Imron Corporation Azure Access BLU-RI2M User manual

Azure Access BLU-RI2M

Hardware Manual

Revision A1

June 10th, 2022

© 2022 IMRON Corporation

All rights reserved. No parts of this work may be reproduced in any form or by any means - graphic, electronic, or

mechanical, including photocopying, recording, taping, or information storage and retrieval systems - without written

permission.

While every precaution has been taken in the preparation of this document, Author assumes no responsibility for errors or

omissions, or for damages resulting from the use of information contained in this document or from the use of programs

and source code that may accompany it. In no event shall the publisher and the author be liable for any loss of profit or any

other commercial damage caused or alleged to have been caused directly or indirectly by this document.

BLU-RI2M Hardware Manual

Downstream 2-Door Reader Interface

by IMRON Corporation

Azure Access BLU-RI2M Hardware Manual

i

2022 IMRON Corporation

This manual contains confidential information and may only be reproduced or distributed with the written consent of IMRON Corporation.

IMPORTANT INFORMATION

W A R N I N G

HIGH VOLTAGE, AC MAIN POWER SHOULD ONLY BE CONNECTED BY QUALIFIED,

LICENSED ELECTRICIANS. ALL APPLICABLE LAWS AND CODES MUST BE FOLLOWED.

IF THIS PRECAUTION IS NOT OBSERVED,PERSONAL INJURY ORDEATH COULD OCCUR

Power should not be applied to the system until after the installation has been completed. If this

precaution is not observed, personal injury or death could occur, and the equipment could be

damaged beyond repair.

-Verify thatthe external circuit breaker which supplies power to the device powersupplyis turned

off prior to installation.

-Verify that the output voltage of the power supply is within specifications prior to connection to

the device.

C A U T I O N

Several important procedures should be followed to prevent electro-static discharge (ESD)

damage to sensitive CMOS integrated circuits and modules.

-All transport of electronic components, including completed reader assemblies, should be in

static shield packaging and containers.

-Handle all ESD sensitive components at an approved static controlled work station. These work

stationsconsist of a desk mat, floor mat and an ESD wriststrap.Workstations are available from

various vendors including the 3M company.

FCC Compliant

This device complies with Part 15 of FCC Rules. Operation is subject to the following two

conditions:

1.This device may not cause harmful interference, and

2.This device must accept any interference received, including interference that may cause

undesired operation.

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. Theselimits are designed to provide reasonableprotection

against harmful interference when the equipment is operatedin a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this device in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his/her own

expense. The user is advised that any equipment changes or modifications not expressly

approved by the party responsible for compliance would void the compliance to FCC regulations

and therefore, the user's authority to operate the equipment.

Azure Access BLU-RI2M Hardware Manual

ii

2022 IMRON Corporation

This manual contains confidential information and may only be reproduced or distributed with the written consent of IMRON Corporation.

Table of Contents

1

INTRODUCTION..................................................................................................... 1

1.1 General Features......................................................................................................................................1

2

HARDWARE LAYOUT............................................................................................ 2

2.1 Terminal Connectors ................................................................................................................................2

2.2 Jumpers ...................................................................................................................................................5

2.3 LEDs........................................................................................................................................................6

2.4 Dip Switches.............................................................................................................................................7

2.5 Mounting ..................................................................................................................................................8

3

SYSTEM WIRING & SETUP.................................................................................. 9

3.1 Power (TB3).............................................................................................................................................9

3.1.1 Powering Peripherals............................................................................................................................9

3.2 Grounding ................................................................................................................................................9

3.2.1 DC Ground ...........................................................................................................................................9

3.3 Upstream RS-485 Serial Port (TB8)........................................................................................................10

3.3.1 Device Wiring......................................................................................................................................10

3.3.2 Bus Configuration ...............................................................................................................................10

3.3.3 Termination.........................................................................................................................................10

3.3.4 Signal Ground (SG) ............................................................................................................................11

3.4 Unsupervised Cabinet Tamper & Power Fault (TB8)...............................................................................11

3.5 Reader Ports (TB6 & TB7)......................................................................................................................11

3.5.1 TTL Readers.......................................................................................................................................12

3.5.2 RS-485 (OSDP) Readers....................................................................................................................12

3.6 Supervised Alarm Inputs (TB1 & TB2).....................................................................................................13

3.6.1 End of Line (EOL) Termination Resistors ............................................................................................13

3.7 Output Relays (TB4 & TB5) ....................................................................................................................14

3.7.1 Door Strike Wiring...............................................................................................................................15

3.7.2 Auxiliary Output Relay.........................................................................................................................15

3.7.3 Voltage Spike Suppression .................................................................................................................15

3.8 Door / Access Point Setup......................................................................................................................15

3.8.1 Reader................................................................................................................................................16

3.8.2 Door Contact & Exit Pushbutton/REX Inputs .......................................................................................16

3.8.3 Door Strike..........................................................................................................................................16

4

OPERATION..........................................................................................................17

4.1 Firmware................................................................................................................................................17

4.2 Serial COM Configuration.......................................................................................................................17

4.3 Network..................................................................................................................................................17

4.3.1 Web Server.........................................................................................................................................17

4.3.2 Telnet.................................................................................................................................................19

4.3.3 Encryption Configuration.....................................................................................................................19

5

TROUBLESHOOTING..........................................................................................21

5.1 Serial RS-485.........................................................................................................................................21

5.2 Alarm Device Input .................................................................................................................................21

5.3 Output Relays.........................................................................................................................................21

6

SPECIFICATIONS ................................................................................................22

7

REVISION HISTORY............................................................................................24

BLU-RI2M Hardware Manual

© 2022 IMRON Corporation

This manual contains confidential information and may only be reproduced or distributed with the written consent of IMRON Corporation.

1

Part I

Introduction

1 Introduction

The BLU-RI2M is the next generation, downstream reader-interface board. This is a low-profile, RS-485, Ethernet

and PoE+ device that can be installed near or at the door. NOTE: As of this writing, only the RS-485 board is

supported with UniytyIS. It features 2-door control with two independent TTL or OSDP reader ports, supporting 6

supervised inputs, and 4 relay outputs. It is a downstream, serial or network device that requires communication

with a controller (BLU-IC series) to fully function. The board runs an enhanced version of OSDP protocol to

communicate with the controller.

The BLU-RI2M provides interface connections for a variety of card reader technologies, including proximity, smart

card, biometric, bar code, and infrared readers. Card readers with standard Wiegand or Clock/Data output can be

connected to the BLU-RI2M as well as card readers that use OSDP protocol.

1.1 General Features

●Two onboard reader ports for TTL or OSDP readers with paired reader support

●Communication: One 2-wire RS-485 & one 10/100 Ethernet port

●6 Supervised Alarm Inputs

oConfigurable termination resistor values for supervised inputs

●4 Relay Outputs

●Inputs & Outputs fully re-assignable

●One 2-wire RS-485 port for upstream communication

oSupports proprietary or OSDP protocol

●1 Unsupervised Cabinet Tamper Input

●1 Unsupervised Power Fault Input

●1 LED Output per reader port (tri-state control)

●1 Buzzer Output (open collector) per reader port

oBuzzer output can be repurposed for 2-wire LED control

●12 VDC only or PoE+

BLU-RI2M Hardware Manual

© 2022 IMRON Corporation

This manual contains confidential information and may only be reproduced or distributed with the written consent of IMRON Corporation.

2

Part II

Hardware Layout

2 Hardware Layout

Figure 2.1: BLU-RI2M Diagram

2.1 Terminal Connectors

The BLU-RI2M uses terminal blocks for connecting power, readers & door control signals, communications,

supervised alarm inputs, and relay output connections. The connection terminals are factory equipped with

removable screw-down quick connectors which are easily removed from the board by firmly grasping the

connector and pulling away from the board. If pliers are used to remove the connectors, they should be of the

rubber-tipped type. Take care to not damage onboard components when using any tools near the board. The

proper location of the quick connectors is outlined in white on the board.

The SDK allows for any readers, inputs, and outputs to be assigned to any door, but a recommended connection

is listed in parenthesis in the function column.

BLU-RI2M Hardware Manual

© 2022 IMRON Corporation

This manual contains confidential information and may only be reproduced or distributed with the written consent of IMRON Corporation.

3

BLU-RI2M Terminal Connections

Location

Type

Label

Function

(Recommended Connection)

Reader Connections

TB6-1

Ground (Reader

Power)

GND

Reader 2 Device Connections

(Door 2 Reader)

TB6-2

TTL: Data/Data 0

RS485: TR-/B

DAT/

D0

TB6-3

TTL: Clock/Data 1

RS485: TR+/A

CLK/

D1

TB6-4

Beeper

(Buzzer) Control

BZR

TB6-5

Green LED

Control

LED

TB6-6

VDC

(Reader Power)

RVO

TB7-1

Ground

(Reader Power)

GND

Reader 1 Device Connections

(Door 1 Reader)

TB7-2

TTL: Data/Data 0

RS485: TR-/B

DAT/

D0

TB7-3

TTL: Clock/Data 1

RS485: TR+/A

CLK/

D1

TB7-4

Beeper

(Buzzer) Control

BZR

TB7-5

Green LED

Control

LED

TB7-6

VDC

(Reader Power)

RVO

Input Connections

TB1-6

Input 1

IN1

Input 1

(Door 1 Door Contact)

TB1-5

Input 1 Return

IN1G

BLU-RI2M Hardware Manual

© 2022 IMRON Corporation

This manual contains confidential information and may only be reproduced or distributed with the written consent of IMRON Corporation.

4

TB1-4

Input 2

IN2

Input 2

(Door 1 REX/EPB)

TB1-3

Input 2 Return

IN2G

TB1-2

Input 3

IN3

Input 3

(Door 1 AUX Input)

TB1-1

Input 3 Return

IN3G

TB2-6

Input 4

IN4

Input 4

(Door 2 Door Contact)

TB2-5

Input 4 Return

IN4G

TB2-4

Input 5

IN5

Input 5

(Door 2 REX/EPB)

TB2-3

Input 5 Return

IN5G

TB2-2

Input 6

IN6

Input 6

(Door 2 AUX Input)

TB2-1

Input 6 Return

IN6G

Serial Connections

TB8-6

Cabinet Tamper

TMP

Cabinet Tamper & Power Fault

with shared GND

TB8-5

Ground

GND

TB8-4

Power Fault

PFLT

TB8-3

Signal Ground

SG

Serial 2-wire RS-485

TB8-2

Transmit/Receive

Data (-)

TR-

TB8-1

Transmit/Receive

Data (+)

TR+

Relay Output Connections

TB4-6

Normally Open

NO

OUT1 Relay

(Door 1 Strike)

TB4-5

Common

C

TB4-4

Normally Closed

NC

BLU-RI2M Hardware Manual

© 2022 IMRON Corporation

This manual contains confidential information and may only be reproduced or distributed with the written consent of IMRON Corporation.

5

TB4-3

Normally Open

NO

OUT2 Relay

(Door 2 Strike)

TB4-2

Common

C

TB4-1

Normally Closed

NC

TB5-6

Normally Open

NO

OUT3 Relay

(Door 1 AUX Output)

TB5-5

Common

C

TB5-4

Normally Closed

NC

TB5-3

Normally Open

NO

OUT4 Relay

(Door 2 AUX Output)

TB5-2

Common

C

TB5-1

Normally Closed

NC

Power Connections

TB3-4

AUX Power Output

VO

12 Vout AUX Power

Connection

TB3-3

Ground

GND

TB3-2

Input Power

VIN

12 Vin Power Input

Connection

TB3-1

Ground

GND

Table 2.1: BLU-RI2M Terminal Connections

2.2 Jumpers

Figure 2.2: BLU-RI2M Jumpers

BLU-RI2M Hardware Manual

© 2022 IMRON Corporation

This manual contains confidential information and may only be reproduced or distributed with the written consent of IMRON Corporation.

6

JUMPER

SETTING

DESCRIPTION

J1

ON/OFF

RS485 termination - Serial Port (UPSTREAM

COM)

J3

Labeled

PoE VIN

PoE VIN

12-24V DC/DC Power supply. DEFAULT

PoE VIN

PoE (Power over Ethernet) power source

J4

ON/OFF

RS485 termination - Reader Port 2 (RDR2)

J5

ON/OFF

RS485 termination - Reader Port 1 (RDR1)

Note: RS485 termination jumpers (J1, J4, & J5) are shipped from the factory in the OFF (termination

disengaged) position. Only turn ON termination if the RI2M is at the end of the serial bus.

2.3 LEDs

The BLU-RI2M has 19 LEDs for use in monitoring panel functions and diagnosing issues.

HB

Heartbeat & Offline / Online status

Offline: 200ms ON, 800ms OFF

Online & Unencrypted: 800ms ON, 200ms OFF

Online & Encrypted: 0.1 sec ON, 0.1 sec OFF, 0.1 sec ON, 0.1 sec OFF, 0.1

sec ON, 0.1 sec OFF, 0.1 sec ON, 0.3 sec OFF

COM

RS-485 Serial Port –Flashes when data is received

TMP

Cabinet Tamper –ON when in ALARM, OFF when SECURE. See Note 1

PFLT

Power Fault –ON when in ALARM, OFF when SECURE. See Note 1

RDR1

Reader Port 1 –OSDP Reader: Always ON

Wiegand Reader: Flashes ON when receiving data

RDR2

Reader Port 2 –OSDP Reader: Always ON

Wiegand Reader: Flashes ON when receiving data

Alarm Zone Inputs LEDs

IN1

Input IN1 Status: OFF = Secure, ON = Alarm, Flash = Fault. See Note 1

IN2

Input IN2 Status: OFF = Secure, ON = Alarm, Flash = Fault. See Note 1

IN3

Input IN3 Status: OFF = Secure, ON = Alarm, Flash = Fault. See Note 1

IN4

Input IN4 Status: OFF = Secure, ON = Alarm, Flash = Fault. See Note 1

IN5

Input IN5 Status: OFF = Secure, ON = Alarm, Flash = Fault. See Note 1

IN6

Input IN6 Status: OFF = Secure, ON = Alarm, Flash = Fault. See Note 1

Output Relays

K1

Relay OUT 1 (K1): ON = Energized

K2

Relay OUT 2 (K2): ON = Energized

K3

Relay OUT 3 (K3): ON = Energized

K4

Relay OUT 4 (K4): ON = Energized

Ethernet –P1

Speed (left side)

Green: OFF = 10Mbps, ON = 100Mbps

Link (right side)

Yellow: flashing –network activity

PoE Power

PoE PWR

ON = PoE power available (Power over Ethernet)

Note 1: Every 4 seconds the LED is pulsed to its opposite state for 0.1 seconds

BLU-RI2M Hardware Manual

© 2022 IMRON Corporation

This manual contains confidential information and may only be reproduced or distributed with the written consent of IMRON Corporation.

7

2.4 Dip Switches

DIP Switch Functions

The BLU-RI2M has 12 DIP switches. These switches are used to set various configuration options.

Communications Address

Sets this device’s address on the RS-485 bus.

Address must be unique for each device on a

single RS-485 communications line.

1

2

3

4

5

Address

OFF

OFF

OFF

OFF

OFF

0

ON

OFF

OFF

OFF

OFF

1

OFF

ON

OFF

OFF

OFF

2

ON

ON

OFF

OFF

OFF

3

OFF

OFF

ON

OFF

OFF

4

ON

OFF

ON

OFF

OFF

5

OFF

ON

ON

OFF

OFF

6

ON

ON

ON

OFF

OFF

7

OFF

OFF

OFF

ON

OFF

8

ON

OFF

OFF

ON

OFF

9

OFF

ON

OFF

ON

OFF

10

ON

ON

OFF

ON

OFF

11

OFF

OFF

ON

ON

OFF

12

ON

OFF

ON

ON

OFF

13

OFF

ON

ON

ON

OFF

14

ON

ON

ON

ON

OFF

15

OFF

OFF

OFF

OFF

ON

16

ON

OFF

OFF

OFF

ON

17

OFF

ON

OFF

OFF

ON

18

ON

ON

OFF

OFF

ON

19

OFF

OFF

ON

OFF

ON

20

ON

OFF

ON

OFF

ON

21

OFF

ON

ON

OFF

ON

22

ON

ON

ON

OFF

ON

23

OFF

OFF

OFF

ON

ON

24

ON

OFF

OFF

ON

ON

25

OFF

ON

OFF

ON

ON

26

ON

ON

OFF

ON

ON

27

OFF

OFF

ON

ON

ON

28

ON

OFF

ON

ON

ON

29

OFF

ON

ON

ON

ON

30

ON

ON

ON

ON

ON

31

Table 2.1: BLU-RI2M DIP Switch Settings

DIP RS485 Config Override

Select if OSDP cmds are accepted to set baud

and address

8

Accept OSDP cmds to set baud/address

OFF

Do not accept OSDP cmds to set baud and

address and instead honor DIP switch settings

ON

Network Configuration

(not supported at this time)

9

Use user config

OFF

Use default config

ON

Default Network Login

Disable or Enable default login

(not supported at this time)

10

Disable Default Login

OFF

Enable Default Login

ON

FACT/OSDP Key Reset

11

Power up board with switch ON and all LEDs

blink 50ms ON, 50ms OFF, repeating for 3

seconds. If the switch is turned OFF then ON

within the 3 seconds, the board performs factory

reset including wiping out custom OSDP keys.

Toggling this DIP switch during normal operation

does nothing.

Toggle

Reserved

12

X

OFF

Baud Rate (Upstream RS-485 Port)

Note: The baud rate must be the

same for every device on this port.

6

7

9600 Baud

OFF

OFF

38400 Baud

ON

OFF

57600 Baud

OFF

ON

115200 Baud

ON

ON

BLU-RI2M Hardware Manual

© 2022 IMRON Corporation

This manual contains confidential information and may only be reproduced or distributed with the written consent of IMRON Corporation.

8

2.5 Mounting

Eight holes are provided for mounting the BLU-RI2M. Mount at least 0.25 inches above the conductive surfaces.

One mounting hole is plated for connecting to Chassis (Earth) ground.

Figure 2.3: BLU-RI2M Mounting Holes [inches (mm)]

The BLU-RI2M also has an optional, metal mounting bracket with standoffs for installation in a triple-gang box

BLU-RI2M Hardware Manual

© 2022 IMRON Corporation

This manual contains confidential information and may only be reproduced or distributed with the written consent of IMRON Corporation.

9

Part III

System Wiring & Setup

3 System Wiring & Setup

This section will provide installation and wiring instructions as well as hardware interface information as it

applies to the access control system. To guard personal safety and avoid damaging equipment it is important

to have a full understanding of electrical wiring best-practices and safety. The following sections provide

general guidelines relating to the BLU-RI2M, but are not a substitute for formal training in safely handling

electrical systems!

3.1 Power (TB3)

DC/DC

Take care when selecting a power supply for use with the BLU-RI2M. Most power supplies on the market

today provide good input/output isolation, however those which do not provide isolation (or have high leakage

capacitance), coupled with accidental AC power line interchange, presents serious ground fault problems for

installers. With ground fault, the signal reference between subsystems may be 115 Vac (230 Vac) apart. If

these subsystems are interconnected, the large potential difference will cause equipment damage orpersonal

injury. Azure Access recommends the use of isolated continuous power from supplies only.

In the case of over-current, solid-state fuses integrated on the BLU-RI2M panel will ‘trip’ to protect the

components of the panel. In many cases, the solid-state fuses will reset automatically when normal current

resumes, however itmay be necessary to interrupt the supply of power to allow the fuses to reset.

3.1.1 Powering Peripherals

The BLU-RI2M has multiple output ports for distributing power to peripheral devices. Each port has its own

voltage and current specs and have overcurrent protection.

The installer must adhere to overall current maximums of the power supply, whether PoE or DC/DC from the

wall. Detailed electrical specs are located in the “Specifications” section of this document (section 6).

To maximize longevity, it is not recommended to fully load all peripheral power ports when operating at the

top of the operating temperature range.

Auxiliary Output Power “VO” (TB3 – pin 4)

The VO port can be used to power peripheral devices such as strikes, IO modules, readers, etc. This port is

a direct passthrough from the primary power VIN (same voltage as VIN), whether using PoE or wall supply.

This port has a 1 Amp current maximum.

Reader Port Power “RVO” (TB6 – pin 6) & (TB7 –pin 6)

Readers can be powered directlyfrom the two readerports. Each port hasa maximum current rating of500mA.

3.2 Grounding

3.2.1 DC Ground

This is typically the minus (-) side of the DC output of the power supply. It is to be connected to the DC ground

input of all devices being powered by one supply. It must not be connected in any way to any of the RS-485

signals or the AC side of the line including Safety (Earth) ground.

Note: AC Ground (“Safety” / “Earth” / “Chassis” Ground)

To avoid ground loop current, there must be only ONE point at which the AC ground connects to the DC

BLU-RI2M Hardware Manual

© 2022 IMRON Corporation

This manual contains confidential information and may only be reproduced or distributed with the written consent of IMRON Corporation.

10

ground (usually through the DC/DC power supply). The plated, “chassis” mounting hole should be electrically

connected the conductive surface of the mounting plate or enclosure.

3.3 Upstream RS-485 Serial Port (TB8)

RS-485 is an electrical interface standard for multi-point communication on bus transmission lines. It allows

high speed data transfer over extended distance (4000ft, 1219m). An RS-485 Serial Bus is a typical

connection for field devices (such as the BLU-RI2M) to a controller. The BLU-RI2M is a client node device on

the bus that responds to communications from the controller.

3.3.1 Device Wiring

2-wire RS-485 consists of three wires; TR+, TR-, & SG (signal ground). Both TX and RX are done on the

same pair of wires. Match the polarities; connect positive (+) to positive and negative (-) to negative. Wiring

recommendation of 24 AWG, shielded twisted-pair. Wiring requirements satisfied by Belden 9841 or

equivalent.

3.3.2 Bus Configuration

The maximum number of field devices on one RS-485 communications bus is 32. Communication cables for

RS-485 should be laid out in a "multi-drop topology". This means that there should only be two ends to the

line and devices should be located directly along this line. The BLU-RI2M can be located at any point along

the line. Long stubs (T connection) and Star Topology will cause communication problems and must be

avoided. Each field device must have a unique address, and all the devices must use the same baud rate. All

devices on the RS-485 bus must be communicating with the same protocol.

Serial Bus Topology (Main node in Middle) - Correct

Serial Bus Topology (Main node at End) - Correct

“Star” Topology - Incorrect

“T stub” Topology - Incorrect

Figure 3.1: RS-485 Bus Topologies

3.3.3 Termination

For the most reliable communications, the RS-485 bus must be terminated at both ends. The terminators are

integrated on the board and are engaged via user installed jumpers. Never engage termination of devices in

the middle of the communication bus.

BLU-RI2M Hardware Manual

© 2022 IMRON Corporation

This manual contains confidential information and may only be reproduced or distributed with the written consent of IMRON Corporation.

11

External termination modules (ATM-48) are not required but can be used. If using the ATM-48 termination

module, DO NOT install the jumpers on the board. The wiring is as follows:

ATM-48 Pin 1 -> TR+

ATM-48 Pin 2 -> TR-

3.3.4 Signal Ground (SG)

When devices are powered from different power supplies, a common ground reference must be established

on the RS-485 bus. This is the ground (GND) connection on the Serial port connector. Failure to have a

common ground between devices may cause communication errors. If connecting the RS-485 bus with

shielded wire, the shielding can be used as the signal ground connection. Or, if the environment is known to

be electrically noisy, the wire’s shield can be connected to safety/chassis/Earth ground and a separate wire

can be used for signal ground.

Grounding Potential Difference Checks Before Connecting

Before a device is connected to an RS-485 subsystem, it must be checked for ground fault. Ground faults can

damage all devices connected to the RS-485 communication line. To check if there is ground fault for a new

unit, follow the steps below:

1. Apply power to all devices already successfully connected to the RS-485 line.

2. Power up the new unit, but DO NOT connect it to the RS-485 line.

3. Connect the signal ground (SG) of the RS-485 line through a 10k limiting resistor.

4. Measure the AC and DC voltage across the resistor. There should NOT be more than 1 volt across the

resistor. Otherwise find and clear the fault.

5. Connect the new unit to the RS-485 line only if no ground fault is found.

3.4 Unsupervised Cabinet Tamper & Power Fault (TB8)

The cabinet tamper (TMP) and power fault (PFLT) inputs only support unsupervised configurations. The

cabinet tamper input is wired to the enclosure and detects when the enclosure door is opened and closed.

The power fault input is wired to the power supply and detects when there is an issue with the power supply.

Wire these inputs with 24 AWG minimum. See “Unsupervised” in Section 3.6.1 wiring diagram.

Note: Even though PFLT and TMP share a GND connection, both inputs will report separately during normal

operation. However, if the shared GND connection comes loose, both a PFLT and TMP alarm will be reported

simultaneously.

Figure 3.2: Cabinet Tamper & Power Fault Wiring

3.5 Reader Ports (TB6 & TB7)

The BLU-RI2M has two onboard reader ports that support both TTL (Wiegand, Clock & Data, etc) and RS-

BLU-RI2M Hardware Manual

© 2022 IMRON Corporation

This manual contains confidential information and may only be reproduced or distributed with the written consent of IMRON Corporation.

12

485 (OSDP) readers. The RS-485 reader bus is a true RS-485 port, meeting all requirements of the electrical

standard.

PIN

DESCRIPTION

GND

Ground connection for the reader

DAT/D0 & CLK/D1

TTL or RS-485 reader data connections (see 3.5.1 and 3.5.2 below).

BZR

Open-collector buzzer output. Can also be used for 2-wire LED control

LED

Tri-state LED signal

RVO

Reader power; jumper selectable to either be VIN passthrough or a

regulated 12VDC

3.5.1 TTL Readers

Each reader port on the BLU-RI2M can support one TTL reader. TTL readertypes includeWiegand, magnetic

stripe, proximity, bar code, smart card, biometric, keypad, etc. A different type of reader can go on each port.

TTL readers usually utilize all pins on the reader port. The wiring to a TTL reader should be made using 24

AWG minimum, shielded cable with 6 conductors (Belden 9536 or equivalent). Do not exceed 500 feet (152

m) between the BLU-RI2M and reader. 18 AWG cable may be required for long cable lengths or for large

current requirements. If twisted pair cable is used, do not wire Data 1/Clock and Data 0/Data in the same pair.

Connect the shield drain wire of the cable at the GND terminal of the appropriate reader connector on the

BLU-RI2M. Carefully insulate the drain wire with sleeving for a reliable installation.

Power for each reader port is provided through the “RVO” pins. Power supplied on RVO is a passthrough of

VIN (12 VDC).Each reader port can supply 500mA. If the readers have agreater total power requirement, or

if there are other wiring concerns, external power supplies should be used to power the readers. In this case,

only connect the reader power lines to the external power supply; do not connect the reader to two power

supplies.

For basic operation of the reader, at a minimum the Data 1/Clock and Data 0/Data wires must be connected

from the reader to the BLU-RI2M and power supplied to the reader. LED and beeper control lines do not have

to be connected, but in this case, the LED and beeper may not function on the reader.

Figure 3.3: BLU-RI2M TTL Reader Wiring

3.5.2 RS-485 (OSDP) Readers

BLU-RI2M Hardware Manual

© 2022 IMRON Corporation

This manual contains confidential information and may only be reproduced or distributed with the written consent of IMRON Corporation.

13

Both reader ports on the BLU-RI2M can communicate with RS-485 readers; OSDP being the most popular.

The Reader Port is a true RS-485 port meeting TIA-485-A. By default, the firmware allows up to four OSDP

readers which is enough for paired-reader configuration on two doors/access points.

In this section, “OSDP reader” will be used to represent what is really any RS-485 reader. The OSDP protocol

standard expands the functionality of readers by enabling a large (and growing) command set.

OSDP uses a 2-wire interface (transmit and receive on same wires). Always observe polarity of the lines;

connecting positive (+) to positive and negative (-) to negative terminals. The Signal Ground (GND) must be

connected between the readers and the reader port for reliable communications. “Star” wiring or “T stubs”

longer than 10ft must never be used!

Figure 3.4: OSDP Wiring

OSDP connections should be made observing polarity of the lines from the reader.Signal ground

should always be connected.

3.6 Supervised Alarm Inputs (TB1 & TB2)

The BLU-RI2M has 6 Supervised Alarm Inputs. These inputs are multi-purpose and are configured with the

Host software. Any input can be assigned as a door contact, REX, or auxiliary alarm input (i.e.motion or glass-

break sensors).With the use of end-of-line termination resistors, the alarms are monitored for not only secure

and alarm states, but also the detection of fault conditions from tampering and accidental damage.

These alarm inputs can be configured as either “Normally Open” or “Normally Closed” and can also operate

in an Unsupervised mode. Unsupervised configuration does not require any external, end of line resistors.

However, unsupervised mode is the least secure and damage or tampering of the line can go undetected,

resulting in missed or false alarms. The unsupervised configuration should not be used in any situation that

requires security. An example of unsupervised input wiring can be seen in Figure 3.5.

Input wiring requiresminimum 22 AWG up to 1,000ft (304.8m) and a maximum of30 Ohms of loop resistance.

3.6.1 End of Line (EOL) Termination Resistors

Using two End-of-Line (EOL) termination resistors, the Supervised mode can detect fault conditions resulting

from accidental damage or tampering. The BLU-RI2M will not confuse this condition with a valid secure or

alarm condition. For maximum security, the end-of-line termination resistors should be placed at the END of

the cable, farthest away from the BLU-RI2M. There are multiple EOL options, ranging from ready-made

terminal block connectors to individual, hand-placed resistors. The following wiring diagram shows some of

the pre-defined termination resistor configurations. For ease of installation, pre-assembled resistor packs for

termination are available; the ATM-30 is 300/10K Ohms & ATM-3D is 3K/4.5K Ohms.

BLU-RI2M Hardware Manual

© 2022 IMRON Corporation

This manual contains confidential information and may only be reproduced or distributed with the written consent of IMRON Corporation.

14

Figure 3.5: Input Supervision

Supervised inputs can be configured with Host Software to use different EOL resistor combinations.

3.7 Output Relays (TB4 & TB5)

The BLU-RI2M has four output relays onboard. These relays can either control a door strike (lock) or other

electrical device connections or other miscellaneous output control. Relay functions are defined in the Host

software. The onboard relays are capable of switching up to 2A @ 30VDC or 0.5A @ 120VAC.

BLU-RI2M Hardware Manual

© 2022 IMRON Corporation

This manual contains confidential information and may only be reproduced or distributed with the written consent of IMRON Corporation.

15

3.7.1 Door Strike Wiring

A typical electric door strike (lock) will require around 250mA (0.25 Amps) to operate. If the particular locking

device requires more than 2 Amps to control, another external power-switching device/relay of adequate

power rating must be used. Some strikes such as magnetic strikes are inductive loads, in which case is

recommended to derate the relay’s rated current by 50%.

Wiring between the strike power supply, strike relay (internal or external) and the electric lock should be of

sufficient gauge (16 to 18 AWG recommended) to prevent excessive voltage drop under all circumstances.

The strike can be wired in a fail-safe (door unlocks on power outage) or fail-secure (door locks on power

outage) manner by using either the Normally Closed (NC) or Normally Open (NO) relay contacts.

3.7.2 Auxiliary Output Relay

Aside from controlling door strikes, relay outputs can be used for controlling other audible and visual devices.

Auxiliary relay functionality is configured via the Host software.

3.7.3 Voltage Spike Suppression

Due to inductive nature of a door strike, energizing and deenergizing of the relay can cause voltage spikes

across the relay contacts. If no suppression is used to defend against these voltage spikes, communication

problems and permanent damage to the hardware may occur.

Strike Type

Suppression Method

DC Strike

Reverse-biased DIODE with a continuous current rating of at least 1x the strike

current and a breakdown voltage (Vbr) rating of at least 2x the strike voltage. Usually

a 1N4001 –1N4006 will work.

AC Strike

A Metal Oxide Varistor (MOV) will usually be included with the strike. If a MOV does

not come with the strike, contact the strike manufacturer for the appropriate MOV

ratings. Be sure to use a UL approved MOV.

Figure 3.6: Strike Wiring Diagram (DC w/ Diode)

Both DC and AC suppression components are placed identically; across the output device’s electrical

terminals.

3.8 Door / Access Point Setup

An Access Point (sometimes referred to simply as “Door”) is the grouping of at least one reader, supervised

inputs, and relay outputs to yield full control and monitoring of a door/entryway. A “complete” Access Point

consists of at least one reader, two supervised inputs (for door contact and REX), and one relay output

controlling the door strike. The BLU-RI2M supports 2 complete Access Points with onboard interfaces.

Configuration and assignment of the Access Point’s interfaces is done through the Host software.

Recommended connections are listed in the Terminal Block table in section 2.

BLU-RI2M Hardware Manual

© 2022 IMRON Corporation

This manual contains confidential information and may only be reproduced or distributed with the written consent of IMRON Corporation.

16

Figure 3.7: Door / Access Point Wiring

3.8.1 Reader

An Access Point needs at least one reader to receive credentials. The BLU-RI2M supportsboth TTL and RS-

485 (OSDP readers). Access Points can also use two readers in a “paired” configuration.

3.8.2 Door Contact & Exit Pushbutton/REX Inputs

The door contact input is a normally closed input used to monitor the position of the door (open or closed).

This will typically be connected to a magnetic sensor in the frame of the door that will provide a short circuit

when the door is closed and an open circuit when the door is opened. Door Contact inputs are required for

features that require knowledge of door usage; such as Anti-Passback, Door Forced / Held Open, and more

precise strike timing.

The Exit Pushbutton, sometimes referred to as a REX (Request-to-Exit/Enter) input, is a Normally Open input

that is used to inform the Access Point the door needs to, or will be opening without an access request being

made with a user’s credential (card, pin, etc). It is usually in the form of a pushbutton, but it could also be in

the form of a motion sensor or other user-activated sensor. Note that different types of sensors will require

different strike timing calibrations.

If input supervision is enabled (see Part 3.6.1 above), end of line (EOL) terminating resistors must be installed.

The terminating resistors should be installed as close to sensor (away from the BLU-RI2M) as possible.

3.8.3 Door Strike

Door strikes come in a variety of different styles. They can come in different voltages (both AC and DC), and

can operate in a Fail-Secure or Fail-Safe manner. The most common voltages are 12 & 24 Volts. A Fail-Safe

door uses electrical current to keep the strike locked; meaning in the case of power failure, the strike will

default toan unlocked state. A Fail-Secure strike uses electricalcurrent tounlockthe door;meaning in apower

failure situation, the door will default to a locked state.

Table of contents

Popular Network Hardware manuals by other brands

Cisco

Cisco ONS 15600 Reference manual

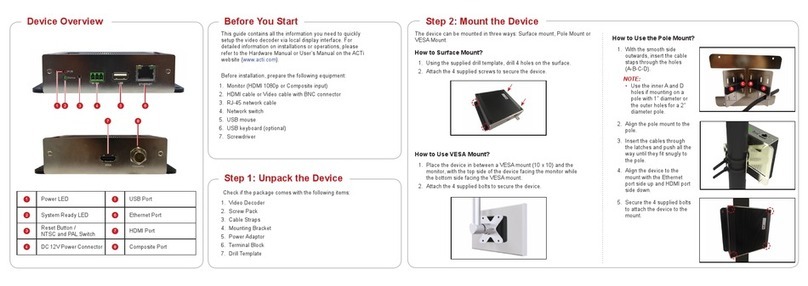

ACTi

ACTi ECD-1000 Quick installation guide

Accedian

Accedian Skylight Flex 100 Hardware installation guide

D-Link

D-Link DHP-347AV user manual

Cisco

Cisco Linksys Business Series Network Storage System... Getting started guide

ExtraHop

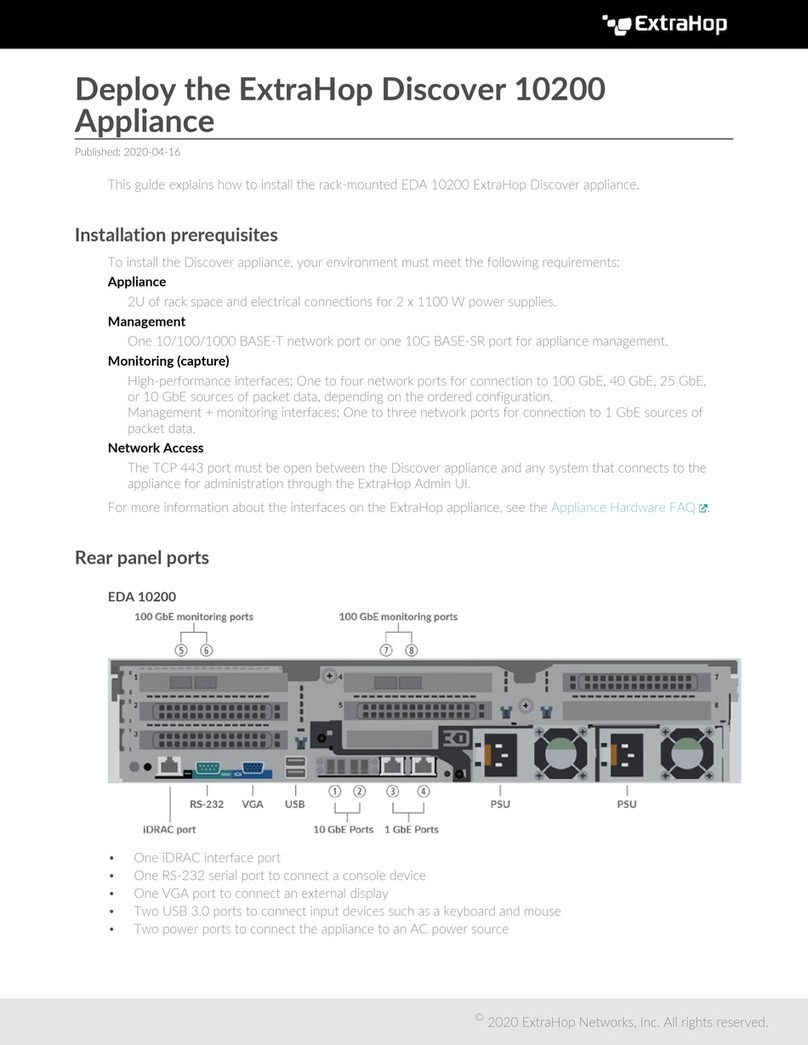

ExtraHop EDA 10200 Quick Deploy Guide

Chatsworth Products

Chatsworth Products RIM-750 quick start guide

Ubiquiti

Ubiquiti UF-Instant quick start guide

ADTRAN

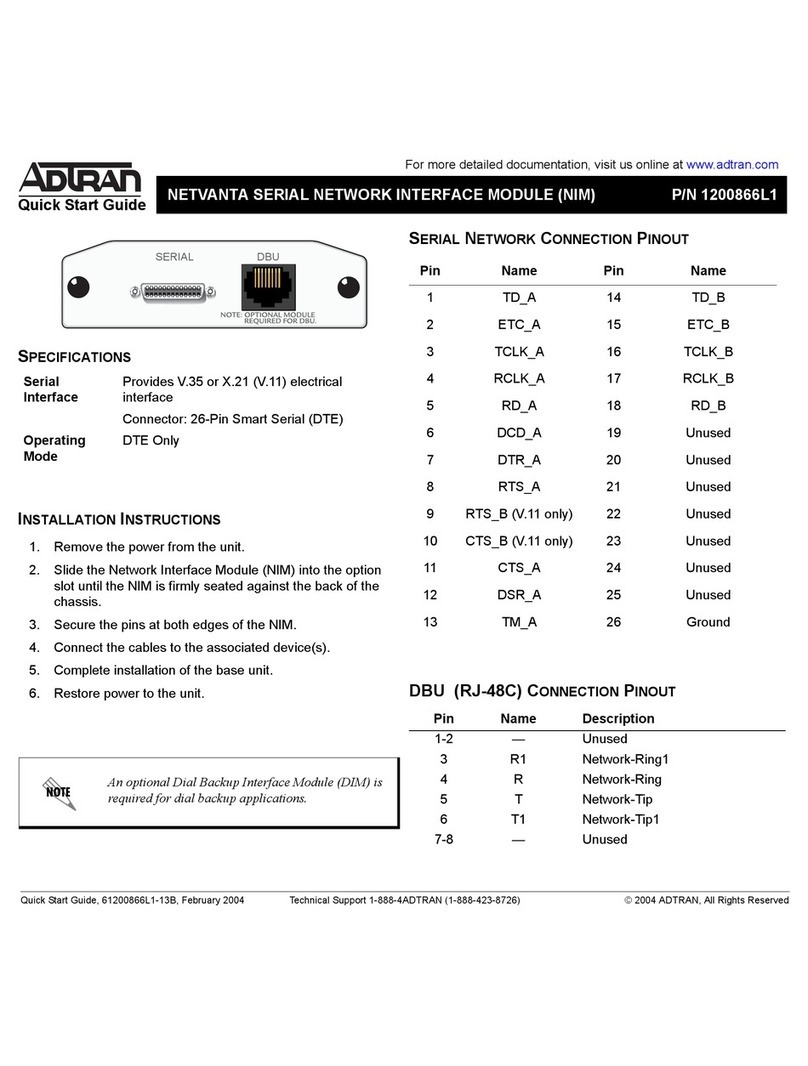

ADTRAN NetVanta 8044M quick start guide

Teltonika

Teltonika Maxview MXL050 Roam Installation & user's instructions

Axiometrix Solutions

Axiometrix Solutions imc EOS manual

IBM

IBM TS4300 user guide