IMI SENSORS 699A07 User manual

Model 699A07

PORTABLE VIBRATION CALIBRATOR

Installation and Operating Manual

For assistance with the operation of this product,

contact the PCB Piezotronics, Inc.

Toll-free: 800-959-4464

24-hour SensorLine: 716-684-0001

Fax: 716-684-3823

E-mail: [email protected]

Web: www.imi-sensors.com

The information contained in this document supersedes all similar information that

may be found elsewhere in this manual.

Service –Due to the sophisticated

nature of the sensors and associated

instrumentation provided by PCB

Piezotronics, user servicing or repair is

not recommended and, if attempted,

may void the factory warranty. Routine

maintenance, such as the cleaning of

electrical connectors, housings, and

mounting surfaces with solutions and

techniques that will not harm the

physical material of construction, is

acceptable. Caution should be observed

to ensure that liquids are not permitted

to migrate into devices that are not

hermetically sealed. Such devices

should only be wiped with a dampened

cloth and never submerged or have

liquids poured upon them.

Repair –In the event that equipment

becomes damaged or ceases to

operate, arrangements should be made

to return the equipment to PCB

Piezotronics for repair. User servicing or

repair is not recommended and, if

attempted, may void the factory

warranty.

Calibration –Routine calibration of

sensors and associated instrumentation

is recommended as this helps build

confidence in measurement accuracy

and acquired data. Equipment

calibration cycles are typically

established by the users own quality

regimen. When in doubt about a

calibration cycle, a good “rule of thumb”

is to recalibrate on an annual basis. It is

also good practice to recalibrate after

exposure to any severe temperature

extreme, shock, load, or other

environmental influence, or prior to any

critical test.

PCB Piezotronics maintains an ISO-

9001 certified metrology laboratory and

offers calibration services, which are

accredited by A2LA to ISO/IEC 17025,

with full traceability to SI through

N.I.S.T. In addition to the normally

supplied calibration, special testing is

also available, such as: sensitivity at

elevated or cryogenic temperatures,

phase response, extended high or low

frequency response, extended range,

leak testing, hydrostatic pressure

testing, and others. For information on

standard recalibration services or

special testing, contact your local PCB

Piezotronics distributor, sales

representative, or factory customer

service representative.

Returning Equipment –Following

these procedures will ensure that your

returned materials are handled in the

most expedient manner. Before

returning any equipment to PCB

Piezotronics, contact your local

distributor, sales representative, or

factory customer service representative

to obtain a Return Warranty, Service,

Repair, and Return Policies and

Instructions Materials Authorization

(RMA) Number. This RMA number

should be clearly marked on the outside

of all package(s) and on the packing

Service, Repair, and Return

Policies and Instructions

list(s) accompanying the shipment. A

detailed account of the nature of the

problem(s) being experienced with the

equipment should also be included

inside the package(s) containing any

returned materials.

A Purchase Order, included with the

returned materials, will expedite the

turn-around of serviced equipment. It is

recommended to include authorization

on the Purchase Order for PCB to

proceed with any repairs, as long as

they do not exceed 50% of the

replacement cost of the returned

item(s). PCB will provide a price

quotation or replacement

recommendation for any item whose

repair costs would exceed 50% of

replacement cost, or any item that is not

economically feasible to repair. For

routine calibration services, the

Purchase Order should include

authorization to proceed and return at

current pricing, which can be obtained

from a factory customer service

representative.

Contact Information –International

customers should direct all inquiries to

their local distributor or sales office. A

complete list of distributors and offices

can be found at www.pcb.com.

Customers within the United States may

contact their local sales representative

or a factory customer service

representative. A complete list of sales

representatives can be found at

www.pcb.com. Toll-free telephone

numbers for a factory customer service

representative, in the division

responsible for this product, can be

found on the title page at the front of this

manual. Our ship to address and

general contact numbers are:

PCB Piezotronics, Inc.

3425 Walden Ave.

Depew, NY14043 USA

Toll-free: (800) 828-8840

24-hour SensorLineSM: (716) 684-0001

Website: www.pcb.com

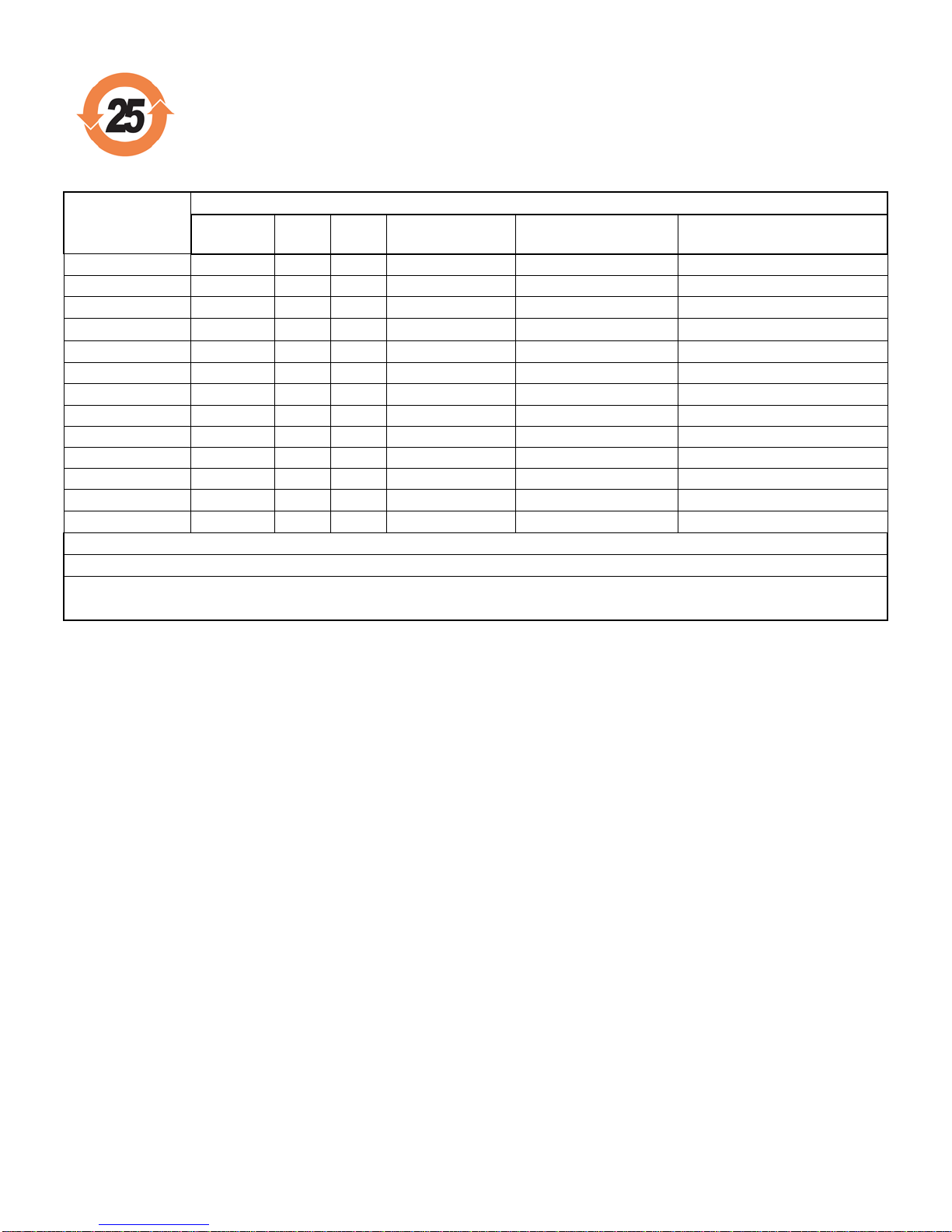

PCB工业监视和测量设备 - 中国RoHS2公布表

PCB Industrial Monitoring and Measuring Equipment - China RoHS 2 Disclosure Table

部件名称

有害物质

铅(Pb)

汞

(Hg)

镉

(Cd)

六价铬(Cr(VI))

多溴联苯 (PBB)

多溴二苯醚(PBDE)

住房

O

O

O

O

O

O

PCB板

X

O

O

O

O

O

电气连接器

O

O

O

O

O

O

压电晶体

X

O

O

O

O

O

环氧

O

O

O

O

O

O

铁氟龙

O

O

O

O

O

O

电子

O

O

O

O

O

O

厚膜基板

O

O

X

O

O

O

电线

O

O

O

O

O

O

电缆

X

O

O

O

O

O

塑料

O

O

O

O

O

O

焊接

X

O

O

O

O

O

铜合金/黄铜

X

O

O

O

O

O

本表格依据 SJ/T 11364 的规定编制。

O:表示该有害物质在该部件所有均质材料中的含量均在 GB/T 26572 规定的限量要求以下。

X:表示该有害物质至少在该部件的某一均质材料中的含量超出 GB/T 26572 规定的限量要求。

铅是欧洲RoHS指令2011/65/ EU附件三和附件四目前由于允许的豁免。

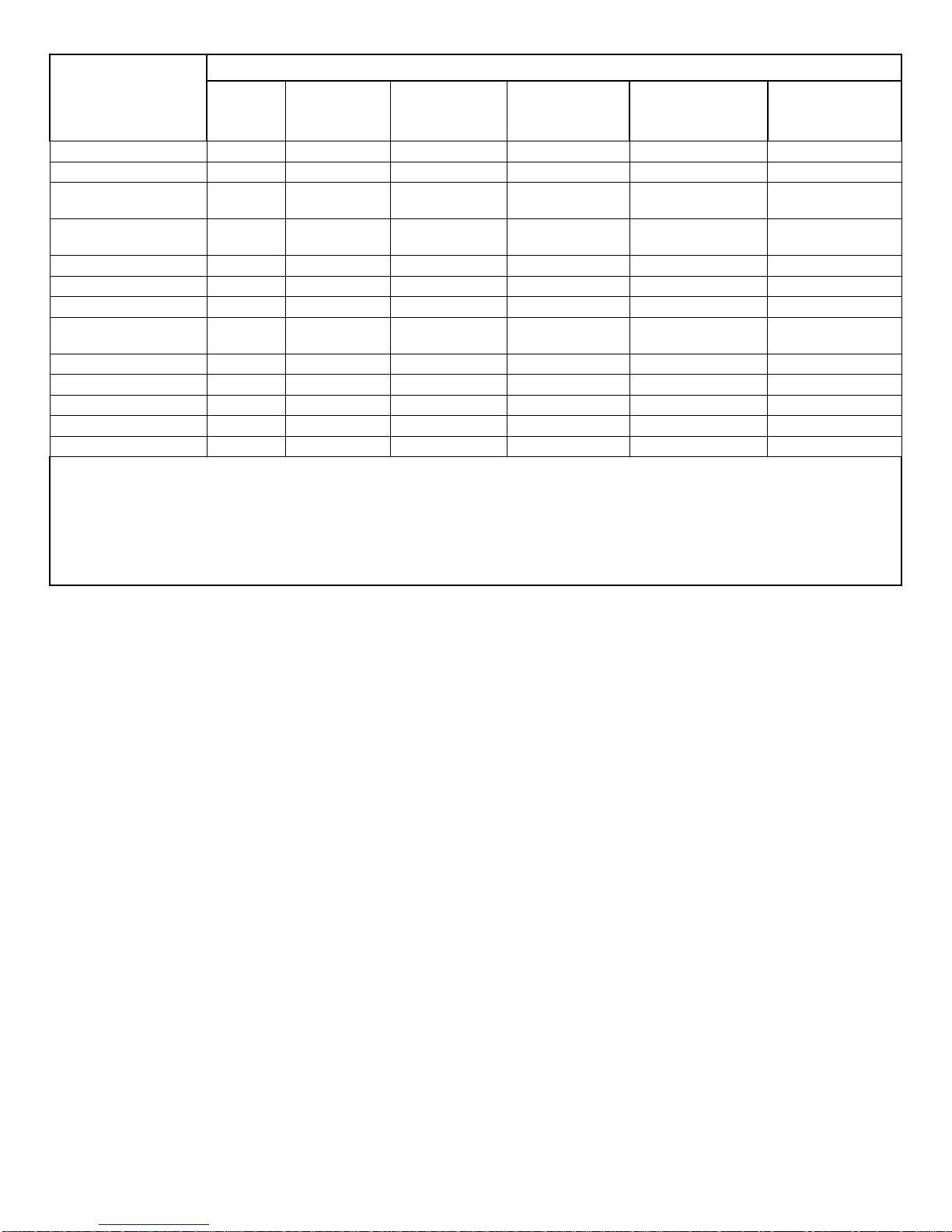

CHINA RoHS COMPLIANCE

DOCUMENT NUMBER: 21354

DOCUMENT REVISION: D

ECN: 46162

Component Name

Hazardous Substances

Lead

(Pb)

Mercury

(Hg)

Cadmium

(Cd)

Chromium VI

Compounds

(Cr(VI))

Polybrominated

Biphenyls

(PBB)

Polybrominated

Diphenyl

Ethers (PBDE)

Housing

O

O

O

O

O

O

PCB Board

X

O

O

O

O

O

Electrical

Connectors

O

O

O

O

O

O

Piezoelectric

Crystals

X

O

O

O

O

O

Epoxy

O

O

O

O

O

O

Teflon

O

O

O

O

O

O

Electronics

O

O

O

O

O

O

Thick Film

Substrate

O

O

X

O

O

O

Wires

O

O

O

O

O

O

Cables

X

O

O

O

O

O

Plastic

O

O

O

O

O

O

Solder

X

O

O

O

O

O

Copper Alloy/Brass

X

O

O

O

O

O

This table is prepared in accordance with the provisions of SJ/T 11364.

O: Indicates that said hazardous substance contained in all of the homogeneous materials for this part is below the limit

requirement of GB/T 26572.

X: Indicates that said hazardous substance contained in at least one of the homogeneous materials for this part is above

the limit requirement of GB/T 26572.

Lead is present due to allowed exemption in Annex III or Annex IV of the European RoHS Directive 2011/65/EU.

User Manual

Portable Vibration

Calibrator

699A07

69142

REV. A

IMI Sensors: A PCB Piezotronics Div 699A07 User Manual

MAN-0192 rev A Page 2 of 39 800-959-4464

MODEL 699A07 Portable Vibration Calibrator User Manual

Product Support

For answers to questions about the 699A07 Portable Vibration Calibrator, consult this manual. For

additional product support, contact IMI Sensors at 800-959-4464 in the U.S.A. or 716-684-0003, 9

a.m. to 5 p.m. EST. If it is more convenient, fax questions or comments to IMI Sensors at 716-

684-3823 or email our sales staff at [email protected]m.

Warranty

IMI Sensors Model 699A07 Portable Vibration Calibrator is warranted against defective materials

and workmanship for TWO YEARS from the date of shipment, unless otherwise specified.

Damage to equipment caused by incorrect power, misapplication or procedures inconsistent with

this manual are not covered by warranty. If there are any questions concerning the intended

application of the product, contact IMI Sensors. Batteries and other expendable accessory

hardware items are excluded.

Copyright

Copyright ã 2017 IMI Sensors. This manual is copyrighted with all rights reserved. The manual

may not be copied in whole or in part for any use without prior written consent of IMI Sensors.

Disclaimer

The following paragraph does not apply in any state or country where such statements are not

agreeable with local law:

IMI Sensors provides this publication “as is” without warranty of any kind, express or implied,

including but not limited to, the implied warranties of merchantability or fitness for a particular

purpose. This document is subject to change without notice and should not be construed as a

commitment or representation by IMI Sensors.

This publication may contain inaccuracies or typographical errors. IMI Sensors will periodically

update the material for inclusion in new editions. Changes and improvements to the product

described in this manual may be made at any time.

Trademarks

ICP® is a registered trademark of PCB Piezotronics, Inc. Pelican® is a trademark of

Pelican Products, Inc.

MAN-0192 Rev A

October 2017

3425 Walden Avenue

Depew, NY 14043

Phone: 716.684.0001

Fax: 716-684-0987

www.pcb.com

69142

REV. A

IMI Sensors: A PCB Piezotronics Div 699A07 User Manual

MAN-0192 rev A Page 3 of 39 800-959-4464

Table of Contents

INTRODUCTION ............................................................................................................................. 4!

Welcome ............................................................................................................................ 4!

Customer Support .............................................................................................................. 4!

Cautionary Notes ................................................................................................................ 4!

Supplied Accesories ........................................................................................................... 5!

Optional Fixturing and Accessories .................................................................................... 6!

Replacement Accessories .................................................................................................. 6!

699A07 OPERATION GUIDE ......................................................................................................... 7!

Basic Operation .................................................................................................................. 7!

Report Generation Workbook ............................................................................................. 9!

Additional Features ........................................................................................................... 11!

Calibration Route .............................................................................................................. 13!

Definition of Frequency Units ........................................................................................... 18!

Definition of Amplitude Units ............................................................................................ 18!

Mounting Basics ............................................................................................................... 19!

Input / Output .................................................................................................................... 19!

THEORY OF OPERATION ........................................................................................................... 21!

Instrumentation ................................................................................................................. 21!

Battery and Charger ......................................................................................................... 23!

Battery Information and Care ........................................................................................... 23!

SPECIFICATIONS AND PERFORMANCE .................................................................................. 24!

General ............................................................................................................................. 24!

Accuracy of Readout ........................................................................................................ 24!

Units of Readout ............................................................................................................... 24!

Power Requirements ........................................................................................................ 25!

Temperature ..................................................................................................................... 25!

Physical ............................................................................................................................ 25!

Shaker Loading ................................................................................................................ 25!

RECOMMENDED PRACTICES .................................................................................................... 28!

Operational Verification and Recalibration ....................................................................... 28!

Standard Checks for Transducers .................................................................................... 28!

Typical Accelerometer & Velocity Sensor Checkout ........................................................ 29!

Calibrating Charge-Mode Accelerometers ....................................................................... 30!

Non-Contact Displacement Sensor Calibration ................................................................ 30!

Non-Contact Displacement Sensor Test Setup ................................................................ 31!

Proximity Probe Dynamic Linearity Calibration & Confirmation of Vibration Alarms ........ 35!

Troubleshooting the proximity probe system .................................................................... 36!

Creating a Proximity Probe Curve in Mils ......................................................................... 36!

Testing 4-20 mA Vibration Transmitters ........................................................................... 37!

Maintenance ..................................................................................................................... 39!

69142

REV. A

IMI Sensors: A PCB Piezotronics Div 699A07 User Manual

MAN-0192 rev A Page 4 of 39 800-959-4464

Introduction

Welcome

Thank you for choosing IMI Model 699A07.

The IMI Model 699A07 Portable Vibration Calibrator provides a field tested method

for on-the-spot dynamic verification of accelerometers, velocity pickups and non-

contact displacement transducers. Optional mounting fixtures and hardware

needed to connect transducers to the 699A07 mounting platform are available upon

request.

A closed-loop control algorithm provides enhanced stability and accuracy of

frequency and amplitude levels.

The 699A07 incorporates a built-in sine wave oscillator, power amplifier,

electrodynamic shaker, NIST traceable reference accelerometer, digital display, and

internal memory. The 699A07 is completely self-contained and operates on battery

or AC power.

The built-in reference accelerometer is attached permanently to the shaker

armature, maximizing the accuracy between the reference accelerometer and the

test transducer. The 699A07 is designed to provide long-term reliable performance

over the frequency range of 5 Hz to 10 kHz. The 699A07 can be used for a variety

of applications that include:

• Verification and calibration of vibration transducers and related vibration

test systems

• Verification of connector and cabling integrity

• Confirm machine vibration alarm trip points are set properly and ensure

end-to-end functionality of vibration monitoring systems.

Customer Support

IMI Sensors is a PCB Group Company, and we are 100% committed to the PCB

Group’s pledge of ‘Total Customer Satisfaction.’ If at any time you have questions

or problems with the 699A07 system, please contact an Application Engineer at IMI

Sensors:

Telephone: 716-684-0001

Toll Free: 800-828-8840

Email: imi@pcb.com

Cautionary Notes

• Loads of up to 800 gram (28.3 oz) can be mounted directly to the

699A07 mounting platform. Larger loads may be applied to the platform,

however, if prolonged testing of a heavy load is planned, we recommend

using an external transducer suspension system. Under these

conditions the vibration waveform should be viewed on the oscilloscope

to aid in positioning the test transducer and platform to reduce distortion

that can occur with very heavy weights.

• The 699A07 should always be operated on a stable, flat surface.

69142

REV. A

IMI Sensors: A PCB Piezotronics Div 699A07 User Manual

MAN-0192 rev A Page 5 of 39 800-959-4464

• The 699A07 is designed for field test applications but care must be taken

to maintain the integrity of the mounting platform assembly.

• Hearing protection recommended when operating the 699A07 for an

extended amount of time.

Supplied Accessories

Accessories pictured below are included with each 699A07 Portable Vibration

Calibrator.

USB Flash Drive Pre-Loaded with Report Generating Worksheet

Mounting Wrench

1 – Mounting Pad (080A118)

2 – ¼-28 to ¼-28 Adaptor (081B20)

3 – 10-32 to ¼-28 Adaptor

(081A08)

Accessory Pouch

Universal Power Supply

and Plug Adaptors (600A25)

69142

REV. A

IMI Sensors: A PCB Piezotronics Div 699A07 User Manual

MAN-0192 rev A Page 6 of 39 800-959-4464

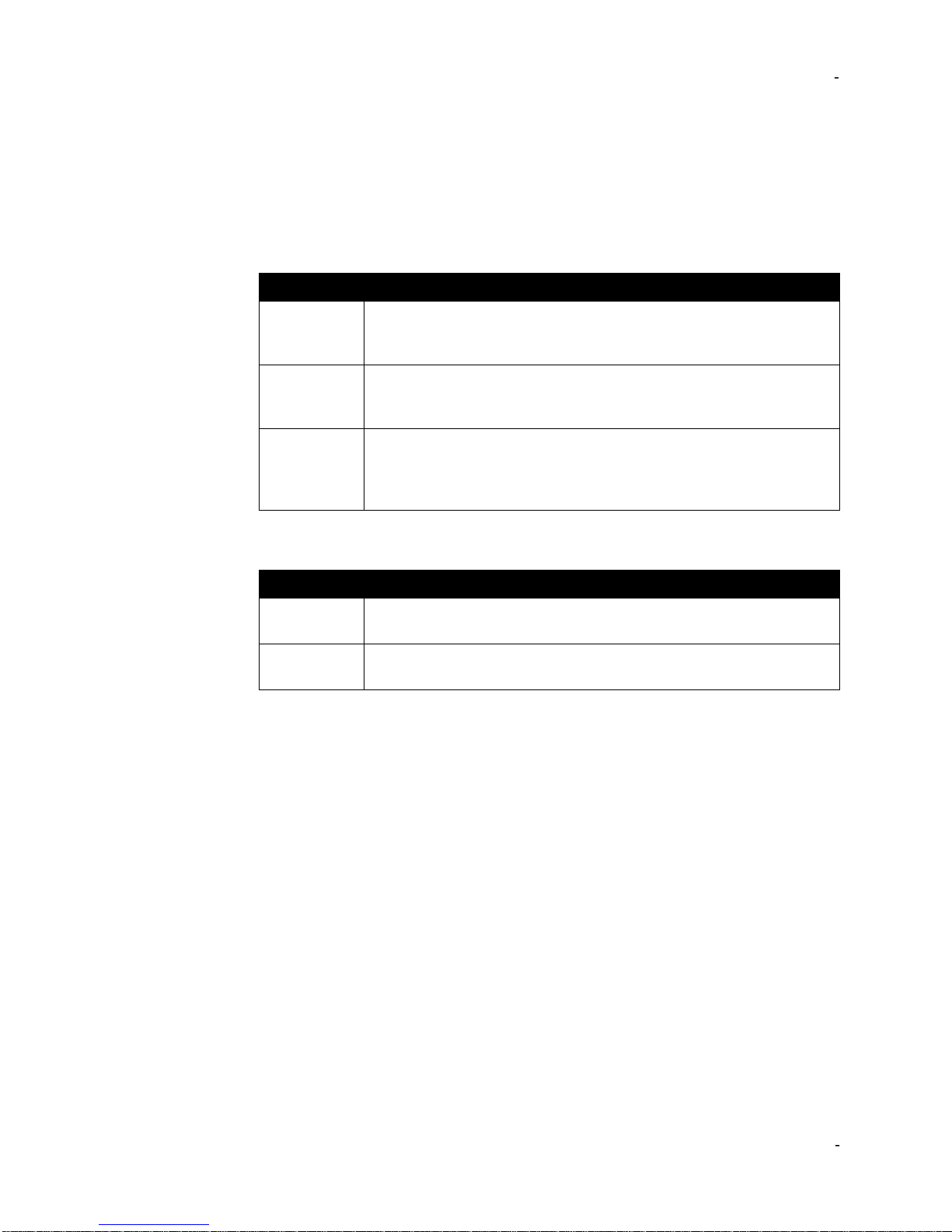

Optional Fixturing and Accessories

For operation in certain applications, such as calibration of non-contact

displacement sensors, IMI offers optional mounting fixturing. Reference the table

below when ordering these optional adaptors and accessories.

Accessory

Description

600A22

Proximity probe adaptor kit, supports probes with common case

threads ranging from M6 to 3/8”. Includes Mitutoyo micrometer

and nickel plated 4140 steel target.

600A23

Proximity probe adaptor kit, supports probes with common case

threads ranging from M6 to 3/8”. Includes Mitutoyo micrometer

(metric) and nickel plated 4140 steel target.

600A24

Mounting accessory kit for 699A07 Series Portable Vibration

Calibrators to adapt to ¼-28 threaded mounting platforms.

Includes studs/inserts (1/4-38, 10-32, 6-32 and 5-40) and bases

(for adhesive, magnetic and custom thread patterns).

Replacement Accessories

Accessory

Description

600A25

18 Volt, 1 amp power supply/charger for 699A07 Portable

Vibration Calibrator, universal 100-240 V, 50/60 Hz.

600A26

Replacement battery for 699A07 Series Portable Vibration

Calibrators.

69142

REV. A

IMI Sensors: A PCB Piezotronics Div 699A07 User Manual

MAN-0192 rev A Page 7 of 39 800-959-4464

699A07 Operation Guide

For the following section, “point” is defined as the numerical value of the amplitude

at a given frequency. “Record” is defined as the collection of all numerical calibration

points at different frequencies and amplitudes saved together.

Basic Operation

For the basic operation of the 699A07, a vibration sensor and appropriate cable are

needed. Typically, the 699A07 is used as a vibration excitation source and as a

readout device with the vibration sensor connected to the 699A07’s Test Sensor

BNC Input. Alternatively, the 699A07 unit can be used to test different types of

vibration equipment (i.e. a vibration meter or vibration monitoring system), in which

case the sensor will be directly connected to the vibration measurement equipment

and the 699A07 is used just as a controlled excitation source.

Test Setup

1. Mount your sensor to the 699A07 mounting platform

• The 699A07 sensor mounting platform is threaded for a ¼-28 stud. Select an

appropriate adaptor for mounting the sensor.

• While tightening the sensor, secure the 699A07 mounting platform with the supplied

wrench to prevent damage from torque.

2. Connect sensor under test (SUT) to “Test Sensor In.” Make sure that connections are

secure.

3. Power the unit ON by pressing and holding the FREQUENCY dial for 3 seconds.

NOTE: It is good practice to perform calibrations on battery power. Disconnecting

from line power ensures a power surge will not cause the calibrator to power down

during test. If excess current is detected during use, the portable calibrator shuts

down to prevent damage.

Selecting Input Mode

4. The 699A07 can accept ICP® as well as AC voltage and AC current output sensors.

Press and hold the AMPLITUDE dial to select between ICP®, Voltage Mode or

Modulated Current mode. Modulated Current mode is only available if the firmware

option is ordered, otherwise user will not see this mode as an option.

Note: ICP® (or IEPE) mode sensors are the most popular type of accelerometer

transducers and require a 2 mA to 20 mA constant current supply to operate.

The 699A07 unit supplies the necessary constant current to power this class of sensors.

Voltage output sensors are typically moving coil velocity sensors but can also be the

voltage output of a signal conditioner associated with any type of vibration transducer

such as the output from the probe driver in a proximity probe system. Refer to the Sensor

Signal Measurement Electronics (SUT Input Characteristics and Considerations) for

details.

Setting the Frequency and Amplitude Units

5. Select the correct Frequency Units for your test by pressing the FREQUENCY dial to

enter into the CALIBRATION OPTIONS menu:

• Use the FREQUENCY dial to highlight TEST SETTINGS then press.

• Within the Test Settings Menu rotate the FREQUENCY dial to highlight

FREQUENCY UNIT then press to toggle between Hertz and CPM.

69142

REV. A

IMI Sensors: A PCB Piezotronics Div 699A07 User Manual

MAN-0192 rev A Page 8 of 39 800-959-4464

6. Select the correct Amplitude Units for your test by pressing and releasing the

AMPLITUDE dial. The following options are available:

Acceleration

Velocity

Displacement

g’s pk

g’s RMS

m/s2 pk

m/s2 RMS

in/s pk

in/s RMS

mm/s pk

mm/s RMS

mils p-p

µm p-p

7. Select the desired vibration amplitude and frequency for testing by turning the

AMPLITUDE and FREQUENCY dials clockwise to increase or counter clockwise to

decrease the setting.

• Slow Turns – settings will increase or decrease by single steps

• Fast Turns – settings will increase or decrease by larger increments

Record and Save Calibration Points

8. Once the frequency and amplitude are set to desired values, with the file menu set to

“Save Point,” press the FILE dial to store the calibration data point.

9. Repeat steps 7 through 9 to set the frequency and amplitude to increment to the next

calibration data point and save.

Completing and Storing Record to Memory

10. Once all data points have been saved in a record and record is complete, rotate FILE

dial and press it to select “End Record.”

• The screen will prompt with:

11. Rotate the FILE dial to “Edit” to enter the model number, serial number and axis. The

FILE menu for this screen also includes the tools “Next” and “Back.”

• Push the FILE dial to choose “Next,” which goes to the next save screen.

12. To “Save” the record without inputting an annotation, press the FILE dial two more times.

13. Rotate the FILE dial to “Edit” and press to store any annotations or additional notes (such

as technician initials, etc):

69142

REV. A

IMI Sensors: A PCB Piezotronics Div 699A07 User Manual

MAN-0192 rev A Page 9 of 39 800-959-4464

• Turn the FILE dial to the left and right to select each individual letter or number you

wish to input as part of an annotation. Push the FILE dial to save each character.

• Rotate the FILE dial and select “Save.” This will save all data points in the listed

record number. The record number shown on the screen increments automatically.

Transfer Records to USB Flash Drive

14. Rotate FILE dial and press to select “Tools.”

15. Rotate FILE dial and press to select “USB Menu.”

• A USB flash drive must be connected to the unit. The USB must be formatted to

FAT32. You can use the 699A07 or a PC to format the flash drive.

16. To copy all data points and records to a USB Flash Drive, rotate FILE dial and press to

select “Copy All Records.”

• This will leave current records on unit memory and also create a copy on the USB.

17. To move all data points and records to USB, rotate FILE dial and press to select “Move

All Records.”

• This will remove current records on unit memory and move onto the USB.

Note: The USB hardware may not always recognize a USB flash drive if it is

plugged into the USB port while the 699A07 is in sleep mode. IMI Sensors

recommends connecting the USB drive while the 699A07 is on and operational.

Powering Off

19. Suggested Best Practice: Before powering the unit OFF, reduce the vibration

amplitude. The 699A07 retains the settings used prior to shutdown when it is

powered back ON. Reducing the amplitude prior to shutdown ensures the sensor

under test will not be jarred when the 699A07 is powered ON.

20. Power the unit OFF by pressing and holding the FREQUENCY dial for

approximately 3 seconds.

• To preserve battery charge, the 699A07 will automatically power off after 20

minutes of inactivity when not plugged in to the charger.

After Testing

21. Suggested Best Practice: Plug the 699A07 into an AC power source when not

in use. This will ensure the batteries are fully charged for your next test and also

help to maximize the lifespan of the batteries.

22. Periodic calibration checks are recommended:

• A dedicated “verification sensor” can be used to check the system readings and

results. By using a dedicated sensor, you can ensure that the system is providing

the same result during each test.

• The 699A07 should be returned to IMI Sensors for regular recalibration or for any

maintenance or repair. The most current factory calibration date or the calibration

due date is displayed on the LCD screen during the 699A07 boot up sequence. The

default due date is set for 12 months after the last factory calibration, but the

calibration interval can be user defined to be anywhere from 1 to 72 months, or set

up to never expire.

Report Generation Workbook

Calibration data can be saved into the 699A07’s internal memory and easily

exported to a personal computer using a USB Flash Drive.

The 699A07 Portable Vibration Calibrator includes a pre-formatted USB Flash Drive

with a Microsoft Excel Report Generation Workbook for the creation of customizable

calibration certificates. The Excel file provides an intuitive interface which allows a

69142

REV. A

IMI Sensors: A PCB Piezotronics Div 699A07 User Manual

MAN-0192 rev A Page 10 of 39 800-959-4464

user to create and print a calibration certificate with just a few mouse clicks. In order

to use the file, make sure macros are enabled, otherwise Excel won’t be able to load

data and create the certificates.

The Excel workbook consists of the following worksheets or tabs:

• FRData – Use this tab to create a frequency response certificates in just 2 steps:

1. Clicking on Import Data from File button prompts the user to select and import a

.csv calibration data file previously created by the 699A07

2. Once data is loaded into the table, click View Certificate to see and print a

calibration certificate containing the frequency response data (the reference

frequency for the calibration certificate is 100Hz and can be changed by the user as

needed)

Note: If testing a charge-mode accelerometer and calibration certificate in pC

units is desired, click the box at top left of the FRData tab and enter the sensitivity of

the charge amplifier in the “mV/pC” box located at cell D8. See the section

“Calibrating Charge-Mode Accelerometers” for more information.

• LINData – Use this tab to create linearity response certificates. The worksheet

applies linear regression to interpolate the data. The Max Linearity is calculated for

the worst deviation of a particular point from the best-fit straight line (BFSL) of all

tested points. The table also displays the specific results at each test level.

The LINData worksheet has 2 tables. The left table should be used for creating

dynamic linearity data calibration certificates in just 2 steps:

1. Click on Import Data from File to select and import a .csv calibration data file

previously created by the 699A07

2. Once data is loaded into the table, click View Certificate to see and print a

calibration certificate containing the linearity response data. The worksheet expects

the data points to be taken at the same frequency (speed). A checkbox option

labeled Set Y-intercept to zero is available to force the interpolation to go through

the origin point.

The right table in the LINData worksheet is used to create a DC proximity probe

curve or linearity certificate for 4-20 mA vibration transmitter. Creating a DC

proximity probe curve requires the 600A22 or 600A23 proximity probe adaptor kits

and a DC voltmeter (not included). Creating a linearity certificate for a 4-20 mA

vibration transmitter requires DMM set to DC current input.

1. Select the appropriate vibration scale (Acceleration, Velocity or Displacement) by

clicking in cell H12 and selecting from drop down menu.

2. Select the appropriate units (g’s pk, g’s RMS, m/sec2 pk, m/sec2 RMS, in/sec pk,

in/sec RMS, mm/sec pk, mm/sec RMS, mils p-p or µm p-p) in cell H13. Make sure

cell H12 is set to the right scale first.

3. Enter known amplitude and output for the first test point next to “Starting Point”

and repeat for each additional test point moving down the table. Once data is

entered into the table, click View Certificate to see and print a calibration certificate

containing the linearity response data.

• FRCert - Displays the frequency response calibration certificate using the current

data and information from FRData.

• LINCert - Displays the linearity response calibration certificate using dynamic

linearity data from LINData.

• SLINCert - Displays the linearity response calibration certificate using static

linearity data from LINData.

69142

REV. A

IMI Sensors: A PCB Piezotronics Div 699A07 User Manual

MAN-0192 rev A Page 11 of 39 800-959-4464

• Route Creator – If firmware option 600A31 is ordered, this tab can be used to

create semi-automated tests with instant pass/fail notification for almost any

vibration sensor. See “Calibration Route” for more information.

Additional Features

Delete

The “Delete” feature can be found under the FILE dial > “Delete.” When “Delete” is

selected, the shaker will stop moving and four options will appear:

1. “Delete Point” will delete a current point.

2. “Delete Record” will delete the entire current record.

3. “Delete All” will delete all data points and all records that are stored on the internal unit

memory.

4. “Back” will return to the main screen.

USB Options

The “USB Options” feature can be found under the FILE dial > “Tools” > “USB

Menu” > “USB Options.” When “USB Options” is selected, the following information

will appear on the screen:

• “Status” – USB flash drive connected or not connected.

• “Partition” – Format of USB flash drive connected to the unit.

• “Available” – Memory space available on USB flash drive.

• “Required” – Space required to save all records on USB flash drive.

And the following actions are available:

• “Eject Drive” will safely eject the USB flash drive from the unit.

• “Format USB” for formatting the USB flash drive. (FAT32 partition)

• “Back” to go back to the USB Menu.

Date and Time

The “Date and Time” feature can be found under the FILE dial > “Tools” > “Options”

> “Date and Time.”

1. Press the FILE dial to select “Adjust.”

2. Turn the AMPLITUDE dial to the select the current month, day and year and push the

FREQUENCY dial to confirm or the AMPLITUDE dial to change.

3. Press the AMPLITUDE dial to select “yes” this is correct.

4. Turn the AMPLITUDE dial to select the current hours and minutes then push the

FREQUENCY dial to confirm the time is correct.

5. Press the AMPLITUDE dial to select “yes” this is correct.

Calibration Interval

The “Calibration Interval” can be adjusted under the FILE dial > “Tools” > “Options”

> “Calibration Interval.”

1. Select “Adjust” and press FILE dial.

2. Turn AMPLITUDE dial to select number of months for Calibration Interval.

• Suggested Best Practice: 12 months. The calibration interval can be defined to be

anywhere from 1 to 72 months, or set up to never expire.

3. Press FREQUENCY dial to confirm selected Calibration Interval.

Traceability

The “Traceability” feature can be found under FILE dial > “Tools.”

69142

REV. A

IMI Sensors: A PCB Piezotronics Div 699A07 User Manual

MAN-0192 rev A Page 12 of 39 800-959-4464

1. Press FILE dial to select “Traceability.” A screen with the following information will

appear:

• Model

• Serial Number

• Firmware Revision Number

• Calibration Date

• Reference Sensor Sensitivity

• PRD-P

• NIST Traceability Number

• PTB Traceability Number

2. Press FILE dial to go back to main screen and shaker will go back to shaking.

Test Settings

The “Test Settings” menu can be found by pressing FREQUENCY dial > “Test

Settings.” A screen with the following will appear, use the FREQUENCY dial to

highlight and toggle all settings:

• Back – returns user to “Calibration Options” menu

• Cal Route: N/A, Active or off

o N/A indicates the Calibration Route firmware option has not been

purchased. Calibration Route allows users to program semi-automated test

points with instant pass/fail notification. See “Calibration Route” section for

more information. Contact IMI Sensors to unlock this feature.

• Source: Internal or External

o If external is selected the shaker can be controlled with an external source.

See “Input/Output” for more information.

• Frequency Unit: Hertz or CPM (cycles per minute)

• Sensor Type: ICP®, Voltage or Modulated Current

o Use ICP® for most accelerometers, Voltage for proximity probes and

moving coil sensors, Modulated Current for high-temp turbine vibration

sensors with AC current output. See “Selecting the Input Mode” for more

information. Modulated current is optional; contact IMI Sensors to unlock

this feature.

• Sensor Readout: mV/EU or mV

o Changes the display to show the sensor under test’s sensitivity (output

voltage divided by input vibration, mV/EU) or the sensor under test’s raw

AC output voltage.

Amplitude Units

Amplitude units that are seldom or never used can be turned off by using the

“Amplitude Units” feature, found by pressing FREQUENCY dial > “Amplitude Units.”

The “Amplitude Unit Screen” shows all 10 available amplitude scales on model

699A07 Portable Vibration Calibrator. Use the FREQUENCY dial to highlight each

scale and press the dial to toggle the scale on or off. A filled circle next to the scale

indicates it is active. An empty circle next to the scale indicates it is inactive. Inactive

scales do not appear when cycling through scales using the AMPLITUDE dial

during normal operation.

69142

REV. A

IMI Sensors: A PCB Piezotronics Div 699A07 User Manual

MAN-0192 rev A Page 13 of 39 800-959-4464

To go back to the “Calibration Options” menu use the FREQUENCY dial to highlight

“Back” then press.

Calibration Route

Firmware Option: 600A31

The Calibration Route firmware is factory-installed on every Model 699A07. For the

firmware to be activated, it must be ordered as a separate line item (Model 600A31).

If ordered at the same time as Model 699A07, the firmware will be activated in the

factory prior to shipment. If ordered after the fact, IMI Sensors will provide an

activation code that the user can enter in order to activate the firmware in the field.

Contact IMI Sensors for additional ordering and installation information.

The Calibration Route firmware allows users to create and run semi-automated

frequency response and amplitude linearity tests for vibration sensors on model

699A07 with instant pass/fail notification. Tests or “routes” are created in the Report

Generation Workbook then uploaded to the 699A07 via supplied USB drive. Once

uploaded the test is activated. But the test can also be de-activated at any time,

putting the 699A07 back into manual operation mode. When a Calibration Route is

active the 699A07 can only adjust to the pre-defined amplitude and frequency points

that have been programmed.

Creating A New Test (Route)

Version 2010 or later of Microsoft Excel® is required for the CalRoute features in

Report Generation Workbook to operate correctly. Drop-down arrows for frequency

and amplitude units may not appear if using older versions of this software.

1. Open the Report Generation Workbook (version 3.0.2 or later required) using

Microsoft Excel®

2. At bottom, select the Route Creator tab

3. Route Name: Enter the name of the test in cell B7 next to “Route Name”. When the

test file is created and saved the file name will be this value followed by

“_Route.pvc”.

4. Frequency Unit: Use the drop down arrow to choose the frequency unit (Hertz or

CPM) in cell B8. One cannot toggle between Hertz and CPM during the test.

5. Amplitude Unit: Use the drop down arrow to choose the amplitude unit (g pk, g

RMS, m/sec2 pk, m/sec2 RMS, in/sec pk, in/sec RMS, mm/sec pk, mm/sec RMS,

mils p-p or µm p-p) in cell D7.

6. Amplitude: If desired, enter the amplitude for all test points in cell B9 next to

“Amplitude”. This is useful for a frequency response test where all test points will

69142

REV. A

IMI Sensors: A PCB Piezotronics Div 699A07 User Manual

MAN-0192 rev A Page 14 of 39 800-959-4464

have the same amplitude value. If creating a linearity test leave this cell blank since

the amplitude values will change for each test point.

7. Sensor Type: Use the drop down arrow in cell F7 to select the sensor type (ICP®,

Voltage or Modulated Current).

8. Sensor MN: If desired, enter the sensor model number in cell F8. This is optional.

The sensor model number that is entered will print on the calibration certificate. It

can be changed at any time. If the model number is not consistent leave this cell

blank.

9. Lower Bound: In cell D8, enter the minimum sensitivity value for the sensor under

test at each test point that will pass calibration test. For example, the minimum

acceptable sensitivity for 100 mV/g accelerometer with +/- 5% sensitivity tolerance is

95 mV/g, thus lower bound would be: 95.00.

10. Upper Bound: In cell D9, enter the maximum sensitivity value for the sensor under

test at each test point that will pass calibration test. For example, the maximum

acceptable sensitivity for 100 mV/g accelerometer with +/- 5% sensitivity tolerance is

105 mV/g, thus upper bound would be: 105.00.

11. Press Table Auto-Fill. The grey cells in the table will automatically populate with the

values chosen in steps 3-10. All cells will populate. The table is capable of creating a

30-point test. But any number of test points can be programmed. Before creating the

route file user must delete values in cells for test points that should not be created

(see example).

12. Enter the desired Frequency values for each test point in column A beginning with

cell A13. The test will be conducted in the exact order as programmed. The first test

point will be as programmed in row 13; the next will use row 14 values and so on.

a. The 699A07 can only simulate vibration in CPM values that are multiples of

60. I.e. 1800 CPM, 3600 CPM, 4200 CPM, etc. If a value is entered that is

not a multiple of 60, the 699A07 will adjust down to the nearest CPM value

that is a multiple of 60.

b. Example: 1900 CPM is entered as a test point. The 699A07 will adjust to

1860 CPM and 1860 CPM will be displayed.

13. Enter the desired Amplitude values for each test point in column B beginning with

cell B13. Skip this step if all amplitude values have been automatically populated

using the Table Auto-Fill button.

14. Modify any individual test point as desired. For example, most accelerometers have

a wider sensitivity tolerance at extreme low and high frequencies. User may wish to

expand the upper and lower bounds for certain test points.

15. Delete undesired test points. For example, a 10-point test only requires rows 13-22.

The Table Auto-Fill feature saves typing but one must delete data from cells that are

not needed. For a 10-point test rows 23-42 should be blank thus they can be

highlighted and cleared.

16. Press Create Route File. A .pvc file will be created, save this file to the USB drive in

the Calibration_Route folder.

a. When prompted to save, open the USB Disk

b. Open the IMI_PVC folder

c. Open the Calibration_Route folder

d. Press save

69142

REV. A

IMI Sensors: A PCB Piezotronics Div 699A07 User Manual

MAN-0192 rev A Page 15 of 39 800-959-4464

Example Accelerometer Test (Route)

An example of a 10-point accelerometer test, created in the Report Generation

Workbook, is shown above. Some helpful notes…

• When run, this test will shake the accelerometer at 1g pk at all points. If the shaker

cannot generate 1g pk it will output the maximum vibration possible given the

sensor’s weight and test speed. The shaker will not allow user to program points

that can damage the shaker.

• The test will begin at 10 Hz and end at 5000 Hz, with test points at 50,100, 300,

500, 1000, 2000, 3000 and 4000 Hz as well.

• If the sensor under test’s sensitivity is above 105 mV/g or below 95 mV/g the

699A07 will alert the user that test point failed.

• The file name will be CaseAccel_Route.pvc, when uploading to the 699A07 one

would choose this file.

• ICP® power is active for all test points. If this test were applied to a self-powered

sensor data would be invalid. One would select “Voltage” for a self-powered sensor

such as a moving coil velocity transducer.

69142

REV. A

Table of contents

Popular Test Equipment manuals by other brands

Westinghouse

Westinghouse AMPTECTOR Instruction leaflet

Viavi

Viavi OneAdvisor 1000 Quick Card User Guide

Tool it

Tool it PBT 550 Translation of the original instructions

ADC

ADC DSXpert 2005R installation instructions

Agilent Technologies

Agilent Technologies InfiniiVision 3000 X- Series Advanced training guide

Industrial Fiber Optics

Industrial Fiber Optics IF-FOM Operator's manual

Rohde & Schwarz

Rohde & Schwarz MXO 4 Series Getting started

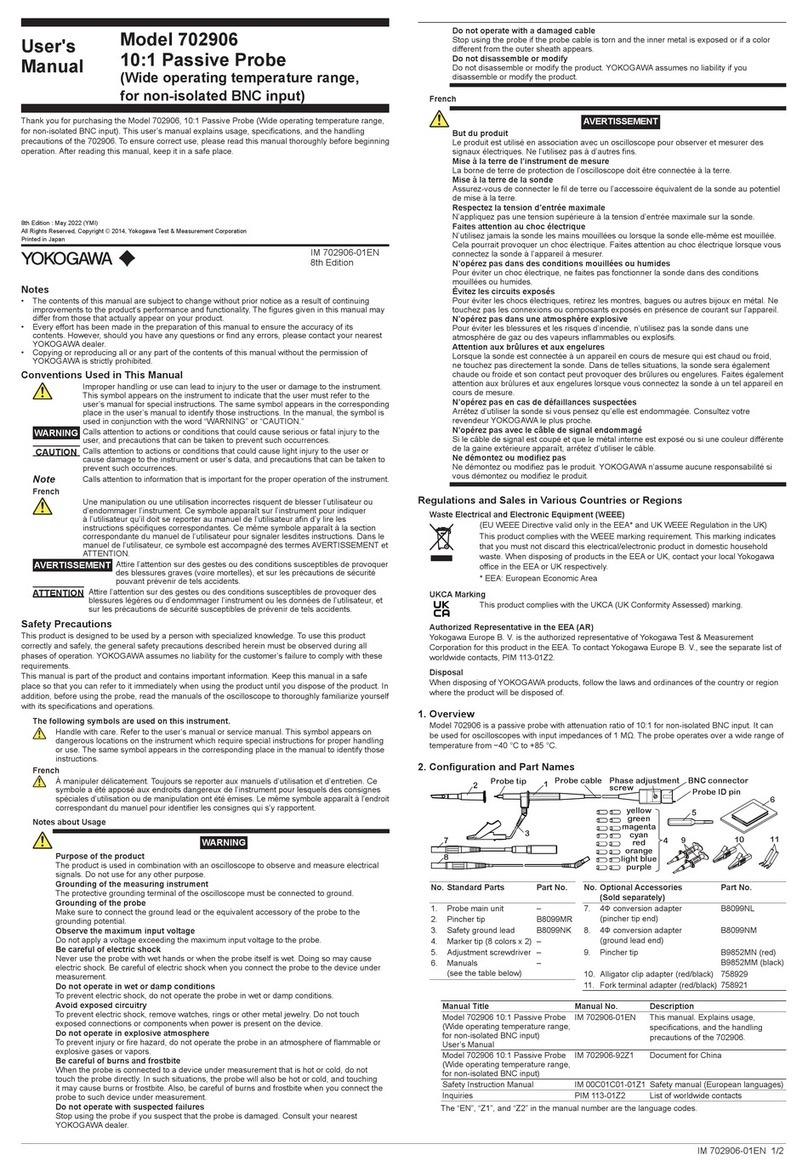

YOKOGAWA

YOKOGAWA 702906 user manual

EUTECH INSTRUMENTS

EUTECH INSTRUMENTS ECOTESTR PH 2 operating instructions

Inficon

Inficon ULTRATEST UL3000 Fab PLUS operating instructions

GREENLINE

GREENLINE NETcat Pro NC-500 instruction manual

Tektronix

Tektronix TDS 400 Series instruction manual