Page 7

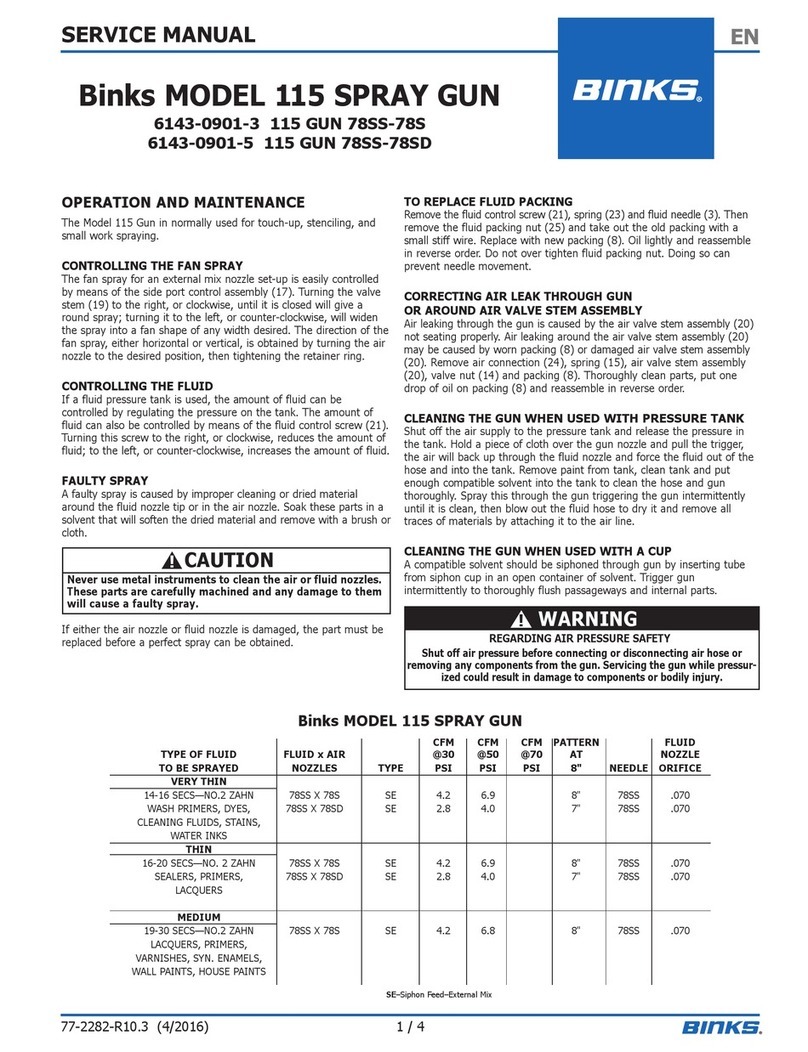

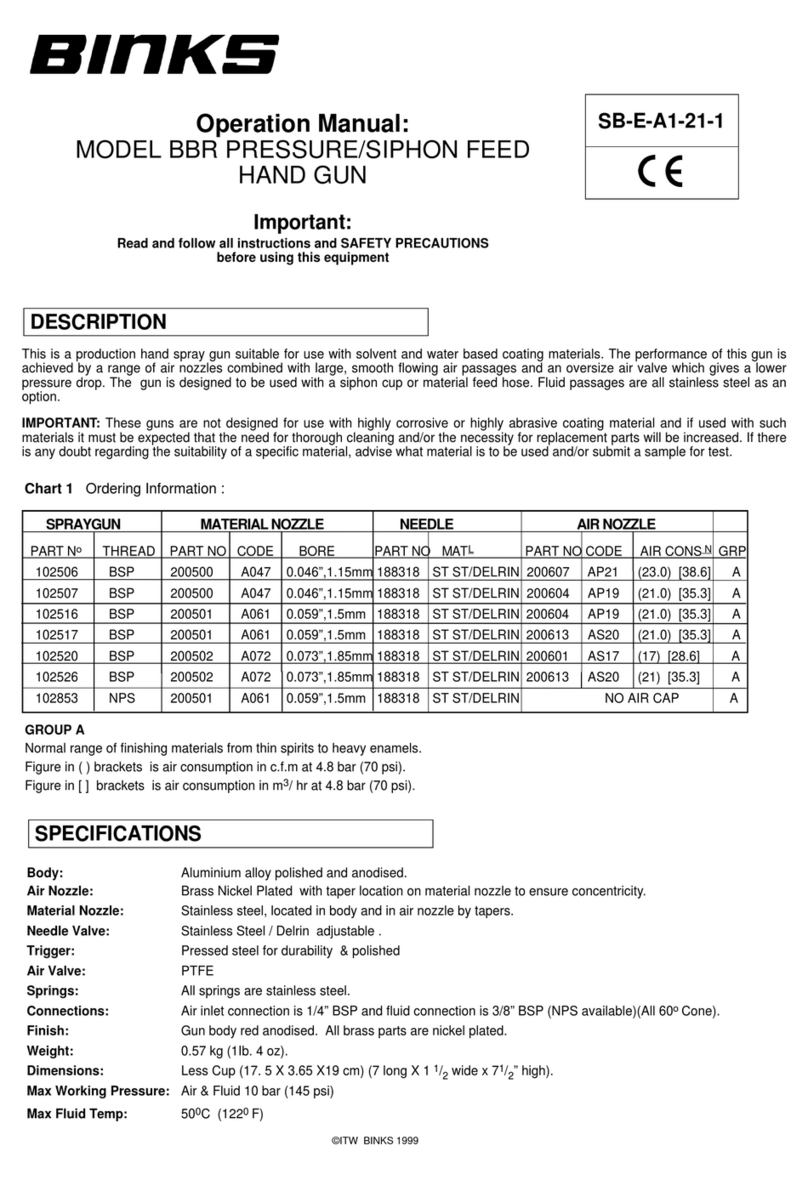

Selection Chart for Spray Tips

Bore

mm Fan

Width Fan

Angle Flow Rate approx.

ltrs. Water/min. at

Standard Tips

Super ZIP Tips mm 70 bar 100 bar

94-98-0030023 0,23 134 30° 0,13 0,29

94-98-0040023 0,23 182 40° 0,13 0,29

94-98-0060023 0,23 289 60° 0,13 0,29

94-98-0040028 90-98-0059411HP

0,28 182 40° 0,2 0,45

94-98-0050028 0,28 233 50° 0,2 0,45

94-98-0060028 0,28 289 60° 0,2 0,45

94-98-0040033 0,33 182 40° 0,31 0,68

94-98-0050033 0,33 233 50° 0,31 0,68

94-98-0060033 0,33 289 60° 0,31 0,68

94-98-0030038 0,38 134 30° 0,39 0,87

94-98-0040038 0,38 182 40° 0,39 0,87

94-98-0050038 0,38 233 50° 0,39 0,87

94-98-0060038 0,38 289 60° 0,39 0,87

94-98-0030043 0,43 134 30° 0,52 1,05

94-98-0040043 90-98-0059417HP

0,43 182 40° 0,52 1,05

94-98-0050043 0,43 233 50° 0,52 1,05

94-98-0060043 90-98-0059617HP

0,43 289 60° 0,52 1,05

94-98-0040053 90-98-0059421HP

0,53 182 40° 0,79 1,76

94-98-0050053 90-98-0059521HP

0,53 233 50° 0,79 1,76

94-98-0060053 90-98-0059621HP

0,53 289 60° 0,79 1,76

94-98-0040063 90-98-0059425HP

0,63 182 40° 1,09 2,4

94-98-0050063 90-98-0059525HP

0,63 233 50° 1,09 2,4

94-98-0040078 90-98-0059431HP

0,78 182 40° 1,53 3,28

94-98-0050078 0,78 233 50° 1,53 3,28

94-98-0050094 90-98-0059537HP

0,94 233 50° 1,82 3,91

94-98-0060094 0,94 289 60° 1,82 3,91

Tip Bore Fan Width

Adjustable Spray Tips mm mm

JACT-415 0,13-0,46 30-350

JACT-420 0,18-0,48 30-500

JACT-424 0,18-0,66 30-350

JACT-428 0,28-0,66 30-550

JACT-441 0,44-0,89 30-600

JACT-449 0,53-1,36 30-650

Tip Grip Protection for High Pressure Guns

According to CE-Rule PR EN 1953 all guns of Airless equipment must be equipped with a contact

proof device in order to avoid injections.

Please order the tip grip protection (tip base) separately.