IMC EASYJET E400P User manual

Ink-jet Printer

E400P

MANUAL

The Manual of Ink-jet Printer

1

EASYJET INK-JET SYSTEM TECH. CO., LTD.

Table of contents

Declare

Safety Instruction

2

3

Packing List

4

Technical Data

5

Environment/Electrical Requirement

6

Install & Test

7

Switch On/Off

9

Operation

10

1. <the main screen> description

10

2. <the switch of modes> description

11

2.1 <system>

11

2.1.1 “password”

11

2.1.2 “load”

12

2.1.3 “ink information”

12

2.1.4 “date time’

12

2.1.5 “calibrate”

13

2.1.6 “idle-jet”

13

2.1.7 “counter continue”

13

2.2 <Parameter>

14

2.3 <Print>

14

2.4 <Browse>

14

2.5 <Edit>

15

2.5.1 zone of display printing content

15

2.5.2 zone of create & save text block

15

2.5.2.1 create “character/number”

16

2.5.2.2 create “date/time/serial No./ shift group

17

2.5.2.3 create “bar code”

19

2.5.3 tools to edit text block

20

Eliminate Troubles

21

Daily Maintenance

23

The Manual of Ink-jet Printer

2

Declare

!Please read the manual seriously before running machine. Any mistake or damage caused by user’s

incorrect operation, shall be not on our responsibility.

!In any circumstances, the ink-jet printer shall use the accessories and consumables (include inks &

cleaner) approved by our company. Disassemble machine without our agreement is strictly prohibit.

!The machine we produced which includes appearance, structure, hardware and software, has already

got patent. Any piracy shall bears the legal liability.

!Our company reserves the right of final interpretation. If you have any questions, please feel free to

contact us.

!Our company reserves the right of update at any moment, and unnecessary to notify the users.

!Copyright reserved by EASYJET. Any unauthorized reproduction, articles picked or other

non-approved usages shall bears the legal liability.

The Manual of Ink-jet Printer

3

Safety Instructions

Personal Safety

!Some inks & cleaners are harmful, please installing & running machine in well ventilated conditions.

!Some inks& cleaners are flammable, Keep away from all sources of heat and ignition.

Fire-extinguisher shall be equipped nearby the machine.

!Wear safety glasses, gloves and masks when handling inks & cleaners.

!In the condition of inhalation and eye contact, please flush thoroughly with water and seek medical aid

immediately.

!Turn the power off before maintenance.

!Forbid to disassemble machine without our technician’s instruction. The ink-jet printer must be

properly grounded. When connecting electricity, the cabinet is powered with high voltage to risk life.

!Only trained technicians are authorized to carry out installation, maintenance or repair.

Machine Safety

!Loading Requirement

1、Ink-jet printer shall be packaged in standard carton which filled with anti-vibration materials.

2、Purge the inside and outside of print head and plug up the ink inlet. The print head shall be covered by

cap and packed by anti-vibration film to prevent from scratch.

3、Just left an empty cartridge in Ink system before loading.

!The warranty claims will not be accepted in the following situations:.

1、Print head or inks system damages caused by using unauthorized inks and cleaners.

2、Print head or inks system damages caused by replacing different types of consumable randomly. Such

as replaced oil-base inks into solvent-base inks, the two types of ink will cause chemical reaction to

damage machine.

3、Damages caused by running in unsuitable environments or electrical requirements.

4、Damages caused by unauthorized disassembling and assembling.

5、The permanent damages caused by not performing scheduled maintenance, or printhead scratching.

6、Damages caused by disassembling or assembling through unauthorized people .

7、Damages caused by the Force Majeure.

Environmental Protection

Dispose of the waste inks & cleaners shall be in accordance with Local Authority Regulation. The wastes

are not allowed into the sewer system.

The Manual of Ink-jet Printer

4

Packing List

Name

Quantity

Controller

1 PC

Print head System

1 Set

Photoelectric sensor & Clip

1 Set

Encoder & Accessories

1 Set (choose accessory)

Stands & Fittings Installation

1 Set

AC/DC Adapter & Power code

1 PC

Manual

1 Copy

Ink cartridge & cleaner

1 Set (purchased in separate)

Injector

1 PC (only used in solvent-base ink printer)

The Manual of Ink-jet Printer

5

Technical Data

!System: 32-bit high-speed processor

!Print head: 128 dots height, hole diameter in 50 um, 185dpi in vertical.

!Print head number: 1

!Print height from 1mm to17.5mm.

!Print Lines capability: Multi-lines (up to character height)

!Line speed capability: Max.33mt/min(200 dpi in lateral).

!Print Information: Date, Time, Character, Photo, Shift group, Serial number and Bar code.

!Storage: 100 text files and a bitmap in 256*128.

!Operation: Color touch screen with photo menu

Independence Print Parameters

PC Editing

!Display:3.5 inch color touch screen

!Inks: Porous ink, Non-porous ink, UV anti-counterfeit inks, food grade ink, invisible ink etc.

!Inks color: red, yellow, blue, green, black, white etc.

!Through USB interface to import single color bitmap which can be operated by mouse.

The Manual of Ink-jet Printer

6

Environment/Electrical Requirement

!Electrical requirement:AC 100-240V 50/60Hz

!Max Power:13W (average﹤5W)

!Temperature:5-40

!Humidity:10-90%(non-condensing)

!Electromagnetic interference: running far away from electromagnetic radiation zone

The Manual of Ink-jet Printer

7

Install & Test

Only trained technicians are authorized to carry out installation.

Before install, confirm the machine was stay in a solid & smooth place without electromagnetic radiation.

Installed as stipulated in manufacturer’s specification, do not change the relative position of ink system and

print head. Any special requirements, please consult the manufacturer and supplier directly.

Ink-jet Printer Installation & Testing

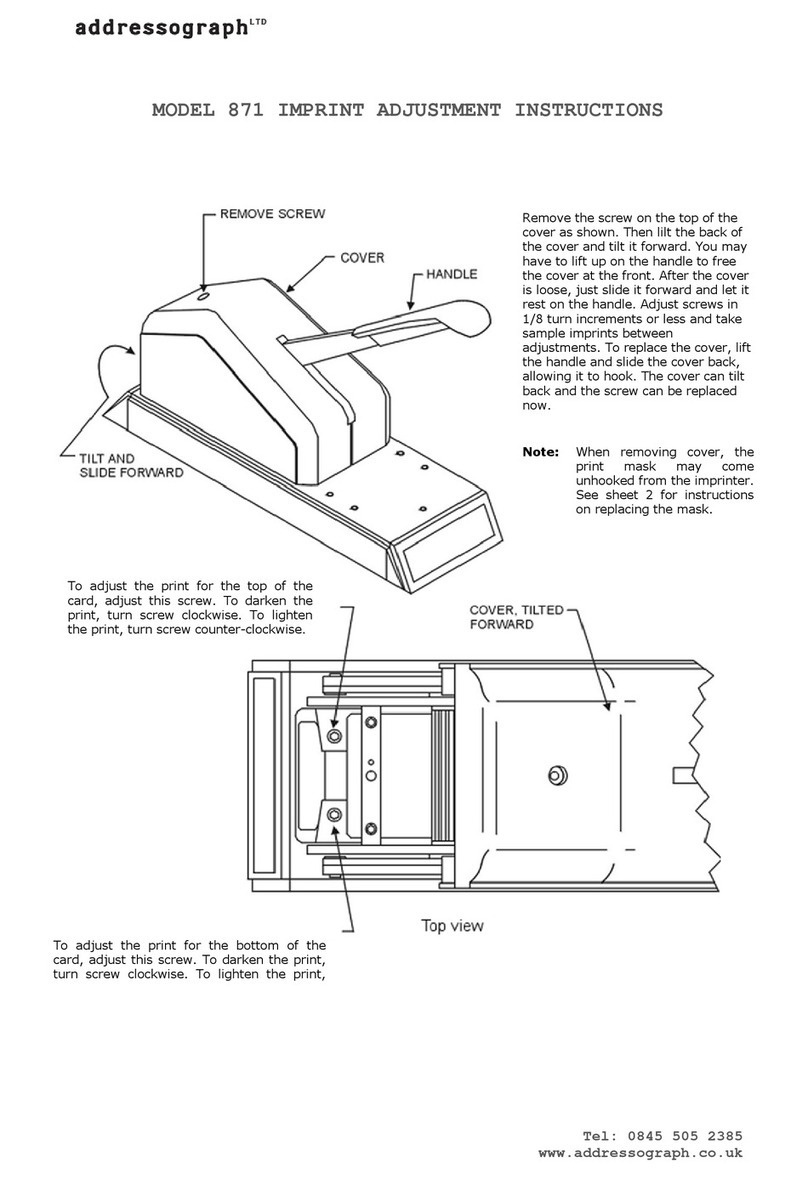

Photo1

1、Unpacking: open the package and move out print head, host machine, suspension pad etc.

2、Suspension Pad Installation: 1) fix pads into triangle stands with same height. 2) adjust the three pads

so as to keep the triangle stand in vertically. 3) fasten the three screw nuts with the spanner.

3、Ink tank installation: 1) Put small steel pipes into large ones and put large steel pipes into triangle

stands, after adjusted the height, fasten the star like screw.2) Put the two-hole aluminum stand in

profile of ink tank system into small steel pipe, and then fasten by star like screw.

4、Host Machine Installation: Put the two-hole aluminum stand in profile of host machine into small steel

pipe, and then fasten by star like screw.

5、Print head Installation: 1) put the aluminum stick into the two-hole aluminum stand, and fastened by

star like screw. 2) Screw the print head on aluminum stick. 3) connect one side of ink tube to filter and

the other side to ink inlet.

The Manual of Ink-jet Printer

8

Install & Test

6、Photoelectric Sensor Installation: 1. Screw the photoelectric clip on the print head stand. 2. screw the

photoelectric sensor on the clip or other position as request, or use different types of sensor. When

using solvent-base inks, the sensor shall be fixed in front of print head.

7、Encoder Installation: If the production line is not in constant velocity, it must be equipped with

encoder.

8、Power connection: connect AC adapter to suitable AC power. Connect DC to the socket behind of

main machine.

9、Printing Test: 1. Put the ink cartridge into the ink system in correct position. 2. Remove the cap of the

printhead, and squeeze the ink cartridge to drain out the air and cleaner until no bubbles. 3. Clean

up the surface by blotting-paper. 4. Tested by blank papers(with more details see page 26).

10、Product moving position: the speed of production line shall be slower than the speed of printing. A

guide plate can be installed to receive the exactly position of product which has passed the print

head. In principal, the distance between product and print head more closer, the printing result will

be better.

11、Production Line adjustment: more details see page10.

The Manual of Ink-jet Printer

9

Installation manual of print head and ink system

1. When performing sideward print, the lowest print hole inside the print head should be 10mm higher than

the ink cartridge. This position creates the best ink level difference and is also the design standard on

which we fix the support based. The safety area is within 10mm. When the print head placed downward

exceeds 10mm from standard position, the bottom print hole inside the print head will spill the ink firstly

which will cause the bottom part of the print character can not be printed out or even no ink dots can spill

out. When the print head moves upward exceeds 10mm from standard position, it will leads to

non-continuous ink supply. It requires to press the ink cartridge continuously to guarantee the print quality.

Below is the installation guide for reference

2. When performing downward print, the bottom of the print head system should be 10mm higher than the

top of the ink cartridge. This position creates the best ink level difference and is also the design standard

on which we fix the support based. The safety area is within 10mm. When the print head placed downward

exceeds 10mm from standard position, the bottom print hole inside the print head will spill the ink firstly

which will cause the bottom part of the print character can not be printed out or even no ink dots can spill

out. When the print head moves upward exceeds 10mm from standard position, it will leads to

non-continuous ink supply. It requires to press the ink cartridge continuously to guarantee the print quality.

Below is the installation guide for reference

The Manual of Ink-jet Printer

10

Installation manual of print head and ink system

3. When performing upward print, the top of the print head system should be parallel to the top of the ink

cartridge. This position creates the best ink level difference and is also the design standard on which we fix

the support based. The safety area is within 5mm. When the print head placed downward exceeds 5mm

from standard position, the print hole inside the print head will spill the ink which will cause the character

can not be printed out or even no ink dots can spill out. When the print head moves upward exceeds 5mm

higher from standard position, it will leads to non-continuous ink supply. It requires to press the ink

cartridge continuously to guarantee the print quality.

Below is the installation guide for reference

The Manual of Ink-jet Printer

11

Switch on/off

!Switch on:

Checked up the power connection status before switch on. After switch on, it will enter into the operation

system within 15 seconds. Remove the print head cap and press PRINT key to start printing when using

oil-based inks.

When using solvent-base inks, please purged print head and drained out the dry-inks by blotting-paper.

After that, test the printing result by a blank paper.(more details see page24)

The procedure for using solvent-base inks: purge-squeeze-clean-test.

!Switch off:

Press the power button off and cover up the print head cap.

Note: Before switch off, ensured the print head under normal condition.

It is forbidden to purge the print head gap before or after switch off! Just need to seal it by print

head cap!

The Manual of Ink-jet Printer

12

Operation

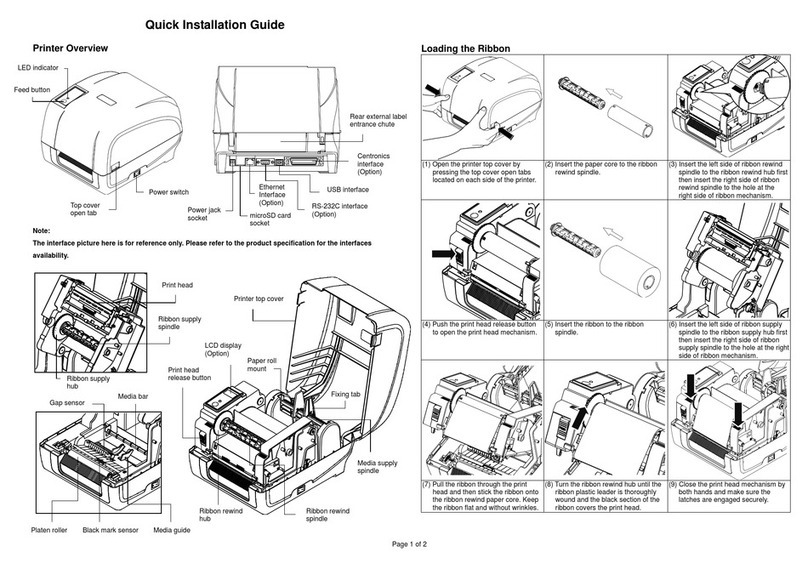

"<The main screen>

Power on the printer, it will display <the main screen > as photo 2.

Pic 2

On the operator interface, you will clearly find five menu items :System 、

Parameter 、print 、File 、Edit

Preview Area with scale is located in the middle of screen. 128 dots height *20000 dots width with

graduated scale. what you edit in the screen is what can be printed out.

In the bottom of the screen is the counter. It can count the printing times.

Also you can find the file name of the printing file, date and time here.

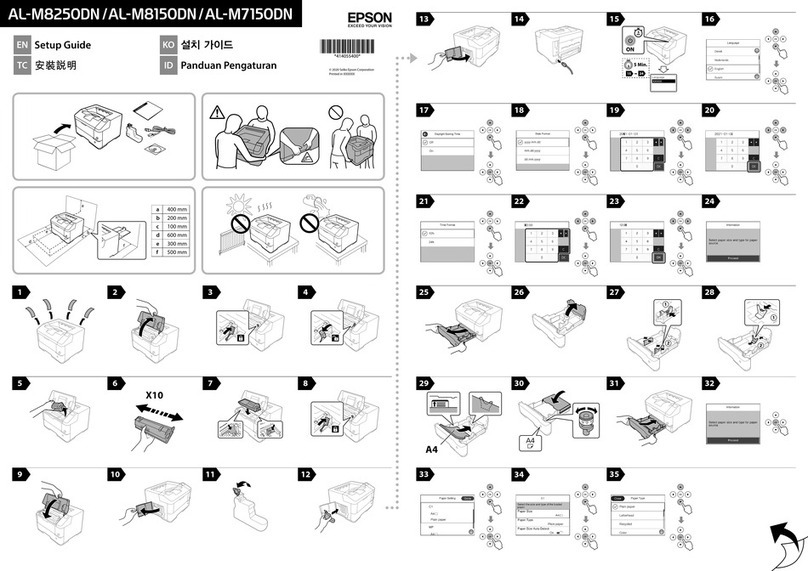

"System

Click the button <system> opens a screen as photo3, which shows the following buttons:

“Authority”“InkLook”“Printhead”“Appearance”“Disk”“Date&time”

“Remote”“Calibrate”“shutdown”“close”

The Manual of Ink-jet Printer

13

Operation

Pic3

1.Printhead management

Click this button will open the interface of print head management. You can set the value of idle-jet

and the continual serial no on this page.

A. Idle-jet

!If you choose non-porous ink system, in order to prevent the ink on the surface of the print head

becoming dry out which will cause illegible printing result you may need to start idle-jet printing

function according to the chosen ink type, temperature, moisture and air flow rate to set the interval

and number of columns for idle-jet printing. Recommend idle-jet printing interval is 10 seconds and

number of columns for idle-jet printing is 10. (if the air flow rate is fast or the temperature is high the

number of columns for idle-jet printing need to be 20 or more.)

It is not necessary to use idle-jet printing in porous system. But if in the environment with a large number of

dust, use idle-jet can be used for dust-protection.

B. Continue serial No

The serial no will change automatically when the print times changes. When you activate this function, the

system will record the current serial no for the text no matter when power off or print with the other files, it

will not back to the initial value.

Pic 3

The Manual of Ink-jet Printer

14

Operation

2. “Authority”

Click the button “Permission management”opens a screen as photo5. and then, click <OK> button of

photo5 to open screen as photo4.

Pic4

According to your requirement, two options is available if you need to set permission

Low degree permission:Restrained only to editing function, need to input password to log in.

High degree permission: Restrained to 4 functions including System & Parameter & File & Edit, need

to input password to log in.

Authorized administrator can revise the password.

Authorized administrator can maintain the devise properly in order to avoid the file be deleted Or

revised by others and prevent from parameter error& time error. Also printing error caused by

choosing wrong file can be avoided.

Final value should be confirmed with button “OK”or the reference value is returned by button

“Cancel”or “Close”.

3. “Disk”

Insert a storage disk into USB interface and click the button “Load”opens a screen as photo5.

Pic 5

The Manual of Ink-jet Printer

15

Operation

It just can upload and download a bmp format single color files from a storage disk through USB interface.

Click the required file from the left side of screen, and click an arrow <rightwards> in the middle part.

When the required file shows in the right side of screen means download successful.

4. Ink Look

Click the button “Ink Look”, it shows the ink information as following:

Pic 6

< Ink use> - the dot numbers of the current printing content takes up.

<Ink information> - number of times for printing current content by 1 liter ink.

5.Appearance

Click the button “Apparent”opens a screen as photo7.

Pic 7

You can set the length of screen saver and the screen display format.

6. System information

Shows the information of the system.

The Manual of Ink-jet Printer

16

Operation

7. Date & time

Pic 8

You can adjust time and date when click “date & time”button. Final value should be confirmed with button

<setting> or back by button <cancel>.

8.“Calibrate”

Click the button<Calibrate> to open screen as photo 9.

Pic 9-1

If the keypad is not alignment, click CALIBRATION for adjustment.

Pic 9-1

Use nib to click the cross center shows in photo10. when target moving above the screen, please repeat it.

After the first click, the latest calibration will be settled. If the second click is correct, please back to system

window and click OK to finish.

The Manual of Ink-jet Printer

17

Operation

Pic 9-3

If the two times calibration are different, it means failed. Please click again for a new calibration.

Parameter

Pic10

Change "Print speed ,print delay, print direction, horizon bold, quantity of files you want to print, interval of

each file you choose to print and whether to operate with synchronizer.

Print head parameter

Adjust print speed and print delay according to the speed of production line, the slower the print speed the

shorter print delay is. After sensed by Photoelectric sensor, the print time will be reduced.-In about a few

milliseconds.

1. Print content

Change the horizontal width of print content that is to change the horizontal bold times. Change the the

quantity of file that you want to print on the product and interval between each current editing file.

7、Bold

This function enable you to adjust the horizontal width of the print content that is to change the horizontal

bold times, print files numbers, interval between each of the print images and print direction of the print

content.

3. How to choose a photoelectrical sensor

In order to print in the exact position and prevent from error of printing, you are recommended to

The Manual of Ink-jet Printer

18

Operation

choose a photoelectric sensor according to the size and color of the product and speed of production line

4.How to choose an encoder

If you want to prevent from unstable length and definition of the text printed out due to unstable

production line speed, you may need to choose an encoder. Also if you need to print in each fixed

length(such as print per meter on the cable) or high identification rate is needed when printing you need to

choose an encoder.

Pic11

5. File association

In certain circumstance, there will be requirement for print several files together after sensed by

the sensor. Then you should tick in the File List option, and click setting to enter the file selection

int interface as pic below.

Pic12-1 Pic 12-2

Then click import to start print the files one by one as listed in the File List sequentially. Finally, click close

to exit.

The Manual of Ink-jet Printer

19

Operation

File association is used for the purpose of printing several pieces of print texts by sequence after sensed

by the sensor one time. Thus to achieve cycle print

In PIC 12-3

I

!Print

If you want to print what you have edited, please click Print. The icon shows red and yellow frame, that

means it is under print condition if you choose photoelectrical sensor to print, the printer can print directly

with what you have edited.

Pic13

Operation

Table of contents

Other IMC Printer manuals