imants ShockWave 100 User manual

ShockWave

100 / 155 / 210

Manual

998-094-2

Original document

Copyright © Imants® BV

Imants® BV reserves the right to alter parts at any desired moment, without prior or direct notification to the purchaser.

The contents of this document may equally be amended without prior warning.

For information about settings, maintenance work or repair that this document does not cover, you are recommended to contact your supplier’s service

department.

This document has been produced with the greatest of care. Imants® BV cannot, however, accept any responsibility for any errors in this document or

any consequences they may have.

All rights reserved. Nothing in this document may be duplicated, stored in an automated database, or made public, in any form or way, whether electronic,

mechanical, by photocopying, recording or in any other way, without prior written permission from Imants® BV. This also applies to the associated

drawings and diagrams.

100 / 155 / 210

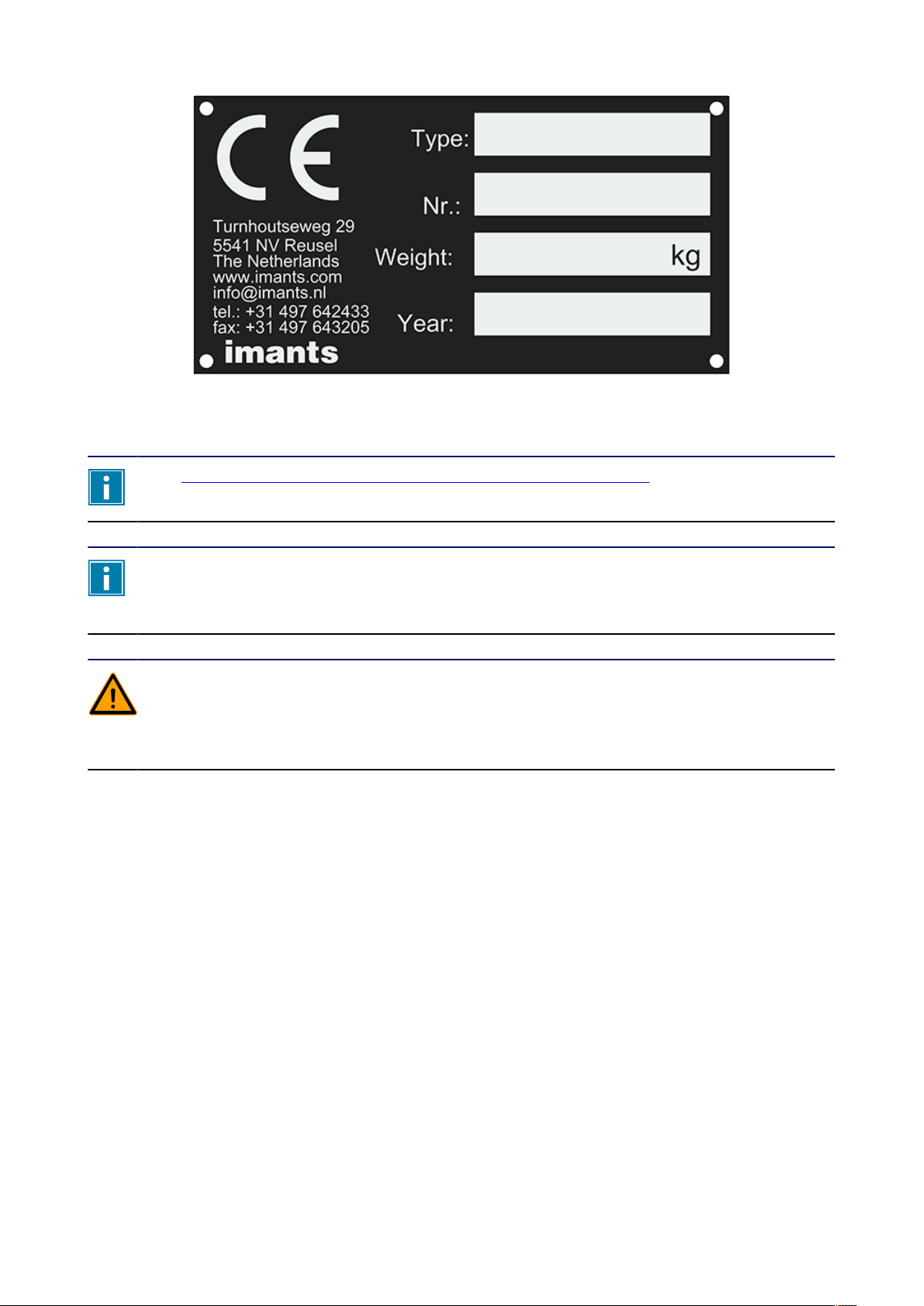

Illustration 1: Type plate

See Position of the warning stickers and type plate on the machineon page 14 for the

exact location of the type plate on the ShockWave.

Keep the details of your type plate in a safe location. If you have any questions about your

100 / 155 / 210ShockWave or wish to order parts, those specific details will allow us to help

you quickly and efficiently.

Carefully read the full contents of this document. A failure to do so may result in serious

injury or damage to the 100 / 155 / 210ShockWave. Keep this document in a safe place.

Always ensure that everybody who uses the 100 / 155 / 210ShockWave or performs

maintenance on it has read and understood the contents of this document.

Table of contents 5

Table of contents

1 Foreword........................................................................................................................................7

2 Safety instructions....................................................................................................................... 8

2.1 Explanation of pictograms...................................................................................................... 8

2.1.1 Hazard indications.......................................................................................................... 8

2.1.2 Meanings of pictograms................................................................................................. 9

2.1.3 Meanings of operating pictograms............................................................................... 10

2.2 General safety instructions................................................................................................... 11

2.3 Warning stickers on the machine.........................................................................................13

2.4 Position of the warning stickers and type plate on the machine.......................................... 14

2.5 Operator’s responsibilities.................................................................................................... 15

3 Residual risks............................................................................................................................. 16

4 General description of machine............................................................................................... 17

5 Machine specifications.............................................................................................................. 18

5.1 ShockWave........................................................................................................................... 18

6 Loading and unloading the machine....................................................................................... 19

7 Putting the machine into operation..........................................................................................20

7.1 Putting the PTO shaft into operation....................................................................................21

8 Transport..................................................................................................................................... 22

9 Working with the machine.........................................................................................................23

9.1 Tractor settings..................................................................................................................... 25

9.2 Coupling the machine...........................................................................................................26

9.3 Machine settings...................................................................................................................27

9.3.1 Fitting and configuring the coulters.............................................................................. 27

9.3.2 Runner.......................................................................................................................... 28

9.4 Starting and stopping work and settings..............................................................................29

9.5 Blocking the machine........................................................................................................... 31

9.6 Uncoupling the machine....................................................................................................... 32

10 Maintenance of the machine................................................................................................... 33

10.1 Daily inspection...................................................................................................................33

10.2 Drive train........................................................................................................................... 34

10.2.1 PTO drive shaft...........................................................................................................34

10.2.2 Gear box..................................................................................................................... 35

10.2.2.1 Middle gearbox................................................................................................... 36

10.3 Periodic maintenance and inspection: Checking the vent nipples..................................... 37

10.4 Wear parts.......................................................................................................................... 38

Table of contents 6

10.4.1 ReplaceAeration blade................................................................................................38

11 Cleaning..................................................................................................................................... 39

12 Decommissioning..................................................................................................................... 40

13 Warranty.....................................................................................................................................41

14 Appendix/Appendices.............................................................................................................. 42

15 CE declaration...........................................................................................................................43

Foreword 7

1Foreword

First of all, we would like to congratulate you on purchasing a Imants® machine. You have

chosen a high-quality product. If used correctly, your machine will bring you many years of

enjoyment.

This Manual is an important document to ensure the machine is used correctly. It contains all the

information required to use the machine safely and optimally.

We recommend that you read this Manual thoroughly and that you study and follow all the

instructions before using the machine for the first time. The illustrations used in this Manual may

differ from the configuration of your machine; they are merely intended to explain a working

principle.

Please contact your point of sale/dealer should there be any questions or ambiguities as regards

this Manual.

We update our manuals regularly. Your suggestions help us to make our manuals even more user

friendly. You can e-mail your suggestions to [email protected] with ‘manuals’ in the subject line.

Imants® BV accepts no responsibility whatsoever for any damage or consequential damage due

to the incorrect use of the machine.

For this Manual, it is a “Original document”.

Safety instructions 8

2Safety instructions

The machine has been carefully designed and professionally built to allow it to be worked with

safely. The CE Declaration confirms this. There are always however hazards and safety risks that

cannot be excluded. The functions of the machine and its operation by the operator give rise to

these hazards and risks.

This chapter covers the safety instructions and precautions, how these are brought to your

attention and with which the operator must comply. It is extremely important that you are properly

familiar with the safety instructions and rules and that you respect them in all circumstances!

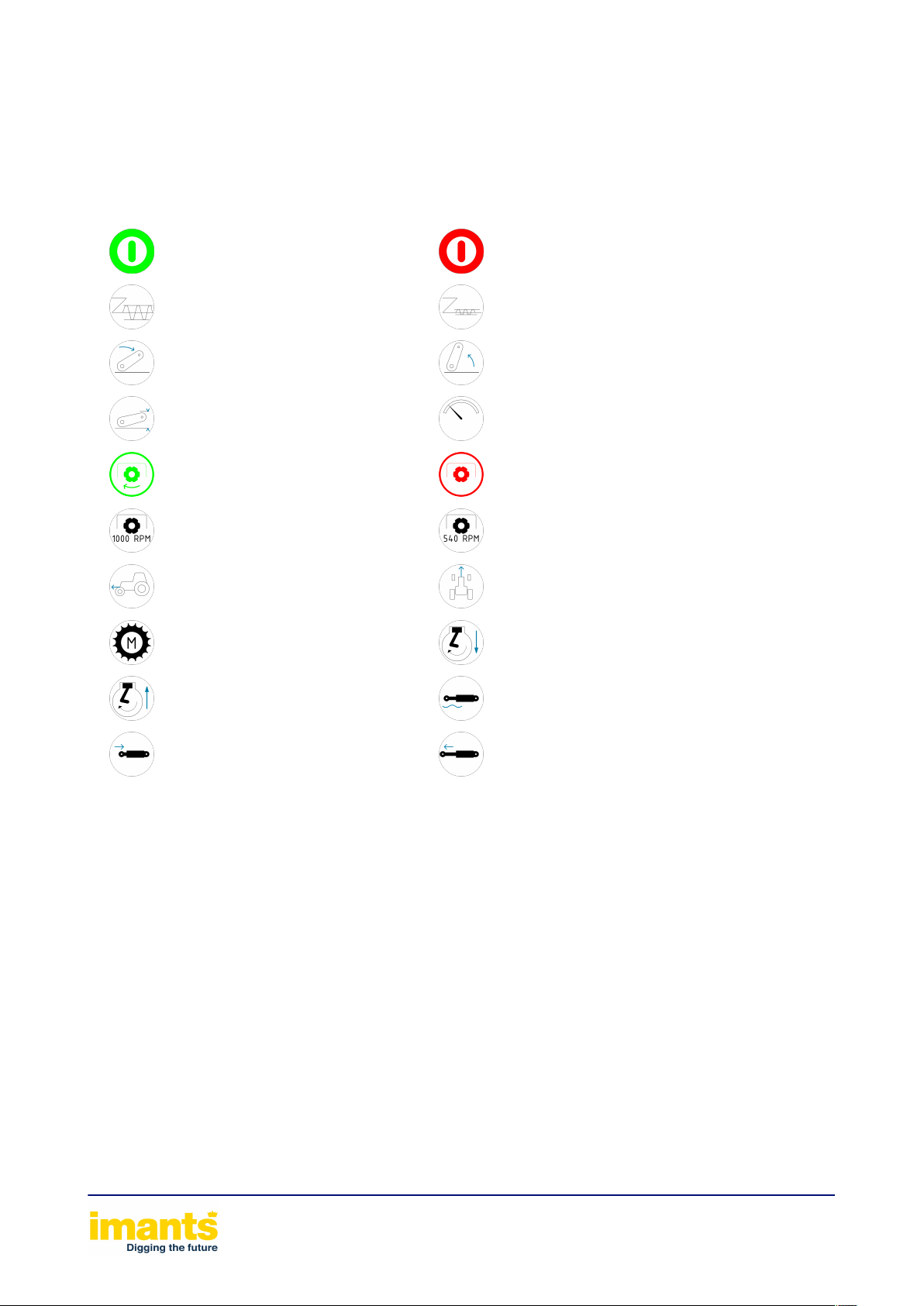

2.1Explanation of pictograms

Pictograms are present under many headings in this manual. Symbols have also been applied to

the machine. In this chapter, you can see what these pictograms and symbols mean, what they

refer to, or what they are warning you about.

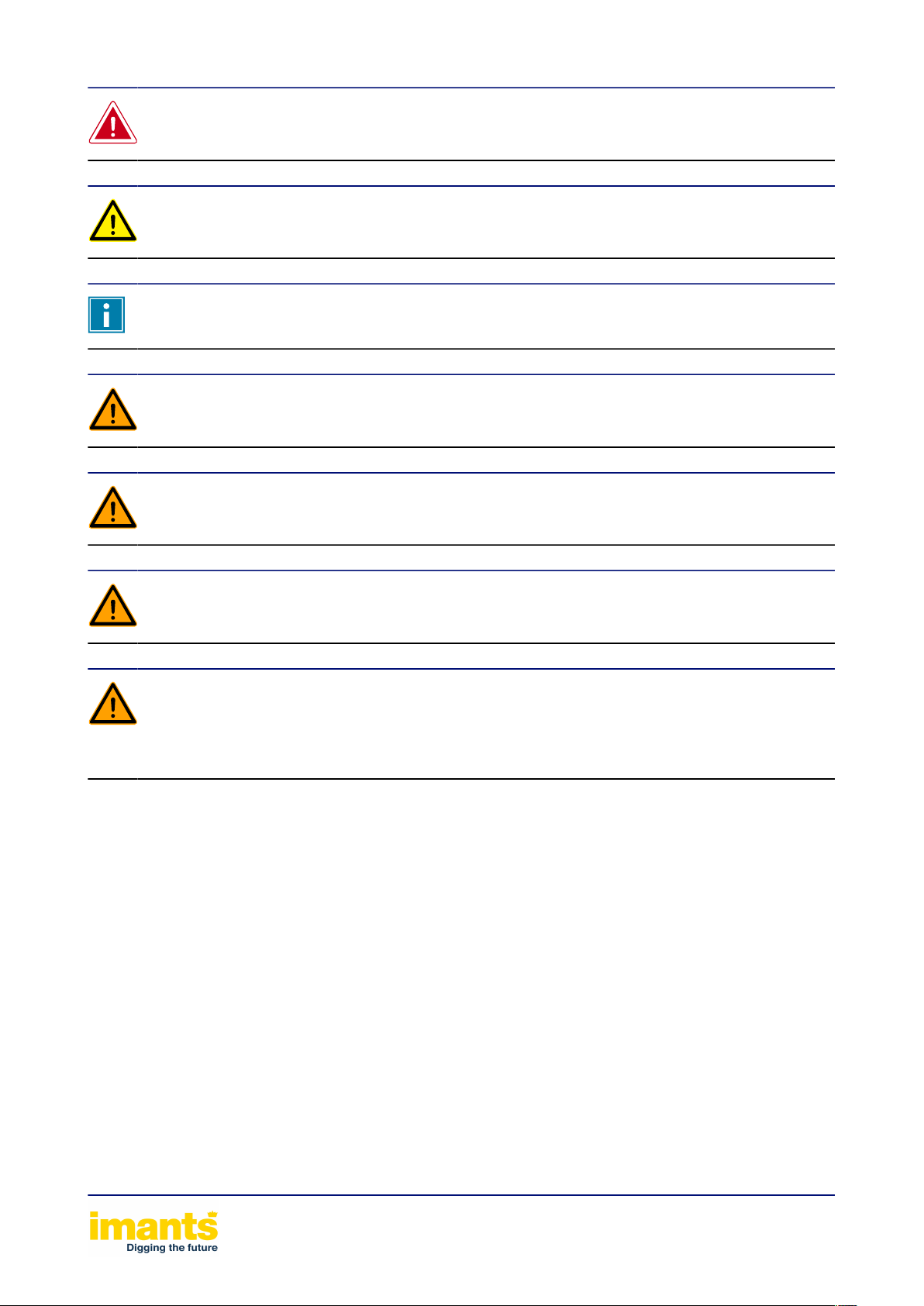

2.1.1Hazard indications

The symbols below indicate a possible danger of personal injury. The symbol is composed of an

equilateral triangle surrounding an exclamation mark.

Warning pictograms that are used in the Manual but are not present on the machine as stickers.

Warns of hazardous situations which must be avoided absolutely and are likely to result in

death or serious injury.

Warns of a hazardous situation that, if not avoided, could lead to death or serious injury.

Warns of a hazardous situation that, if not avoided, could lead to slight or more significant

injury.

This symbol is not a hazard symbol but rather an information symbol.

Provides additional information aimed at facilitating or improving the use of the machine.

Safety instructions 9

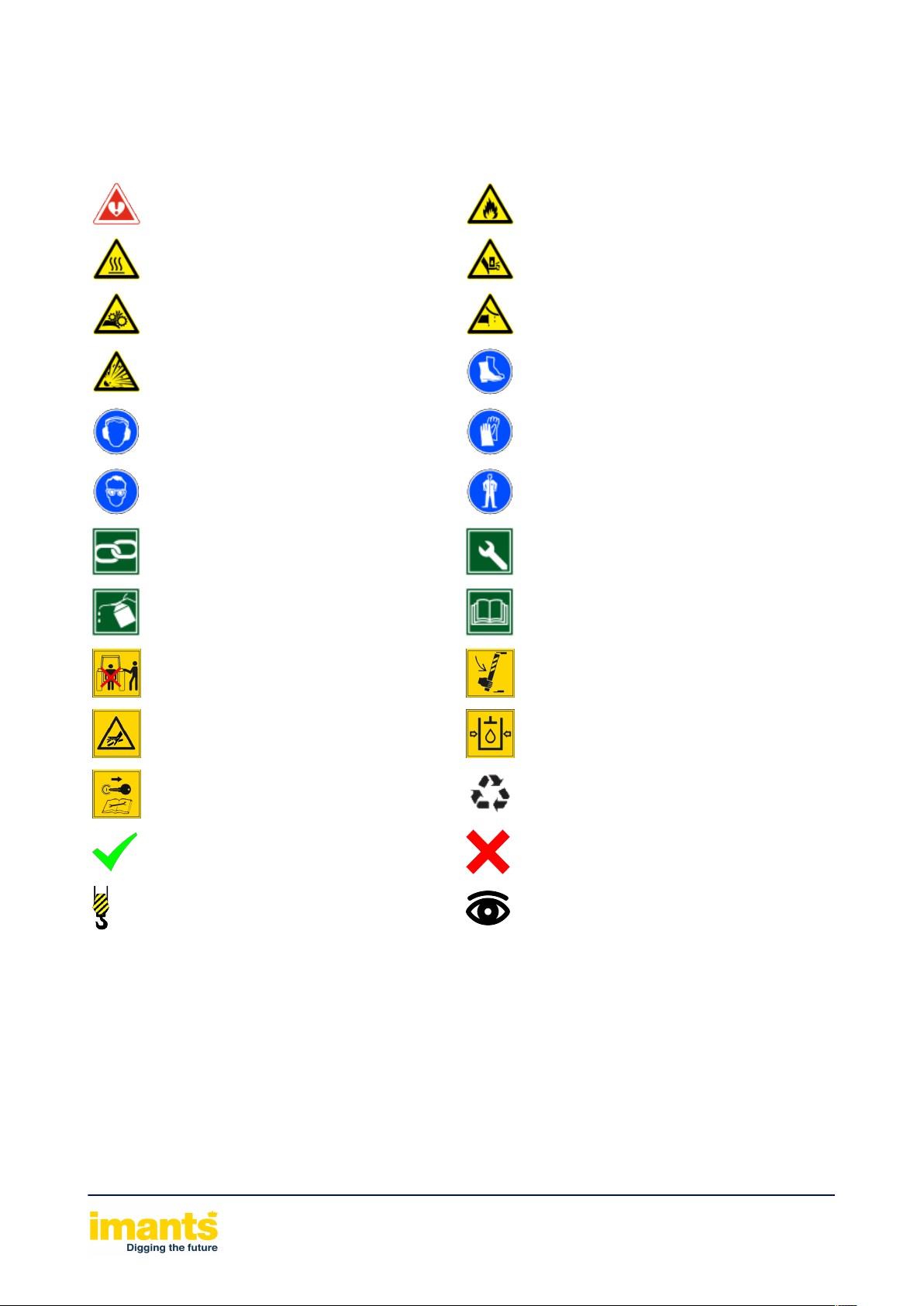

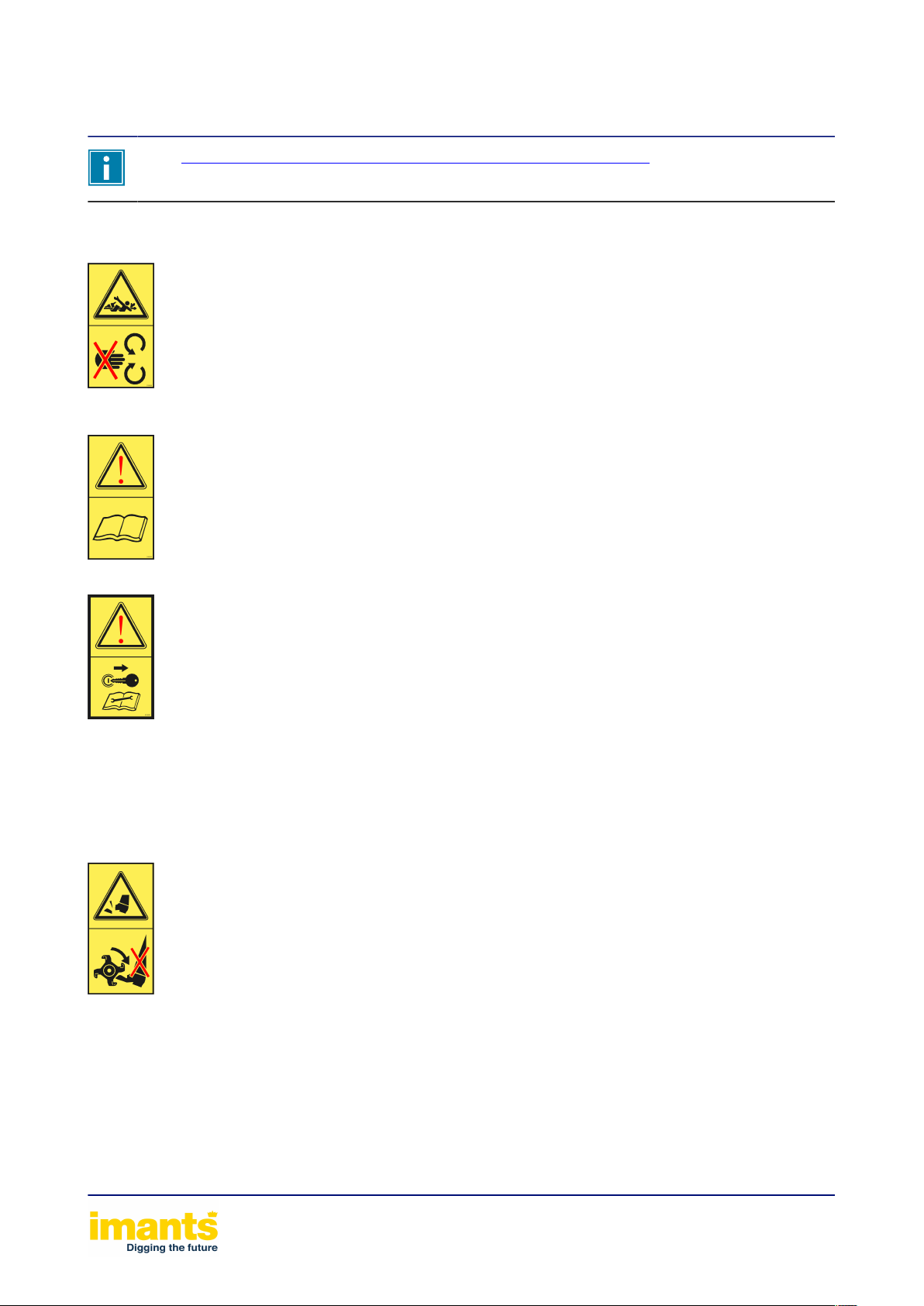

2.1.2Meanings of pictograms

Below, you can see what the illustrations in the manual mean, what they refer to, or what they are

warning you about.

Danger of personal injury Fire hazard

Hot surfaces Trapping risk

Moving parts Leakage

Explosive substances Safety footwear

Hearing protection Gloves

Eye protection Clothing stipulations

Document reference Use of tools

Material use Read the manual

Danger of becoming trapped due to

being present within the lifting range Danger of becoming trapped due to the

machine lowering unintentionally

Danger from hydraulic oil under high

pressure as a result of leaking hydraulic

hoses! Max. hydraulic system pressure

Unintentional starting and rolling away

of the machine Recycle

Acceptable, correct Unacceptable, wrong

Use lifting hook Visual inspection

Safety instructions 10

2.1.3Meanings of operating pictograms

Operating pictograms indicate schematically what action must be taken or what setting must be

chosen.

The summary below includes all possible pictograms, which does not mean they are all used in

this Manual:

On Off

Hitch tension adjustment Hitch position adjustment

Hitch downwards Hitch upwards

Hitch working depth Pressure gauge

PTO on PTO off

PTO 1000 rpm PTO 540 rpm

Front wheel drive Direction of travel

Engage gear Engine speed down

Engine speed up Ram in floating position

Ram in Ram out

Safety instructions 11

2.2General safety instructions

The user must hold a valid tractor driving licence in order to operate the machine.

The user must be at least 16 years old, unless the local legislation stipulates a higher

minimum age. The higher age limit shall prevail.

The user of the machine is responsible at all times for compliance with local safety

regulations and guidelines.

The user must have read through the whole contents of this manual and must follow to the

letter the instructions therein.

Keep this manual and that of the PTO drive shaft within reach.

Use the machine solely for the purpose it was designed for.

The machine may only be used and maintained by persons who are familiar with the

machine and have been made aware of the risks. No-one who could not be expected to

make correct use of the machine is to be permitted to commission or operate the machine.

No one should be standing between the machine and the tractor while these are being

coupled or uncoupled.

All safety facilities must be assembled on to the machine and be in good conditions. Never

remove or open a guard when the machine is running.

Always follow the specifications and requirements set by the manufacturer of the tractor in

relation to its use. Please refer to Tractor manual.

Always comply with the requirements regarding the maximum load of the front and rear

axles, given by the tractor manufacturer.

Safety instructions 12

Standing on or within the range of the machine during work is prohibited. This also applies

during transport.

The maximum load of the tractor tyres, given by the tyre manufacturer, should not be

exceeded during operation of the machine.

Warning labels should always be legible.

Work may only be carried out under a raised machine if the machine has been properly

supported.

For reasons of quality and safety, only use original Imants® parts.

Maintain the machine as indicated later in the manual. Only perform this work when the

machine is at a complete stop. Remove the key from the tractor’s ignition.

Modifications, additions or developments on or to the machine are not allowed without the

written permission of Imants BV. This includes welding on load bearing parts. Without this

written authorisation, Imants BV’s responsibility for the CE marking is invalidated and is

passed on to the buyer.

Safety instructions 13

2.3Warning stickers on the machine

See Position of the warning stickers and type plate on the machineon page 14 for the

position of the warning stickers.

The warning stickers below can be found on the machine.

Danger of hands or arms being pulled in or locked in by the moving parts

of the power transmission.

It could cause serious injury, possibly leading to the loss of body parts.

Never open or remove the protective devices while the tractor engine is running

and the PTO drive shaft and/or hydraulic system are connected.

Read and observe the operating instructions and safety regulations before

you operate the machine.

Risk of the tractor and machine unexpectedly being started and rolling

away while work is being carried out on the machine, such as installation,

set-up, troubleshooting, cleaning, maintenance and repair work.

There is a risk of serious injury or even death.

•Before any intervention on the machine, protect the tractor and the

machine against being unintentionally started and against unintentional

rolling away.

•Read the relevant sections in the user manual and follow the

instructions.

Danger of feet being cut or torn off altogether. Keep away from exposed

moving parts that are part of the work process!

It could cause serious injury, possibly leading to the loss of body parts.

•Keep your feet away from the hazardous area while the tractor engine is

running and the PTO drive shaft and/or hydraulic system are connected.

•Wait until the machine’s moving parts come to a complete standstill

before you place your foot in the hazardous area.

Safety instructions 14

2.4Position of the warning stickers and type plate on the

machine

Warning labels should always be legible.

The illustration below shows where the safety stickers and type plate are to be found on the

machine

Illustration 2: Position of the pictograms and type plate

Safety instructions 15

2.5Operator’s responsibilities

It is the operator’s responsibility to ensure the machine is used safely. If the operator does not

obey the safety instructions and rules, serious physical injury and major damage to the machine

and the surroundings could be the result.

The operator must

•always be trained and qualified to operate the machine,

•remain alert and avoid hazardous situations,

•always conduct an inspection before use,

•conduct functional tests,

•check the workplace,

•keep bystanders at a safe distance,

•use the machine only for its intended purpose,

•wear the correct protective equipment and work clothing,

•not work under the influence of medicines, alcohol or drugs,

•be fully aware of the safety and usage rules, and

•know what the local government and official body instructions and rules are.

Residual risks 16

3Residual risks

The people operating the machine are responsible for ensuring the work is carried out

safely.

Every machine has inherent hazards. It is therefore always recommended to exercise the

greatest caution when working.

Even if all the safety precautions are taken and the machine is used in accordance with the

regulations, there are still residual risks:

Residual risks

•Contact with rotating parts of the machine.

•Material being ejected from the machine, which may cause an injury.

•Hinged parts, which may cause body parts being pinched.

•Human errors (e.g. fatigue, mental overload, etc.)

General description of machine 17

4General description of machine

The machine has been designed for professional use:

•On sports fields and golf courses

The machine is constructed as follows: Some parts are available as an optional extra.

Components Drive

•Aeration shaft

•Runner

•Aeration blades

•Main gearbox

•Centre drive

•Torque limiter

Table 1: Machine parts and drive

Depending on the model, the machine functions are as follows:

•Restoring/maintaining stretches of grass

A tractor provides the power needed to drive and tow the machine.

The power of the tractor is transferred to the machine via a: PTO drive shaft

The PTO shaft must rotate at: 540 revolutions per minute

The machine is operated from the tractor driver’s seat

The tractor’s three-point hitch is used to couple up the machine. The machine is fitted with coupling

points for a tractor with a lifting hitch of Category 1

Machine specifications 18

5Machine specifications

5.1ShockWave

ShockWave 1.00 ShockWave 1.55 ShockWave 2.10

Dimensions

Working width [mm](") 1000 39.4 1550 61.0 2100 82.7

Machine width [mm](") 1200 47.2 1750 68.9 2250 88.6

Machine length [mm](") 1350 53.1 1350 53.1 1350 53.1

Machine height (on legs) [mm](") 1150 42.3 1150 42.3 1135 42.3

Centre of gravity distance [mm](") 635 25 635 25 635 25

Weight

Machine weight [kg](lbs) 475 1045 580 1276 630 1386

Working speed

Max. working speed [Km/h](mph) 1.5 0.9 1.5 0.9 1.5 0.9

Working depth

Max. working depth [mm](") 250 9.8 250 9.8 250 9.8

Power

Min. power [KW(pK)] 18 (25) 22 (30) 30 (40)

Max. power [KW(pK)] 33 (45) 36 (50) 44 (60)

PTO drive shaft

Rotational speed of the

drive [/min](rpm) 540 540 540

PTO drive shaft type W2300 W2300 W2300

Torque limiter protection [Nm](lbf ft) 850 630 850 630 850 630

Noise level

Noise level dB(A) < 80 < 80 < 80

Loading and unloading the machine 19

6Loading and unloading the machine

Never go under a hoisted-up machine.

Use only approved lifting equipment (wire ropes, belts, chains, etc.) that:

•have a permissible load that is greater than the weight of the machine, see type

plate

•do not have any defects.

Only qualified personnel should hoist machines.

The machine’s centre of gravity is indicated by the symbol: This is for a standard

machine without options

Putting the machine into operation 20

7Putting the machine into operation

The user must have read through the whole contents of this manual and must follow to the

letter the instructions therein.

20% of the unladen weight of the tractor must always rest on the front axle.

A PTO drive shaft of the wrong length may cause serious damage to the tractor and the

machine. This would invalidate the CE marking of the PTO drive shaft. Putting the PTO

shaft into operationon page 21

Connect the overload clutch according to the instructions provided by the manufacturer of

the PTO drive shaft.

Check whether the clearance around the PTO drive shaft is sufficient whatever the

operating conditions. The PTO drive shaft will become damaged if there is too little

clearance.

Procedure

1. Check:

•That all bolted connections are tight

•The oil level in the gearbox(es)

2. Couple the machine up to the tractor (see section on coupling and uncoupling)

3. Do not connect the PTO drive shaft yet

4. Carefully read the manufacturer’s instructions for the PTO drive shaft

5. Shorten the PTO drive shaft Putting the PTO shaft into operationon page 21

6. Connect the PTO shaft to the tractor

7. Fit the coulter set

This manual suits for next models

2

Table of contents

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions