2

Table of Contents

Contents of the kit ..........................................................................................3

Product description ........................................................................................4

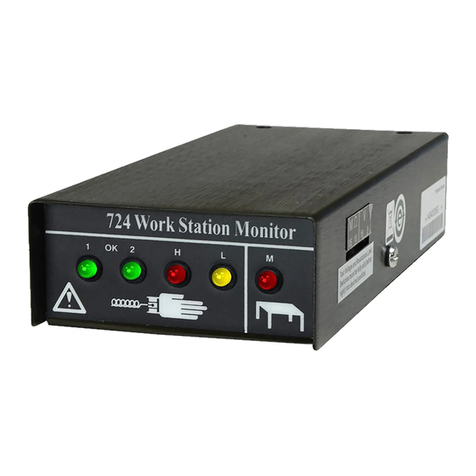

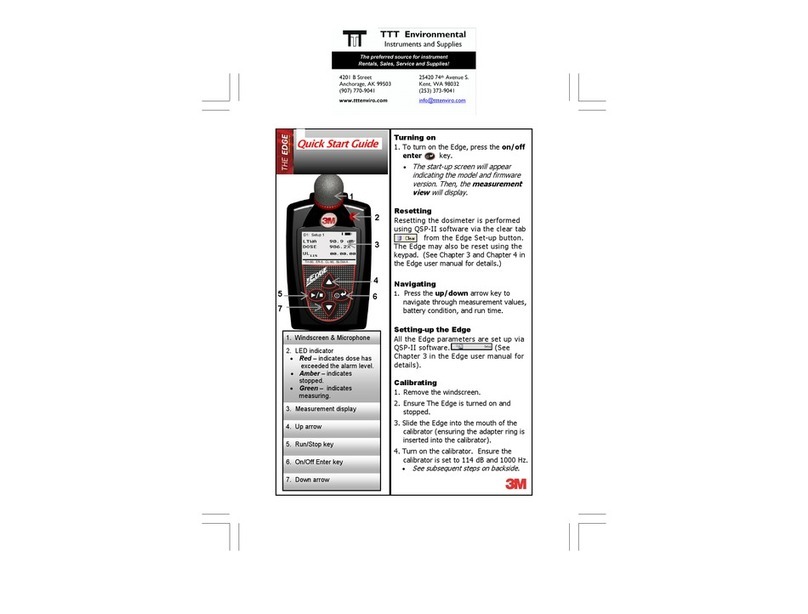

3M™ ScanEM-QC Electromagnetic Near-Field Probe Kit

controls and connector ..................................................................................6

Using ScanEM-QC Probe ................................................................................7

Basics of operation ....................................................................................................7

Stand-alone operation ...............................................................................................8

Quick set-up ..............................................................................................................8

Setting the level dial...................................................................................................9

Sound on/off ............................................................................................................10

EM level LED bar ......................................................................................................10

Operation as a probe ....................................................................................11

Basics ......................................................................................................................11

Amplified near-field probes for a spectrum analyzer ................................................12

Non-contact oscilloscope probes .............................................................................12

Broadband field strength probe for a multimeter .....................................................14

Examples of applications of ScanEM-QC probes ......................................................15

Analyzing the results ....................................................................................21

Troubleshooting ............................................................................................23

Common places to look for excessive emissions .....................................................23

During the design phase ..........................................................................................24

Checking the prototype ............................................................................................24

Before the EMC test .................................................................................................24

Should things go wrong ...........................................................................................24

Seeking help ............................................................................................................24

EMC101 ........................................................................................................25

Why EMC? ...............................................................................................................25

Near-field primer .....................................................................................................25

The validity of the near-field measurements ............................................................26

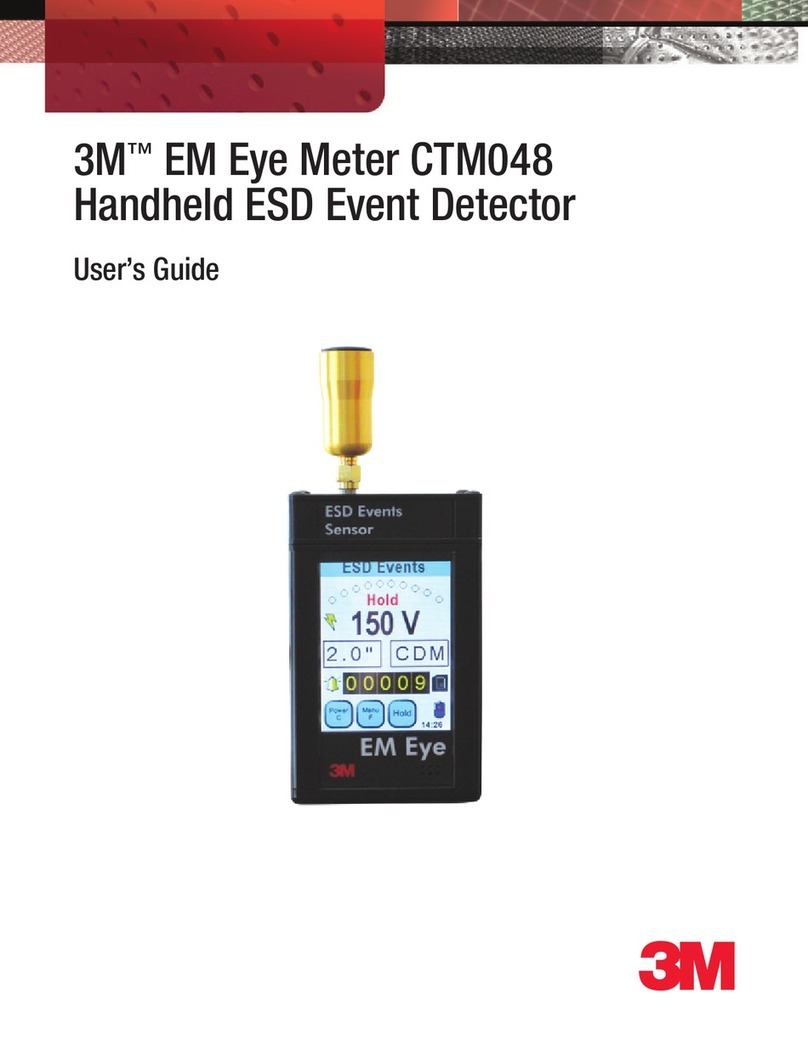

ESD Primer ...................................................................................................27

Taking care of your ScanEM-QC probes ......................................................28

Changing batteries ...................................................................................................28

What if: ....................................................................................................................29

Specifications ...............................................................................................31