1.1 Location

NOTE: Corken compressors are designed to handle

toxic or flammable gases and should be located

outdoors in a well ventilated area.

Proper installation of your compressor is essential for

peak performance and reliable service. The installation

area should be clean, well ventilated and have ample

space to install and maintain your compressor. A

double-acting compressor generates more heat than

a typical single-acting compressor. As a result your

compressor should be located in an area where good

air flow and ventilation can be provided. In extreme

cases, external cooling fans can be used to provide

additional air flow across the cylinders. A minimum of

18 inches clearance between the unit and the nearest

wall is advisable. This space will allow access from all

sides and provide unrestricted air flow for adequate

cooling of the motor and compressor. The unit should

be firmly bolted to a solid, level base.

Corken compressors are designed and manufactured

for outdoor duty. For applications where the compressor

will be subjected to extreme conditions such as corrosive

environments or arctic conditions for extended periods

of time, consult Corken.

Check local safety regulations and building codes to

assure installation will meet local safety standards.

Noise:

Corken horizontal compressors should not exceed an 85

DBA noise level when properly installed.

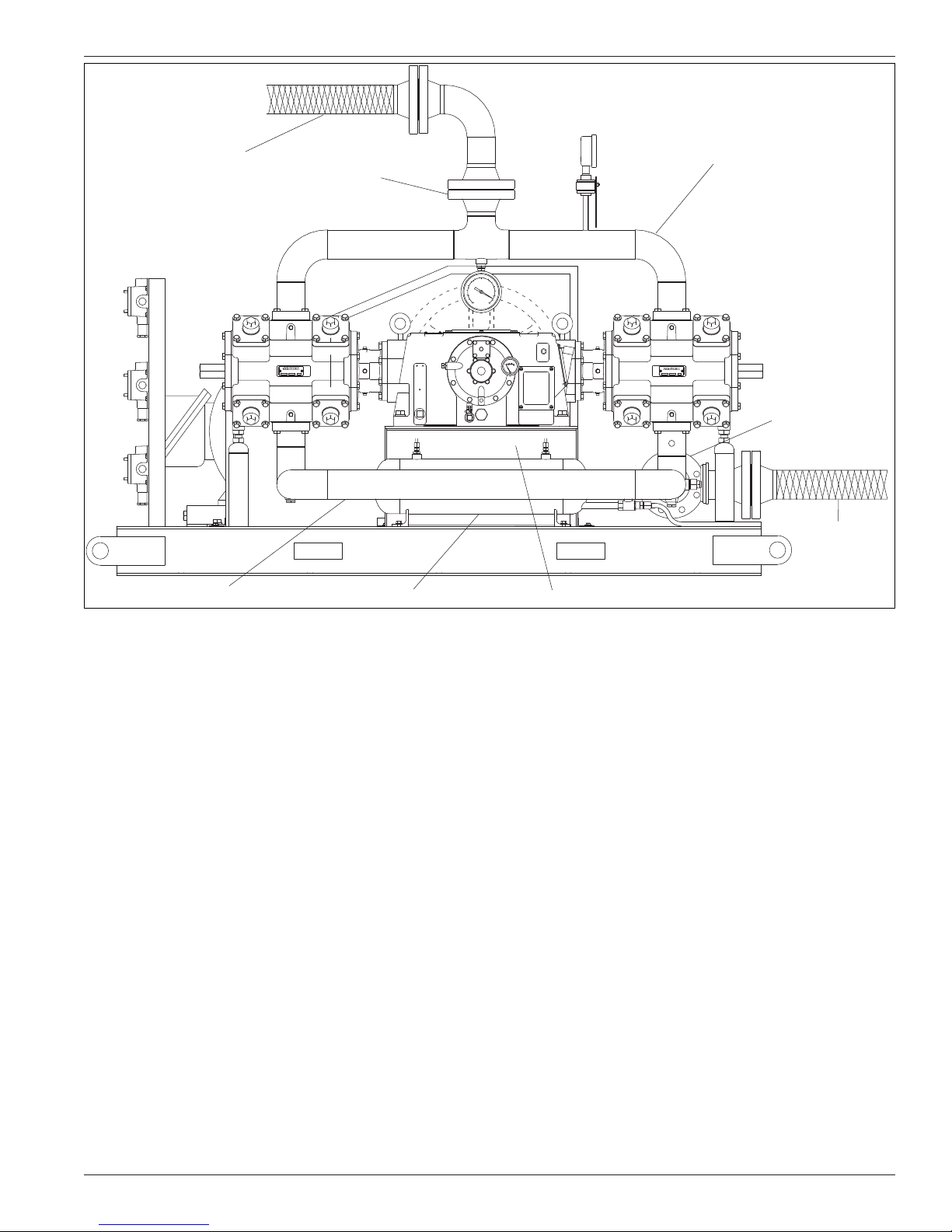

1.2 Foundation

Proper foundations are essential for a smooth running

compression system. The compressor should be

attached to a concrete slab a minimum of 8 inches

thick with a 2 inch skirt around the circumference of

the steel structural skid. The steel structural skid should

be securely anchored into the foundation by 3/4 inch

diameter “J” bolts that are 8 inches long. The total mass

of the concrete foundation should be approximately

twice the weight of the compressor system (i.e. steel

structural skid, compressor, motor, etc.). See figure 1.2

for details.

1.3 Piping

Proper piping design and installation is as important as a

proper foundation is to a smooth operating compressor.

Improper piping installation will result in undesirable

transmission of compressor vibration to the piping. The

compressor piping should be designed for the rate of

flow anticipated and for minimum pressure drop; in no

case should the piping be smaller than the compressor

nozzle to which it connects. If the length of the line must

exceed 100 ft., the next larger size pipe should be used.

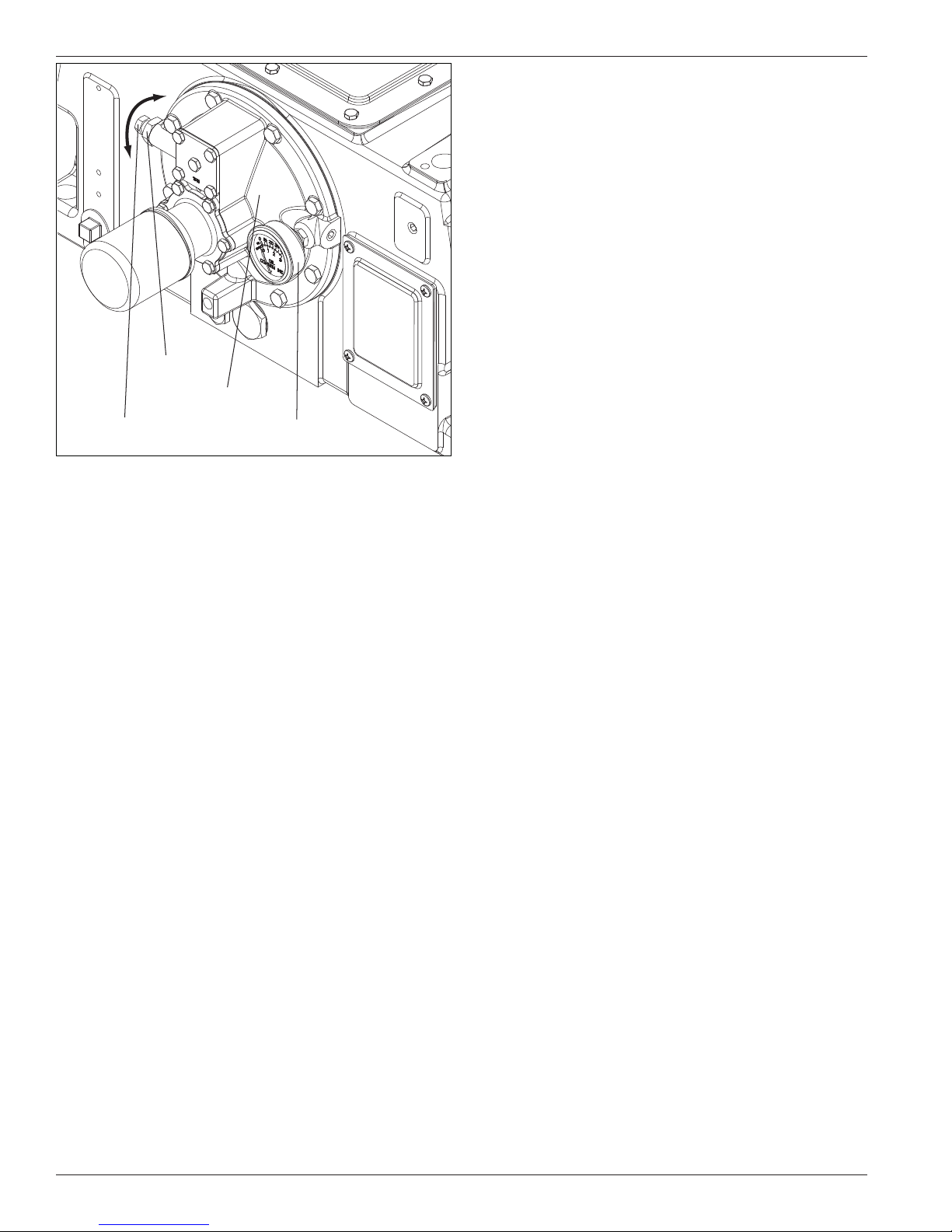

Install a strainer at the compressor inlet. Never install

a shut-off valve in the discharge piping unless a safety

relief valve is placed in the line between the shut-off

valve and the compressor. Remember to consider future

expansion in your pipe sizing and layout.

DO NOT SUPPORT PIPING WITH THE COMPRESSOR.

Unsupported piping is the most frequent cause of vibration

of the pipe. The best method to minimize transmission of

vibration from the compressor to the piping is to use

flexible connectors (see figure 1.3 for details).

Pipe must be adequately sized to prevent excessive

pressure drop between the suction source and the

compressor as well as between the compressor and the

final discharge point. In most cases, piping should be

at least the same diameter as the suction nozzle on the

compressor.

If a restrictive device such as a valve, pressure regulator,

or back-check valve is to be installed in the compressor’s

suction line, care must be taken. The suction line volume

between the restrictive device and the compressor

suction nozzle must be at least ten times the swept

cylinder volume.

On liquefied gas applications such as LPG, it is of

extreme importance to prevent the entry of liquid into

the compressor. Installing a liquid trap on the inlet side

will prevent liquid from entering the compressor (see

section 1.4).

Chapter 1—Installation Of Your Compressor

Figure 1.2

Main beam (C-Beam)

Cross beam (H-Beam)

3/4″ diameter “J” bolt

Hex nut

&

washer

Concrete foundation

Note: The depth of the concrete foundation will

vary based on local soil conditions.

6