Dear Customer,

Our compliments for having chosen a top-quality Immergas product, able to assure well-being and safety for a long period of time. As an Immergas

customer you can also count on a qualied aer-sales service, prepared and updated to guarantee constant eciency of your boiler. Read the following

pages carefully: you will be able to draw useful suggestions regarding the correct use of the appliance, the respect of which, will conrm your satisfaction

for the Immergas product. Contact our area authorised aer-sales centre as soon as possible to request commissioning. Our technician will verify the

correct functioning conditions; he will perform the necessary calibrations and will demonstrate the correct use of the generator. For any interventions or

routine maintenance contact Immergas Authorised Centres: these have original spare parts and boast of specic preparation directly from the manufacturer.

General recommendations

All Immergas products are protected with packaging suitable for transport. e material must be stored in dry environments and protected from bad weather.

e instruction book is an integral and essential part of the product and must be consigned to the new user also in the case of transfer or succession of ownership.

It must be stored with care and consulted carefully, as all of the warnings provide important safety indications for installation, use and maintenance stages.

is instruction booklet contains technical information on how installing Immergas boilers. For other issues related to installation of boilers (i.e.: safety in

work sites, environment protection, injury prevention), comply with the laws in force and technical standards. In compliance with legislation in force, the

systems must be designed by qualied professionals, within the dimensional limits established by the Law. Installation and maintenance must be performed in

compliance with the regulations in force, according to the manufacturer’s instructions and by professionally qualied sta, intending sta with specic technical

skills in the plant sector, as envisioned by the Law. Improper installation or assembly of Immergas appliance and/or components, accessories, kit and devices

can cause unexpected problems to persons, animals and objects. Read the provided product instructions carefully in order to install the product correctly.

Maintenance must be carried out by skilled technical sta. e Immergas Authorised Aer-sales Service represents a guarantee of qualications and profes-

sionalism. e appliance must only be destined for the use for which it has been expressly declared. Any other use will be considered improper and therefore

potentially dangerous. If errors occur during installation, operation and maintenance, due to non compliance with technical laws in force, standards or

instructions contained in this book (or however supplied by the manufacturer), the manufacturer is excluded from any contractual and extra-contractual

liability for any damages and the appliance warranty is invalidated.

For further information regarding legislative and statutory provisions relative to the installation of gas heat generators, consult the Immergas site at the fol-

lowing address: www.immergas.com

INDICE

USER pag.

Immergas S.p.A. declines all liability due to printing or transcription errors, reserving the right to make any modications to its technical and commercial

documents without forewarning.

INSTALLATOR pag. MAINTENANCE pag.

DECLARATION OF CONFORMITY

For the purpose and eect of the Gas Appliance Directive 2009/142/CE, EMC Directive 2004/108/CE, Boiler Eciency Directive 92/42/CE and Low

Voltage Directive 2006/95/CE.

e Manufacturer: Immergas S.p.A. v. Cisa Ligure n° 95 42041 Brescello (RE)

DECLARES THAT: the Immergas boiler model: Hercules Condensing 26 2 E - 32 2 I

is in compliance with the same European Community Directives Signature:

Mauro Guareschi

Research & Development Director

1 Boiler installation. ................................................3

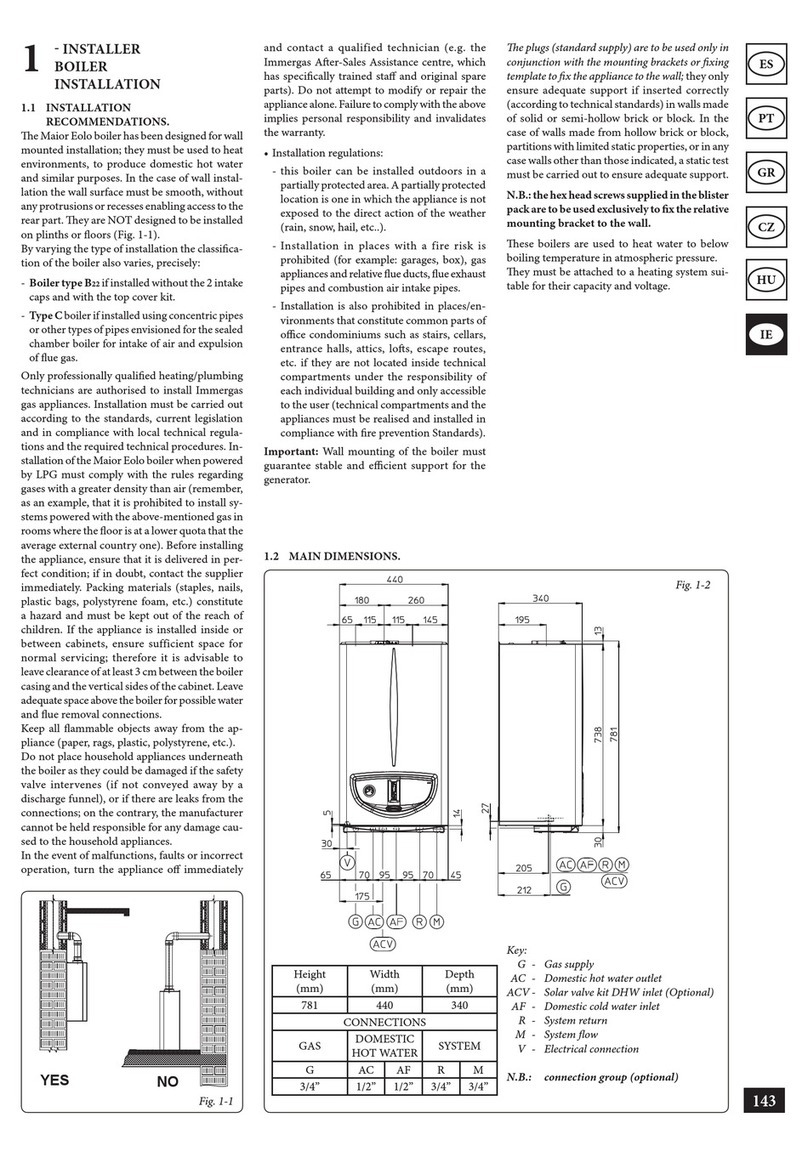

1.1 Installation recommendations. ..........................3

1.2 Main dimensions. ................................................3

1.3 Attachments. ........................................................................4

1.4 Remote controls and room timer thermostats

(optional). .............................................................5

1.5 External temperature probe (optional). ............5

1.6 Immergas ue systems. .......................................6

1.7 Tables of resistance factors and equivalent

lengths. ..................................................................6

1.8 Installation of boiler type b23open chamber

and fan (assisted). ................................................8

1.9 Horizontal concentric kit installation. ..............9

1.10 Vertical concentric kit installation. .................10

1.11 Separator kit installation. ..................................11

1.12 Adapter kit installation c9. ...............................12

1.13 Ducting of ues or technical slots. ..................13

1.14 Conguration type b23 open chamber and

forced draught for inside...................................13

1.15 Flue exhaust to ue/chimney. ...........................13

1.16 Flues, chimneys, chimney caps and

terminals. ............................................................14

1.17 System lling. .....................................................14

1.18 Filling the condensate trap. ..............................14

1.19 Gas system start-up. ..........................................14

1.20 Boiler start up (ignition). ..................................14

1.21 Domestic hot water storage tank unit. ............15

1.22 Kits available on request. ..................................15

1.23 Circulation pump. Version ‘1’ ..........................16

1.24 Circulation pump. Version ‘2’ ..........................16

1.25 Boiler components. ............................................18

2 User and maintenance instructions. ................19

2.1 Cleaning and maintenance. ..............................19

2.2 General warnings. ..............................................19

2.3 Control panel. .....................................................19

2.4 Description of functioning states. ...................20

2.5 Using the boiler. .................................................20

2.6 Fault and anomaly signals.................................21

2.7 Boiler shutdown. ................................................23

2.8 Restore central heating system pressure. ........23

2.9 System draining..................................................23

2.10 Draining the boiler. ...........................................23

2.11 Anti-freeze protection. ......................................23

2.12 Case cleaning. .....................................................23

2.13 Decommissioning. .............................................23

2.14 Parameters and information menu. ................24

3 Boiler start-up (initial check). ..........................25

3.1 Hydraulic diagram. ............................................25

3.2 Wiring diagram. .................................................26

3.3 Troubleshooting. ................................................26

3.4 Converting the boiler to other types of gas. ...26

3.5 Calibration of number of fan revs. ..................27

3.6 Adjustment of the air-gas ratio. .......................27

3.7 Checks following conversion to another

type of gas. ..........................................................27

3.8 Programming the P.C.B. ...................................28

3.9 “Chimney sweep function”. ...............................32

3.10 Pump anti-block function. ...............................32

3.11 ree-way anti-block function.........................32

3.12 Radiators anti-freeze function. ........................32

3.13 P.C.B. Periodical self-check. .............................32

3.14 Automatic vent function. ..................................32

3.15 Solar panels coupling function. .......................32

3.16 Yearly appliance check and maintenance. ......32

3.17 Casing removal. ..................................................32

3.18 Variable heat output. .........................................34

3.19 Combustion parameters. ..................................35

3.20 Technical data. ....................................................36