Operation manual EPM-Peak

Software Release 1.0.8.0 2019-01-29

Page 2 of 19

1

Introduction___________________________________________________________ 3

1.1 General __________________________________________________________________3

2

Scope of supply ________________________________________________________ 3

3

Important information __________________________________________________ 4

3.1 Use of the operator manual__________________________________________________4

4

Description ___________________________________________________________ 4

4.1 Introduction ______________________________________________________________4

4.2 Measure functions _________________________________________________________4

4.3 Functional description______________________________________________________5

5

Operation_____________________________________________________________ 5

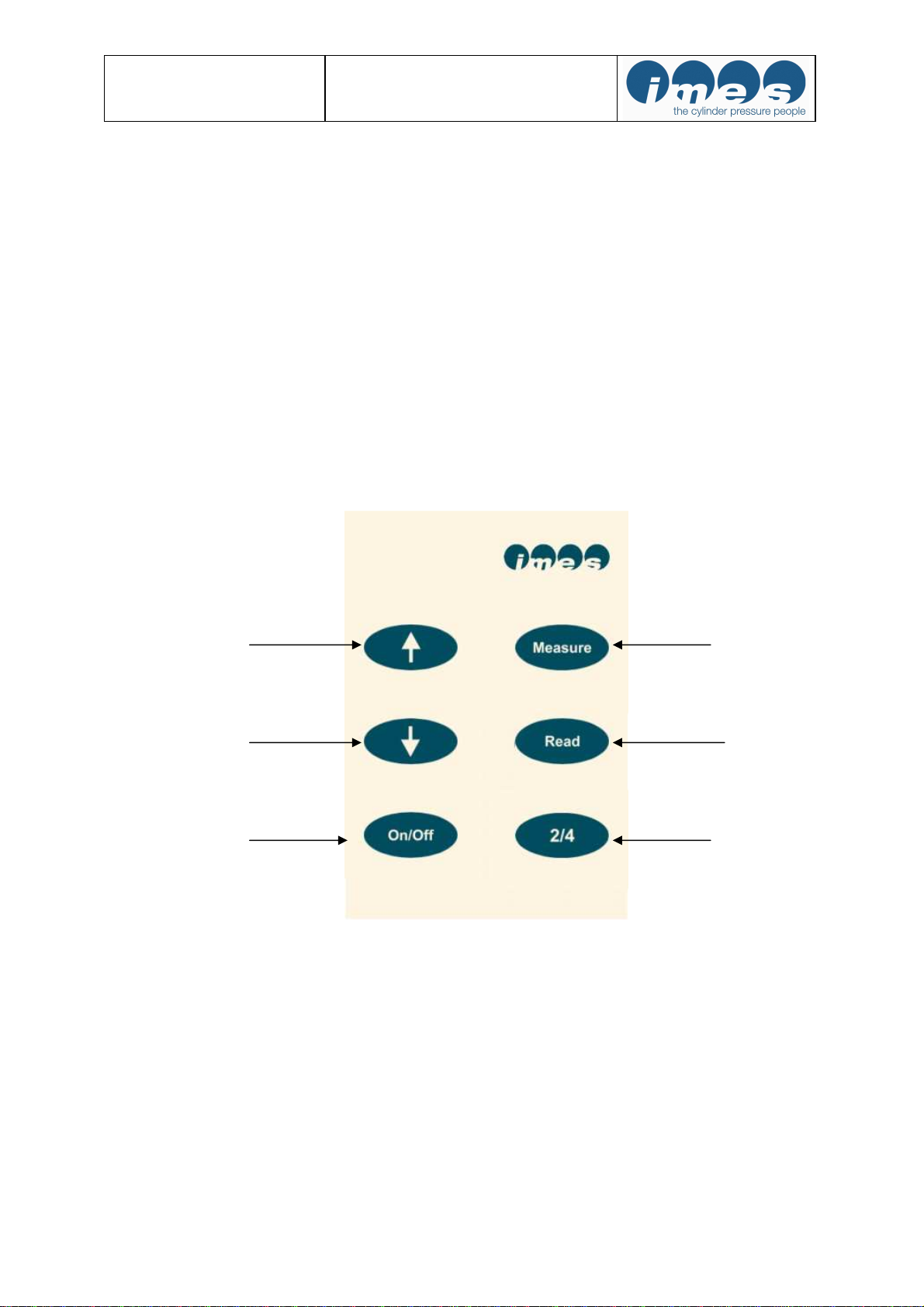

5.1 Operator push buttons _____________________________________________________5

5.2 Operating functions________________________________________________________6

5.3 Charge battery ____________________________________________________________7

5.4 Change battery____________________________________________________________8

5.5 Mounting instructions on marine engines ______________________________________9

5.6 Measurements with EPM-Peak ______________________________________________9

6

Accuracy check _______________________________________________________ 10

6.1 Connection of EPM-Peak to pressure calibrator _______________________________11

6.2 Generate pressure at pressure calibrator _____________________________________12

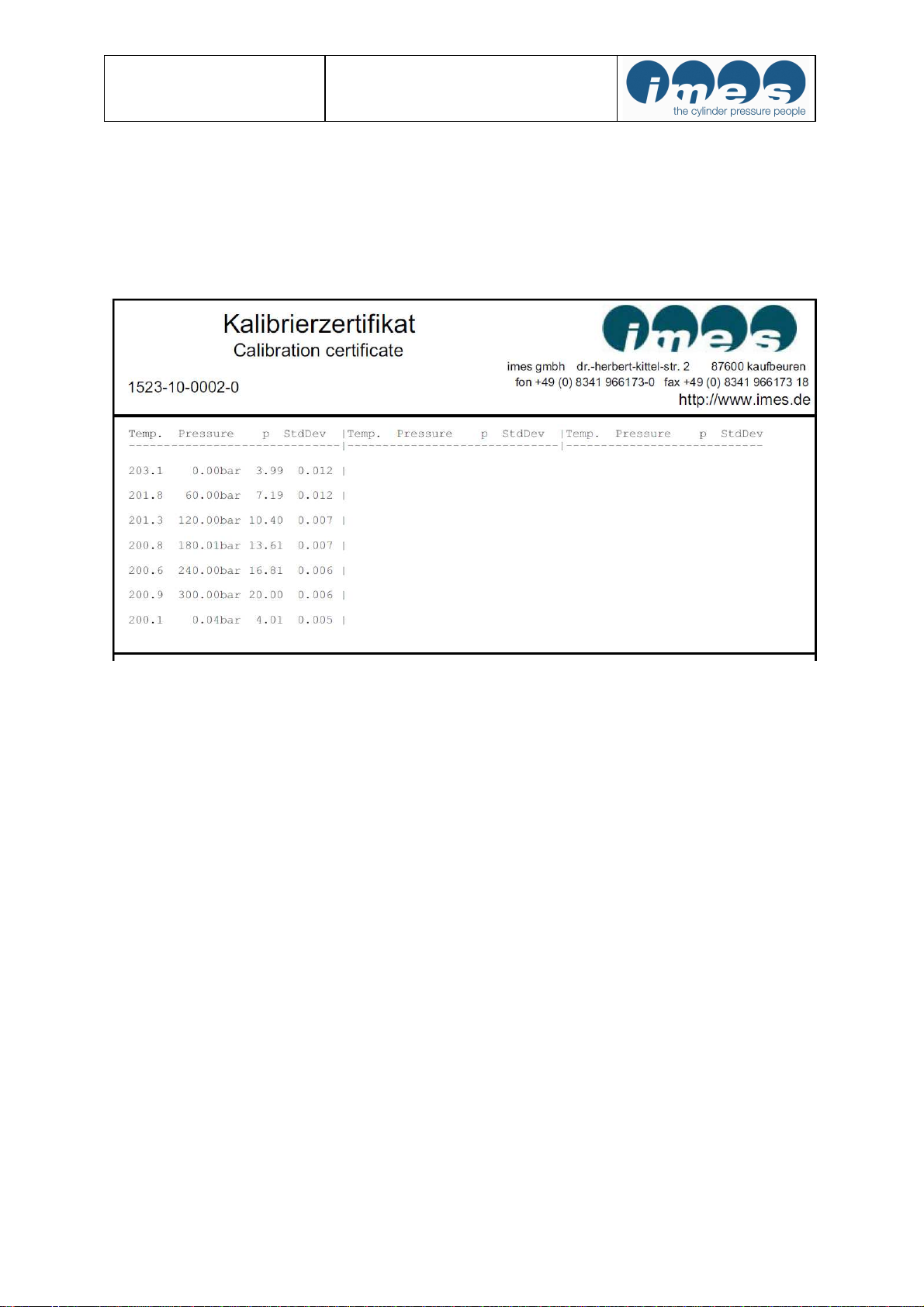

6.3 Example of displayed EPM-Peak values during pressure check___________________13

6.4 Disconnect EPM-Peak from pressure calibrator _______________________________13

7

Cleaning ____________________________________________________________ 14

7.1 Periodically cleaning ______________________________________________________14

7.2 Cleaning in case of hard deposit_____________________________________________14

7.3 Cleaning procedure of adaptor______________________________________________15

7.4 Cleaning procedure of cylinder pressure sensor _______________________________15

8

Check tightening of sensor on adaptor ____________________________________ 16

9

Basic check for fault finding ____________________________________________ 17

10

Nomenclature ________________________________________________________ 18

11

Technical data________________________________________________________ 18

12

Warranty ____________________________________________________________ 18

13

IMES Sales and service organization _____________________________________ 18

14

Declaration of conformity_______________________________________________ 19