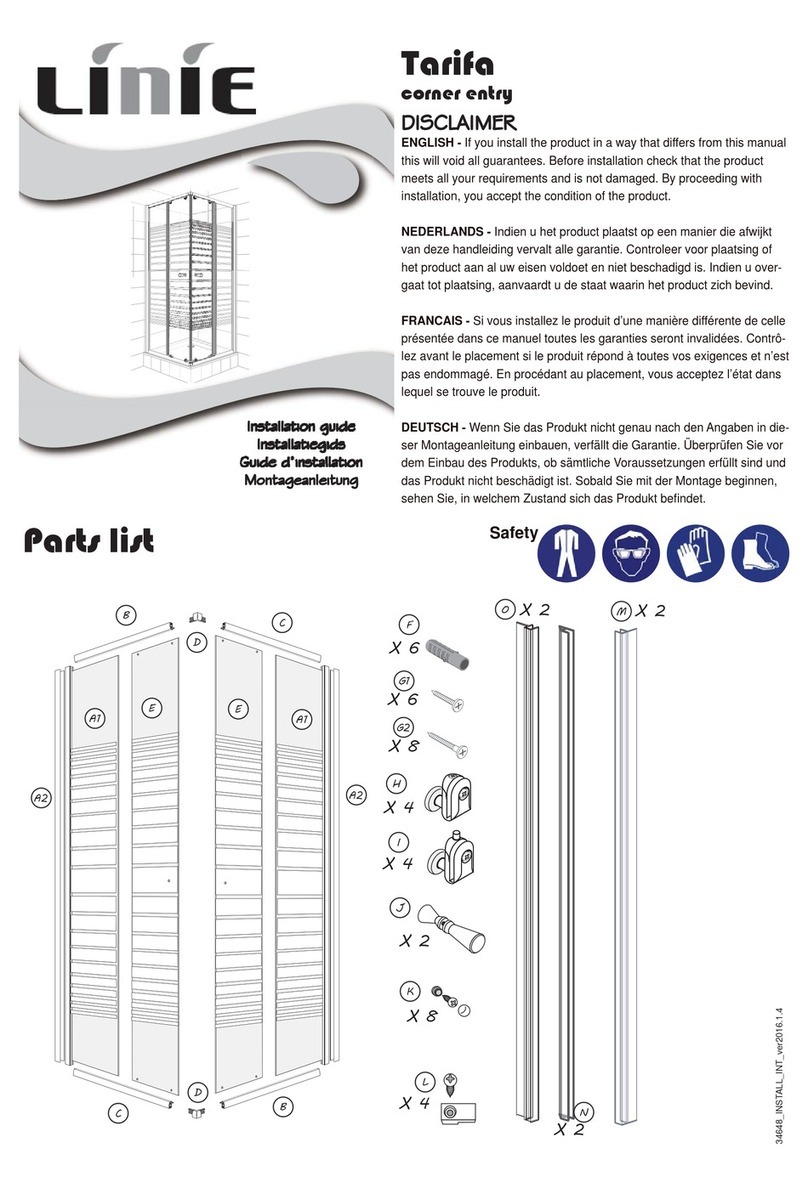

Check contents of the pack before installation. If there is anything missing, contact our Technical Helpline Number for assistance.

The fixings may be spread across several packs - please check the contents of each pack carefully.

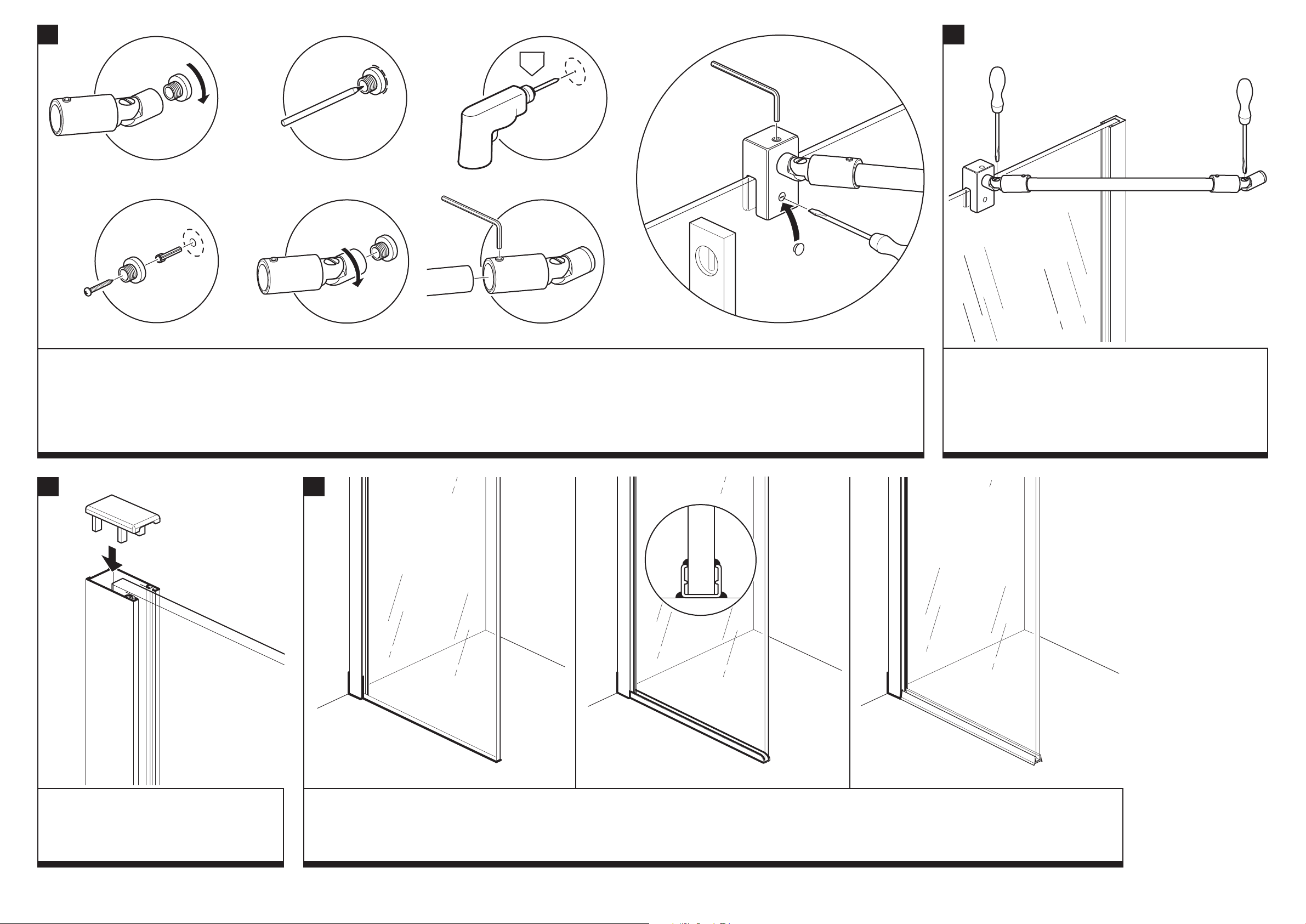

Screw

cover cap

2 & 3mm

Allen keys

PN50247

PN4745

PN60162

PN50266

Top cap

Corner

joint cap

Shower

panel foot

Top

panel

bracket

Plastic

threshold

strip

PN80501

PN80500

*PN10785

2

2

1/2

1

1

1/2

2

0

2

1

0

1

32mm

Screw

Tie bar

bracket

PN8212

PN8203

PN80499

PN40166

PN60210

Wall plug

Tie bar

bracket

Washer

2

2

0

0

2

5

5

4

0

1

10

10

8

2

4

5

5

4

1

1

OPTIONS: 54

23

OPTIONS: 542 3 OPTIONS:

1 1 1

1

0

1

1

0

5

5

4

PN40177

Aluminium

threshold

strip

1

1

5

4

5

6

PN80506

Seal

02422 2

*1

*1

0

Note: The quantities of the threshold

strips will depend on size of panels.

*Optional Extras, not included in pack.

6

Note: The *Spacer Plate PN80573 50

is only included with option 6.

Note: The *Spacer Plate PN80583 is

only included with option 6.

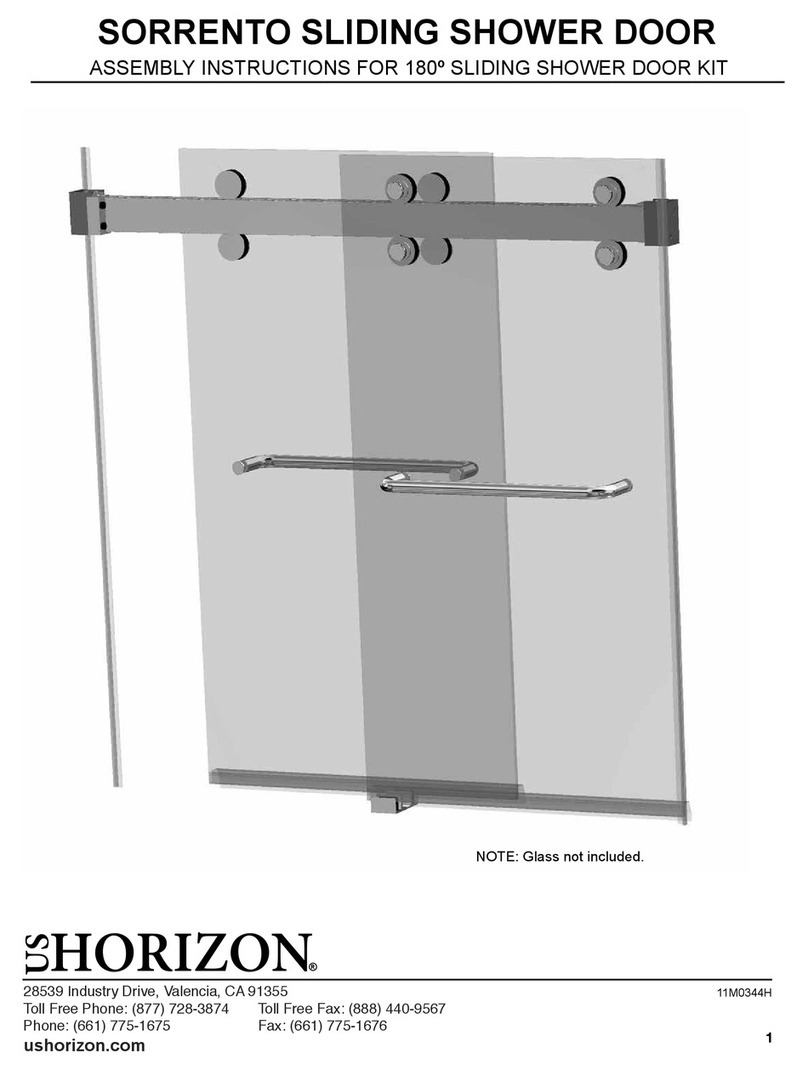

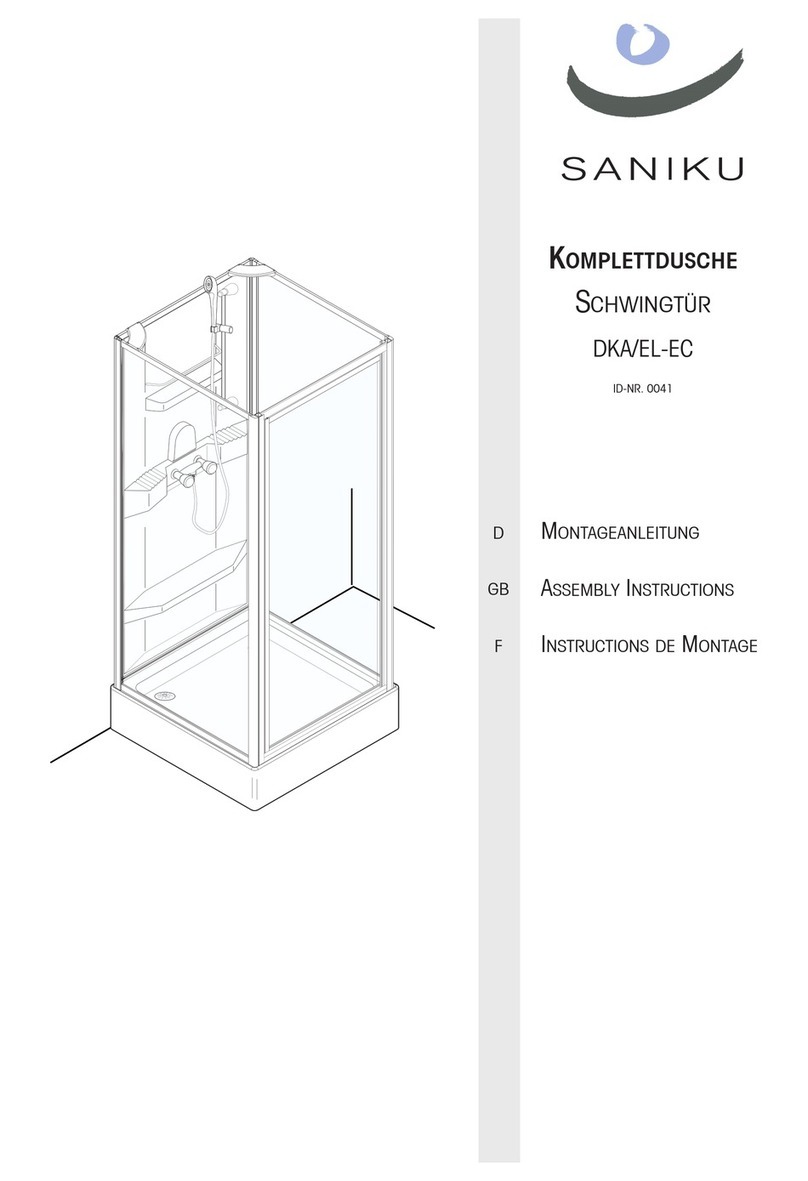

AQUA SCREEN PURE

PAGE 1

71399 00 / Issue 11 / 16

TECHNICAL HELPLINE: 01460 258682

542 3

2

2/4

0

1/1

1

1/2

1

1/1

0

2

2

1/1

0

1

1

1/1

1

1

0

1/1

1/2

1

0

1/1

6

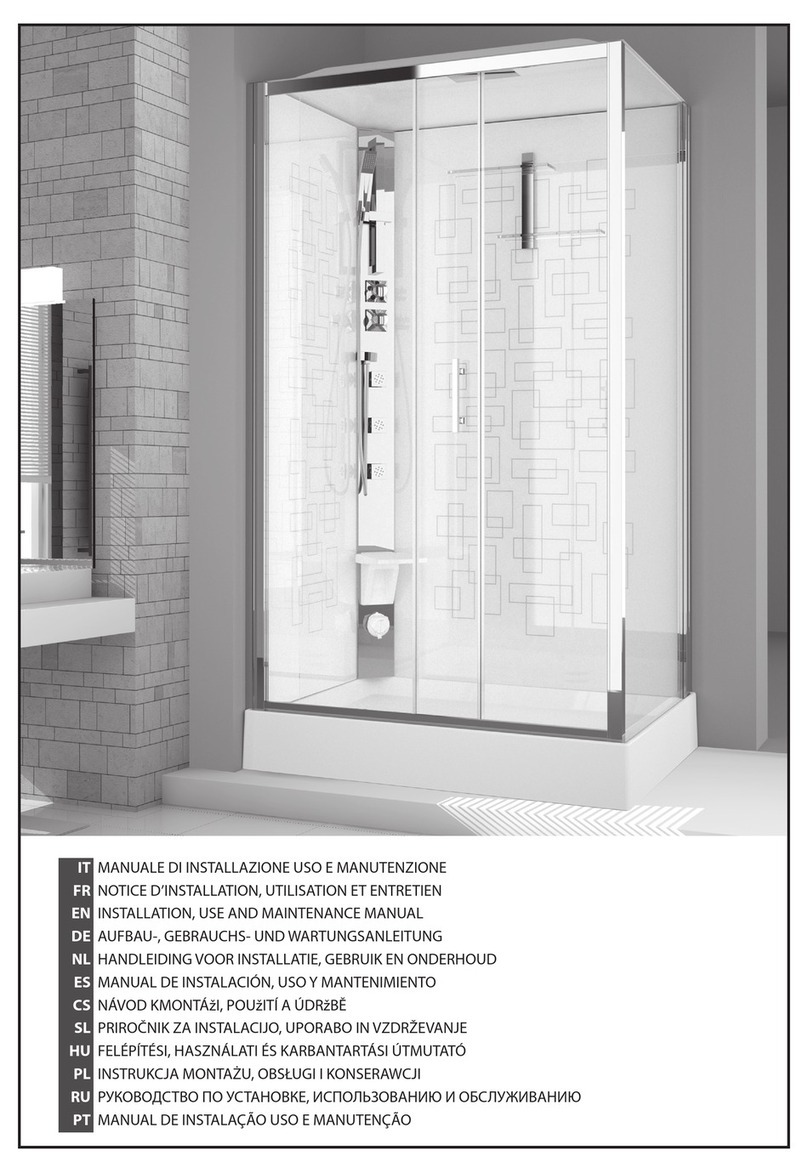

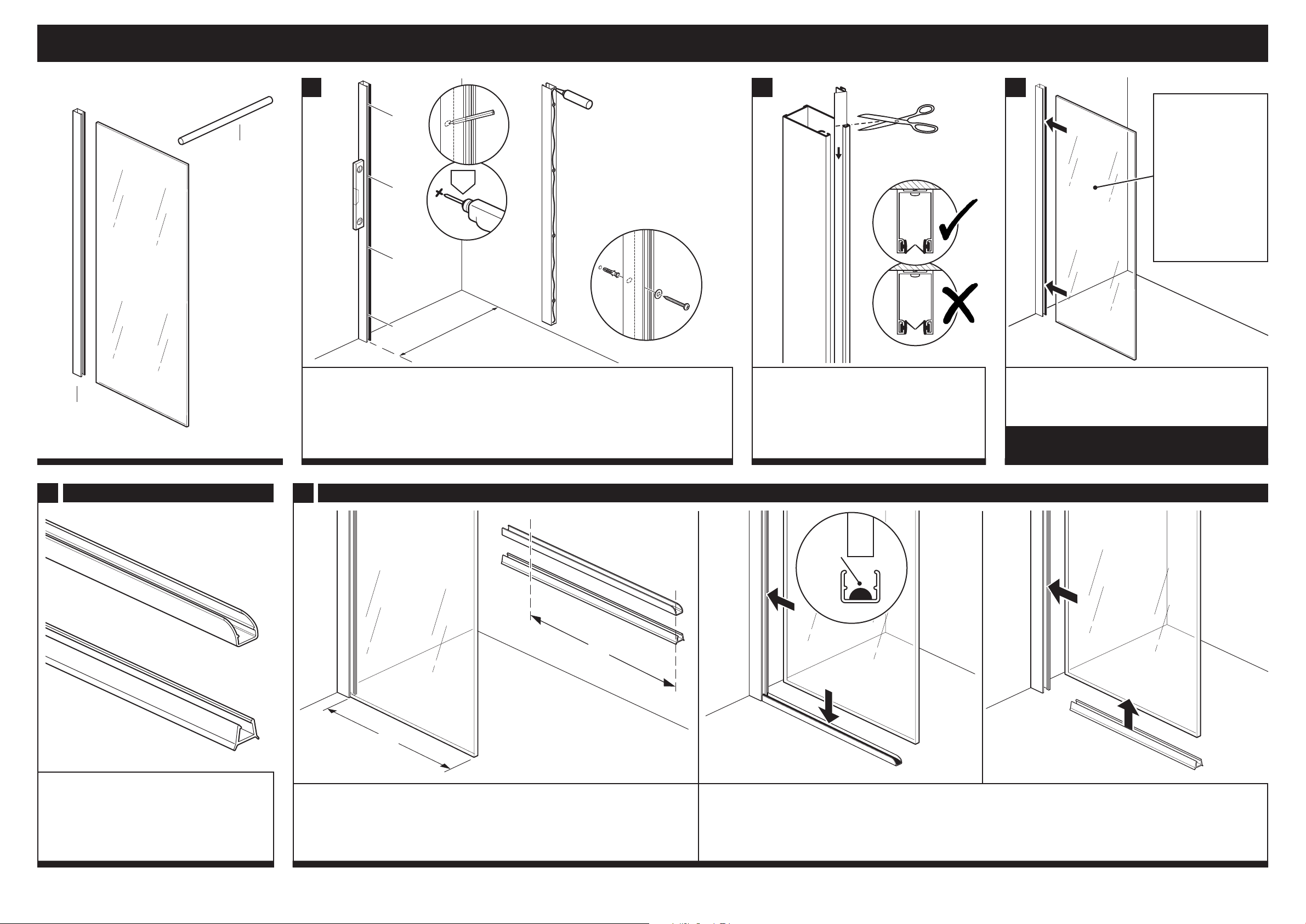

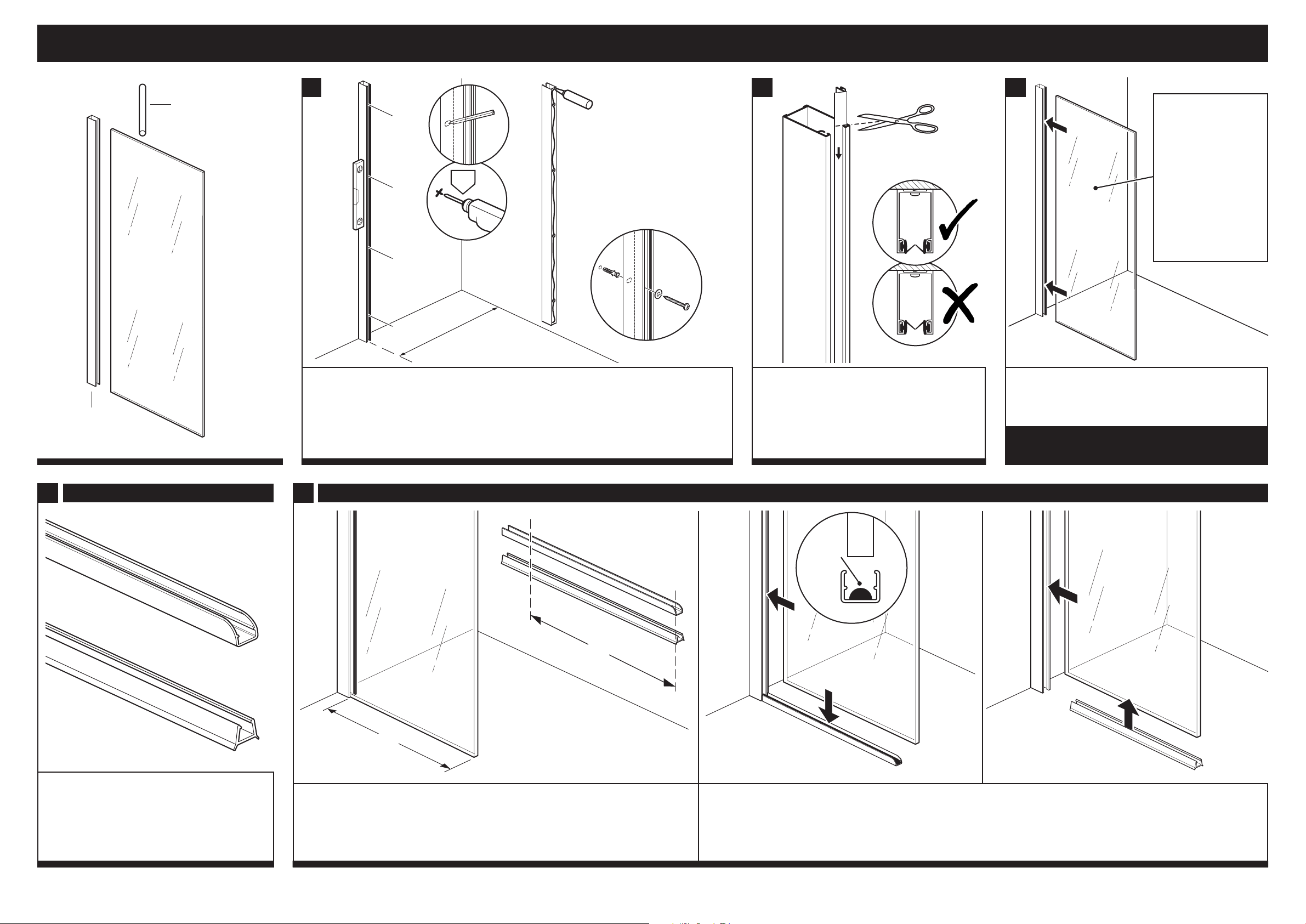

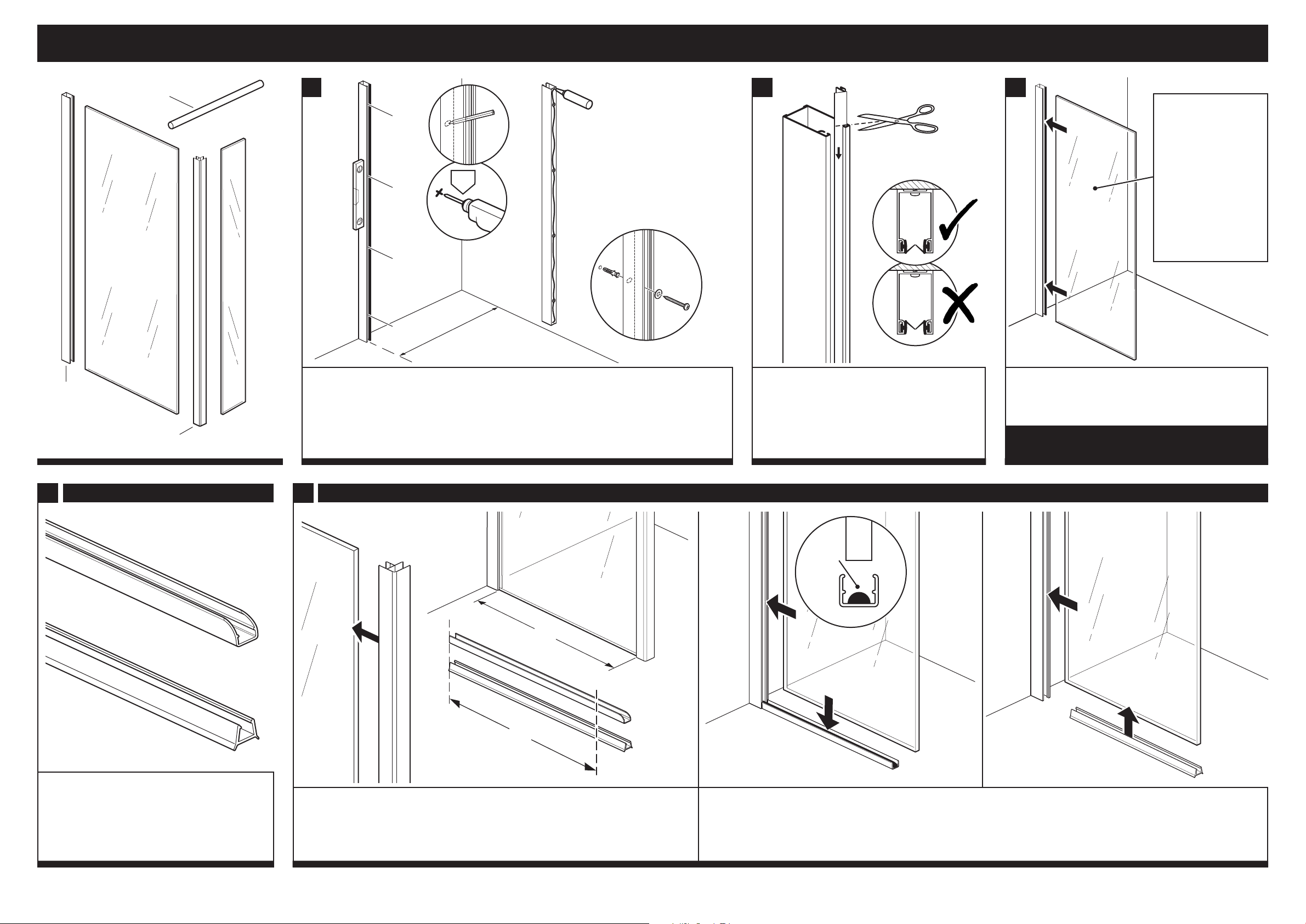

Please read these instructions carefully and keep for future reference.

Incorrect fitting will invalidate the guarantee.

SAFETY

● Handle glass with care. Although the glass is very tough, sharp impacts can damage

both the glass and metal frame.

●Do not remove the plastic corner protectors from the glass panels until the panels

are about to be fitted.

● As the parts are large, we recommend that two people are needed to carry out parts

of the installation.

● Make sure there are no hidden pipes or cables in the floor and walls where you

intend to drill.

● Wear safety goggles, shoes and appropriate clothing.

BEFORE INSTALLATION

● The panel/s will not sit correctly on an uneven surface. If uneven, the wall

channels may not fit.

● Note: If not fitted on a tray, ensure panel/s are fitted to a tiled or waterproof

composite floor.

● The panel/s should be fitted on tiled walls which are sealed with waterproof grout.

● Always check very carefully that components are vertical.

EQUIPMENT NEEDED:

Drill, 4mm & 6mm Masonry Bits, Crosshead Screwdriver, Flatblade Screwdriver (small &

medium), Spirit Level, Pencil, Fine Tooth Saw, Silicone Sealant, Scissors, Masking Tape,

Tape Measure.

Note: The screws and wall plugs supplied are for masonry walls. For lightweight walls

i.e. stud partitions, plasterboard etc, use the correct type of fixings.

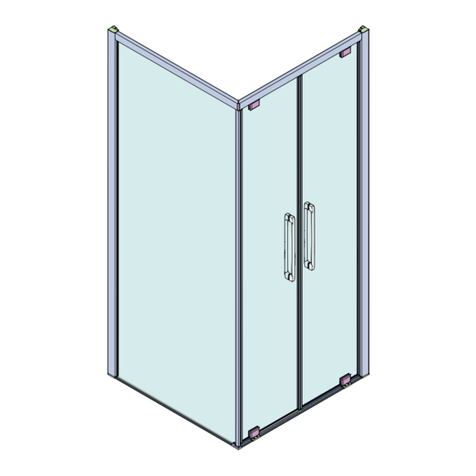

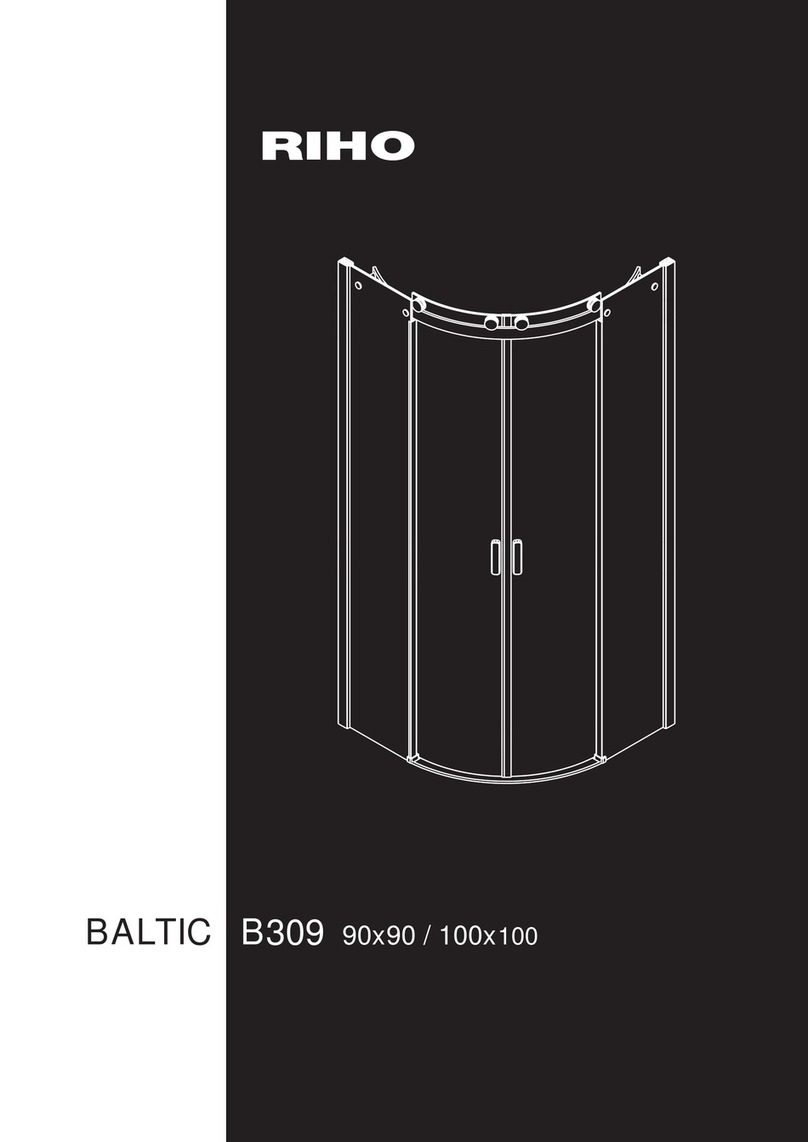

OPTION 1 - PAGES 2 - 4 OPTION 4 - PAGES 9 - 13OPTION 3 - PAGES 5 - 8OPTION 2 - PAGES 5 - 7 OPTION 5 - PAGES 14 - 17 OPTION 6 - PAGES 18 - 20

OR

*

*