Imed PITCH ANGLE User manual

User Manual

I. OVERVIEW

II. FEATURES

III. Operation

V. SETUP

VI. TROUBLESHOOTING

1

1

3

6

10

VII. Specifications 13

IV. wiring 4

IMED Pitch Angle Indicator v2.0

IMED’s Pitch Angle Indicator (PAI) displays the propeller pitch angle in

real time. The design is microcontroller based which makes it easy to

configure and eliminates the need for any trim pots, etc. IMED’s PAI will

work directly off most existing pitch feedback units, basically any

potentiometer from 1kΩ to 100kΩ and utilizes CAN bus for master/slave

setups.

The PAI only needs to be set up once at the time of installation. It then

stores all the essential data in the microcontroller’s non-volatile memory.

The configuration process is simple and makes use of the three push

buttons mounted on back of the PAI.

Available angle sense inputs: 0-3.3V, 4-20mA, CAN bus

Flexible sense

inputs

Best readability under any circumstances with very high maximum

brightness.

Automatically follows the dash brightness or can be set individually to

optimize visibility. No external components required.

No more fine tuning or offset adjustments. Simple setup process derives

all required parameters. Intuitive adjustment of sensitivity.

The standalone version has backlighting included for best night time

visibility. Brightness is set automatically.

Figure 1.

IMED PAI User Interface

3

IMED Pitch Angle Indicator v2.0

As the pitch angle changes, the LED display updates according to the

angle.

When the pitch angle is less than 0°, the red ‘Astern’ section of the PAI is

active.

When the pitch angle is 0°, only the Neutral LED is active.

When the pitch angle is between 0° and Ahead, the green ‘Ahead’

section of the PAI is active.

When the pitch angle is between Ahead and Feather, the ‘Travel’ section

of the PAI is active. This shows which direction the propellor pitch is

travelling by blinking the respective arrow.

If the pitch angle stops travelling between Ahead and Feather, both

LEDs will blink to indicate that the propellor pitch has stopped moving

without reaching either Ahead or Feather.

Once the pitch angle reaches the Feather position, only the Feather LED

remains on.

LED Operation

Resolution For best performance, the potentiometer’s movement should have a

large span from Astern to Feather i.e. having a 10 turn, 10 kΩ pot, which

only does 1 full turn over the full span of the pitch will have less

resolution than that of a single turn, 10 KΩ pot doing close to one full

rotation.

The 2nd potentiometer is not required for normal operation. It may be

added to further enhance resolution and improve noise immunity (see

wiring diagram).

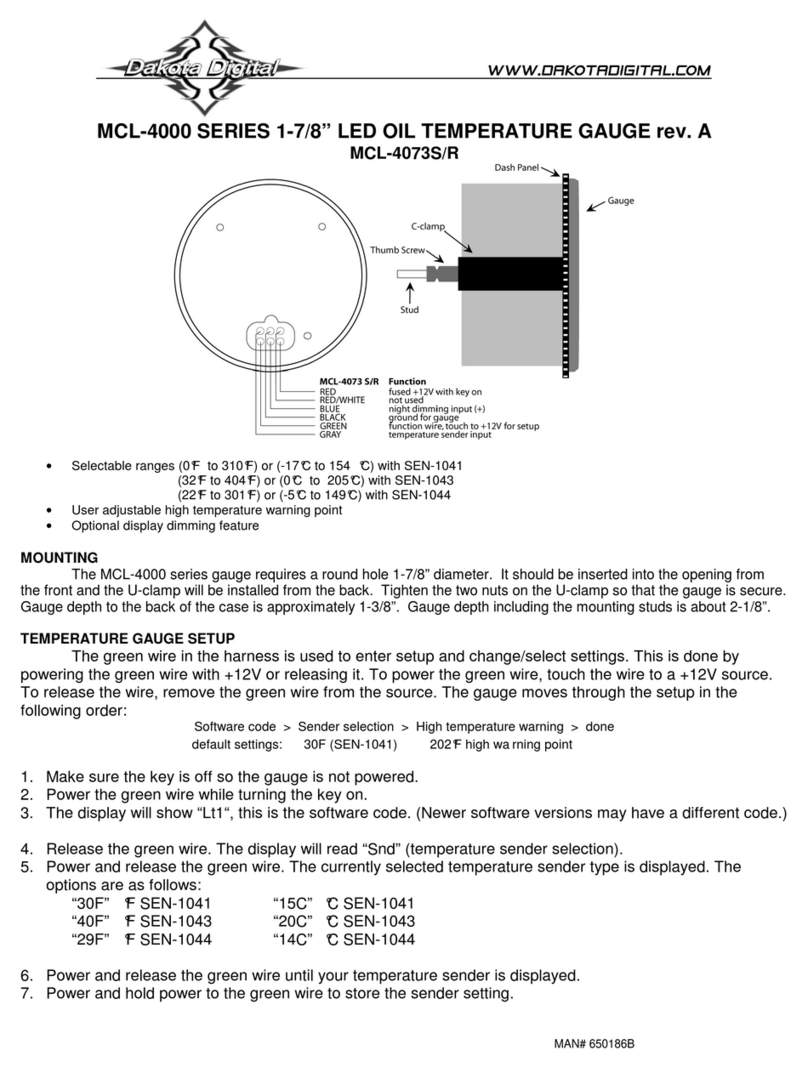

V+ V- 3V3 V-V+ 0V 12V LH 0V -+ PWM+

Supply POT CAN 4-20 DIM

To AI

IMED Pitch Angle Indicator v2.0

CAN

CAN 12VDC

CAN HIGH

12V

V+

V-

0V

120R

CAN termination at both ends of the bus! CAN LOW

CAN GND

4 - 20

+

-

4-20mA IN

4-20mA OUT

POT

3V3

V+

V-

0V

Potentiometer

2nd Potentiometer

(inverted, optional)

One end only

One end only

SUPPLY

V+

V-

12 ... 30VDC

GND

DIM

+

PWM

MASTER 12 ... 30VDC

MASTER PWM

The PAI has three pushbuttons labelled P/A (Pitch at Astern), C/N (Pitch

at Neutral) and S/F (Pitch at Feather). These buttons are used to setup

the PAI.

A specific setup procedure must be followed to setup the PAI for use.

The Receipt LED is located at the back of the PAI on the bottom-left

side of the pushbuttons. The receipt LED blinks green three times to

indicate when an input has been received. This LED should be used as a

visual confirmation of a value being received and saved into the PAI

memory.

D3

Receipt LED ( or )

P/A

C/N

S/F

3

IMED Pitch Angle Indicator v2.0

Switch 1 selects the dimmer input (external or internal).

If internal is used, the LED brightness is controlled with

button S5 on the top side of the PCB, or by connecting an

external 1 way IME-BTN to the 10 way header P3. If a third party

button is used, connect between pin 1 and 2 of P3.

In external mode the LED brightness is controlled by an external

dimmer connected to the DIM terminals on the I/O board (see

Figure 2).

Switch 2 selects the analogue input: potentiometer or 4-20mA.

Switch 3 selects whether the unit should act as a master or slave. In

slave mode it reads its angle from CAN bus and therefore depends on

another master. In master mode the angle is measured directly off the

The first step of the setup procedure is to configure the board using the

4 DIP switches.

DIP switch

For the PAI to operate, five points need to be programmed in order to

calculate the required offset and gain for the scale. The angle indicator

will also negate the signal automatically if required, based on these two

inputs. The points are: Astern, Neutral, Point ‘A’ , Ahead and Feather.

Each point is illustrated in Figure 7. for a visual reference.

IMED Pitch Angle Indicator v2.0

1. Move pitch to Astern position.

2. Press and hold button P/A until Receipt LED blinks green 3x. 1)

3. Move pitch to Neutral position.

4. Press and hold button C/N until Receipt LED blinks green 3x. 1)

5. Move pitch to Point ‘A’ position.

6. Press and hold buttons P/A + C/N until Receipt LED blinks green 3x. 1)

7. Move pitch to Ahead position.

8. Press and hold buttons C/N + S/F until Receipt LED blinks green 3x. 1)

9. Move pitch to Feather position.

10. Press and hold button S/F until Receipt LED blinks green 3x. 1)

Set up is now finished and the pitch angle indicator is ready for operation

in master mode.

1) If at any stage the Receipt LED blinks yellow instead, finish setup

process. If it still blinks yellow after completing step 10, a logical fault has

been detected in the setup, e.g. the Feather set point coming before

Ahead. Repeat setup in this case.

If the unit is set to slave mode using DIP switch #3 no setup is required.

The unit will receive all information it needs via CAN bus from the bus

master.

9

Setup master

Setup slave

10

It is possible to display the current DIP switch configuration. To do so,

press and hold the P/A and S/F button together.

Display current

DIP switch setting

D3

Receipt LED ( or )

P/A

C/N

S/F

The Receipt LED will start indicating the state of each of the 4 DIP

switches by blinking green a number of times followed by red once for

OFF or twice for ON. The number of green blinks indicates the switch

number.

For example, the following DIP switch configuration will give blink

sequence:

IMED Pitch Angle Indicator v2.0

This is an indication that the current unit is configured to be a slave

(using DIP switch #3, see Figure 11.) and there has no message been

received from another master unit for a minimum of 20 seconds.

In this case check the wiring of the CAN bus connection to the master

unit and confirm that the master unit is functional.

Also check that there’s only one termination resistor (120 Ohm, see

Figure 3.) at either end of the bus (2 in total).

Single BLUE centre

LED blinking

11

This means that the unit is currently configured to be a slave (using DIP

switch #3, see Figure 11.) and is therefore not using its analogue inputs.

Connect it to a functional master unit via CAN bus to solve this issue or

change DIP switch #3 to master mode (OFF position).

Receipt LED

blinking red 3x during

analog input setup

This indicates that there is a problem with the programmed setup

points. Please follow the setup steps at the master unit to solve

this.

Receipt LED

constantly blinking

yellow

This indicates that there is a problem with the programmed setup

points. Please follow the setup steps at the master unit to solve

this.

Receipt LED

constantly blinking

yellow

If the PAI does not respond to pitch movement, confirm the wiring

matches the wiring diagram on Page 5.

If the display only shows the neutral position and does not respond to

pitch movement, check the Receipt LED D3 on the back of the PCB for

other errors

No response

or only neutral LED

12

10 - 30 V

0 - 3.3 V, 4 - 20 mA, CAN

TBD

TBD

160 mm x 60 mm x 80 mm

Supply voltage:

Input type:

Operating temperature:

Case material:

Dimensions:

IMED Pitch Angle Indicator v2.0

13

IMED LED LIGHTING DIMMER v2.0