizing the image the Industrial DashCam is acquiring. This page should be used for

setting focus, choosing field of view and so on.

For starting the acquisition “Start” button, located at the bottom of the page, should be pressed. Stopping

the acquisition is performed by means of the “Stop” button. During the acquisition the “Start” button is

grayed out and vice versa the “Stop” button is grayed out when the acquisition is not running, see Figure 6.

Note, that when the View Live is active, all of the other buttons are grayed out. In order to return onto the

Welcome page, the “Back” button must be pressed.

Figure 6: View Live page. This shows the live view while no acquisition is running. Mouse cursor position is indicated

in “x” and “y” text fields.

By pressing the “Trigger” button a software trigger event can be generated, and the video will be recorded

according to the recording mode set by the user. Even a hardware encoder is not able to create the MP4

video in real time. Therefore, depending on frame rate and length of sequence writing the video will take

several seconds. While writing the video further trigger impulses are ignored.

Text fields “x” and “y” are indicating the mouse cursor position in image-related coordinate system. “fps”

shows the current acquired frames per second. The scale can be selected in the drop-down list in the right-

bottom corner.

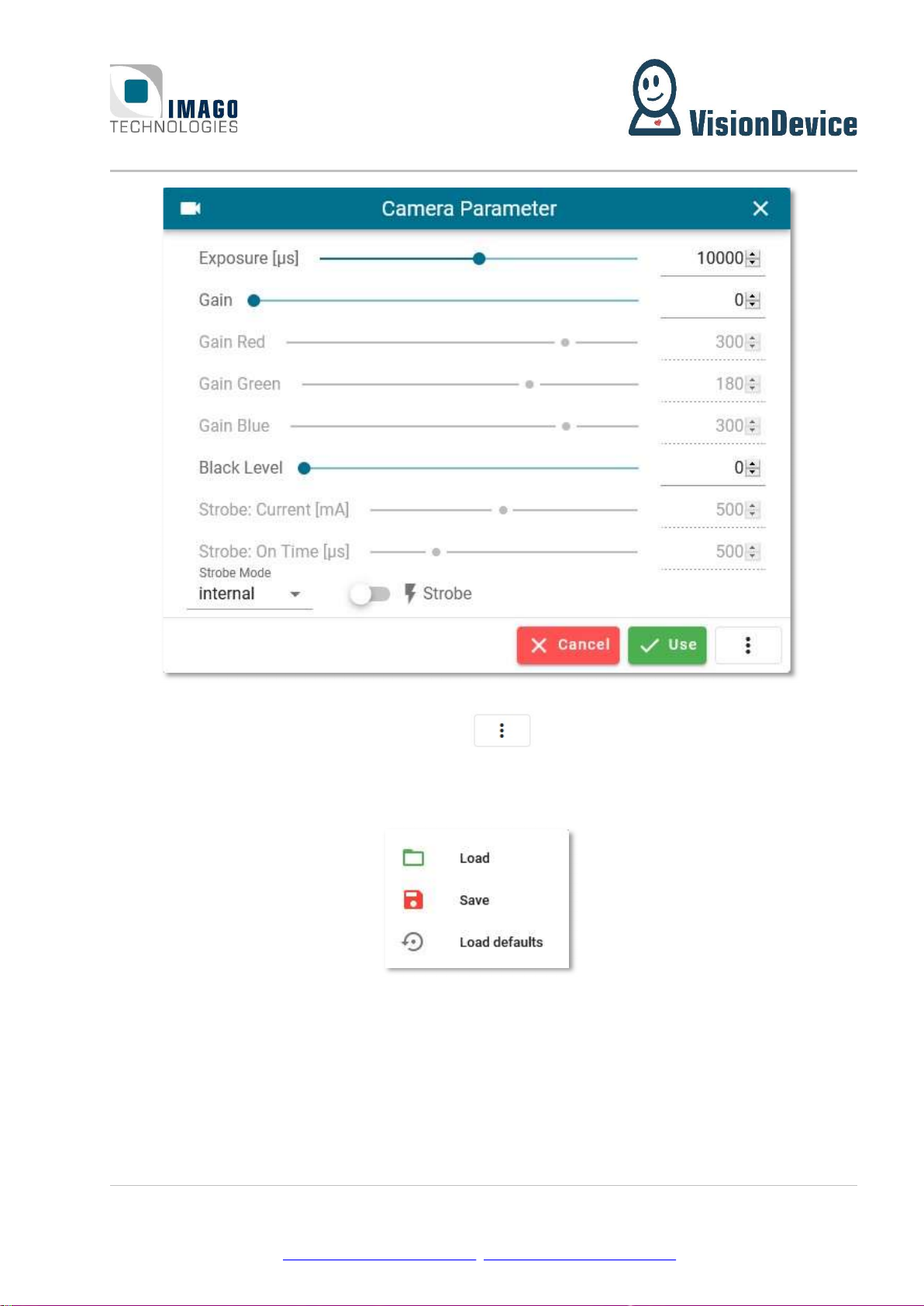

“Setup Camera” button opens the Camera setting dialog, which is also available via the Configuration page.

The dialog is for adjusting acquisition parameter, in contrast to the Industrial DashCam parameters as Re-

cording mode, Trigger event types and others. The dialog allows adjusting exposure time, gain, gain per

channel (in case of the Bayer sensor) and the black level. While acquisition is running, the user can change

the area of interest with the sliders below and right of the image.

To make the selected area take effect, press the “Set AOI” button. For the Industrial DashCams equipped

with a strobe, it also provides the corresponding control. Setting a long exposure time might lead to decrease

of the acquisition framerate, therefore please consider opening the aperture or bringing more light into the

scene.

6 Web Based Graphical User Interface (WebGUI) Page 17 / 31

IMAGO Technologies GmbH

Strassheimer Str. 45; 61169 Friedberg; Germany; Tel. +49(0)6031-6842611

info@imago-technologies.com; www.imago-technologies.com

Figure 7: Camera parameter dialog

All the settings can be saved or loaded by hovering button and choosing “Save” or “Load” from

the drop-down menu. The settings are applied only after pressing the “Use” button. Pressing the “Cancel”

or “X” button results in closing the dialog. Further the drop-down offers the possibility to “Load defaults”

for the sensors to setup the camera.

Figure 8: Camera Parameter drop-down

The drop-down menu “Strobe Mode” can be used to select the source for the strobe. “Internal” is to use

the internal LEDs of the Industrial DashCam (S-Mount only), whereas “External” sets up the digital output

0 to send out the exposure signal so an external LED can be triggered. When setting the mode to “Both”,

internal LEDs as well as the digital output 0 are set up to be used (Internal still S-Mount only).

6 Web Based Graphical User Interface (WebGUI) Page 18 / 31

IMAGO Technologies GmbH

Strassheimer Str. 45; 61169 Friedberg; Germany; Tel. +49(0)6031-6842611

info@imago-technologies.com; www.imago-technologies.com

Configuration Page

The Configuration page is a service page containing the hardware related settings, which consists of four

tabs: “General”, “Camera”, “Dashcam” and “Triggering”, see Figure 9. The Configuration page is blocking,

thus clicking outside the page will close it, as well as pressing “X” or “Cancel” button. All the settings can

be saved or loaded by pressing button and choosing “Save” or “Load” from the drop-down menu.

The settings are applied only after pressing the “Use” button, some settings might require restart of the

application or even reboot of the whole system.

Figure 9: Configuration page and three tabs, the “General” is selected

6 Web Based Graphical User Interface (WebGUI) Page 19 / 31

IMAGO Technologies GmbH

Strassheimer Str. 45; 61169 Friedberg; Germany; Tel. +49(0)6031-6842611

info@imago-technologies.com; www.imago-technologies.com

6.6.1 Setting IP-address and Web-Service Port

By default, an Industrial DashCam device is configured for getting IP-address via DHCP. It is possible to assign

a static IP-address and the gateway address to the device from the WebGUI. In order to perform this oper-

ation, press the “Set IP Address” button on the “General” tab, see Figure 9. The Set IP Address dialog will

show up. Pay attention to the warnings below the text fields. Enter the IP-address and the gateway address

and press “Set” button. For the changes to take place the Industrial DashCam must be rebooted. This can

be done on the Exit page.

Note, that after changing the IP-address of the Industrial DashCam and rebooting, the WebGUI will be ac-

cessible under different IP-address. Please make sure to update the address in the browser address field.

Accessing the WebGUI by serial number is not affected with change of IP address.

Web service port field specifies the TCP-IP port where the WebGUI is accessible. Default value used by a

browser is 80. If the port is set to any other value, then the port must be specified in the address line after

the IP-address, with a colon as a separation mark. For instance, the port is set to 8945 and the IP-address is

192.152.132.122, then the line entered to access the WebGUI is “192.152.132.122:8945”. Additionally,

pay attention to the warning displayed above the text field. In order for the port changes to take place the

application must be restarted.

6.6.2 Language and System Name

In the Language drop-down menu interface language can be chosen, the default value is English. There are

two languages available at the moment: English and German. System name is displayed in the Indicator

panel, see Welcome page chapter. This feature helps to distinguish between the interface of different sys-

tems, when several Industrial DashCams are connected to the same network. Enter desired name into the

“System Name” test field and press “Use” button.

The System name can also be used as overlay on the image, for that make sure the “Show Overlay” check-

box is checked and press the “Use” button. Note, that overlay will only be available on the videos recorded

after the button “Use” is pressed. Already recorded videos though being on the Industrial DashCam’s SD-

card remain unchanged.

Finally, the user can reset the counting up number within the naming of the video files by pressing “Reset

video count” on the general configuration page.

6.6.3 Synchronize Time

The “Sync. Time” Button on top of the general tab can be used to synchronize the time between the

browser in use and the Industrial DashCam. This means the local time of the Industrial DashCam will be set

to the time of the browser and thus the system that is used to enter the Web-GUI.

Note: The synchronization of the time will only last until the camera is rebooted or shut down the next

time. After this, the user is required to synchronize the time manually again.

6 Web Based Graphical User Interface (WebGUI) Page 20 / 31

IMAGO Technologies GmbH

Strassheimer Str. 45; 61169 Friedberg; Germany; Tel. +49(0)6031-6842611

info@imago-technologies.com; www.imago-technologies.com

6.6.4 Camera Settings

Most settings like exposure time, gain, gain per channel and others can be set via the Camera Parameter

dialog, see Figure 10 and refer to the View Live Page section for more details on this dialog. The check box

“De-Bayer” is now reserved for the Industrial DashCam with Bayer filters.

Figure 10: Configuration page and three tabs, the “Camera” is selected

The button “Sensor” opens a dialog where the user can select between acquiring images from the sensor

or taking previously saved image sequences from the file system.

“Illumination Module” configures parameters of an optionally installed Universal Illumination Module,

which allows different light configurations for consecutive steps.

Table of contents